Horn loudspeaker: Difference between revisions

Binksternet (talk | contribs) →Mantaray: tech note |

Binksternet (talk | contribs) quadratic |

||

| Line 75: | Line 75: | ||

}}</ref> The flange at the mouth solved some remaining problems with lobing at higher frequencies.<ref name=Henricksen454/> Don Keele specified in one version of his design a wider horizontal flare for pattern control appropriate to public address purposes. Keele's paper<ref>[http://www.xlrtechs.com/dbkeele.com/PDF/Keele%20(1975-05%20AES%20Preprint)%20-%20Whats%20So%20Sacred%20Exp%20Horns.pdf D. B. Keele, Jr., Electro-Voice. ''What's So Sacred About Exponential Horns?'' May 1975.]</ref> set forth the relationships between mouth size, frequency and coverage angle, providing a basis for many future developments of horn design.<ref name=Henricksen454/> One problem found with constant directivity horns is that the horizontal coverage pattern can't be narrowed without making the vertical coverage pattern too small to be useful.<ref name=Peavey2000/> |

}}</ref> The flange at the mouth solved some remaining problems with lobing at higher frequencies.<ref name=Henricksen454/> Don Keele specified in one version of his design a wider horizontal flare for pattern control appropriate to public address purposes. Keele's paper<ref>[http://www.xlrtechs.com/dbkeele.com/PDF/Keele%20(1975-05%20AES%20Preprint)%20-%20Whats%20So%20Sacred%20Exp%20Horns.pdf D. B. Keele, Jr., Electro-Voice. ''What's So Sacred About Exponential Horns?'' May 1975.]</ref> set forth the relationships between mouth size, frequency and coverage angle, providing a basis for many future developments of horn design.<ref name=Henricksen454/> One problem found with constant directivity horns is that the horizontal coverage pattern can't be narrowed without making the vertical coverage pattern too small to be useful.<ref name=Peavey2000/> |

||

===Mantaray=== |

====Mantaray==== |

||

Subsequent to Keele's work and using his principles, Clifford A. Henricksen and Mark S. Ureda of Altec designed a strikingly different hybrid horn, the horizontal diffraction or "Mantaray" horn.<ref name=Henricksen455>Henricksen, ''Loudspeakers, Enclosures, and Headphones'', 455.</ref> The Mantaray separated desired vertical coverage pattern from horizontal, making it possible to design horns for a variety of coverage patterns. The Mantaray shape starts with a vertically-oriented JBL-style diffraction horn leading into a conical waveguide (earliest designs) or a square or rectangular horn with four planar sides.<ref>{{US patent reference |

Subsequent to Keele's work and using his principles, Clifford A. Henricksen and Mark S. Ureda of Altec designed a strikingly different hybrid horn displaying constant directivity traits, the horizontal diffraction or "Mantaray" horn.<ref name=Henricksen455>Henricksen, ''Loudspeakers, Enclosures, and Headphones'', 455.</ref> The Mantaray separated desired vertical coverage pattern from horizontal, making it possible to design horns for a variety of coverage patterns. The Mantaray shape starts with a vertically-oriented JBL-style diffraction horn leading into a conical waveguide (earliest designs) or a square or rectangular horn with four planar sides.<ref>{{US patent reference |

||

| number = 4187926 |

| number = 4187926 |

||

| y = 1980 |

| y = 1980 |

||

| Line 84: | Line 84: | ||

| title = Loudspeaker horn ''[Horizontal diffraction "Mantaray"]' |

| title = Loudspeaker horn ''[Horizontal diffraction "Mantaray"]' |

||

}}</ref> For midrange beaming control, the outer mouth was expanded further with a short, flared flange in the Keele style, or with added planar sides of a greater flare angle. Low frequency efficiency wasn't as pronounced as the constant directivity design.<ref name=Henricksen455/> Unlike previous designs, the apparent apex,<ref>[http://alteclansingunofficial.nlenet.net/publications/techletters/TL_262.pdf Altec Lansing Engineering Notes. Technical Letter No. 262. ''Coverage of Multiple Mantaray Horns.'' Mark Ureda, Ted Uzzle.] Definition of 'apparent apex' and approximate locations for a number of Mantaray horn models.</ref> the focal point of pattern dispersion, was not the same for every frequency, making for an ellipsoidal wavefront rather than spherical. Because of this, the Mantaray could only be arrayed satisfactorally in one plane. Its abrupt breaks in flare rate caused diffraction, reflection and distortion components.<ref name=Peavey2000/> |

