Electron backscatter diffraction: Difference between revisions

Citation bot (talk | contribs) Add: s2cid. | Use this bot. Report bugs. | Suggested by FuzzyMagma | #UCB_toolbar |

FuzzyMagma (talk | contribs) No edit summary |

||

| Line 19: | Line 19: | ||

=== Pattern indexing === |

=== Pattern indexing === |

||

[[File:Overview of EBSD indexing procedure.jpg|thumb|Overview of EBSD indexing procedure showing pattern capture through to determination of crystal orientation<ref>{{Cite journal |last1=Britton |first1=T. B. |last2=Jiang |first2=J. |last3=Guo |first3=Y. |last4=Vilalta-Clemente |first4=A. |last5=Wallis |first5=D. |last6=Hansen |first6=L. N. |last7=Winkelmann |first7=A. |last8=Wilkinson |first8=A. J. |date=2016-07-01 |title=Tutorial: Crystal orientations and EBSD — Or which way is up? |url=https://www.sciencedirect.com/science/article/pii/S1044580316300924 |journal=Materials Characterization |language=en |volume=117 |pages=113–126 |doi=10.1016/j.matchar.2016.04.008 |s2cid=138070296 |issn=1044-5803}}</ref>]] |

[[File:Overview of EBSD indexing procedure.jpg|thumb|Overview of EBSD indexing procedure showing pattern capture through to determination of crystal orientation<ref name=":15">{{Cite journal |last1=Britton |first1=T. B. |last2=Jiang |first2=J. |last3=Guo |first3=Y. |last4=Vilalta-Clemente |first4=A. |last5=Wallis |first5=D. |last6=Hansen |first6=L. N. |last7=Winkelmann |first7=A. |last8=Wilkinson |first8=A. J. |date=2016-07-01 |title=Tutorial: Crystal orientations and EBSD — Or which way is up? |url=https://www.sciencedirect.com/science/article/pii/S1044580316300924 |journal=Materials Characterization |language=en |volume=117 |pages=113–126 |doi=10.1016/j.matchar.2016.04.008 |s2cid=138070296 |issn=1044-5803}}</ref>]] |

||

Often, the first step in the EBSD process after pattern collection is indexing. This allows for the identification of the crystal orientation at the single volume of the sample from where the pattern was collected. With EBSD software, pattern bands are typically detected via a mathematical routine using a modified [[Hough transform]], in which every pixel in Hough space denotes a unique line/band in the EBSP. The Hough transform is used to enable band detection, which is difficult to locate by computer in the original EBSP. Once the band locations have been detected it is possible to relate these locations to the underlying crystal orientation, as angles between bands represent angles between lattice planes. Thus when the position/angles between three bands are known an orientation solution can be determined. In highly symmetric materials, typically more than three bands are used to obtain and verify the orientation measurement. There are two leading methods of the indexing performed by most commercial EBSD software: triplet voting;<ref>{{Cite journal |last1=Wright |first1=Stuart I. |last2=Zhao |first2=Jun-Wu |last3=Adams |first3=Brent L. |date=NaN/NaN/NaN |title=Automated Determination of Lattice Orientation From Electron Backscattered Kikuchi Diffraction Patterns |journal=Texture, Stress, and Microstructure |language=en |volume=13 |issue=2–3 |pages=123–131 |doi=10.1155/TSM.13.123 |issn=1687-5397|doi-access=free }}</ref><ref>{{Cite journal |last1=Wright |first1=Stuart I. |last2=Adams |first2=Brent L. |last3=Kunze |first3=Karsten |date=1993-02-28 |title=Application of a new automatic lattice orientation measurement technique to polycrystalline aluminum |url=https://dx.doi.org/10.1016/0921-5093%2893%2990452-K |journal=Materials Science and Engineering: A |language=en |volume=160 |issue=2 |pages=229–240 |doi=10.1016/0921-5093(93)90452-K |issn=0921-5093}}</ref> minimising the 'fit' between the experimental pattern and a computationally determined orientation,<ref>{{Cite journal |last=Lassen |first=Niels Chr. Krieger |date=1992-01-01 |title=Automatic crystal orientation determination from EBSPs |url=https://dx.doi.org/10.1016/0739-6260%2892%2990133-X |journal=Micron and Microscopica Acta |language=en |volume=23 |issue=1 |pages=191–192 |doi=10.1016/0739-6260(92)90133-X |issn=0739-6260}}</ref><ref>{{Cite journal |last1=Krieger Lassen |first1=N.C. |last2=Juul Jensen |first2=Dorte |last3=Condradsen |first3=K. |date=May 1994 |title=Automatic Recognition of Deformed and Recrystallized Regions in Partly Recrystallized Samples Using Electron Back Scattering Patterns |url=http://dx.doi.org/10.4028/www.scientific.net/msf.157-162.149 |journal=Materials Science Forum |volume=157-162 |pages=149–158 |doi=10.4028/www.scientific.net/msf.157-162.149 |s2cid=137129038 |issn=1662-9752}}</ref> and or/and neighbour pattern averaging and re-indexing NPAR<ref>{{Cite journal |last1=Wright |first1=Stuart I. |last2=Nowell |first2=Matthew M. |last3=Lindeman |first3=Scott P. |last4=Camus |first4=Patrick P. |last5=De Graef |first5=Marc |last6=Jackson |first6=Michael A. |date=2015-12-01 |title=Introduction and comparison of new EBSD post-processing methodologies |url=https://www.sciencedirect.com/science/article/pii/S0304399115300188 |journal=Ultramicroscopy |language=en |volume=159 |pages=81–94 |doi=10.1016/j.ultramic.2015.08.001 |pmid=26342553 |issn=0304-3991}}</ref>) to give a unique solution to the single crystal orientation that is related to the other crystal orientations within the field-of-view.<ref>{{cite journal|last1=Randle|first1=Valerie|title=Electron backscatter diffraction: Strategies for reliable data acquisition and processing|journal=Materials Characterization|date=1 September 2009|volume=60|issue=9|pages=913–922|doi=10.1016/j.matchar.2009.05.011}}</ref><ref name=":14">{{Cite thesis |last=Lassen |first=Niels Christian Krieger |title=Automated Determination of Crystal Orientations from Electron Backscattering Patterns |date=1994 |degree=PhD |publisher=The Technical University of Denmark |url=http://www.ebsd.info/pdf/PhD_KriegerLassen.pdf}}</ref> |

