Scramjet: Difference between revisions

| Line 57: | Line 57: | ||

All scramjet engines have fuel injectors, a combustion chamber, a thrust nozzle and an intake, which compresses the incoming air. Sometimes engines also include a region which acts as a [[flame holder]], although the high [[stagnation temperature]]s mean that an area of focused waves may be used, rather than a discrete engine part as seen in turbine engines. Other engines use [[pyrophoric]] fuel additives, such as [[silane]], to avoid such issues. An isolator between the inlet and combustion chamber is often included to improve the homogeneity of the flow in the combustor and to extend the operating range of the engine. |

All scramjet engines have fuel injectors, a combustion chamber, a thrust nozzle and an intake, which compresses the incoming air. Sometimes engines also include a region which acts as a [[flame holder]], although the high [[stagnation temperature]]s mean that an area of focused waves may be used, rather than a discrete engine part as seen in turbine engines. Other engines use [[pyrophoric]] fuel additives, such as [[silane]], to avoid such issues. An isolator between the inlet and combustion chamber is often included to improve the homogeneity of the flow in the combustor and to extend the operating range of the engine. |

||

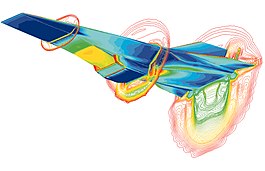

[[Image:X-43A (Hyper - X) Mach 7 computational fluid |

[[Image:X-43A (Hyper - X) Mach 7 computational fluid dynamic (CFD).jpg|thumb|265px|Computational fluid dynamics (CFD) image of the [[X-43A]] with scramjet attached to the underside at Mach 7]] |

||

A scramjet is reminiscent of a [[ramjet]]. In a typical ramjet, the supersonic inflow of the engine is decelerated at the inlet to subsonic speeds and then reaccelerated through a nozzle to supersonic speeds to produce thrust. This deceleration, which is produced by a normal [[shock wave|shock]], creates a total [[pressure]] loss which limits the upper operating point of a ramjet engine. |

A scramjet is reminiscent of a [[ramjet]]. In a typical ramjet, the supersonic inflow of the engine is decelerated at the inlet to subsonic speeds and then reaccelerated through a nozzle to supersonic speeds to produce thrust. This deceleration, which is produced by a normal [[shock wave|shock]], creates a total [[pressure]] loss which limits the upper operating point of a ramjet engine. |

||

| Line 63: | Line 63: | ||

For a scramjet, the kinetic energy of the freestream air entering the scramjet engine is large compared to the energy released by the reaction of the oxygen content of the air with a fuel (say [[hydrogen]]). Thus the heat released from combustion at [[Mach number|Mach]] 25 is around 10% of the total [[enthalpy]] of the working fluid. Depending on the fuel, the [[kinetic energy]] of the air and the potential combustion heat release will be equal at around [[Mach number|Mach]] 8. Thus the design of a scramjet engine is as much about minimizing drag as maximizing thrust. |

For a scramjet, the kinetic energy of the freestream air entering the scramjet engine is large compared to the energy released by the reaction of the oxygen content of the air with a fuel (say [[hydrogen]]). Thus the heat released from combustion at [[Mach number|Mach]] 25 is around 10% of the total [[enthalpy]] of the working fluid. Depending on the fuel, the [[kinetic energy]] of the air and the potential combustion heat release will be equal at around [[Mach number|Mach]] 8. Thus the design of a scramjet engine is as much about minimizing drag as maximizing thrust. |

||

This high speed makes the control of the flow within the combustion chamber more difficult. Since the flow is supersonic, no upstream influence propagates within the freestream of the combustion chamber. Thus throttling of the entrance to the thrust nozzle is not a usable control technique. In effect, a block of gas entering the combustion chamber must mix with fuel and have sufficient time for initiation and reaction, all the while |

This high speed makes the control of the flow within the combustion chamber more difficult. Since the flow is supersonic, no upstream influence propagates within the freestream of the combustion chamber. Thus throttling of the entrance to the thrust nozzle is not a usable control technique. In effect, a block of gas entering the combustion chamber must mix with fuel and have sufficient time for initiation and reaction, all the while traveling supersonically through the combustion chamber, before the burned gas is expanded through the thrust nozzle. This places stringent requirements on the pressure and temperature of the flow, and requires that the fuel injection and mixing be extremely efficient. Usable dynamic pressures lie in the range 20 to 200 kPa (0.2-2 bar), where |

||

:<math>q = \frac{1}{2}\rho v^2 </math> |

:<math>q = \frac{1}{2}\rho v^2 </math> |

||

Revision as of 15:50, 27 April 2010

driving propellers, rotors, ducted fans or propfans

| Scramjet | |

|---|---|

| |

| Reaction engines | |

A scramjet (supersonic combustion ramjet) is a variation of a ramjet distinguished by supersonic combustion. A scramjet, like a ramjet, essentially consists of a constricted tube through which inlet air is compressed by the high speed of the vehicle, a combustion chamber where fuel is combusted, and a nozzle through which the exhaust jet leaves at higher speed than the inlet air.

