Semi-automatic transmission

This article has multiple issues. Please help improve it or discuss these issues on the talk page. (Learn how and when to remove these messages)

|

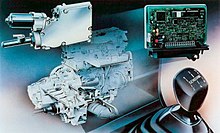

A semi-automatic transmission (also known as a clutchless manual[1], auto-manual[2], semi-manual (in passenger cars), or (in motorsports) a paddle-shift gearbox, is an automobile transmission that combines mechanisms of a manual and automatic transmission.

Semi-automatic transmission refers to a conventional manual transmission with an automatic clutch. They facilitate gear shifts for the driver by operating the clutch system automatically, while still requiring the driver to manually shift gears. This system is commonly found on older vehicles, such as automobiles and buses, without a clutch pedal, and on some motorcycles, minus the hand clutch lever.[3][4] These transmission systems will generally use paddle-shifters in racecars.

Operation

Semi-automatics facilitate gear shifts by dispensing the need to depress a clutch pedal at the same time as changing gears. Depending on the mechanical build and design, they can use electronic sensors, hydraulics, pneumatics, processors, and actuators to execute gear shifts when requested by the driver. This removes the need for a clutch pedal which the driver otherwise needs to depress before making a gear change since the clutch itself is actuated by electronic equipment which can synchronize the timing and torque required to make quick, smooth gear shifts. The system was designed by automobile manufacturers to provide a better driving experience through fast overtaking maneuvers on highways. Motorcycles with this system use a conventional sequential foot-shift lever (like on a manual motorcycle), but use a centrifugal (automatic) clutch system, removing the need for a hand-clutch lever, and manual clutch actuation.

The operation of semi-automatic transmissions has evolved over time. Many different times of clutch actuation systems have been used, from electro-hydraulic, pneumatic, and electromechanical clutches, while other manufactures have used alternate methods of actuation, like vacuum-operated or electromagnetic clutches. Semi-automatic transmissions have evolved as vehicle manufacturers experimented with different systems. The clutches are usually connected to an electronic control system, which uses various electrical sensors and actuators to detect when the driver touches the gearshift and requests a shift. The gearshift will usually be connected electronically to the clutch, and the clutch will disengage once the driver moves the gearshift. In one example, Ferrari offered their Mondial model with a clutchless manual, which Ferrari called the Valeo transmission. In this system, the gearshift of a conventional manual transmission was retained; and moving the shifter automatically engaged the electro-mechanical clutch. Saab's Sensonic transmission worked in a similar fashion. Most semi-automatic transmissions work in a similar fashion, once the driver moved the shift lever to switch gears, the clutch would disengage, and re-engage once the gear was selected.

Hall effect sensors sense the direction of the requested shift, and this input, together with a sensor in the gear box which senses the current speed and gear selected, feeds into a central processing unit. This unit then determines the optimal timing and torque required for smooth clutch engagement, based on input from these two sensors as well as other factors, such as engine rotation, the Electronic Stability Control, air conditioner and dashboard instruments.

The central processing unit powers a hydro-mechanical unit to either engage or disengage the clutch, which is kept in close synchronization with the gear-shifting action the driver has started. In some cases, the hydro-mechanical unit contains a servomotor coupled to a gear arrangement for a linear actuator, which uses brake fluid from the braking system to impel a hydraulic cylinder to move the main clutch actuator. In other cases, the clutch actuator may be completely electric. The actuators and sensors which control the clutch are usually connected to an electronic servomechanism, operated via the transmission control unit (TCU).

The power of the system lies in the fact that electronic equipment can react much faster and more precisely than a human and takes advantage of the precision of electronic signals and hydraulic actuators to complete the clutch operation faster, and without the manual intervention of the driver.

Types

- Automated manual transmission (Mainly older semi-automatic versions, which control the clutch automatically, but manual shifting still requires driver involvement.)

- Saxomat

Usage in passenger cars

1900s to 1920s

In 1901, Amédée Bollée developed a method of shifting gears which did not require the use of a clutch and was activated by a ring mounted within the steering wheel.[5] One car using this system was the 1912 Bollée Type F Torpedo.

1930s to 1940s

Prior to the arrival of the first mass-produced hydraulic automatic transmission in 1940 (the General Motors Hydra-Matic), several American manufacturers offered various devices to reduce the amount of clutch or gear shifter usage required. These devices were intended to reduce the difficulty of operating the unsynchronised manual transmissions ("crash gearboxes") that were commonly used, especially in stop-start driving.