Often, the first step in the EBSD process after pattern collection is indexing. This allows for the identification of the crystal orientation at the single volume of the sample from where the pattern was collected. With EBSD software, pattern bands are typically detected via a mathematical routine using a modified [[Hough transform]], in which every pixel in Hough space denotes a unique line/band in the EBSP. The Hough transform is used to enable band detection, which is difficult to locate by computer in the original EBSP. Once the band locations have been detected it is possible to relate these locations to the underlying crystal orientation, as angles between bands represent angles between lattice planes. Thus when the position/angles between three bands are known an orientation solution can be determined. In highly symmetric materials, typically more than three bands are used to obtain and verify the orientation measurement. There are two leading methods of the indexing performed by most commercial EBSD software: triplet voting;<ref>{{Cite journal |last1=Wright |first1=Stuart I. |last2=Zhao |first2=Jun-Wu |last3=Adams |first3=Brent L. |date=NaN/NaN/NaN |title=Automated Determination of Lattice Orientation From Electron Backscattered Kikuchi Diffraction Patterns |journal=Texture, Stress, and Microstructure |language=en |volume=13 |issue=2–3 |pages=123–131 |doi=10.1155/TSM.13.123 |issn=1687-5397|doi-access=free }}</ref><ref>{{Cite journal |last1=Wright |first1=Stuart I. |last2=Adams |first2=Brent L. |last3=Kunze |first3=Karsten |date=1993-02-28 |title=Application of a new automatic lattice orientation measurement technique to polycrystalline aluminum |url=https://dx.doi.org/10.1016/0921-5093%2893%2990452-K |journal=Materials Science and Engineering: A |language=en |volume=160 |issue=2 |pages=229–240 |doi=10.1016/0921-5093(93)90452-K |issn=0921-5093}}</ref> minimising the 'fit' between the experimental pattern and a computationally determined orientation,<ref>{{Cite journal |last=Lassen |first=Niels Chr. Krieger |date=1992-01-01 |title=Automatic crystal orientation determination from EBSPs |url=https://dx.doi.org/10.1016/0739-6260%2892%2990133-X |journal=Micron and Microscopica Acta |language=en |volume=23 |issue=1 |pages=191–192 |doi=10.1016/0739-6260(92)90133-X |issn=0739-6260}}</ref><ref>{{Cite journal |last1=Krieger Lassen |first1=N.C. |last2=Juul Jensen |first2=Dorte |last3=Condradsen |first3=K. |date=May 1994 |title=Automatic Recognition of Deformed and Recrystallized Regions in Partly Recrystallized Samples Using Electron Back Scattering Patterns |url=http://dx.doi.org/10.4028/www.scientific.net/msf.157-162.149 |journal=Materials Science Forum |volume=157-162 |pages=149–158 |doi=10.4028/www.scientific.net/msf.157-162.149 |s2cid=137129038 |issn=1662-9752}}</ref> and or/and neighbour pattern averaging and re-indexing NPAR<ref>{{Cite journal |last1=Wright |first1=Stuart I. |last2=Nowell |first2=Matthew M. |last3=Lindeman |first3=Scott P. |last4=Camus |first4=Patrick P. |last5=De Graef |first5=Marc |last6=Jackson |first6=Michael A. |date=2015-12-01 |title=Introduction and comparison of new EBSD post-processing methodologies |url=https://www.sciencedirect.com/science/article/pii/S0304399115300188 |journal=Ultramicroscopy |language=en |volume=159 |pages=81–94 |doi=10.1016/j.ultramic.2015.08.001 |pmid=26342553 |issn=0304-3991}}</ref>) to give a unique solution to the single crystal orientation that is related to the other crystal orientations within the field-of-view.<ref>{{cite journal|last1=Randle|first1=Valerie|title=Electron backscatter diffraction: Strategies for reliable data acquisition and processing|journal=Materials Characterization|date=1 September 2009|volume=60|issue=9|pages=913–922|doi=10.1016/j.matchar.2009.05.011}}</ref><ref name=":14">{{Cite thesis |last=Lassen |first=Niels Christian Krieger |title=Automated Determination of Crystal Orientations from Electron Backscattering Patterns |date=1994 |degree=PhD |publisher=The Technical University of Denmark |url=http://www.ebsd.info/pdf/PhD_KriegerLassen.pdf}}</ref> |

||

| Line 30: | Line 30: | ||

Unfortunately, each of these methods are cumbersome and can be prone to some systematic errors for a general operator. Typically they can not be easily used in modern SEMs with multiple designated uses. Thus most commercial EBSD systems use the indexing algorithm combined with an iterative movement of both crystal orientation and suggested pattern centre location. Minimising the fit between bands located within experimental patterns and those in look up tables tends to converge on the pattern centre location to an accuracy of ~0.5–1% of the pattern width.<ref name=":1" /> |

Unfortunately, each of these methods are cumbersome and can be prone to some systematic errors for a general operator. Typically they can not be easily used in modern SEMs with multiple designated uses. Thus most commercial EBSD systems use the indexing algorithm combined with an iterative movement of both crystal orientation and suggested pattern centre location. Minimising the fit between bands located within experimental patterns and those in look up tables tends to converge on the pattern centre location to an accuracy of ~0.5–1% of the pattern width.<ref name=":1" /> |

||

Recent development of AstroEBSD<ref>{{Cite journal |last=Britton |first=Thomas Benjamin |last2=Tong |first2=Vivian S. |last3=Hickey |first3=Jim |last4=Foden |first4=Alex |last5=Wilkinson |first5=Angus J. |date=2018-12-01 |title=AstroEBSD : exploring new space in pattern indexing with methods launched from an astronomical approach |url=http://scripts.iucr.org/cgi-bin/paper?S1600576718010373 |journal=Journal of Applied Crystallography |volume=51 |issue=6 |pages=1525–1534 |doi=10.1107/S1600576718010373 |issn=1600-5767}}</ref> and PCGlobal,<ref>{{Cite journal |last=Pang |first=Edward L. |last2=Larsen |first2=Peter M. |last3=Schuh |first3=Christopher A. |date=2020-02-01 |title=Global optimization for accurate determination of EBSD pattern centers |url=https://www.sciencedirect.com/science/article/pii/S030439911930292X |journal=Ultramicroscopy |language=en |volume=209 |pages=112876 |doi=10.1016/j.ultramic.2019.112876 |issn=0304-3991}}</ref> open-source [[MATLAB]] codes, increased the precision of determining the pattern centre (PC) and – consequently – elastic strains<ref>{{Cite journal |last=Tanaka |first=Tomohito |last2=Wilkinson |first2=Angus J. |date=2019-07-01 |title=Pattern matching analysis of electron backscatter diffraction patterns for pattern centre, crystal orientation and absolute elastic strain determination – accuracy and precision assessment |url=https://www.sciencedirect.com/science/article/pii/S0304399118302961 |journal=Ultramicroscopy |language=en |volume=202 |pages=87–99 |doi=10.1016/j.ultramic.2019.04.006 |issn=0304-3991}}</ref> by using a pattern matching approach<ref>{{Cite journal |last=Foden |first=A. |last2=Collins |first2=D.M. |last3=Wilkinson |first3=A.J. |last4=Britton |first4=T.B. |date=2019-12 |title=Indexing electron backscatter diffraction patterns with a refined template matching approach |url=http://dx.doi.org/10.1016/j.ultramic.2019.112845 |journal=Ultramicroscopy |volume=207 |pages=112845 |doi=10.1016/j.ultramic.2019.112845 |issn=0304-3991}}</ref> which simulates the pattern using EMSoft.<ref>{{Cite journal |last=Jackson |first=M. A. |last2=Pascal |first2=E. |last3=De Graef |first3=M. |date=2019-06-01 |title=Dictionary Indexing of Electron Back-Scatter Diffraction Patterns: a Hands-On Tutorial |url=https://doi.org/10.1007/s40192-019-00137-4 |journal=Integrating Materials and Manufacturing Innovation |language=en |volume=8 |issue=2 |pages=226–246 |doi=10.1007/s40192-019-00137-4 |issn=2193-9772}}</ref> |

|||

=== EBSD maps === |

=== EBSD maps === |

||

| Line 57: | Line 59: | ||

<math>q=\beta r-(\beta r.\widehat{r})\widehat{r}</math> |

<math>q=\beta r-(\beta r.\widehat{r})\widehat{r}</math> |

||

<math>\beta=\begin{pmatrix} {\partial u_1 \over x_1} & {\partial u_1 \over x_2} &{\partial u_1 \over x_3} \\{\partial u_2 \over x_1} & {\partial u_2 \over x_2} &{\partial u_2 \over x_3} \\{\partial u_3 \over x_1} & {\partial u_3 \over x_2} &{\partial u_3 \over x_3} \end{pmatrix}, \qquad r=\begin{pmatrix} {r_1} \\{r_2} \\{r_3} \\\end{pmatrix}</math> |

|||

| ⚫ | |||

The shifts are measured in the phosphor (detector) plane (<math>\beta_3 r_3=0</math>), and the relationship is simplified; thus, eight out of the nine displacement gradient tensor components can be calculated by measuring the shift ( and ) at four distinct, widely spaced regions on the EBSP.<ref name=":6" /><ref name=":16">{{Citation |last=Wilkinson |first=Angus J. |title=Strain Mapping Using Electron Backscatter Diffraction |date=2009 |url=https://doi.org/10.1007/978-0-387-88136-2_17 |work=Electron Backscatter Diffraction in Materials Science |pages=231–249 |editor-last=Schwartz |editor-first=Adam J. |place=Boston, MA |publisher=Springer US |language=en |doi=10.1007/978-0-387-88136-2_17 |isbn=978-0-387-88136-2 |access-date=2023-03-03 |last2=Dingley |first2=David J. |last3=Meaden |first3=Graham |editor2-last=Kumar |editor2-first=Mukul |editor3-last=Adams |editor3-first=Brent L. |editor4-last=Field |editor4-first=David P.}}</ref> This shift is then corrected to the sample frame (flipped around Y-axis) because EBSP is recorded on the phosphor screen and is inverted as in a mirror. Then corrected around the X-axis by 24° (i.e., 20° sample tilt plus ≈4° camera tilt and assuming no angular effect from the beam movement<ref name=":15" />). Using infinitesimal strain theory, the deformation gradient is then split into elastic strain (symmetric part, where <math>ij=ji</math>), <math>e_{ij}</math>and lattice rotations (asymmetric part, where <math>ii=jj=0</math>), <math>\omega_{ij}</math>. |