}}</ref> For midrange beaming control, the outer mouth was expanded further with a short, flared flange in the Keele style, or with added planar sides of a greater flare angle. Low frequency efficiency wasn't as pronounced as the constant directivity design.<ref name=Henricksen455/> Unlike previous designs, the apparent apex,<ref>[http://alteclansingunofficial.nlenet.net/publications/techletters/TL_262.pdf Altec Lansing Engineering Notes. Technical Letter No. 262. ''Coverage of Multiple Mantaray Horns.'' Mark Ureda, Ted Uzzle.] Definition of 'apparent apex' and approximate locations for a number of Mantaray horn models.</ref> the focal point of pattern dispersion, was not the same for every frequency, making for an ellipsoidal wavefront rather than spherical. Because of this, the Mantaray could only be arrayed satisfactorally in one plane. Its abrupt breaks in flare rate caused diffraction, reflection and distortion components.<ref name=Peavey2000/> |

||

====Bi-Radial==== |

|||

By 1980, Keele was at JBL where he took both his and Altec's designs a step further. He mated a JBL-style diffraction horn to a secondary horn consisting of exponentially-curved sides derived by using two radial formulas. This resulted in a hybrid constant directivity horn that was free from the distortion components associated with abrupt angle changes.<ref name=Henricksen455/> The market responded well to the design in products such as the JBL model 4430 studio monitor with its 100° x 100° model 2344 Bi-Radial high frequency horn often called "butt-cheeks".<ref>[http://www.audioheritage.org/html/profiles/jbl/4430-35.htm Audioheritage. ''JBL 4430 and 4435 Studio Monitors.'' David Smith. 2005]</ref> The Bi-Radial design had problems with apparent apex and arrayability in the same manner as the Mantaray.<ref name=Peavey2000/> |

|||

====Twin Bessel==== |

|||

Ramsa, the [[professional audio]] division of [[Panasonic Corporation]], introduced a twin Bessel constant directivity horn shortly after the Mantaray appeared. The design was very similar to the Mantaray and the Bi-Radial but it used a dual series Bessel expansion formula to determine the flare rate of the secondary horn section.<ref name=Henricksen455-456>Henricksen, ''Loudspeakers, Enclosures, and Headphones'', 455-456.</ref> |

|||

Most popular constant directivity horns (also known as CD horns) suffer from non-spherical wavefronts, limitations in arrayability, distortion at high [[sound pressure]] levels and resonances, reflections and distortions related to the transition from diffraction slot to secondary horn.<ref name=Peavey2000/> |

|||

===Quadratic-Throat Waveguide=== |

|||

In 1999, Charles Emory "Charlie" Hughes, II of [[Peavey Electronics]] filed for a patent on a hybrid horn he called Quadratic-Throat Waveguide.<ref>{{US patent reference |

|||

| number = 6059069 |

|||

| y = 2000 |

|||

| m = 05 |

|||

| d = 09 |

|||

| inventor = Charles Emory Hughes, II ([[Peavey Electronics]]) |

|||

| title = Loudspeaker waveguide design ''[Quadratic-Throat Waveguide]' |

|||

}}</ref> The horn was basically a simple conic section but its throat was curved in a circular arc to match the desired throat size for proper mating to the speaker driver. Instead of increasing the horn mouth size with a flare to control midrange beaming, a relatively thin layer of foam covering the mouth edge was found to suit the same end. The QT waveguide, when compared to popular CD horns produced about {{nowrap|3-4 dB}} lower levels of second harmonic distortion across all frequencies, and an average of {{nowrap|9 dB}} lower levels of the more annoying third harmonic distortion. Being without a diffraction slot, the QT waveguide was free from problems with apparent apex, making it arrayable as needed for public address purposes.<ref name=Peavey2000/> |

|||

Modern horn designs typically feature some form of conical, exponential or [[tractrix]] [[taper]]. Roughly speaking, the slower the flare rate, the deeper and lower frequencies the horn will reproduce for a given length of horn. For example, a horn area growth rate of 30% per foot will allow reproduction down to about 30 [[Hertz|Hz]]; 1000% per foot (10 times area) per foot provides midrange reproduction; 100 times area per foot is used in high frequency horns. |