Most jet engines use a compressor to squeeze air into the engine, then spray fuel into the compressed air and ignite it to produce thrust by funneling it through the back. A scramjet uses the speed of the aircraft to compress the air, so very few moving parts are needed to operate it. In particular there is no high-speed turbine, as in a turbofan or turbojet engine, that is expensive to produce and can be a major point of failure. The minimum functional speed, however, requires acceleration by other means to hypersonic speed before the scramjet can become active. A scramjet requires supersonic airflow through the engine; thus, similar to a ramjet, scramjets have a minimum functional speed, about Mach 4.5 for current models.[1] A hybrid ramjet/scramjet would have a lower minimum functional Mach number, and some sources indicate the NASA X-43A research vehicle is a hybrid design. Recent tests of prototypes have used a booster rocket to obtain the necessary velocity. Air breathing engines should have significantly better specific impulse while within the atmosphere than rocket engines.

Projections for the top speed of a scramjet engine (without additional oxidiser input) vary between Mach 12 and Mach 24 (orbital velocity). The X-30 research gave Mach 17 due to combustion rate issues. By way of contrast, the fastest conventional air-breathing, manned vehicles, such as the U.S. Air Force SR-71 Blackbird, achieve approximately Mach 3.4 and rockets from the Apollo Program achieved Mach 30+.

Scramjets have weight and complexity issues that must be considered. While very short suborbital scramjet test flights have been performed, no flown scramjet has ever been designed to survive a flight test. The viability of scramjet vehicles is hotly contested in aerospace and space vehicle circles, in part because many of the parameters which would eventually define the efficiency of such a vehicle remain uncertain. This has led to grandiose claims from both sides, which have been intensified by the large amount of funding involved in any hypersonic testing. Some notable aerospace commentators such as Henry Spencer and Jim Oberg have gone so far as calling orbital scramjets "the hardest way to reach orbit", or even "scamjets" due to the extreme technical challenges involved. Major, well funded projects, like the X-30 were cancelled before producing any working hardware.

History

During and after World War II, tremendous amounts of time and effort were put into researching high-speed jet- and rocket-powered aircraft. The Bell X-1 attained supersonic flight in 1947 and, by the early 1960s, rapid progress towards faster aircraft suggested that operational aircraft would be flying at "hypersonic" speeds within a few years. Except for specialized rocket research vehicles like the North American X-15 and other rocket-powered spacecraft, aircraft top speeds have remained level, generally in the range of Mach 1 to Mach 3.

In the 1950s and 1960s a variety of experimental scramjets engines were built and ground tested in US and the UK. In 1981 tests were made in Australia under the guidance of Professor Ray Stalker in the T3 ground test facility at ANU.[2]

The main goal of civilian air transport has been reducing operating cost, rather than increasing flight speeds. Because supersonic flight using conventional jet engines requires significant amounts of fuel, airlines have favored subsonic jumbo jets rather than supersonic transports. The production supersonic airliners, Concorde and the Tupolev Tu-144, operated with little profit for the French and Russian airlines, but British Airways flew Concorde at a 60% profit margin over its commercial life[3] (though this does not include government-subsidized initial costs). Military combat aircraft design has focused on maneuverability, more recently combined with stealth. These features are thought to be incompatible with hypersonic aerodynamics because of the very high speeds and temperatures of hypersonic flight.

In the United States, from 1986–1993, a reasonably serious attempt to develop a single stage to orbit reusable spaceplane using scramjet engines was made, but the Rockwell X-30 (NASP) program was discontinued before it yielded any working hardware.

Hypersonic flight concepts haven't gone away, however, and low-level investigations have continued over the past few decades. Presently, the US military and NASA have formulated a "National Hypersonics Strategy" to investigate a range of options for hypersonic flight. The UK, Australia, France, Russia, and India have also progressed in hypersonic propulsion research.

Different U.S. organizations have accepted hypersonic flight as a common goal. The U.S. Army desires hypersonic missiles that can attack mobile missile launchers quickly. NASA believes hypersonics could help develop economical, reusable launch vehicles. The Air Force is interested in a range of hypersonic systems, from air-launched cruise missiles to orbital spaceplanes, that the service believes could bring about a true "aerospace force."

There are several claims as to which group were the first to demonstrate a "working" scramjet, where "working" in this case can refer to:

- Demonstration of supersonic combustion in a ground test

- Demonstration of net thrust in a ground test

- Demonstration of supersonic combustion or net thrust in a ground test with realistic fuels and/or realistic wind tunnel flow conditions.

- Demonstration of supersonic combustion in a flight test

- Demonstration of net thrust in a flight test.

The problem is complicated by the release of previously classified material and by partial publication, where claims are made, but specific parts of an experiment are kept secret. Additionally experimental difficulties in verifying that supersonic combustion actually occurred, or that actual net thrust was produced mean that at least four consortia have legitimate claims to "firsts", with several nations and institutions involved in each consortium (For a further listing see Scramjet Programs). On June 15, 2007, the US Defense Advanced Research Project Agency (DARPA) and the Australian Defence Science and Technology Organization (DSTO), announced a successful scramjet flight at Mach 10 using rocket engines to boost the test vehicle to hypersonic speeds, at the Woomera Rocket Range in Central Australia.