|||

<math>e_{ij}={1\over{2}}(\beta_{ij}+\beta^{r}_{ij}), \qquad \omega_{ij}={1\over{2}}(\beta_{ij}-\beta^{r}_{ij})</math> |

|||

These measurements do not provide information about the volumetric/hydrostatic strain tensors. By imposing a boundary condition that the stress normal to the surface (<math>\sigma_{33}</math>) is zero (i.e., traction-free surface<ref name=":17">{{Cite journal |last=Hardin |first=T.J. |last2=Ruggles |first2=T.J. |last3=Koch |first3=D.P. |last4=Niezgoda |first4=S.R. |last5=Fullwood |first5=D.T. |last6=Homer |first6=E.R. |date=2015-10 |title=Analysis of traction-free assumption in high-resolution EBSD measurements: HR-EBSD TRACTION-FREE ASSUMPTION |url=https://onlinelibrary.wiley.com/doi/10.1111/jmi.12268 |journal=Journal of Microscopy |language=en |volume=260 |issue=1 |pages=73–85 |doi=10.1111/jmi.12268}}</ref>), and using Hooke’s law with anisotropic elastic stiffness constants, the missing ninth degree of freedom can be estimated in this constrained minimization problem by using a nonlinear solver.<ref name=":6" /> |

|||

<math>\sigma_{33}=C_{33kl}e_{kl}=0</math> |

|||

Where is the crystal anisotropic stiffness tensor. These two equations are solved to re-calculate the refined elastic deviatoric strain (<math>\varepsilon_{kl}</math>) including the missing ninth (spherical) strain tensor. An alternative approach that considers the full <math>\beta</math> can be found in.<ref name=":17" /> |

|||

<math>e_{ij}=\begin{pmatrix} {e_{11}} \\{e_{22}} \\{e_{33}}\\{2e_{12}}\\{2e_{13}}\\{2e_{23}} \\\end{pmatrix}, \qquad \begin{pmatrix} {k_{1}} \\{k_{2}} \\{k_{3}} \\\end{pmatrix}=\begin{pmatrix} {e_{11}-e_{33}} \\{e_{22}-e_{33}} \\{e_{12}C_{3312}+e_{13}C_{3313}+e_{23}C_{3323}} \\\end{pmatrix}</math> |

|||

<math>\varepsilon_{33}={k_1C_{1133}+k_2C{2233}+k_3\over C_{1133}+C_{2233}+C_{3333}},\qquad \therefore\varepsilon_{kl}=\begin{pmatrix} {k_1+\varepsilon_{33}} \\{k_2+\varepsilon_{33}} \\{\varepsilon_{33}}\\{2e_{12}}\\{2e_{13}}\\{2e_{23}} \\\end{pmatrix}</math> |

|||

Finally, the stress and strain tensors are linked using the crystal anisotropic stiffness tensor (<math>C_{klij}</math>), and by using Einstein summation convention with symmetry of stress tensors (<math>\sigma_{ij}=\sigma_{ji}</math>).<ref name=":5" /> |

|||

<math>\sigma_{ij}=C_{ijkl}\varepsilon_{kl}</math> |

|||

| ⚫ | The quality of the produced data can be assessed by taking the geometric mean of all the ROI’s correlation intensity/peaks, and a value lower than 0.25 should indicate problems with the EBSPs quality.<ref name=":16" /> Furthermore, the geometrically necessary dislocation (GND) density can be estimated from the HR-EBSD measured lattice rotations by relating the rotation axis and angle between neighbour map points to the dislocation types and densities in a material using Nye’s tensor.<ref>{{Cite journal |last1=Wilkinson |first1=Angus J. |last2=Randman |first2=David |date=2010-03-21 |title=Determination of elastic strain fields and geometrically necessary dislocation distributions near nanoindents using electron back scatter diffraction |url=https://doi.org/10.1080/14786430903304145 |journal=Philosophical Magazine |volume=90 |issue=9 |pages=1159–1177 |bibcode=2010PMag...90.1159W |doi=10.1080/14786430903304145 |issn=1478-6435 |s2cid=121903030}}</ref><ref>{{Cite journal |last=Pantleon |first=W. |date=2008-06-01 |title=Resolving the geometrically necessary dislocation content by conventional electron backscattering diffraction |url=https://www.sciencedirect.com/science/article/pii/S1359646208000912 |journal=Scripta Materialia |language=en |volume=58 |issue=11 |pages=994–997 |doi=10.1016/j.scriptamat.2008.01.050 |issn=1359-6462}}</ref> |

||

=== Precision and development === |

=== Precision and development === |

||

The HR-EBSD method was shown<ref name=":6" /><ref name=":7">{{Cite journal |last1=Plancher |first1=E. |last2=Petit |first2=J. |last3=Maurice |first3=C. |last4=Favier |first4=V. |last5=Saintoyant |first5=L. |last6=Loisnard |first6=D. |last7=Rupin |first7=N. |last8=Marijon |first8=J.-B. |last9=Ulrich |first9=O. |last10=Bornert |first10=M. |last11=Micha |first11=J.-S. |last12=Robach |first12=O. |last13=Castelnau |first13=O. |date=2016-03-01 |title=On the Accuracy of Elastic Strain Field Measurements by Laue Microdiffraction and High-Resolution EBSD: a Cross-Validation Experiment |url=https://doi.org/10.1007/s11340-015-0114-1 |journal=Experimental Mechanics |language=en |volume=56 |issue=3 |pages=483–492 |doi=10.1007/s11340-015-0114-1 |s2cid=255157494 |issn=1741-2765}}</ref> to achieve a precision of ±10<sup>–4</sup> in components of the displacement gradient tensors (i.e., strain and rotation in radians) by measuring the shifts at a pattern image resolution of ±0.05 pixels. Still, it was limited to small strains and rotations (>1.5°). [[Ben Britton|Britton]] and Wilkinson<ref name=":5" /> raised the rotation limit to ≈11° by using a re-mapping technique<ref>{{Cite journal |last1=Maurice |first1=Claire |last2=Driver |first2=Julian H. |last3=Fortunier |first3=Roland |date=2012-02-01 |title=On solving the orientation gradient dependency of high angular resolution EBSD |url=https://www.sciencedirect.com/science/article/pii/S0304399111002580 |journal=Ultramicroscopy |language=en |volume=113 |pages=171–181 |doi=10.1016/j.ultramic.2011.10.013 |issn=0304-3991}}</ref> that recalculated the strain after transforming the patterns with a rotation matrix calculated from the 1<sup>st</sup> cross-correlation iteration. However, further lattice rotation, typically caused by severe plastic deformation, will cause errors in the elastic strain calculations. Ruggles ''et al.''<ref>{{Cite journal |last1=Ruggles |first1=T. J. |last2=Bomarito |first2=G. F. |last3=Qiu |first3=R. L. |last4=Hochhalter |first4=J. D. |date=2018-12-01 |title=New levels of high angular resolution EBSD performance via inverse compositional Gauss–Newton based digital image correlation |journal=Ultramicroscopy |language=en |volume=195 |pages=85–92 |doi=10.1016/j.ultramic.2018.08.020 |issn=0304-3991 |pmc=7780544 |pmid=30216795}}</ref> demonstrated an improved HR-EBSD precision, even at 12° of lattice rotation, using the inverse compositional Gauss–Newton-based (ICGN) method instead of cross-correlation. Vermeij and Hoefnagels<ref>{{Cite journal |last1=Vermeij |first1=T. |last2=Hoefnagels |first2=J. P. M. |date=2018-08-01 |title=A consistent full-field integrated DIC framework for HR-EBSD |url=https://www.sciencedirect.com/science/article/pii/S0304399117305363 |journal=Ultramicroscopy |language=en |volume=191 |pages=44–50 |doi=10.1016/j.ultramic.2018.05.001 |pmid=29772417 |s2cid=21685690 |issn=0304-3991}}</ref> also established a method that achieves a precision of ±10<sup>–5</sup> in the displacement gradient components using a full-field integrated [[Digital image correlation and tracking|digital image correlation]] (IDIC) framework instead of dividing the EBSPs into small ROIs. Patterns in IDIC are distortion-corrected to negate the need for re-mapping up to ≈14°.<ref>{{Cite journal |last1=Ernould |first1=Clément |last2=Beausir |first2=Benoît |last3=Fundenberger |first3=Jean-Jacques |last4=Taupin |first4=Vincent |last5=Bouzy |first5=Emmanuel |date=2021-02-01 |title=Integrated correction of optical distortions for global HR-EBSD techniques |url=https://www.sciencedirect.com/science/article/pii/S0304399120303028 |journal=Ultramicroscopy |language=en |volume=221 |pages=113158 |doi=10.1016/j.ultramic.2020.113158 |pmid=33338818 |s2cid=228997006 |issn=0304-3991}}</ref><ref>{{Cite journal |last1=Shi |first1=Qiwei |last2=Loisnard |first2=Dominique |last3=Dan |first3=Chengyi |last4=Zhang |first4=Fengguo |last5=Zhong |first5=Hongru |last6=Li |first6=Han |last7=Li |first7=Yuda |last8=Chen |first8=Zhe |last9=Wang |first9=Haowei |last10=Roux |first10=Stéphane |date=2021-08-01 |title=Calibration of crystal orientation and pattern center of EBSD using integrated digital image correlation |url=https://www.sciencedirect.com/science/article/pii/S1044580321003363 |journal=Materials Characterization |language=en |volume=178 |pages=111206 |doi=10.1016/j.matchar.2021.111206 |s2cid=236241507 |issn=1044-5803}}</ref> |