Modern horn designs typically feature some form of conical, exponential or [[tractrix]] [[taper]]. Roughly speaking, the slower the flare rate, the deeper and lower frequencies the horn will reproduce for a given length of horn. For example, a horn area growth rate of 30% per foot will allow reproduction down to about 30 [[Hertz|Hz]]; 1000% per foot (10 times area) per foot provides midrange reproduction; 100 times area per foot is used in high frequency horns. |

||

Revision as of 08:04, 29 December 2008

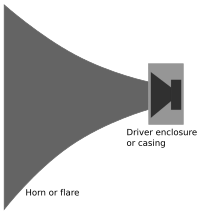

A horn speaker is a complete loudspeaker or loudspeaker element which uses a horn to increase the overall efficiency of the driving element, typically a diaphragm driven by an electromagnet. The horn itself is a passive component and does not amplify the sound from the driving element as such, but rather improves the coupling efficiency between the speaker driver and the air. The horn can be thought of as an "acoustic transformer" that provides impedance matching between the relatively dense diaphragm material and the air of low density. The result is greater acoustic output from a given driver.[1]

The narrow part of the horn next to the speaker driver is called the "throat" and the large part farthest away from the speaker driver is called the "mouth".[1]

Horns have been used to extend the low frequency limit of a speaker driver. The flare rate and the mouth size determine the low frequency limit. The throat size is more of a design choice. Horns have been known to extend the frequency range of a driver beyond five octaves.[1]

Horns have been used to modify the directional characteristics of the produced sound waves. Horizontal coverage angle is the primary determinant of horn width, and vertical coverage angle determines horn height. On- and off-axis performance will differ depending on the shape of the horn.[1] Compromises in performance such as distortions of the wavefront must be balanced against the design goal.[2]

Operation

Acoustic horns convert large pressure variations with a small displacement into a low pressure variation with a large displacement and vice versa. It does this through the gradual, often exponential increase of the cross sectional area of the horn. The small cross-sectional area of the throat restricts the passage of air thus presenting a high impedance to the driver. This allows the driver to develop a high pressure for a given displacement. Therefore the sound waves at the throat are of high pressure and low displacement. The tapered shape of the horn allows the sound waves to gradually decompress and increase in displacement until they reach the mouth where they are of a low pressure but large displacement.

A modern electrically driven horn speaker works the same way, replacing the mechanically excited diaphragm with a dynamic or piezoelectric speaker.

Horn technology history

The physics (and mathematics) of horn operation were developed for many years, reaching considerable sophistication before WWII. The most well known early horn speakers were those on mechanical phonographs, where the record moved a heavy metal needle that excited vibrations in a small metal diaphragm that acted as the driver for a horn. A famous example was the horn through which Nipper the RCA dog heard "His Master's Voice". The horn improves the loading and thus gets a better "coupling" of energy from the diaphragm into the air, and the pressure variations therefore get smaller as the volume expands and the sound travels up the horn. This kind of mechanical amplification was absolutely necessary in the days of pre-electrical sound reproduction in order to achieve a usable sound level.[3]

Cone

The cone is the oldest and simplest acoustic horn and, as the megaphone, is still used by cheerleaders and lifeguards as a passive amplifier of their voices. Because the conic section shape describes a portion of a perfect sphere of radiated sound, cones have no phase or amplitude distortion of the wavefront.[2] The acoustic loading provided by the cone does not extend the low frequency limit low enough for most modern purposes, with its output energy markedly lower than later designs throughout the bottom two octaves of the cone's intended frequency range.[2]

Exponential

The exponential horn has an acoustic loading property that allows the speaker driver to remain evenly balanced in output level over its frequency range.[5] A major drawback is that the exponential horn allows for a narrowing of the radiation pattern as frequency increases, making for high frequency 'beaming' on axis and dull sound off axis.[2] Another concern is that a throat of small diameter is needed for high efficiency at high frequencies but a larger throat is best for low frequencies. A common solution is to use two or more horns, each with the appropriate throat size, mouth size and flare rate for best performance in a selected frequency range, with sufficient overlap between the frequency ranges to provide a smooth transition between horns. Another solution tried in the late 1930s by Harry F. Olson of RCA was to use multiple exponential flare rates, either by connecting increasingly larger horns in series or by subdividing the interior of a single horn.[6]