An early step towards automated transmissions was the 1933-1935 REO Self-Shifter,[6] which automatically shifted between two forward gears in the "Forward" mode (or between two shorter gear ratios in the "Emergency low" mode). Standing starts required the driver to use the clutch pedal. The Self-Shifter first appeared in May 1933 and was offered as standard on the Royale and as an option on the Reo Flying Cloud S-4.[7]

In 1937, the Oldsmobile 4-speed Automatic Safety Transmission was introduced on the Oldsmobile Six and Oldsmobile Eight models.[6] It used a planetary gearset with a clutch pedal for starting from standstill and switching between the "Low" and "High" ranges.[8][9][10] The Automatic Safety Transmission was replaced by the fully automatic Hydra-Matic for the 1940 model year.

The 1938-1939 Buick Special was available with the Self-shifter 4-speed semi-automatic transmission.[11][citation needed] transmission. This transmission uses a manual clutch for starting from standstill, and an automated clutch for gear changes.

The 1941 Chrysler M4 Vacamatic transmission used a two-speed manual transmission with integral underdrive unit, a traditional manual clutch and a fluid coupling between the engine and the clutch.[12][13][14] The two-speed transmission was used as "High" and "Low" ranges, and the clutch was needed when the driver wanted to switch between ranges. For normal driving, the driver would press the clutch, select High range and then release the clutch. One the accelerator was pressed, the fluid coupling would engage and the car would begin moving forward, with the underdrive unit engaged to provide a lower gear ratio. At between 15–20 mph (24–32 km/h), the driver would lift off the accelerator and the underdrive unit would disengage. The Vacmatic was replaced by the similar M6 Presto-Matic transmission for the 1946 model year.

Similar designs were used for the 1941-1950 Hudson Drive-Master[15][16] and the ill-fated 1942 Lincoln Liquimatic.[17][18] Both of these used a 3-speed transmission with automated shifting between 2nd and 3rd gears, instead of the Vacamatic's underdrive unit.

The Packard Electro-Matic — introduced in the 1941 Packard Clipper and Packard 180 — is an early a clutchless manual transmission that uses a traditional friction clutch with automatic operation. In the case of the Electro-Matic, the clutch was vacuum-operated and controlled by the position of the accelerator.

1950s to 1960s

The Automotive Products Manumatic system, available on the 1953 Ford Anglia 100E was a vacuum-powered automatic clutch system that was actuated by a switch that was triggered whenever the gear level was moved. The system could control the throttle cable (to keep the engine at the required RPM for the gear change) and could vary the rate of clutch engagement.[19] The successive Newtondrive system, available on the 1957-1958 Ford Anglia, also had a provision for choke control.

The Citroën DS, introduced in 1955, used a hydraulic system to select gears and operate the conventional clutch using hydraulic servos. There was also a speed controller and idle speed step-up device, all hydraulically operated. This allowed clutchless shifting with a single selector mounted behind the steering wheel. This system was nicknamed 'Citro-Matic' in the U.S.

The Chevrolet Torque Drive transmission, introduced on the 1968 Chevrolet Nova and Camaro, is one of few examples where a semi-automatic transmission was based on a hydraulic automatic transmission (rather than a manual transmission). The Torque Drive was essentially a 2-speed Powerglide transmission without the vacuum modulator, requiring the driver to manually shift gears between Low and High. The quadrant indicator on Torque Drive cars was, Park R N Hi 1st. The driver would start the car in "1st," then move the lever to "Hi" when desired. The torque drive was discontinued at the end of 1971 and replaced by a traditional hydraulic automatic transmission. Other examples of semi-automatic transmissions based on hydraulic automatics are the Ford Semi-Automatic Transmission 3-speed transmission used in the 1970-1971 Ford Maverick (Americas), early versions of Honda's 1976-1988 Hondamatic 2-speed and 3-speed transmissions, and the Diahatsu Diamatic 2-speed transmission used in the 1985-1991 Daihatsu Charade.