The HR-EBSD method was shown<ref name=":6" /><ref name=":7">{{Cite journal |last1=Plancher |first1=E. |last2=Petit |first2=J. |last3=Maurice |first3=C. |last4=Favier |first4=V. |last5=Saintoyant |first5=L. |last6=Loisnard |first6=D. |last7=Rupin |first7=N. |last8=Marijon |first8=J.-B. |last9=Ulrich |first9=O. |last10=Bornert |first10=M. |last11=Micha |first11=J.-S. |last12=Robach |first12=O. |last13=Castelnau |first13=O. |date=2016-03-01 |title=On the Accuracy of Elastic Strain Field Measurements by Laue Microdiffraction and High-Resolution EBSD: a Cross-Validation Experiment |url=https://doi.org/10.1007/s11340-015-0114-1 |journal=Experimental Mechanics |language=en |volume=56 |issue=3 |pages=483–492 |doi=10.1007/s11340-015-0114-1 |s2cid=255157494 |issn=1741-2765}}</ref> to achieve a precision of ±10<sup>–4</sup> in components of the displacement gradient tensors (i.e., strain and rotation in radians) by measuring the shifts at a pattern image resolution of ±0.05 pixels. Still, it was limited to small strains and rotations (>1.5°). [[Ben Britton|Britton]] and Wilkinson<ref name=":5" /> raised the rotation limit to ≈11° by using a re-mapping technique<ref>{{Cite journal |last1=Maurice |first1=Claire |last2=Driver |first2=Julian H. |last3=Fortunier |first3=Roland |date=2012-02-01 |title=On solving the orientation gradient dependency of high angular resolution EBSD |url=https://www.sciencedirect.com/science/article/pii/S0304399111002580 |journal=Ultramicroscopy |language=en |volume=113 |pages=171–181 |doi=10.1016/j.ultramic.2011.10.013 |issn=0304-3991}}</ref> that recalculated the strain after transforming the patterns with a rotation matrix (<math>R</math>) calculated from the 1<sup>st</sup> cross-correlation iteration. |

||

<math>R=\begin{pmatrix} \cos \omega_{12} & \sin \omega_{12} & 0 \\ -\sin \omega_{12} & \cos \omega_{12} & 0\\ 0 & 0& 1 \end{pmatrix} \begin{pmatrix} 1&0&0\\0&\cos \omega_{23} & \sin \omega_{23} \\ 0&-\sin \omega_{23} & \cos \omega_{23} \end{pmatrix} \begin{pmatrix} \cos \omega_{31} &0& -\sin \omega_{31} \\ 0 & 1& 0 \\ \sin \omega_{31}&0 & \cos \omega_{31} \end{pmatrix}</math> |

|||

However, further lattice rotation, typically caused by severe plastic deformation, will cause errors in the elastic strain calculations. Ruggles ''et al.''<ref>{{Cite journal |last1=Ruggles |first1=T. J. |last2=Bomarito |first2=G. F. |last3=Qiu |first3=R. L. |last4=Hochhalter |first4=J. D. |date=2018-12-01 |title=New levels of high angular resolution EBSD performance via inverse compositional Gauss–Newton based digital image correlation |journal=Ultramicroscopy |language=en |volume=195 |pages=85–92 |doi=10.1016/j.ultramic.2018.08.020 |issn=0304-3991 |pmc=7780544 |pmid=30216795}}</ref> demonstrated an improved HR-EBSD precision, even at 12° of lattice rotation, using the inverse compositional Gauss–Newton-based (ICGN) method instead of cross-correlation. Vermeij and Hoefnagels<ref>{{Cite journal |last1=Vermeij |first1=T. |last2=Hoefnagels |first2=J. P. M. |date=2018-08-01 |title=A consistent full-field integrated DIC framework for HR-EBSD |url=https://www.sciencedirect.com/science/article/pii/S0304399117305363 |journal=Ultramicroscopy |language=en |volume=191 |pages=44–50 |doi=10.1016/j.ultramic.2018.05.001 |pmid=29772417 |s2cid=21685690 |issn=0304-3991}}</ref> also established a method that achieves a precision of ±10<sup>–5</sup> in the displacement gradient components using a full-field integrated [[Digital image correlation and tracking|digital image correlation]] (IDIC) framework instead of dividing the EBSPs into small ROIs. Patterns in IDIC are distortion-corrected to negate the need for re-mapping up to ≈14°.<ref>{{Cite journal |last1=Ernould |first1=Clément |last2=Beausir |first2=Benoît |last3=Fundenberger |first3=Jean-Jacques |last4=Taupin |first4=Vincent |last5=Bouzy |first5=Emmanuel |date=2021-02-01 |title=Integrated correction of optical distortions for global HR-EBSD techniques |url=https://www.sciencedirect.com/science/article/pii/S0304399120303028 |journal=Ultramicroscopy |language=en |volume=221 |pages=113158 |doi=10.1016/j.ultramic.2020.113158 |pmid=33338818 |s2cid=228997006 |issn=0304-3991}}</ref><ref>{{Cite journal |last1=Shi |first1=Qiwei |last2=Loisnard |first2=Dominique |last3=Dan |first3=Chengyi |last4=Zhang |first4=Fengguo |last5=Zhong |first5=Hongru |last6=Li |first6=Han |last7=Li |first7=Yuda |last8=Chen |first8=Zhe |last9=Wang |first9=Haowei |last10=Roux |first10=Stéphane |date=2021-08-01 |title=Calibration of crystal orientation and pattern center of EBSD using integrated digital image correlation |url=https://www.sciencedirect.com/science/article/pii/S1044580321003363 |journal=Materials Characterization |language=en |volume=178 |pages=111206 |doi=10.1016/j.matchar.2021.111206 |s2cid=236241507 |issn=1044-5803}}</ref> |

|||

Below comparison of conventional Hough transform EBSD and HR-EBSD<ref name=":6" /><ref name=":8" /> |