Multicell

A number of symmetrical, narrow dispersion, usually exponential horns can be combined in an array driven by a single driver to produce multicell horns. Multicell horns have been used to address the problem of directivity since the 1930s, and they provide excellent low frequency loading. Their directional control begins to beam both vertically and horizontally in the middle of their target frequency range, narrowing further at high frequencies.[2] Multicell horns are complex, difficult to fabricate and thus have a higher associated expense. They persisted in public address applications for many years because, even with their faults, they sounded relatively good.[7]

Radial

Radial horns have two surfaces based on an exponential flare rate, and two straight walls that determine the output pattern. The radial horn exhibits some of the beaming of the exponential horn.[2] Altec sectoral horns were radial horns with vanes placed in the mouth of the horn for the stated purpose of pattern control. For ease in mounting to speaker cabinets, flat front radial horns have been used, for instance by Community in their SQ 90 high-frequency horn.[8] JBL's diffraction or "Smith" horn was a variation on the radial design, using a very small vertical dimension at the mouth as a method of avoiding the mid-range horizontal beaming of radial horns that have a larger vertical dimension at the mouth. Counterintuitively, the narrow vertical dimension provided for an expansive vertical output pattern approaching 90° for frequencies of a wavelength equal to the narrow vertical dimension.[7]

Constant directivity

In May 1975,[9] to address problems of beamwidth changing at different frequencies, D. Broadus "Don" Keele, Jr. of Electro-Voice introduced a hybrid horn with an exponential expansion rate near the throat followed by a conical expansion section and ending with a rapidly flaring flange at the mouth.[10] The flange at the mouth solved some remaining problems with lobing at higher frequencies.[7] Don Keele specified in one version of his design a wider horizontal flare for pattern control appropriate to public address purposes. Keele's paper[11] set forth the relationships between mouth size, frequency and coverage angle, providing a basis for many future developments of horn design.[7] One problem found with constant directivity horns is that the horizontal coverage pattern can't be narrowed without making the vertical coverage pattern too small to be useful.[2]

Mantaray

Subsequent to Keele's work and using his principles, Clifford A. Henricksen and Mark S. Ureda of Altec designed a strikingly different hybrid horn displaying constant directivity traits, the horizontal diffraction or "Mantaray" horn.[12] The Mantaray separated desired vertical coverage pattern from horizontal, making it possible to design horns for a variety of coverage patterns. The Mantaray shape starts with a vertically-oriented JBL-style diffraction horn leading into a conical waveguide (earliest designs) or a square or rectangular horn with four planar sides.[13] For midrange beaming control, the outer mouth was expanded further with a short, flared flange in the Keele style, or with added planar sides of a greater flare angle. Low frequency efficiency wasn't as pronounced as the constant directivity design.[12] Unlike previous designs, the apparent apex,[14] the focal point of pattern dispersion, was not the same for every frequency, making for an ellipsoidal wavefront rather than spherical. Because of this, the Mantaray could only be arrayed satisfactorally in one plane. Its abrupt breaks in flare rate caused diffraction, reflection and distortion components.[2]

Bi-Radial

By 1980, Keele was at JBL where he took both his and Altec's designs a step further. He mated a JBL-style diffraction horn to a secondary horn consisting of exponentially-curved sides derived by using two radial formulas. This resulted in a hybrid constant directivity horn that was free from the distortion components associated with abrupt angle changes.[12] The market responded well to the design in products such as the JBL model 4430 studio monitor with its 100° x 100° model 2344 Bi-Radial high frequency horn often called "butt-cheeks".[15] The Bi-Radial design had problems with apparent apex and arrayability in the same manner as the Mantaray.[2]

Twin Bessel

Ramsa, the professional audio division of Panasonic Corporation, introduced a twin Bessel constant directivity horn shortly after the Mantaray appeared. The design was very similar to the Mantaray and the Bi-Radial but it used a dual series Bessel expansion formula to determine the flare rate of the secondary horn section.[16]

