Stick–slip phenomenon: Difference between revisions

Reverted 1 edit by WeirdNAnnoyed (talk): Misunderstanding: the work from these authors is very strong. |

Expanded the explanation, maybe needs a few more specific refs. Tags: Visual edit Disambiguation links added |

||

| Line 2: | Line 2: | ||

The '''stick–slip phenomenon''', also known as the '''slip–stick phenomenon''' or simply '''stick–slip''', is a type of motion exhibited by objects in contact sliding over one another. The motion of these objects is usually not perfectly smooth, but rather irregular, with brief accelerations (slips) interrupted by stops (sticks). Stick-slip motion is normally connected to [[friction]], and may generate [[vibration]] (noise) or be associated with mechanical wear of the moving objects, and is thus often undesirable in mechanical devices.<ref name=Berman>{{cite journal|last1=Berman|first1=A.D.|last2=Ducker|first2=W.A.|last3=Israelachvili|first3=J.N.|date=1996|title=Origin and characterization of different stick-slip friction mechanisms|journal=Langmuir|volume=12|issue=19|pages=4559–4563|doi=10.1021/la950896z }}</ref> On the other hand, stick-slip motion can be useful in some situations, such as the movement of a bow across a string to create musical tones in a [[bowed string instrument]].<ref name=Gresham>{{Cite web|last1=Gresham|first1=Robert M.|title=Slip-stick: What's it all about?|url=https://www.stle.org/images/pdf/STLE_ORG/BOK/LS/Friction/Slip-Stick_What%27s%20it%20all%20about_tlt%20article_June11.pdf|publisher=Society of Tribologists and Lubrication Engineers|access-date=2023-10-01|website=Tribology & Lubrication Technology}}</ref> |

The '''stick–slip phenomenon''', also known as the '''slip–stick phenomenon''' or simply '''stick–slip''', is a type of motion exhibited by objects in contact sliding over one another. The motion of these objects is usually not perfectly smooth, but rather irregular, with brief accelerations (slips) interrupted by stops (sticks). Stick-slip motion is normally connected to [[friction]], and may generate [[vibration]] (noise) or be associated with mechanical wear of the moving objects, and is thus often undesirable in mechanical devices.<ref name=Berman>{{cite journal|last1=Berman|first1=A.D.|last2=Ducker|first2=W.A.|last3=Israelachvili|first3=J.N.|date=1996|title=Origin and characterization of different stick-slip friction mechanisms|journal=Langmuir|volume=12|issue=19|pages=4559–4563|doi=10.1021/la950896z }}</ref> On the other hand, stick-slip motion can be useful in some situations, such as the movement of a bow across a string to create musical tones in a [[bowed string instrument]].<ref name=Gresham>{{Cite web|last1=Gresham|first1=Robert M.|title=Slip-stick: What's it all about?|url=https://www.stle.org/images/pdf/STLE_ORG/BOK/LS/Friction/Slip-Stick_What%27s%20it%20all%20about_tlt%20article_June11.pdf|publisher=Society of Tribologists and Lubrication Engineers|access-date=2023-10-01|website=Tribology & Lubrication Technology}}</ref> |

||

== |

== Details == |

||

| ⚫ | Stick-slip may be caused by |

||

[[File:Static_kinetic_friction_vs_time.png|thumb|Static kinetic friction vs time]] |

|||

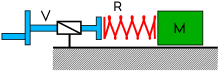

Stick-slip can be modeled as a mass coupled by an elastic spring to a constant drive force (see diagram). |

|||

With stick-slip there is typically a jagged type of behavior for the friction force as a function of time as illustrated in the static kinetic friction figure. Initially there is relatively little movement and the force climbs until it reaches some critical value which is set by the multiplication of the [[static friction]] coefficient and the applied [[load]] -- the retarding force here follows the standard ideas of friction from [[Amontons' laws]]. Once this force is exceeded movement starts at a much lower load which is determined by the [[kinetic friction]] coefficient which is almost always smaller than the static coefficient. At times the object moving can get 'stuck', with local rises in the force before it starts to move again. There are many causes of this depending upon the size scale, from atomic to processes involving millions of atoms.<ref>{{Cite book |last=Persson |first=Bo N. J. |url=http://link.springer.com/10.1007/978-3-662-03646-4 |title=Sliding Friction |date=1998 |publisher=Springer Berlin Heidelberg |isbn=978-3-662-03648-8 |series=NanoScience and Technology |location=Berlin, Heidelberg |doi=10.1007/978-3-662-03646-4}}</ref><ref>{{Cite book |last=Gnecco |first=Enrico |title=Elements of friction theory and nanotribology |last2=Meyer |first2=Ernst |date=2015 |publisher=Cambridge university press |isbn=978-1-107-00623-2 |location=Cambridge}}</ref> |