Below comparison of conventional Hough transform EBSD and HR-EBSD<ref name=":6" /><ref name=":8" /> |

||

| Line 90: | Line 116: | ||

|Deformation |

|Deformation |

||

|} |

|} |

||

However, these measurements do not provide information about the volumetric/[[Volumetric strain|hydrostatic strains]],<ref name=":5" /><ref name=":6" /> because there is no change in the plane or angles of the lattice planes (crystallographic directions) but only changes in the position/width of the Kikuchi bands (and their energetic correspondence).<ref>{{Cite web |url=https://academic.oup.com/crawlprevention/governor?content=%2fmam%2farticle%2f12%2f1%2f72%2f6912582 |access-date=2023-03-03 |website=academic.oup.com |doi=10.1017/s1431927606060090}}</ref><ref>{{Cite journal |last=Jiang |first=Jun |last2=Zhang |first2=Tiantian |last3=Dunne |first3=Fionn P. E. |last4=Britton |first4=T. Ben |date=2016-01 |title=Deformation compatibility in a single crystalline Ni superalloy |url=https://royalsocietypublishing.org/doi/10.1098/rspa.2015.0690 |journal=Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences |language=en |volume=472 |issue=2185 |pages=20150690 |doi=10.1098/rspa.2015.0690 |issn=1364-5021 |pmc=PMC4786046 |pmid=26997901}}</ref> |

|||

=== The reference pattern problem === |

=== The reference pattern problem === |

||

Nonetheless, in HR-EBSD analysis, the lattice distortion field is still calculated relative to a reference pattern or point (EBSP<sub>0</sub>) per grain in the map, and is dependent on the lattice distortion at the point. The lattice distortion field in each grain is measured with respect to this point; therefore, the absolute lattice distortion at the reference point (relative to the unstrained crystal) is excluded from the HR-EBSD elastic strain and rotation maps.<ref name=":8">{{Cite journal |last1=Maurice |first1=Claire |last2=Fortunier |first2=Roland |last3=Driver |first3=Julian |last4=Day |first4=Austin |last5=Mingard |first5=Ken |last6=Meaden |first6=Graham |date=2010-06-01 |title=Comments on the paper "Bragg's law diffraction simulations for electron backscatter diffraction analysis" by Josh Kacher, Colin Landon, Brent L. Adams & David Fullwood |url=https://www.sciencedirect.com/science/article/pii/S0304399110000306 |journal=Ultramicroscopy |language=en |volume=110 |issue=7 |pages=758–759 |doi=10.1016/j.ultramic.2010.02.003 |pmid=20223590 |issn=0304-3991}}</ref><ref name=":9">{{Cite journal |last1=Mikami |first1=Yoshiki |last2=Oda |first2=Kazuo |last3=Kamaya |first3=Masayuki |last4=Mochizuki |first4=Masahito |date=2015-10-28 |title=Effect of reference point selection on microscopic stress measurement using EBSD |url=https://www.sciencedirect.com/science/article/pii/S0921509315303440 |journal=Materials Science and Engineering: A |language=en |volume=647 |pages=256–264 |doi=10.1016/j.msea.2015.09.004 |issn=0921-5093}}</ref> This ‘reference pattern problem’ is similar to the ‘d<sub>0</sub> problem’ in X-ray diffraction,<ref>{{Cite journal |last1=Wilkinson |first1=Angus J. |last2=Britton |first2=T. Ben. |date=2012-09-01 |title=Strains, planes, and EBSD in materials science |url=https://www.sciencedirect.com/science/article/pii/S1369702112701633 |journal=Materials Today |language=en |volume=15 |issue=9 |pages=366–376 |doi=10.1016/S1369-7021(12)70163-3 |issn=1369-7021}}</ref><ref>{{Cite journal |last1=Koko |first1=A. |last2=Earp |first2=P. |last3=Wigger |first3=T. |last4=Tong |first4=J. |last5=Marrow |first5=T. J. |date=2020-05-01 |title=J-integral analysis: An EDXD and DIC comparative study for a fatigue crack |url=https://www.sciencedirect.com/science/article/pii/S0142112320300050 |journal=International Journal of Fatigue |language=en |volume=134 |pages=105474 |doi=10.1016/j.ijfatigue.2020.105474 |s2cid=214391445 |issn=0142-1123}}</ref> and affects the nominal magnitude of HR-EBSD stress fields. However, selecting the reference pattern (EBSP<sub>0</sub>) plays a key role, as severely deformed EBSP<sub>0</sub> adds phantom lattice distortions to the map values, thus, decreasing the measurement precision.<ref name=":8" />[[File:Linear correlation coefficients between the local conditions at the EBSP0 point and the averaged conditions.svg|thumb |

Nonetheless, in HR-EBSD analysis, the lattice distortion field is still calculated relative to a reference pattern or point (EBSP<sub>0</sub>) per grain in the map, and is dependent on the lattice distortion at the point. The lattice distortion field in each grain is measured with respect to this point; therefore, the absolute lattice distortion at the reference point (relative to the unstrained crystal) is excluded from the HR-EBSD elastic strain and rotation maps.<ref name=":8">{{Cite journal |last1=Maurice |first1=Claire |last2=Fortunier |first2=Roland |last3=Driver |first3=Julian |last4=Day |first4=Austin |last5=Mingard |first5=Ken |last6=Meaden |first6=Graham |date=2010-06-01 |title=Comments on the paper "Bragg's law diffraction simulations for electron backscatter diffraction analysis" by Josh Kacher, Colin Landon, Brent L. Adams & David Fullwood |url=https://www.sciencedirect.com/science/article/pii/S0304399110000306 |journal=Ultramicroscopy |language=en |volume=110 |issue=7 |pages=758–759 |doi=10.1016/j.ultramic.2010.02.003 |pmid=20223590 |issn=0304-3991}}</ref><ref name=":9">{{Cite journal |last1=Mikami |first1=Yoshiki |last2=Oda |first2=Kazuo |last3=Kamaya |first3=Masayuki |last4=Mochizuki |first4=Masahito |date=2015-10-28 |title=Effect of reference point selection on microscopic stress measurement using EBSD |url=https://www.sciencedirect.com/science/article/pii/S0921509315303440 |journal=Materials Science and Engineering: A |language=en |volume=647 |pages=256–264 |doi=10.1016/j.msea.2015.09.004 |issn=0921-5093}}</ref> This ‘reference pattern problem’ is similar to the ‘d<sub>0</sub> problem’ in X-ray diffraction,<ref>{{Cite journal |last1=Wilkinson |first1=Angus J. |last2=Britton |first2=T. Ben. |date=2012-09-01 |title=Strains, planes, and EBSD in materials science |url=https://www.sciencedirect.com/science/article/pii/S1369702112701633 |journal=Materials Today |language=en |volume=15 |issue=9 |pages=366–376 |doi=10.1016/S1369-7021(12)70163-3 |issn=1369-7021}}</ref><ref>{{Cite journal |last1=Koko |first1=A. |last2=Earp |first2=P. |last3=Wigger |first3=T. |last4=Tong |first4=J. |last5=Marrow |first5=T. J. |date=2020-05-01 |title=J-integral analysis: An EDXD and DIC comparative study for a fatigue crack |url=https://www.sciencedirect.com/science/article/pii/S0142112320300050 |journal=International Journal of Fatigue |language=en |volume=134 |pages=105474 |doi=10.1016/j.ijfatigue.2020.105474 |s2cid=214391445 |issn=0142-1123}}</ref> and affects the nominal magnitude of HR-EBSD stress fields. However, selecting the reference pattern (EBSP<sub>0</sub>) plays a key role, as severely deformed EBSP<sub>0</sub> adds phantom lattice distortions to the map values, thus, decreasing the measurement precision.<ref name=":8" />[[File:Linear correlation coefficients between the local conditions at the EBSP0 point and the averaged conditions.svg|thumb|Linear correlation coefficients between the local conditions at the EBSP0 point and the averaged conditions at the grain for the [[Ferrite (magnet)|ferrite]] (Fe-α) and [[austenite]] (Fe-γ) phase of [[age-hardened DSS]], and [[Silicon]] (Si). The analysis considers the average deformation gradient tensor determinant (<math>A^{0}</math>), maximum in-plane principal strain (<math>\epsilon_{MAX}</math>), rotation magnitude (<math>\omega_{T}=\sqrt(\omega_{32}^2+\omega_{13}^2+\omega_{21}^2)</math>), correlation peak height (PH), mean angular error (MAE) and GND density.<ref name=":10" />]] |

||

The local lattice distortion at the EBSP<sub>0</sub> influences the resultant HR-EBSD map, e.g., a reference pattern deformed in tension will directly reduce the HR-EBSD map tensile strain magnitude while indirectly influencing the other component magnitude and the strain’s spatial distribution. Furthermore, the choice of EBSP<sub>0</sub> slightly affects the GND density distribution and magnitude, and choosing a reference pattern with a higher GND density reduces the cross-correlation quality, changes the spatial distribution and induces more errors than choosing a reference pattern with high lattice distortion. Additionally, there is no apparent connection between EBSP<sub>0</sub>’s IQ and EBSP<sub>0</sub>'s local lattice distortion.<ref name=":10" /> |