Most popular constant directivity horns (also known as CD horns) suffer from non-spherical wavefronts, limitations in arrayability, distortion at high sound pressure levels and resonances, reflections and distortions related to the transition from diffraction slot to secondary horn.[2]

Quadratic-Throat Waveguide

In 1999, Charles Emory "Charlie" Hughes, II of Peavey Electronics filed for a patent on a hybrid horn he called Quadratic-Throat Waveguide.[17] The horn was basically a simple conic section but its throat was curved in a circular arc to match the desired throat size for proper mating to the speaker driver. Instead of increasing the horn mouth size with a flare to control midrange beaming, a relatively thin layer of foam covering the mouth edge was found to suit the same end. The QT waveguide, when compared to popular CD horns produced about 3-4 dB lower levels of second harmonic distortion across all frequencies, and an average of 9 dB lower levels of the more annoying third harmonic distortion. Being without a diffraction slot, the QT waveguide was free from problems with apparent apex, making it arrayable as needed for public address purposes.[2]

Modern horn designs typically feature some form of conical, exponential or tractrix taper. Roughly speaking, the slower the flare rate, the deeper and lower frequencies the horn will reproduce for a given length of horn. For example, a horn area growth rate of 30% per foot will allow reproduction down to about 30 Hz; 1000% per foot (10 times area) per foot provides midrange reproduction; 100 times area per foot is used in high frequency horns.

Modern high output horns also make the throat area of the horn smaller than the cone diaphram area. This is called the "loading" or "compression" ratio of the horn. The compression ratio is the cone area divided by the throat area. Typically for bass and midrange frequency the compression ratio is from (1.5 to 1) low compression to normal compression (2 to 1) to high compression (3.5 to 1). High frequency tweeters sometimes have compression ratios as high as 10 to 1.

The higher the compression the greater the horn's ability to properly couple the diaphragm to the air at the horn's mouth, increasing efficiency, until the compression ratio is so high that it actually begins to impede cone motion. At this point the maximum sound output power from the horn (at a given distortion) will be reduced. To demonstrate this at an extreme, place a cone woofer face down on a concrete floor. The compression ratio will be very high, however sound output from the back of the speaker will be quite low.

A newer term "waveguide" is used to describe conical, quadratic or oblate spheroidal horns. These are designed more for pattern control than acoustic loading.

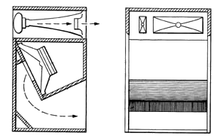

A recent variant on horn design is the multiple entry horn which incorporates multiple bandpass drivers whose diaphragms all exit into a single horn but at differing distances depending on the bandpass. High frequency drivers are at the horn's throat while lower frequency drivers are ported closer to the horn mouth. Servodrive, Renkus-Heinz, Yorkville Sound and Danley Sound Labs offer speakers with configurations like this, called variously CoEntrant Horn,[18] Unity Horn or Synergy Horn. Depending on implementation, more linear transient response and smoother polar patterns are possible.[19] Because the design retains pattern control over a large range of its total bandwidth, and because the acoustic center of the design is near the rear of the enclosure, it is more easily combined in arrays for public address applications.[20]

Applications

Horn speakers are used in many audio applications. The drivers in horn speakers can be very small, even for bass frequencies where conventional speakers would need to be very large for equivalent performance. Horn speakers can be designed to reproduce a wide range of frequencies using a single, small driver; to some extent these can be designed without requiring a crossover. Lowther, Fostex, and Goodmans are firms which have produced such designs.

Horn speakers can provide very high efficiencies, making them a good match for very low-powered amplifiers, such as single-ended triode amps or other tube amplifiers. After WWII, some early hi-fi fans went so far as to build low frequency horns whose mouths took up much of a wall of the listening room. The throats were sometimes outside on the lawn, or in the basement. With the coming of stereo in the 1960s, this approach was rare seen. Many speaker buyers and do-it-yourself speaker fans sought smaller designs for aesthetic reasons.

Some audiophiles use horn speakers for audio reproduction, while others eschew horn systems for their harmonic resonances, finding in them an unpleasant form of distortion. Since there are a variety of horn designs (of differing length, material, and taper, as well as different drivers) it is, to some extent, impossible to give such blanket characterizations to horn speakers.