|||

| ⚫ | [[File:Stick-slip.svg|right|thumb|Model for stick-slip]]Stick-slip can be modeled as a mass coupled by an elastic spring to a constant drive force (see the model sketch). The drive system V applies a constant force, loading spring R and increasing the pushing force against load M. This force increases until the [[static friction]] coefficient between load and floor is exceeded. The load then starts sliding, and the friction coefficient decreases to the value corresponding to [[dynamic friction]]. Since this frictional force will be lower than the static value, the load accelerates until the decompressing spring can no longer generate enough force to overcome dynamic friction, and the load stops moving. The pushing force due to the spring builds up again, and the cycle repeats.<ref name = Berman /><ref name = Gresham /> |

||

[[File:Stick-slip.svg|500px]] |

|||

| ⚫ | Stick-slip may be caused by many different phenomena, depending on the types of surfaces in contact and also the scale; it occurs with everything from the sliding of [[Atomic force microscopy|atomic force microscope]] tips to large [[Tribometer|tribometers]]. For rough surfaces, it is known that [[Asperity (materials science)|asperities]] play a major role in [[Friction|friction.]]<ref>{{Cite book |last=Bowden |first=Frank Philip |url=https://en.wikipedia.org/wiki/Special:BookSources/9780198507772 |title=The friction and lubrication of solids |last2=Tabor |first2=David |date=2008 |publisher=Clarendon Pr |isbn=978-0-19-850777-2 |edition=Repr |series=Oxford classic texts |location=Oxford}}</ref> The bumping together of [[Asperity (materials science)|asperities]] on the surface creates momentary sticks. For dry surfaces with regular microscopic topography, the two surfaces may need to [[Creep (deformation)|creep]] at high friction for certain distances (in order for bumps to move past one another), until a smoother, lower-friction contact is formed. On lubricated surfaces, the [[Lubrication|lubricating]] fluid may undergo transitions from a solid-like state to a liquid-like state at certain forces, causing a transition from sticking to slipping.<ref name="Berman" /> On very smooth surfaces, stick–slip behavior may result from coupled [[phonons]] (at the interface between the substrate and the slider) that are pinned in an undulating potential well, sticking or slipping with [[thermal fluctuations]].<ref>Bo N.J. Persson and Nicholas D. Spencer, "Sliding Friction: Physical Principles and Applications", ''Physics Today'' 52(1), 66 (1999); doi: 10.1063/1.882557</ref> Stick-slip occurs on all types of materials and on enormously varying length scales.<ref>Ruina, Andy. "Slip instability and state variable friction laws.", ''Journal of Geophysical Research'' 88.B12 (1983): 10359-10 </ref> The frequency of slips depends on the force applied to the sliding load, with a higher force corresponding to a higher frequency of slip.<ref name="Rabinowicz">{{cite journal|last1=Rabinowicz|first1=Ernest|date=May 1956|title=Stick and Slip|journal=Scientific American|volume=194|issue=5|pages=109-119 }}</ref> |

||

| ⚫ | The drive system V applies a constant force, loading spring R and increasing the pushing force against load M. This force increases until the [[static friction]] coefficient between load and floor is exceeded. The load then starts sliding, and the friction coefficient decreases to the value corresponding to [[dynamic friction]]. Since this frictional force will be lower than the static value, the load accelerates until the decompressing spring can no longer generate enough force to overcome dynamic friction, and the load stops moving. The pushing force due to the spring builds up again, and the cycle repeats.<ref name = Berman /><ref name = Gresham /> |

||

== Examples == |

== Examples == |

||

Revision as of 18:22, 19 October 2023

The stick–slip phenomenon, also known as the slip–stick phenomenon or simply stick–slip, is a type of motion exhibited by objects in contact sliding over one another. The motion of these objects is usually not perfectly smooth, but rather irregular, with brief accelerations (slips) interrupted by stops (sticks). Stick-slip motion is normally connected to friction, and may generate vibration (noise) or be associated with mechanical wear of the moving objects, and is thus often undesirable in mechanical devices.[1] On the other hand, stick-slip motion can be useful in some situations, such as the movement of a bow across a string to create musical tones in a bowed string instrument.[2]

Details

With stick-slip there is typically a jagged type of behavior for the friction force as a function of time as illustrated in the static kinetic friction figure. Initially there is relatively little movement and the force climbs until it reaches some critical value which is set by the multiplication of the static friction coefficient and the applied load -- the retarding force here follows the standard ideas of friction from Amontons' laws. Once this force is exceeded movement starts at a much lower load which is determined by the kinetic friction coefficient which is almost always smaller than the static coefficient. At times the object moving can get 'stuck', with local rises in the force before it starts to move again. There are many causes of this depending upon the size scale, from atomic to processes involving millions of atoms.[3][4]

Stick-slip can be modeled as a mass coupled by an elastic spring to a constant drive force (see the model sketch). The drive system V applies a constant force, loading spring R and increasing the pushing force against load M. This force increases until the static friction coefficient between load and floor is exceeded. The load then starts sliding, and the friction coefficient decreases to the value corresponding to dynamic friction. Since this frictional force will be lower than the static value, the load accelerates until the decompressing spring can no longer generate enough force to overcome dynamic friction, and the load stops moving. The pushing force due to the spring builds up again, and the cycle repeats.[1][2]