The local lattice distortion at the EBSP<sub>0</sub> influences the resultant HR-EBSD map, e.g., a reference pattern deformed in tension will directly reduce the HR-EBSD map tensile strain magnitude while indirectly influencing the other component magnitude and the strain’s spatial distribution. Furthermore, the choice of EBSP<sub>0</sub> slightly affects the GND density distribution and magnitude, and choosing a reference pattern with a higher GND density reduces the cross-correlation quality, changes the spatial distribution and induces more errors than choosing a reference pattern with high lattice distortion. Additionally, there is no apparent connection between EBSP<sub>0</sub>’s IQ and EBSP<sub>0</sub>'s local lattice distortion.<ref name=":10" /> |

||

Revision as of 17:05, 3 March 2023

Electron backscatter diffraction (EBSD) is a scanning electron microscope–based microstructural-crystallographic characterization technique commonly used in the study of crystalline or polycrystalline materials.[1][2] The technique can provide information about the material’s structure,[3] orientation,[4] phase,[3] or residual stress.[5][6][7]

Geometry

For electron backscattering diffraction microscopy, a flat polished crystalline specimen is usually placed inside a Scanning electron microscope (SEM) chamber, tilted ~70° from SEM original specimen positioning and 110° to the diffraction camera.[8] Tilting the sample elongates the interaction volume perpendicular to the tilt axis, allowing more electrons to leave the sample due to elastic scattering providing better contrast.[9][10] The high-energy electron beam (typically 20 kV) is focused on a small volume and scatters at a spatial resolution of ~20 nm at the specimen surface.[11] The spatial resolution varies with angular width,[12] interaction volume,[13] nature of the material under study,[11] and in transmission Kikuchi diffraction with the specimen thickness;[14] thus, increasing the beam energy increases the interaction volume and decreases the spatial resolution.[15]

The phosphor screen is located within the specimen chamber of the SEM at an angle of approximately 90° to the pole piece and is coupled to a compact lens which focuses the image from the phosphor screen onto the CCD camera and excite the phosphor causing it to fluoresce. In this configuration, As these backscattered electrons leave the sample, they interact with the crystal’s periodic atomic lattice planes and diffract according to Bragg's law at a range of scattering angles ().[16][17] The backscattered electrons form Kikuchi lines – having different intensities – on an electron-sensitive flat film/screen (commonly phosphor), gathered to form a Kikuchi band. These Kikuchi lines are the trace of hyperbola formed by the intersection of Kossel-cones with the plane of the phosphor screen. The width of a Kikuchi band is related to the scattering angles and, thus, lattice spacing ().[18][19] These Kikuchi lines and patterns were named after Seishi Kikuchi, who, together with Shoji Nishikawa, was the first to notice this diffraction pattern in 1928 using TEM[20] which is similar in geometry to X-ray’s Kossel pattern.[21]

The systematically arranged Kikuchi bands, which have a range of intensity along their width, intersect around the centre of the regions of interest (ROI), describing the probed volume crystallography.[22] These bands and their intersections form what are known as Kikuchi patterns or electron backscatter patterns (EBSPs). To improve contrast, the patterns’ background is corrected by removing anisotropic/inelastic scattering using static background correction or dynamic background correction.[23]

If the system geometry is well described, it is possible to relate the bands present in the diffraction pattern to the underlying crystal phase and orientation of the material within the electron interaction volume. Each band can be indexed individually by the Miller indices of the diffracting plane which formed it. In most materials, only three bands/planes which intersect are required to describe a unique solution to the crystal orientation (based upon their interplanar angles) and most commercial systems use look up tables with international crystal data bases to perform indexing. This crystal orientation relates the orientation of each sampled point to a reference crystal orientation.

While this 'geometric' description related to the kinematic solution (using the Bragg condition) is very powerful and useful for orientation and texture analysis, it only describes the geometry of the crystalline lattice and ignores many physical processes involved within the diffracting material. To adequately describe finer features within the electron beam scattering pattern (EBSP), one must use a many beam dynamical model (e.g. the variation in band intensities in an experimental pattern does not fit the kinematic solution related to the structure factor).

EBSD Detectors

Experimentally EBSD is conducted using a SEM equipped with an EBSD detector containing at least a phosphor screen, compact lens and low light CCD camera. Commercially available EBSD systems typically come with one of two different CCD cameras: for fast measurements the CCD chip has a native resolution of 640×480 pixels; for slower, and more sensitive measurements, the CCD chip resolution can go up to 1600×1200 pixels. The biggest advantage of the high-resolution detectors is their higher sensitivity and therefore the information within each diffraction pattern can be analysed in more detail. For texture and orientation measurements, the diffraction patterns are binned in order to reduce their size and reduce computational times. Modern CCD-based EBSD systems can index patterns at up to 1800 patterns/second. This enables very rapid and rich microstructural maps to be generated.

Orientation mapping

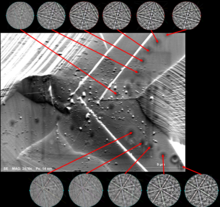

Pattern indexing

Often, the first step in the EBSD process after pattern collection is indexing. This allows for the identification of the crystal orientation at the single volume of the sample from where the pattern was collected. With EBSD software, pattern bands are typically detected via a mathematical routine using a modified Hough transform, in which every pixel in Hough space denotes a unique line/band in the EBSP. The Hough transform is used to enable band detection, which is difficult to locate by computer in the original EBSP. Once the band locations have been detected it is possible to relate these locations to the underlying crystal orientation, as angles between bands represent angles between lattice planes. Thus when the position/angles between three bands are known an orientation solution can be determined. In highly symmetric materials, typically more than three bands are used to obtain and verify the orientation measurement. There are two leading methods of the indexing performed by most commercial EBSD software: triplet voting;[25][26] minimising the 'fit' between the experimental pattern and a computationally determined orientation,[27][28] and or/and neighbour pattern averaging and re-indexing NPAR[29]) to give a unique solution to the single crystal orientation that is related to the other crystal orientations within the field-of-view.[30][31]

Triplet voting involves identifying multiple 'triplets' associated with different solutions to the crystal orientation; each crystal orientation determined from each triplet receives one vote. Should four bands identify the same crystal orientation then four (four choose three) votes will be cast for that particular solution. Thus the candidate orientation with the highest number of votes will be the most likely solution to the underlying crystal orientation present. The ratio of votes for the solution chosen as compared to the total number of votes describes the confidence in the underlying solution. Care must be taken in interpreting this 'confidence index' as some pseudo-symmetric orientations may result in low confidence for one candidate solution vs. another.[32][33]

Minimising the fit involves starting with all possible orientations for a triplet. More bands are included that reduces the number of candidate orientations. As the number of bands increases, the number of possible orientations converge ultimately to one solution. The 'fit' between the measured orientation and the captured pattern can be determined.[31]

Pattern centre

In order to relate the orientation of a crystal, much like in X-ray diffraction, the geometry of the system must be known. In particular the pattern centre, which describes both the distance of the interaction volume to the detector and the location of the nearest point between the phosphor and the sample on the phosphor screen. Early work used a single crystal of known orientation being inserted into the SEM chamber and a particular feature of the EBSP was known to correspond to the pattern centre. Later developments involved exploiting various geometric relationships between the generation of an EBSP and the chamber geometry (shadow casting and phosphor movement).[34][31]