Other examples

| Years | Name | Notes |

|---|---|---|

| 1953-1954 | Plymouth Hy-Drive | Torque convertor added to a 3-speed manual transmission, so it could be driven solely in top gear (to avoid using the manual clutch). |

| 1956-1963 | Renault Ferlec | Automatic clutch (electromagnetic). Used in the Renault Dauphine.[20][21] |

| 1957-1961 | Mercedes-Benz Hydrak | Automatic clutch (vacuum-powered), plus a torque convertor for standing starts.[22] |

| 1959-???? | Citroën Trafficlutch | Automatic clutch (centrifugal). Used in the Citroën 2CV. |

| 1966-???? | Simca automatic clutch | Automatic clutch plus a torque convertor. Used in the Simca 1000.[23][24][25][26] |

| 1967-1977 | NSU automatic clutch | Automatic clutch (vacuum-powered) plus a torque convertor. Used in the NSU Ro 80. |

| 1968-1979 | Volkswagen Autostick | Automatic clutch (electro-pneumatic) plus a torque convertor. Used in the Volkswagen Beetle and Volkswagen Karmann Ghia.[27] |

| 1976-1980 | Citroën C-matic | Automated clutch plus a torque convertor. Used in the Citroën GS and Citroën CX. |

| 1988-1993 | Ferrari Valeo | Automatic clutch (electro-mechanical). Used in the Ferrari Mondial. |

| 1995-1996 | Saab Sensonic | Automatic clutch. Used in the Saab 900 NG. |

Usage in motorcycles

An early example for motorcycles was the use of an automatic centrifugal clutch in the early 1960s by Czechoslovakian manufacturer Jawa Moto.[28] This design was also used without Jawa's permission in the 1965 Honda Cub 50, which resulted in Jawa suing Honda for patent infringement. Eventually, Honda agreed to pay royalties for each motorcycle that used the Jawa design.[28]

The first large-capacity motorcycle with a semi-automatic gearbox was the 1975 948 cc (57.9 cu in) Moto Guzzi Convert (the name was chosen to denote the torque converter which was at the heart of this 110 mph motorcycle)[citation needed] a fairly heavy motorcycle which despite its weight still handled, and cornered remarkably well, which was thanks to the race-bred frame from the Moto Guzzi Le Mans.[citation needed]

Honda also had a range of bikes fitted with a gearbox that mated a torque converter and a two speed gearbox. This style of gearbox still required the rider to manually select neutral and either of the two gears using the foot gear lever.[29] These models were the CB750A, CB400A, CM400A and CM450A. These bikes were badged and marketed as Hondamatics.

In addition to the Hondamatic system noted above, Yamaha Motor Company introduced a semi-automatic transmission on its 2007 model year FJR1300 sport-touring motorcycle in 2006. Notably, this system can be shifted either with the lever in the traditional position near the left foot or with a switch accessible to the left hand where the clutch lever would go on traditional motorcycles.

The BRP Can-Am Spyder Roadster is available with a clutchless semi-automatic transmission (the SE5 or SE6, with five or six speeds, depending on the model).[30]

Small capacity underbone or "step-thru" types of motorcycles, such as the Honda Super Cub, Suzuki FR50 and FR80 and Yamaha Townmate, use a semi-automatic gearbox with a "heel and toe" foot change in the standard motorcycle position but without the need for conventional clutch operation.

On high-performance sports bikes, this system is sometimes called trigger-shift, so-called because the rider shifts gears with a handlebar-mounted trigger or paddle, to switch up and down gears. On dirt bikes, this system is sometimes be referred to as an auto-clutch transmission, since the driver is still required to shift gears manually with the foot-lever, but the clutch system is controlled automatically.

Usage in motor racing

The first Formula One car to use a semi-automatic transmission was the 1989 Ferrari 640.[5][31] This system used electro-hydraulic actuators for controlling the clutch and shifting, and was operated by paddle-shifters mounted behind the steering wheel. Another paddle on the steering wheel controlled the clutch, which was only needed when starting from a standstill. The car won its debut race at the Brazillian Grand Prix, however for much of the season suffered from reliability problems.[32] Other teams began switching to similar semi-automatic transmissions, and the 1991 Williams FW14 was the first to use a sequential drum-rotation mechanism (similar to the system used in motorcycle transmissions) to produce a more compact design that required only one actuator to rotate the drum and move the gear selector forks. A further development was made possible by the introduction of electronic throttle control soon after, which made it possible for the car to automatically rev-match during downshifts.[33] By 1993, most teams were using semi-automatic transmissions. The last F1 car fitted with a conventional manual gearbox, the Forti FG01, raced in 1995.[34]

Following concerns about the potential for Formula One cars to shift gears automatically without any driver input (i.e. a fully automatic transmission), mandatory software was introduced[when?] that ensured that gear changes only occurred when instructed by the driver. Buttons on the steering wheel to skip directly to a particular gear (instead of stepping through the gears using the paddles) are also permitted.