No scramjet powered vehicle has yet been produced outside an experimental program.

Simple description

A scramjet is a type of jet engine designed to operate at the speeds of rockets. Its main difference from a rocket is that it collects air from the atmosphere to burn its fuel rather than carrying an oxidizing substance on board. More conventional jets (turbojets, turbofans, and ramjets) share this characteristic but are unsuitable for the high speeds at which scramjets can operate.

Turbine-based engines, while efficient for flight at subsonic and supersonic speeds, quickly lose their efficiency at higher Mach numbers. As air enters the compressor its pressure and temperature increase, with high Mach numbers resulting in high temperatures. High temperatures can cause melting or structural failure of the engine and reduces the energy released from combustion as the temperature of the fuel-air mixture increases. The drag increases with Mach number squared as the available energy decreases. The maximum operating speed of a turbine-based engine can be increased by cooling the air in the inlet and by combining the turbine with other thrust-producing technologies like afterburners or ramjets (See for example SABRE).

Ramjets are easier to build for higher operating temperatures than turbojets and produce less drag. They are thus capable of flight at higher speeds than turbojets (but with the drawback that they cannot usefully operate below about 400 mph). Ramjets must slow intake air down to subsonic speed for fuel mixing and combustion by compressing it at the inlet. At conventional supersonic speeds with subsonic combustion this is more efficient than using a bladed compressor but at higher speeds a problem develops. The shock wave which slows the air during the inlet process heats the air so much that the air itself becomes chemically reactive and energy is lost producing nitrates and other chemicals even before entering the engine and adding fuel; the combustion of the air then produces little additional useful energy.

The theoretical upper operating limit for engines with subsonic combustion is not a hard line, but lies somewhere between Mach 4 and Mach 8 depending on the fuel used; usually about Mach 5.5.

The scramjet is intended to avoid the high drag and low combustion efficiency of other types of engine at high Mach number by maintaining supersonic airflow through the whole engine. The lack of a strong shock, as in a ramjet, significantly reduces the drag of the engine. Because intake air is decelerated less than with a ramjet, it is also heated less and fuel can be burned more efficiently. The difficulty is that at these higher airflow velocities, the fuel must be mixed and burned in a very short time, and that any error in the geometry of the engine will result in a high drag.

A very simple scramjet would look like two kitchen funnels attached by their small ends. The first funnel is the intake, into which air is forced, compressing and heating in the process. At the narrow section where the funnels join and compression is greatest, fuel is added and combusted which heats the gas further. The gas expands and exits through the second funnel, like the nozzle of a rocket, and thrust is produced.

Note that most artists' impressions of scramjet-powered vehicles depict waveriders, on which the underside of the vehicle forms the intake and nozzle of the engine; the two are asymmetric and contribute directly to the lift of the aircraft. A waverider is the required form for a hypersonic lifting body.

Theory

All scramjet engines have fuel injectors, a combustion chamber, a thrust nozzle and an intake, which compresses the incoming air. Sometimes engines also include a region which acts as a flame holder, although the high stagnation temperatures mean that an area of focused waves may be used, rather than a discrete engine part as seen in turbine engines. Other engines use pyrophoric fuel additives, such as silane, to avoid such issues. An isolator between the inlet and combustion chamber is often included to improve the homogeneity of the flow in the combustor and to extend the operating range of the engine.

A scramjet is reminiscent of a ramjet. In a typical ramjet, the supersonic inflow of the engine is decelerated at the inlet to subsonic speeds and then reaccelerated through a nozzle to supersonic speeds to produce thrust. This deceleration, which is produced by a normal shock, creates a total pressure loss which limits the upper operating point of a ramjet engine.

For a scramjet, the kinetic energy of the freestream air entering the scramjet engine is large compared to the energy released by the reaction of the oxygen content of the air with a fuel (say hydrogen). Thus the heat released from combustion at Mach 25 is around 10% of the total enthalpy of the working fluid. Depending on the fuel, the kinetic energy of the air and the potential combustion heat release will be equal at around Mach 8. Thus the design of a scramjet engine is as much about minimizing drag as maximizing thrust.

This high speed makes the control of the flow within the combustion chamber more difficult. Since the flow is supersonic, no upstream influence propagates within the freestream of the combustion chamber. Thus throttling of the entrance to the thrust nozzle is not a usable control technique. In effect, a block of gas entering the combustion chamber must mix with fuel and have sufficient time for initiation and reaction, all the while traveling supersonically through the combustion chamber, before the burned gas is expanded through the thrust nozzle. This places stringent requirements on the pressure and temperature of the flow, and requires that the fuel injection and mixing be extremely efficient. Usable dynamic pressures lie in the range 20 to 200 kPa (0.2-2 bar), where

where

To keep the combustion rate of the fuel constant, the pressure and temperature in the engine must also be constant. This is problematic because the airflow control systems that would facilitate this are not physically possible in a scramjet launch vehicle due to the large speed and altitude range involved, meaning that it must travel at an altitude specific to its speed. Because air density reduces at higher altitudes, a scramjet must climb at a specific rate as it accelerates to maintain a constant air pressure at the intake. This optimal climb/descent profile is called a "constant dynamic pressure path". It's thought that scramjets might be operable up to an altitude of 75 km.[4]

Fuel injection and management is also potentially complex. One possibility would be that the fuel is pressurized to 100 bar by a turbo pump, heated by the fuselage, sent through the turbine and accelerated to higher speeds than the air by a nozzle. The air and fuel stream are crossed in a comb like structure, which generates a large interface. Turbulence due to the higher speed of the fuel lead to additional mixing. Complex fuels like kerosene need a long engine to complete combustion.