Public address and concert use

Horn speakers can also be used to provide the very high sound pressure levels needed for sound reinforcement and public address applications, although in these high sound pressure applications, high fidelity is sometimes compromised for the sake of the necessary efficiency, and also for the controlled dispersion characteristics which are generally required in most large volume spaces. A new method of counteracting some of the horn distortions has been pioneered by Dave Gunness while he was with EAW. EAW horn-loaded loudspeakers that have been processed with this proprietary system show reduced distortion while retaining high output power and controlled dispersion.[21]

Concert venues often use large arrays of horn speakers for high-volume bass reproduction ("bass bins" or subwoofers), in order to provide bass that concertgoers can not only hear but feel. Combining multiple horn speakers in an array affords the same benefits as having a single horn with a greater mouth area: the low frequency cut-off extends lower as the horn mouth gets larger, and the array has the greater output power of multiple drivers.

See also

Notes

- ^ a b c d Henricksen, Loudspeakers, Enclosures, and Headphones, 446.

- ^ a b c d e f g h i j k Murray, The Quadratic Throat Waveguide

- ^ US patent 1381430, Edward Phipps, "Amplifier for phonographs and the like", issued 1921-06-14

- ^ US patent 4138594, Paul W. Klipsch, "Small dimension low frequency folded exponential horn loudspeaker with unitary sound path and loudspeaker system including same", issued 1979-02-05

- ^ US patent 4171734, Robert S. Peveto; Phillip R. Clements (Beta Sound, Inc.), "Exponential horn speaker", issued 1979-10-23

- ^ US patent 2203875, Harry F. Olson (RCA), "Loud-speaker [horn with multiple exponential flare rates]'", issued 1940-06-11

- ^ a b c d Henricksen, Loudspeakers, Enclosures, and Headphones, 454.

- ^ Henricksen, Loudspeakers, Enclosures, and Headphones, 453.

- ^ AES E-Library. What's So Sacred About Exponential Horns? D.B. (Don) Keele, Jr. May, 1975. 51st AES Convention.

- ^ US patent 4071112, D. Broadus Keele, Jr. (Electro-Voice), "Horn loudspeaker [constant directivity horn]'", issued 1978-01-31

- ^ D. B. Keele, Jr., Electro-Voice. What's So Sacred About Exponential Horns? May 1975.

- ^ a b c Henricksen, Loudspeakers, Enclosures, and Headphones, 455.

- ^ US patent 4187926, Clifford A. Henricksen, Mark S. Ureda (Altec), "Loudspeaker horn [Horizontal diffraction "Mantaray"]'", issued 1980-02-12

- ^ Altec Lansing Engineering Notes. Technical Letter No. 262. Coverage of Multiple Mantaray Horns. Mark Ureda, Ted Uzzle. Definition of 'apparent apex' and approximate locations for a number of Mantaray horn models.

- ^ Audioheritage. JBL 4430 and 4435 Studio Monitors. David Smith. 2005

- ^ Henricksen, Loudspeakers, Enclosures, and Headphones, 455-456.

- ^ US patent 6059069, Charles Emory Hughes, II (Peavey Electronics), "Loudspeaker waveguide design [Quadratic-Throat Waveguide]'", issued 2000-05-09

- ^ U.S. patent 5,526,456

- ^ Danley Sound Labs. A White Paper on Danley Sound Labs Tapped Horn and Synergy Horn Technologies

- ^ Live Sound International. May 2006, Volume 15, Number 5. TechTopic. Pat Brown. Loudspeaker Profile: Danley Sound Labs SH-50

- ^ Audio Engineering Society. "Gunness Focusing" NT whitepaper

References

- Ballou, Glen (1987). "Loudspeakers, Enclosures, and Headphones". Handbook for Sound Engineers: The New Audio Cyclopedia. Indianapolis, Indiana: Howard W. Sams & Co. ISBN 0672219832.

{{cite book}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - The Quadratic Throat Waveguide: A White Paper On An Invention by Charles E. Hughes of Peavey Electronics Corporation. (2000) John Murray, Peavey Electronics.

External links

- Lenard Education on horn systems Illustrated guide to horn loudspeakers

- The Frugal-Horns Site - open source horn projects