Stick-slip may be caused by many different phenomena, depending on the types of surfaces in contact and also the scale; it occurs with everything from the sliding of atomic force microscope tips to large tribometers. For rough surfaces, it is known that asperities play a major role in friction.[5] The bumping together of asperities on the surface creates momentary sticks. For dry surfaces with regular microscopic topography, the two surfaces may need to creep at high friction for certain distances (in order for bumps to move past one another), until a smoother, lower-friction contact is formed. On lubricated surfaces, the lubricating fluid may undergo transitions from a solid-like state to a liquid-like state at certain forces, causing a transition from sticking to slipping.[1] On very smooth surfaces, stick–slip behavior may result from coupled phonons (at the interface between the substrate and the slider) that are pinned in an undulating potential well, sticking or slipping with thermal fluctuations.[6] Stick-slip occurs on all types of materials and on enormously varying length scales.[7] The frequency of slips depends on the force applied to the sliding load, with a higher force corresponding to a higher frequency of slip.[8]

Examples

Stick-slip motion is ubiquitous in systems with sliding components, such as disk brakes, bearings, electric motors, wheels on roads or railways, and in mechanical joints.[9] Stick–slip also has been observed in articular cartilage in mild loading and sliding conditions, which could result in abrasive wear of the cartilage.[10] Many familiar sounds are caused by stick-slip motion, such as the squeal of chalk on a chalkboard, the squeak of basketball shoes on a basketball court, and the sound made by the spiny lobster.[8][11][12]

Stick-slip motion is used to generate sound in several types of musical instruments, most notably bowed string instruments,[2] but also in a glass harp.[13]

Stick–slip can also be observed on the atomic scale using a friction force microscope.[14] The behaviour of seismically-active faults is also explained using a stick–slip model, with earthquakes being generated during the periods of rapid slip.[15]

References

- ^ a b c Berman, A.D.; Ducker, W.A.; Israelachvili, J.N. (1996). "Origin and characterization of different stick-slip friction mechanisms". Langmuir. 12 (19): 4559–4563. doi:10.1021/la950896z.

- ^ a b c Gresham, Robert M. "Slip-stick: What's it all about?" (PDF). Tribology & Lubrication Technology. Society of Tribologists and Lubrication Engineers. Retrieved 2023-10-01.

- ^ Persson, Bo N. J. (1998). Sliding Friction. NanoScience and Technology. Berlin, Heidelberg: Springer Berlin Heidelberg. doi:10.1007/978-3-662-03646-4. ISBN 978-3-662-03648-8.

- ^ Gnecco, Enrico; Meyer, Ernst (2015). Elements of friction theory and nanotribology. Cambridge: Cambridge university press. ISBN 978-1-107-00623-2.

- ^ Bowden, Frank Philip; Tabor, David (2008). The friction and lubrication of solids. Oxford classic texts (Repr ed.). Oxford: Clarendon Pr. ISBN 978-0-19-850777-2.

- ^ Bo N.J. Persson and Nicholas D. Spencer, "Sliding Friction: Physical Principles and Applications", Physics Today 52(1), 66 (1999); doi: 10.1063/1.882557

- ^ Ruina, Andy. "Slip instability and state variable friction laws.", Journal of Geophysical Research 88.B12 (1983): 10359-10

- ^ a b Rabinowicz, Ernest (May 1956). "Stick and Slip". Scientific American. 194 (5): 109–119.

- ^ Ding, Wenjing (2010). Self-excited Vibration. Springer Berlin, Heidelberg. pp. 140–166. doi:10.1007/978-3-540-69741-1. ISBN 978-3-540-69741-1.

- ^ D.W. Lee, X. Banquy, J. N. Israelachvili, Stick–slip friction and wear of articular joints, PNAS. (2013), 110(7): E567-E574

- ^ S. N. Patek (2001). "Spiny lobsters stick and slip to make sound". Nature. 411 (6834): 153–154. Bibcode:2001Natur.411..153P. doi:10.1038/35075656. PMID 11346780. S2CID 4413356.

- ^ Branch, John (2017-03-17). "Why Are Basketball Games So Squeaky? Consider the Spiny Lobster". The New York Times. ISSN 0362-4331. Retrieved 2017-03-19.

- ^ Rossing, Thomas D. (1994). "Acoustics of the glass harmonica". Journal of the Acoustical Society of America. 95: 1106–1111. doi:10.1121/1.408458.

- ^ Atomic-scale friction of a tungsten tip on a graphite surface C.M. Mate, G.M. McClelland, R. Erlandsson, and S. Chiang Phys. Rev. Lett. 59, 1942 (1987)

- ^ Scholz, C.H. (2002). The mechanics of earthquakes and faulting (2 ed.). Cambridge University Press. pp. 81–84. ISBN 978-0-521-65540-8. Retrieved 6 December 2011.

- Zypman, F. R.; Ferrante, J.; Jansen, M.; Scanlon, K.; Abel, P. (2003), "Evidence of self-organized criticality in dry sliding friction", Journal of Physics: Condensed Matter, 15 (12): L191, doi:10.1088/0953-8984/15/12/101, S2CID 250780286