The minimum Mach number at which a scramjet can operate is limited by the fact that the compressed flow must be hot enough to burn the fuel, and of high enough pressure that the reaction is finished before the air moves out the back of the engine. Additionally, in order to be called a scramjet, the compressed flow must still be supersonic after combustion. Here two limits must be observed: Firstly, since when a supersonic flow is compressed it slows down, the level of compression must be low enough (or the initial speed high enough) not to slow the gas below Mach 1. If the gas within a scramjet goes below Mach 1 the engine will "choke", transitioning to subsonic flow in the combustion chamber. This effect is well known amongst experimenters on scramjets since the waves caused by choking are easily observable. Additionally, the sudden increase in pressure and temperature in the engine can lead to an acceleration of the combustion, leading to the combustion chamber exploding.

Secondly, the heating of the gas by combustion causes the speed of sound in the gas to increase (and the Mach number to decrease) even though the gas is still travelling at the same speed. Forcing the speed of air flow in the combustion chamber under Mach 1 in this way is called "thermal choking". It is clear that a pure scramjet can operate at Mach numbers of 6-8,[5] but in the lower limit, it depends on the definition of a scramjet. Certainly there are designs where a ramjet transforms into a scramjet over the Mach 3-6 range (Dual-mode scramjets).[6] In this range however, the engine is still receiving significant thrust from subsonic combustion of "ramjet" type.

The high cost of flight testing and the unavailability of ground facilities have hindered scramjet development. A large amount of the experimental work on scramjets has been undertaken in cryogenic facilities, direct-connect tests, or burners, each of which simulates one aspect of the engine operation. Further, vitiated facilities, storage heated facilities, arc facilities and the various types of shock tunnels each have limitations which have prevented perfect simulation of scramjet operation. The HyShot flight test showed the relevance of the 1:1 simulation of conditions in the T4 and HEG shock tunnels, despite having cold models and a short test time. The NASA-CIAM tests provided similar verification for CIAM's C-16 V/K facility and the Hyper-X project is expected to provide similar verification for the Langley AHSTF,[7] CHSTF[8] and 8 ft (2.4 m) HTT.

Computational fluid dynamics has only recently reached a position to make reasonable computations in solving scramjet operation problems. Boundary layer modeling, turbulent mixing, two-phase flow, flow separation, and real-gas aerothermodynamics continue to be problems on the cutting edge of CFD. Additionally, the modeling of kinetic-limited combustion with very fast-reacting species such as hydrogen makes severe demands on computing resources. Reaction schemes are numerically stiff requiring reduced reaction schemes.

Much of scramjet experimentation remains classified. Several groups including the US Navy with the SCRAM engine between 1968–1974, and the Hyper-X program with the X-43A have claimed successful demonstrations of scramjet technology. Since these results have not been published openly, they remain unverified and a final design method of scramjet engines still does not exist.

The final application of a scramjet engine is likely to be in conjunction with engines which can operate outside the scramjet's operating range. Dual-mode scramjets combine subsonic combustion with supersonic combustion for operation at lower speeds, and rocket-based combined cycle (RBCC) engines supplement a traditional rocket's propulsion with a scramjet, allowing for additional oxidizer to be added to the scramjet flow. RBCCs offer a possibility to extend a scramjet's operating range to higher speeds or lower intake dynamic pressures than would otherwise be possible.

Advantages and disadvantages of scramjets

Special cooling and materials

Unlike a rocket that quickly passes mostly vertically through the atmosphere or a turbojet or ramjet that flies at much lower speeds, a hypersonic airbreathing vehicle optimally flies a "depressed trajectory", staying within the atmosphere at hypersonic speeds. Because scramjets have only mediocre thrust-to-weight ratios, acceleration would be limited. Therefore time in the atmosphere at hypersonic speed would be considerable, possibly 15–30 minutes. Similar to a reentering space vehicle, heat insulation would be a formidable task. The time in the atmosphere would be greater than that for a typical space capsule, but less than that of the space shuttle.

New materials offer good insulation at high temperature, but they often sacrifice themselves in the process. Therefore studies often plan on "active cooling", where coolant circulating throughout the vehicle skin prevents it from disintegrating. Often the coolant is the fuel itself, in much the same way that modern rockets use their own fuel and oxidizer as coolant for their engines. All cooling systems add weight and complexity to a launch system and reduce its efficiency. The increased cooling requirements of scramjet engines result in lower efficiency.