The now-defunct CART Champ Car Series switched from sequential manual transmissions with the manual shift lever, to a new 7-speed paddle-shift system for the 2007 season. This transmission system was introduced with the new Panoz DP01 chassis for 2007.

The rival IRL IndyCar series introduced their 6-speed semi-automatic paddle-shift system for the 2008 season, also replacing the previous sequential manual transmission with the shift lever. This was introduced with the Dallara IR5 chassis for 2008.[35] IndyCars currently use the #P1011 sequential gearbox, supplied by Xtrac. This gearbox uses a semi-automatic shifting system called AGS (Assisted Gearshift System), supplied by Mega-Line. This is a paddle-operated shifting system, which uses a pneumatic gearshift actuator controlled by an internal GCU (Gearbox Control Unit).[36][37][38][39][40]

The European DTM series currently use a 6-speed sequential transmission with steering-wheel-mounted paddle-shifters, which was introduced for the 2012 season with the new rule change. The gearbox is the DTT-200 model, which is supplied by Hewland. This new system replaced the older sequential gearbox with the manual shift lever, which had been used for the previous 12 seasons.

Usage in other vehicles

Other notable uses for semi-automatic transmissions include:

- During the 1940s to 1960s, many small diesels shunting locomotives used epicyclic semi-automatic transmissions. For example, the British Rail Class 03 and British Rail Class 04 used the Wilson-Drewry CA5 R7 transmission.[41]

- Sinclair S.S.S. Powerflow: Used from the 1950s to the early 1960s in Huwood-Hudswell diesel mining locomotives, the British Rail Class D2/7 and the British Rail Class D2/12.[42] The Powerflow design is the layshaft-type with constant-mesh gears and dog clutch engagement, allowing it provide seamless power delivery during upshifts. This transmission was also used in some road vehicles.[43]

- Self-Changing Gears Pneumocyclic: an epicyclic transmission built in the United Kingdom from the 1960s to the 1980s. Using a similar design to their previous preselector gearboxes, the Pneumocyclic transmission was used in several buses, such as the Leyland Leopard Leyland Panther and Leyland Tiger.[44][45] It was also fitted to several thousand British diesel railcars during this time.[citation needed]

- Honda Electric Shift Program: Used in all-terrain vehicles such as the 1998 Honda TRX450FE (also called the Foreman 450ES ESP). Shifting is accomplished by pressing either one of the gear selector arrows on the left handlebar control, which activates an electric shifting system.

See also

| Automotive transmissions |

|---|

| Manual |

| Automatic / Semi-automatic |

- Overdrive

- Shift kit

- Shift time

- Dual clutch transmission (DCT)

- Automated manual transmission

- Direct-Shift Gearbox

- Automatic transmission

- Tiptronic

References

- ^ "The next shift: The clutchless manual". autonews.com. Retrieved 29 February 2020.

- ^ "Automated Manual Transmission (AMT)". x-engineer.org. Retrieved 29 February 2020.

- ^ https://www.autozine.org/technical_school/gearbox/Gearbox_Manual.html

- ^ https://www.wikihow.com/Shift-Gears-on-a-Motorcycle

- ^ a b "The history of the 'paddle shift'". www.lemans.org. 21 February 2011. Retrieved 16 February 2020.

- ^ a b "6 of the worst automatic transmissions ever". www.hagerty.com. 8 August 2019. Retrieved 9 August 2020.

- ^ "How Reo Cars Work". 15 June 2007. Retrieved 24 October 2017.

- ^ "The Oldsmobile automatic safety transmission operated by the short lever shown on the steering column". www.nypl.org. Retrieved 9 August 2020.

- ^ "No clutch to press! No gears to shift!". www.autonews.com. 18 August 1997. Retrieved 9 August 2020.

- ^ "How Oldsmobile Cars Work". www.howstuffworks.com. 20 June 2007. Retrieved 9 August 2020.

- ^ "How Buick Works". www.howstuffworks.com. 5 June 2007. Retrieved 8 August 2020.

- ^ "The M6 automatic transmission". www.allpar.com. Retrieved 9 August 2020.