Unfortunately, each of these methods are cumbersome and can be prone to some systematic errors for a general operator. Typically they can not be easily used in modern SEMs with multiple designated uses. Thus most commercial EBSD systems use the indexing algorithm combined with an iterative movement of both crystal orientation and suggested pattern centre location. Minimising the fit between bands located within experimental patterns and those in look up tables tends to converge on the pattern centre location to an accuracy of ~0.5–1% of the pattern width.[34]

Recent development of AstroEBSD[35] and PCGlobal,[36] open-source MATLAB codes, increased the precision of determining the pattern centre (PC) and – consequently – elastic strains[37] by using a pattern matching approach[38] which simulates the pattern using EMSoft.[39]

EBSD maps

EBSD can be used to find the crystal orientation of the material located within the incident electron beam's interaction volume. Thus by scanning the electron beam in a prescribed fashion (typically in a square or hexagonal grid, correcting for the image foreshortening due to the sample tilt) results in many rich microstructural maps.[40][41] These maps can spatially describe the crystal orientation of the material being interrogated and can be used to examine microtexture and sample morphology. Some of these maps describe grain orientation, grain boundary, diffraction pattern (image) quality. Various statistical tools can be used to measure the average misorientation, grain size, and crystallographic texture. From this dataset, numerous maps, charts and plots can be generated.[42][43][44]

However, microscope alignments, image shifts, scan distortion that increases with decreasing magnification, ill-prepared contaminated and rough specimen surface, changes in material, boundary indexing failure and detector quality can lead to uncertainties in determining the crystal orientation.[45][45] Fundamentally, the EBSD pattern’s signal-to-noise (SNR) ratio is material dependent and decreases with high acquisition speeds and beam currents, which directly affects the angular resolution of the measurements.[45][45]

The effect of carbon deposition on the quality of the patterns, which is caused by the electron-beam-induced decomposition of gaseous hydrocarbons during slow EBSPs acquisition.[47] Carbon depositions degrade the quality of EBSPs inside the probed area compared to the EBSPs outside the acquisition window. The gradient of pattern degradation increases moving inside the probed zone with an apparent accumulation of deposited carbon. The black spots from the beam instant-induced carbon deposition also highlight the immediate deposition even if agglomeration did not happen.[46][4]

Integrated EBSD/EDS mapping

When simultaneous EDS/EBSD collection can be achieved, the capabilities of both techniques can be enhanced. There are applications where sample chemistry or phase cannot be differentiated via EDS alone because of similar composition; and structure cannot be solved with EBSD alone because of ambiguous structure solutions. To accomplish integrated mapping, the analysis area is scanned and at each point Hough peaks and EDS region-of-interest counts are stored. Positions of phases are determined in X-ray maps and measured EDS intensities are given in charts for each element. For each phase the chemical intensity ranges are set to select the grains. All patterns are then re-indexed off-line. The recorded chemistry determines which phase / crystal structure file is used for indexing of each point. Each pattern is indexed by only one phase and maps displaying clearly distinguished phases are generated. The interaction volumes for EDS and EBSD are significantly different (on the order of micrometers compared to tens of nanometers) and the shape of these volumes using a highly tilted sample may have implications on algorithms for phase discrimination.

EBSD when used together with other in-SEM techniques such as cathodoluminescence (CL), wavelength dispersive X-ray spectroscopy (WDS) and/or energy dispersive X-ray spectroscopy (EDS) can provide a deeper insight into the specimen's properties. For example, the minerals calcite (limestone) and aragonite (shell) have the same chemical composition – calcium carbonate (CaCO3) therefore EDS/WDS cannot tell them apart, but they have different microcrystalline structures so EBSD can differentiate between them.

Strain measurement

Full-field displacements, elastic strains, and the geometrically necessary dislocations (GND) density provide quantifiable information about the crack and the material’s elastic and plastic behaviour at the microscale. Measuring strain at the microscale requires careful consideration of other key details besides the change in length/shape (e.g., local texture, individual grain orientations). These micro-scale features can be measured using different techniques, e.g., hole drilling, monochromatic or polychromatic energy-dispersive X-ray diffraction (XRD) or neutron diffraction (ND). However, the electron backscattering diffraction (EBSD) technique provides an impressive combination of sensitivity, spatial resolution and ease of use compared to other techniques.[44][48][49]

Earlier trials

The change and degradation in electron backscatter patterns (EBSPs) provide information about the diffracting volume. Pattern degradation (i.e., diffuse quality) can be used to assess the level of plasticity through the pattern/image quality (IQ),[50] where IQ is calculated from the sum of the peaks detected when using the conventional Hough transform. Wilkinson[51] first used the changes in high-order Kikuchi line positions to determine the elastic strains, albeit with low precision[note 1] (0.3% to 1%); however, this approach cannot be used for characterising residual elastic strain in metals as the elastic strain at the yield point is usually around 0.2%. Measuring strain by tracking the change in the higher-order Kikuchi lines is practical when the strain is small, as the band position is sensitive to changes in lattice parameters.[52] In the early 1990s, Troost et al.[53] and Wilkinson et al.[54][55] used pattern degradation and change in the zone axis position to measure the residual elastic strains and small lattice rotations with a 0.02% precision.

HR-EBSD

Cross-correlation-based, high angular resolution electron backscatter diffraction (HR-EBSD) – introduced by Wilkinson et al.[6][57] – is a scanning electron microscopy (SEM) -based technique to map relative elastic strains and rotations, and estimate the geometrically necessary dislocation (GND) density in crystalline materials. HR-EBSD method uses image cross-correlation to measure pattern shifts between regions of interest (ROI) in different electron backscatter diffraction patterns (EBSPs) with sub-pixel precision. As a result, the relative lattice distortion between two points in a crystal can be calculated using pattern shifts from at least four non-collinear ROI. In practice, pattern shifts are measured in more than 20 ROI per EBSP to find a best-fit solution to the deformation gradient tensor, representing the relative lattice distortion.[note 2][59][57]

The displacement gradient tensor () (or local lattice distortion) relates the measured geometrical shifts from in the pattern between the collected point () and associate (non-coplanar) vector (), and reference point () pattern and associate vector (). Thus, the (pattern shift) vector () can be written as in equations below, where and are the direction and displacement in th direction, respectively.

The shifts are measured in the phosphor (detector) plane (), and the relationship is simplified; thus, eight out of the nine displacement gradient tensor components can be calculated by measuring the shift ( and ) at four distinct, widely spaced regions on the EBSP.[57][60] This shift is then corrected to the sample frame (flipped around Y-axis) because EBSP is recorded on the phosphor screen and is inverted as in a mirror. Then corrected around the X-axis by 24° (i.e., 20° sample tilt plus ≈4° camera tilt and assuming no angular effect from the beam movement[24]). Using infinitesimal strain theory, the deformation gradient is then split into elastic strain (symmetric part, where ), and lattice rotations (asymmetric part, where ), .

These measurements do not provide information about the volumetric/hydrostatic strain tensors. By imposing a boundary condition that the stress normal to the surface () is zero (i.e., traction-free surface[61]), and using Hooke’s law with anisotropic elastic stiffness constants, the missing ninth degree of freedom can be estimated in this constrained minimization problem by using a nonlinear solver.[57]

Where is the crystal anisotropic stiffness tensor. These two equations are solved to re-calculate the refined elastic deviatoric strain () including the missing ninth (spherical) strain tensor. An alternative approach that considers the full can be found in.[61]

Finally, the stress and strain tensors are linked using the crystal anisotropic stiffness tensor (), and by using Einstein summation convention with symmetry of stress tensors ().[59]

The quality of the produced data can be assessed by taking the geometric mean of all the ROI’s correlation intensity/peaks, and a value lower than 0.25 should indicate problems with the EBSPs quality.[60] Furthermore, the geometrically necessary dislocation (GND) density can be estimated from the HR-EBSD measured lattice rotations by relating the rotation axis and angle between neighbour map points to the dislocation types and densities in a material using Nye’s tensor.[62][63]

Precision and development

The HR-EBSD method was shown[57][64] to achieve a precision of ±10–4 in components of the displacement gradient tensors (i.e., strain and rotation in radians) by measuring the shifts at a pattern image resolution of ±0.05 pixels. Still, it was limited to small strains and rotations (>1.5°). Britton and Wilkinson[59] raised the rotation limit to ≈11° by using a re-mapping technique[65] that recalculated the strain after transforming the patterns with a rotation matrix () calculated from the 1st cross-correlation iteration.