Engine weight and efficiency

The performance of a launch system is complex and depends greatly on its weight. Normally craft are designed to maximise range (), orbital radius () or payload mass fraction () for a given engine and fuel. This results in tradeoffs between the efficiency of the engine (takeoff fuel weight) and the complexity of the engine (takeoff dry weight), which can be expressed by the following:

Where :

- is the empty mass fraction, and represents the weight of the superstructure, tankage and engine.

- is the fuel mass fraction, and represents the weight of fuel, oxidiser and any other materials which are consumed during the launch.

- is initial mass ratio, and is the inverse of the payload mass fraction. This represents how much payload the vehicle can deliver to a destination.

A scramjet increases the mass of the engine over a rocket, and decreases the mass of the fuel . It can be difficult to decide whether this will result in an increased (which would be an increased payload delivered to a destination for a constant vehicle takeoff weight. The logic behind efforts driving a scramjet is (for example) that the reduction in fuel decreases the total mass by 30%, while the increased engine weight adds 10% to the vehicle total mass. Unfortunately the uncertainty in the calculation of any mass or efficiency changes in a vehicle is so great that slightly different assumptions for engine efficiency or mass can provide equally good arguments for or against scramjet powered vehicles.

Additionally, the drag of the new configuration must be considered. The drag of the total configuration can be considered as the sum of the vehicle drag () and the engine installation drag (). The installation drag traditionally results from the pylons and the coupled flow due to the engine jet, and is a function of the throttle setting. Thus it is often written as:

Where:

- is the loss coefficient

- is the thrust of the engine

For an engine strongly integrated into the aerodynamic body, it may be more convenient to think of () as the difference in drag from a known base configuration.

The overall engine efficiency can be represented as a value between 0 and 1 (), in terms of the specific impulse of the engine:

Where:

- is the acceleration due to gravity at ground level

- is the vehicle speed

- is the specific impulse

- is fuel heat of reaction

Specific impulse is often used as the unit of efficiency for rockets, since in the case of the rocket, there is a direct relation between specific impulse, specific fuel consumption and exhaust velocity. This direct relation is not generally present for airbreathing engines, and so specific impulse is less used in the literature. Note that for an airbreathing engine, both and are a function of velocity.

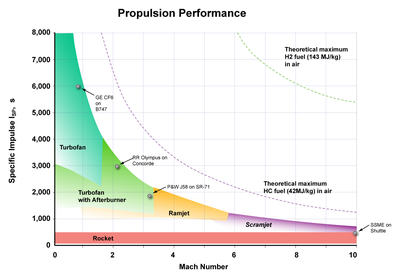

The specific impulse of a rocket engine is independent of velocity, and common values are between 200 and 600 seconds (450s for the space shuttle main engines). The specific impulse of a scramjet varies with velocity, reducing at higher speeds, starting at about 1200s, although values in the literature vary.

For the simple case of a single stage vehicle, the fuel mass fraction can be expressed as:

Where this can be expressed for single stage transfer to orbit as:

or for level atmospheric flight from air launch (missile flight):

Where is the range, and the calculation can be expressed in the form of the Breguet range formula:

Where:

- is the lift coefficient

- is the drag coefficient

This extremely simple formulation, used for the purposes of discussion assumes:

- Single stage vehicle

- No aerodynamic lift for the transatmospheric lifter

However they are true generally for all engines.

Simplicity of design

Scramjets have few to no moving parts. Most of their body consists of continuous surfaces. With simple fuel pumps, reduced total components, and the reentry system being the craft itself, scramjet development tends to be more of a materials and modelling problem than anything else.

Additional propulsion requirements

A scramjet cannot produce efficient thrust unless boosted to high speed, around Mach 5, depending on design, although, as mentioned earlier, it could act as a ramjet at low speeds. A horizontal take-off aircraft would need conventional turbofan or rocket engines to take off, sufficiently large to move a heavy craft. Also needed would be fuel for those engines, plus all engine associated mounting structure and control systems. Turbofan engines are heavy and cannot easily exceed about Mach 2-3, so another propulsion method would be needed to reach scramjet operating speed. That could be ramjets or rockets. Those would also need their own separate fuel supply, structure, and systems. Many proposals instead call for a first stage of droppable solid rocket boosters, which greatly simplifies the design.

Testing difficulties

Unlike jet or rocket propulsion systems facilities which can be tested on the ground, testing scramjet designs use extremely expensive hypersonic test chambers or expensive launch vehicles, both of which lead to high instrumentation costs. Launched test vehicles very typically end with destruction of the test item and instrumentation.

Lack of stealth

There is no published way to make a scramjet powered vehicle (or any other hypersonic vehicle) have any sort of stealth. This is because the vehicle would be very hot due to its high speed within the atmosphere and it would be easy to detect with infrared sensors. Any[citation needed] aggressive act against a scramjet vehicle during flight would be nearly impossible, however, because of the high speed at which it operates. If the aircraft was covered with RADAR absorbent material (RAM) the scramjet vehicle would be slightly more stealthy at lower speeds and altitudes[citation needed].