- ^ "Chrysler transmissions-Vacamatic semi automatic". www.gottransmissions.com. Retrieved 9 August 2020.

- ^ "How Chrysler Works". www.howstuffworks.com. 1 June 2007. Retrieved 9 August 2020.

- ^ "1941-1947 Hudson". www.howstuffworks.com. 16 September 2007. Retrieved 8 August 2020.

- ^ "Step-Down: The 1948-1954 Hudsons". www.ateupwithmotor.com. 6 September 2009. Retrieved 8 August 2020.

- ^ "Automatic Failure: Ford's 1942 Liquamatic Experiment". www.macsmotorcitygarage.com. 7 February 2017. Retrieved 8 August 2020.

- ^ "Automotive History: Lincoln's Liquamatic Drive – Failure to Upshift". www.curbsideclassic.com. Retrieved 8 August 2020.

- ^ Staton, Abbey. Practical Automobile Engineering - Clutch Systems. pp. 193–194.

- ^ "1956-1968 Renault Dauphine". www.howstuffworks.com. 20 August 2007. Retrieved 8 August 2020.

- ^ "Renault Dauphine buyer's guide: what to pay and what to look for". www.classicandsportscar.com. Retrieved 8 August 2020.

- ^ Miller, Jeff. "Mercedes-Benz Ponton Hydrak Automatic Clutch". www.mbzponton.org. Retrieved 24 October 2017.

- ^ "Theme: Simca – 1965 1000 GLS Short Road Test". www.driventowrite.com. 4 March 2017. Retrieved 8 August 2020.

- ^ "Simca 1100". www.uniquecarsandparts.com.au. Retrieved 8 August 2020.

- ^ "Simca 1000 GLA Automatique 1966 lever". Flickr.com. 4 December 2008. Retrieved 1 March 2020.

- ^ Thompson, Andy. "Simca 1000 cars". Rootes-Chrysler.co.uk. VerticalScope Inc. Retrieved 8 August 2012.

{{cite web}}: CS1 maint: url-status (link) - ^ Dingeldein, Wolfgang (2011). "VW Automatic - der Käfer mit halbautomatischem Getriebe" [VW Automatic - the Beetle with a semi-automatic transmission]. Käfertreter Siegerland (in German). Archived from the original on 10 April 2013.

- ^ a b Kožušník, Marek (20 January 2015). "Válka mechaniků: Japonci okopírovali český vynález!". EpochaPlus (in Czech). Retrieved 27 December 2019.

- ^ "Cycle magazine". Ziff Davis. May 1976: 67–73.

{{cite journal}}: Cite journal requires|journal=(help) - ^ https://www.youtube.com/watch?v=rMHKvDYvjpQ

- ^ "Ferrari F1-89". ferrari.com. Archived from the original on 27 September 2013. Retrieved 15 February 2020.

- ^ "Sequential Sorrow - 1989 Ferrari 640". www.drivetribe.com. 1 February 2017. Retrieved 11 August 2020.

- ^ https://www.f1technical.net/features/10705

- ^ "Forti-Corse - full profile". f1rejects.com. Archived from the original on 10 October 2007. Retrieved 29 October 2006.

- ^ https://www.autosport.com/indycar/news/64891/irl-confirms-technical-tweaks

- ^ https://www.xtrac.com/product/p1011-indycar-series-gearbox/

- ^ https://www.xtrac.com/product/assisted-gearchange-system/

- ^ https://www.indycar.com/Fan-Info/INDYCAR-101/The-Car-Dallara/IndyCar-Series-Chassis-Specifications

- ^ http://mega-line.info/index.php/en/products/compressor?productitem=21

- ^ http://www.mega-line.de/index.php/en/company/references

- ^ "Vehicle Diagram Book No. 120 for shunting diesel locomotives" (PDF). www.barrowmoremrg.co.uk. BRB Residuary Ltd. Retrieved 14 August 2020.

- ^ Durham Mining Museum (17 December 2012). "Durham Mining Museum - Colliery Engineering". Dmm.org.uk. Retrieved 18 July 2014.

- ^ "Vulcan-Sinclair Fluidrive Makes Headway". The Commercial Motor. 16 August 1946. p. 69. Archived from the original on 6 September 2017.

- ^ "Leyland Make "Air" Gearbox". www.commercialmotor.com. Retrieved 14 August 2020.

- ^ "Transmissions: a period of change". www.commercialmotor.com. Retrieved 14 August 2020.