Advantages and disadvantages for orbital vehicles

Propellant

An advantage of a hypersonic airbreathing (typically scramjet) vehicle like the X-30 is avoiding or at least reducing the need for carrying oxidizer. For example the space shuttle external tank holds 616,432 kg of liquid oxygen (LOX) and 103,000 kg of liquid hydrogen (LH2) while having an empty weight of 30,000 kg. The orbiter gross weight is 109,000 kg with a maximum payload of about 25,000 kg and to get the assembly off the launch pad the shuttle uses two very powerful solid rocket boosters with a weight of 590,000 kg each. If the oxygen could be eliminated, the vehicle could be lighter at liftoff and maybe carry more payload. That would be an advantage, but the central motivation in pursuing hypersonic airbreathing vehicles would be to reduce cost.

On the other hand, scramjets spend more time in the atmosphere and require more hydrogen fuel to deal with aerodynamic drag. Whereas liquid oxygen is quite a dense fluid, liquid hydrogen has much lower density and takes up much more volume. This means that the vehicle using this fuel becomes much bigger and gives even more drag.[9]

Thrust-to-weight ratio

A rocket has the advantage that its engines have very high thrust-weight ratios (~100:1), while the tank to hold the liquid oxygen approaches a tankage ratio of ~100:1 also. Thus a rocket can achieve a very high mass fraction (Takeoff rocket mass:unfuelled rocket mass+fuel+oxidiser+structure+engines+payload), which improves performance. By way of contrast the projected thrust/weight ratio of scramjet engines of about 2 mean a very much larger percentage of the takeoff mass is engine (ignoring that this fraction increases anyway by a factor of about four due to the lack of onboard oxidiser). In addition the vehicle's lower thrust does not necessarily avoid the need for the expensive, bulky, and failure prone high performance turbopumps found in conventional liquid-fuelled rocket engines, since most scramjet designs seem to be incapable of orbital speeds in airbreathing mode, and hence extra rocket engines are needed.

Need additional engine(s) to reach orbit

Scramjets might be able to accelerate from approximately Mach 5-7 to around somewhere between half of orbital velocity and orbital velocity (X-30 research suggested that Mach 17 might be the limit compared to an orbital speed of Mach 25, and other studies put the upper speed limit for a pure scramjet engine between Mach 10 and 25, depending on the assumptions made). Generally, another propulsion system (very typically rocket is proposed) is expected to be needed for the final acceleration into orbit. Since the delta-V is moderate and the payload fraction of scramjets high, lower performance rockets such as solids, hypergolics, or simple liquid fueled boosters might be acceptable. Opponents of scramjet research claim that most of the theoretical advantages for scramjets only accrue if a single stage to orbit (SSTO) vehicle can be successfully produced. Proponents of scramjet research claim that this is a straw man argument, and that SSTO vehicles are exactly as difficult to produce and bring the same benefits to rocket-powered and scramjet-powered launch vehicles.

Reentry

The scramjet's heat-resistant underside potentially doubles as its reentry system if a single-stage-to-orbit vehicle using non-ablative, non-active cooling is visualised. If an ablative shielding is used on the engine it will probably not be usable after ascent to orbit. If active cooling is used the loss of all fuel during the burn to orbit will also mean the loss of all cooling for the thermal protection system.

Costs

Reducing the amount of fuel and oxidizer does not necessarily improve costs as rocket propellants are comparatively very cheap. Indeed, the unit cost of the vehicle can be expected to end up far higher, since aerospace hardware cost is about two orders of magnitude higher than liquid oxygen, fuel and tankage, and scramjet hardware seems to be much heavier than rockets for any given payload. Still, if scramjets enable reusable vehicles, this could theoretically be a cost benefit. Whether equipment subject to the extreme conditions of a scramjet can be reused sufficiently many times is unclear; all flown scramjet tests only survive for short periods and have never been designed to survive a flight to date.

The eventual cost of such a vehicle is the subject of intense debate since even the best estimates disagree whether a scramjet vehicle would be advantageous. It is likely that a scramjet vehicle would need to lift more load than a rocket of equal takeoff weight in order to be equally as cost efficient (if the scramjet is a non-reusable vehicle).

Applications

Seeing its potential, organizations around the world are researching scramjet technology. Scramjets will likely propel missiles first, since that application requires only cruise operation instead of net thrust production. Much of the money for the current research comes from governmental defense research contracts.

Space launch vehicles may or may not benefit from having a scramjet stage. A scramjet stage of a launch vehicle theoretically provides a specific impulse of 1000 to 4000 s whereas a rocket provides less than 450 s while in the atmosphere,[10][11] potentially permitting much cheaper access to space. A scramjet's specific impulse decreases rapidly with speed, however, and the vehicle would suffer from a relatively low lift to drag ratio.

One issue is that scramjet engines are predicted to have exceptionally poor thrust to weight ratio- around 2.[12] This compares very unfavorably with the 50-100 of a typical rocket engine. This is compensated for in scramjets partly because the weight of the vehicle would be carried by aerodynamic lift rather than pure rocket power (giving reduced 'gravity losses'),[citation needed] but scramjets would take much longer to get to orbit due to lower thrust which greatly offsets the advantage. The takeoff weight of a scramjet vehicle is significantly reduced over that of a rocket, due to the lack of onboard oxidiser, but increased by the structural requirements of the larger and heavier engines.

Whether this vehicle would be reusable or not is still a subject of debate and research.

An aircraft using this type of jet engine could dramatically reduce the time it takes to travel from one place to another, potentially putting any place on Earth within a 90 minute flight. However, there are questions about whether such a vehicle could carry enough fuel to make useful length trips, and there are issues with sonic booms.

There are also questions as to how realistic such a proposal is that revolve around costs (capital and maintenance) of technology that is yet to be developed.

Recent progress

In recent years, significant progress has been made in the development of hypersonic technology, particularly in the field of scramjet engines.

US efforts are probably the best funded, and the Hyper-X group has claimed the first flight of a thrust-producing scramjet with full aerodynamic maneuvering surfaces. However, the first group to demonstrate a scramjet working in an atmospheric test was a project by a joint British and Australian team from UK defense company QinetiQ and the University of Queensland. The HyShot project demonstrated scramjet combustion in July 30, 2002. The scramjet engine worked effectively and demonstrated supersonic combustion in action. However, the engine was not designed to provide thrust to propel a craft. It was designed more or less as a technology demonstrator.[citation needed]

On Friday, June 15, 2007, the US Defense Advanced Research Project Agency (DARPA), in cooperation with the Australian Defence Science and Technology Organization (DSTO), announced a successful scramjet flight at Mach 10 using rocket engines to boost the test vehicle to hypersonic speeds.[citation needed]

On May 22, 2009, Woomera hosted the first successful test flight of a hypersonic aircraft in HIFire. The launch was one of 10 planned test flights. The series of up to 10 planned hypersonic flight experiments are part of a joint research program between the Defence Science and Technology Organisation and the US Air Force, designated as the Hypersonic International Flight Research Experimentation (HIFiRE).[13] HIFiRE is investigating hypersonics technology (the study of flight exceeding five times the speed of sound) and its application to advanced scramjet-powered space launch vehicles — the objective is to support the new Boeing X-51 scramjet demonstrator while also building a strong base of flight test data for quick-reaction space launch development and hypersonic "quick-strike" weapons.[13]

On 22 and 23 March 2010, Australian and United States defence scientists successfully tested a (HIFiRE) hypersonic rocket. It reached an atmospheric veocity of "more than 5,000 kilometres per hour" after taking off from the Woomera Test Range in outback South Australia.[14][15]

At least the following nations have active scramjet programs (by alphabetical order):[original research?]

- Australia

- Brazil

- China

- France

- Germany

- India

- Israel

- Italy

- Japan

- Russia

- South Korea

- Sweden

- United Kingdom

- United States of America

Popular culture

- The 1983 television movie "Starflight: The Plane That Couldn't Land" explores the concept of a hypersonic jetliner for passenger transportation, developed by the fictional company Thornwall Aviation. The jetliner uses scramjet engines to reach a point high in the stratosphere for a quick two-hour jump from Los Angeles to Sydney, and the engines are powered with hydrogen. NASA is accustomed to handling this fuel, and a NASA space shuttle handles a refuelling job while the jetliner is (accidentally) stuck in orbit.

- In the 2005 movie Stealth both the F/A-37 Talon and UCAV EDI are powered by pulse detonation engines with scramjet boosters.

- The Mave fighter in Sentou Yousei Yukikaze has an option within its performance range called "RAM-AIR," which is treated as a ramjet but has performance which more closely resembles a scramjet. It was used by Rei Fukai, the main character, to chase after and catch up to an enemy fighter moments before it made a kamikaze attack on a friendly ship.

- One of the engine types available for the customizable aircraft in Ace Combat X is called the "SCRAMjet."

- In the episode "Pandora's Box" of the CBS television show Numb3rs, a crashed plane was carrying a ScramJet engine prototype as undeclared cargo for testing.

- The V-Wing from the Star Wars comic book series Dark Empire features a booster engine described as a scramjet. The speed of the craft, however, is far below what a scramjet would produce.

- Leela orders the crew to fire up the scramjets in order to escape aliens in the television show Futurama. (This is probably not a real scramjet, as the name was most likely used because of its similarity to the word 'scram').

- The FOX Military Science-Fiction series Space: Above and Beyond featured the 2063 AD USMC and USASF using endo/exo atomspheric Scramjet fighters called SA-71 "Hammerheads".

- The 2005 video game, Dreamfall: The Longest Journey set in the future, depicts scramjets as a common form of transportation.

- The scramjet made a named appearance in Dan Brown's book Angels & Demons as a prototype Boeing X-33. The pilot describes it to Robert Langdon thus: "250,000 kilos fully fueled," the pilot offered like a father bragging about his newborn. "Runs on slush hydrogen. The shell's a titanium matrix with silicon carbide fibers. She packs a 20:1 thrust/weight ratio; most jets run at 7:1".

See also

- Rockwell X-30

- Single-stage to orbit

- X-43A

- X-51

- HyShot

- Liquid air cycle engine/SABRE

- List of emerging technologies

- Atmospheric reentry

- Busemann's Biplane

- Pulse detonation engine

Notes

- ^ "Mach 6 test aircraft set for trials". NetworkWorld. 2009-03-09. Retrieved 2009-09-06.

- ^ "Milestones in the history of scramjets — UQ News Online — The University of Queensland". Uq.edu.au. Retrieved 2009-08-18.

- ^ "Faq". Concorde Sst. Retrieved 2009-08-18.

- ^ "Scramjets". Orbitalvector.com. 2002-07-30. Retrieved 2009-08-18.

- ^ Paull, A. (1995). "Experiments on supersonic combustion ramjet propulsion in a shock tunnel". Jfm 296: 156-183.

{{cite journal}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ Voland, R.T., Auslender, A.H., Smart, M.K., Roudakov, A.S., Semenov, V.L., Kopchenov, V. "CIAM/NASA Mach 6.5 scramjet flight and ground test", AIAA-99-4848.

- ^ "The Langley Arc-Heated Scramjet Test Facility Brochure". Wte.larc.nasa.gov. 2005-11-17. Retrieved 2009-08-18.

- ^ "The Langley Combustion-Heated Scramjet Test Facility Brochure". Wte.larc.nasa.gov. 2005-11-17. Retrieved 2009-08-18.

- ^ pg 78. Books.google.com. 2003-05-14. Retrieved 2009-08-18.

- ^ Kors, D.L. “Design considerations for combined air breathing-rocket propulsion systems.”, AIAA Paper No. 90-5216, 1990.

- ^ Varvill, R., Bond, A. "A Comparison of Propulsion Concepts for SSTO Reuseable Launchers", JBIS, Vol 56, pp 108-117, 2003. Figure 8.

- ^ Varvill, R., Bond, A. "A Comparison of Propulsion Concepts for SSTO Reuseable Launchers", JBIS, Vol 56, pp 108-117, 2003. Figure 7.

- ^ a b Daily Telegraph. 2009-05-24 http://www.dailytelegraph.com.au/news/indepth/woomera-hosts-first-hifire-hypersonic-test-flight/story-e6frewsr-1225715365056.

{{cite news}}: Missing or empty|title=(help) - ^ http://news.smh.com.au/breaking-news-national/scientists-conduct-second-hifire-test-20100322-qqrp.html Sydney Morning Herald Online - (22 March 2010) - 'Scientists conduct second HIFiRE test'

- ^ http://www.abc.net.au/news/stories/2010/03/23/2853372.htm ABC Online - (23 March 2010) - 'Success for hypersonic outback flight'

References

- Billig, FS "SCRAM-A Supersonic Combustion Ramjet Missile", AIAA paper 93-2329, 1993.

- HyShot - The University Of Queensland

- ABC's The Lab The 2002 Hyshot launch.

- Latest results from the 24 March 2006 QinetiQ HyShot launch.

- French Support Russian SCRAMJET Tests.

- A Burning Question. American Scientist.

- Hypersonic Scramjet Projectile Flys in Missile Test. SpaceDaily.

- NASA website for National Hypersonics Plan

- NASA's X-43A

- University of Queensland Centre for Hypersonics

- http://news.yahoo.com/s/nm/20070615/tc_nm/australia_jet_dc;_ylt=AjD55nNEoWlZGJ2UcFk9PrHQn6gB

External links

- "Variable geometry inlet design for scram jet engine". US Patent & Trademark Office. Retrieved October 7, 2005.

{{cite web}}: Unknown parameter|dateformat=ignored (help) - "Airbreather's Burden". Why airbreathing isn't necessarily very good for reaching orbit. Retrieved December 27, 2005.

{{cite web}}: Unknown parameter|dateformat=ignored (help) - [1] Australian Scientists about to make the break through.

- [2] The break through.

- BBC: Scramjet

- Scramjet combustor development-PDF file

![{\displaystyle \Pi _{f}=1-\exp \left[-{\frac {\left({\frac {V_{initial}^{2}}{2}}-{\frac {V_{i}^{2}}{2}}\right)+\int {g}\,dr}{\eta _{0}h_{PR}\left(1-{\frac {D+D_{e}}{F}}\right)}}\right]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/c406e8d888d0b2363d2fff8498e47ac4297db42e)

![{\displaystyle \Pi _{f}=1-\exp \left[-{\frac {g_{0}r_{0}\left(1-{\frac {1}{2}}{\frac {r_{0}}{r}}\right)}{\eta _{0}h_{PR}\left(1-{\frac {D+D_{e}}{F}}\right)}}\right]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/3f8afc2c31ecfdacedd5d5ecc89b98566879f370)

![{\displaystyle \Pi _{f}=1-\exp \left[-{\frac {g_{0}R}{\eta _{0}h_{PR}\left(1-\phi _{e}\right){\frac {C_{L}}{C_{D}}}}}\right]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/b481e1f3fe8bdfbc2826432756168ab6b2b483de)