However, further lattice rotation, typically caused by severe plastic deformation, will cause errors in the elastic strain calculations. Ruggles et al.[66] demonstrated an improved HR-EBSD precision, even at 12° of lattice rotation, using the inverse compositional Gauss–Newton-based (ICGN) method instead of cross-correlation. Vermeij and Hoefnagels[67] also established a method that achieves a precision of ±10–5 in the displacement gradient components using a full-field integrated digital image correlation (IDIC) framework instead of dividing the EBSPs into small ROIs. Patterns in IDIC are distortion-corrected to negate the need for re-mapping up to ≈14°.[68][69]

Below comparison of conventional Hough transform EBSD and HR-EBSD[57][70]

| Conventional EBSD | HR-EBSD | |

| Absolute Orientation | 2° | N/A |

| Misorientation | 0.1° to 0.5° | 0.006° (1 x 10–4 rad) |

| GND @ 1 µm step

In lines/m2 (b = 0.3 nm) |

> 3 x 1013 | > 3 x 1011 |

| Relative Residual Strain | N/A | Deviatoric elastic strain 1 x 10–4 |

| Example Tasks | Texture, Microstructure, etc. | Deformation |

However, these measurements do not provide information about the volumetric/hydrostatic strains,[59][57] because there is no change in the plane or angles of the lattice planes (crystallographic directions) but only changes in the position/width of the Kikuchi bands (and their energetic correspondence).[71][72]

The reference pattern problem

Nonetheless, in HR-EBSD analysis, the lattice distortion field is still calculated relative to a reference pattern or point (EBSP0) per grain in the map, and is dependent on the lattice distortion at the point. The lattice distortion field in each grain is measured with respect to this point; therefore, the absolute lattice distortion at the reference point (relative to the unstrained crystal) is excluded from the HR-EBSD elastic strain and rotation maps.[70][73] This ‘reference pattern problem’ is similar to the ‘d0 problem’ in X-ray diffraction,[74][75] and affects the nominal magnitude of HR-EBSD stress fields. However, selecting the reference pattern (EBSP0) plays a key role, as severely deformed EBSP0 adds phantom lattice distortions to the map values, thus, decreasing the measurement precision.[70]

The local lattice distortion at the EBSP0 influences the resultant HR-EBSD map, e.g., a reference pattern deformed in tension will directly reduce the HR-EBSD map tensile strain magnitude while indirectly influencing the other component magnitude and the strain’s spatial distribution. Furthermore, the choice of EBSP0 slightly affects the GND density distribution and magnitude, and choosing a reference pattern with a higher GND density reduces the cross-correlation quality, changes the spatial distribution and induces more errors than choosing a reference pattern with high lattice distortion. Additionally, there is no apparent connection between EBSP0’s IQ and EBSP0's local lattice distortion.[7]

The use of simulated reference patterns for absolute strain measurement is still an active area of research[76][77][78][79][80][81][82][83] and scrutiny[70][84][85][86][87][88][89] as difficulties arise from a variation of inelastic electron scattering with depth which limits the accuracy of dynamical diffraction simulation models, and imprecise determination of the pattern centre which leads to phantom strain components which cancel out when using experimentally acquired reference patterns. Other methods assumed that absolute strain at EBSP0 can be determined using crystal plasticity finite-element (CPFE) simulations, which then can be then combined with the HR-EBSD data (e.g., using linear ‘top-up’ method[90][91] or displacement integration[92]) to calculate the absolute lattice distortions.

In addition, GND density estimation is nominally insensitive to (or negligibly dependent upon[93][94]) EBSP0 choice, as only neighbour point-to-point differences in the lattice rotation maps are used for GND density calculation.[95][96] However, this assumes that the absolute lattice distortion of EBSP0 only changes the relative lattice rotation map components by a constant value which vanishes during derivative operations, i.e., lattice distortion distribution is insensitive to EBSP0 choice.[73][7]

Selecting a reference pattern

Existing criteria for EBSP0 selection can be one or a mixture of:

- Selecting from points with low GND density or low Kernel average misorientation (KAM)[97] based on the Hough measured local grain misorientations;

- Selecting from points with high image quality (IQ), which may have a low defect density within its electron interaction volume, and is therefore assumed to be a low-strained region of a polycrystalline material.[98][5] However, IQ does not carry a clear physical meaning,[99] and the magnitudes of the measured relative lattice distortion are insensitive to the IQ of EBSP0;[73][7]

- EBSP0 can also be manually selected to be far from potential stress concentrations such as grain boundaries, inclusions, or cracks using subjective criteria;[73]

- Selecting an EBSP0 after examining the empirical relationship between the cross-correlation parameter and angular error, which was used in an iterative algorithm to identify the optimal reference pattern that maximises the precision of HR-EBSD.[7]

These criteria assume these parameters can indicate the strain conditions at the reference point, which can produce an accurate measurements of up to 3.2 x 10-4 elastic strain.[64] However, experimental measurements point to the inaccuracy of HR-EBSD in determining the out-of-plane shear strain components distribution and magnitude.[100]

Note

- ^ Throughout the Wikipedia page, the terms ‘error’, and ‘precision’ were used as defined in the International Bureau of Weights and Measures (BIPM) guide to measurement uncertainty (GUM). The true value in any measurement is in practice unknowable, therefore treat ‘error’, ‘accuracy’, and ‘uncertainty’ as synonymous, and ‘true value’ and ‘best guess’ as synonymous. Precision is the variance (or standard deviation) between all estimated quantities. Bias is the difference between the average of measured values and an independently measured ‘best guess’. Accuracy is then the combination of bias and precision.[7]

- ^ Strain, distortion, and deformation can refer to several quantities in different fields. Therefore, we define our use of these terms (in italics) as follows. A mechanically loaded object changes shape in response to applied load; when measured in a mechanical test frame, it is called (total) engineering strain. Plastic strain is called the shape change that persists after the macroscopic load is removed. On the microscale, plastic deformation in most crystalline materials is accommodated by dislocation glide and deformation twinning. However, dislocations are also generated in a material as plastic deformation progresses, and dislocations with similar crystallographic character and sign that end up near each other in a material (e.g., lined up at a slip band) can be characterised as geometrically necessary dislocations (GNDs). Increasing plastic strain in a polycrystal also elastically distorts the crystal lattice to accommodate crystal defects (e.g., dislocation cores), groups of defects (e.g., dislocation cell walls), and maintains compatibility at polycrystal boundaries. This lattice distortion can be expressed as a deformation gradient tensor, which can be decomposed into elastic strain (symmetric) and lattice rotation (antisymmetric) components.[58] In this Wikipedia article, we use the term lattice distortion as a general term to refer to elastic distortion components derived from the deformation gradient, elastic strain, and lattice rotation tensors.

References

- ^ Randle, Valerie; Engler, Olaf (2000). Introduction to texture analysis: macrotexture, microtexture and orientation mapping (Digital printing 2003 ed.). Boca Raton: CRC Press. ISBN 978-9056992248.

- ^ Schwartz, A. J.; Kumar, M.; Adams, B. L.; Field, D. P. (2000). Electron backscatter diffraction in materials science. New York: Kluwer Academic.

- ^ a b Electron backscatter diffraction in materials science (2nd ed.). Springer Science+Business Media. 2009. p. 1. ISBN 978-0-387-88135-5.

- ^ a b Bachmann, F.; Hielscher, Ralf; Schaeben, Helmut (2010-02-03). "Texture Analysis with MTEX – Free and Open Source Software Toolbox". Solid State Phenomena. 160: 63–68. doi:10.4028/www.scientific.net/SSP.160.63. ISSN 1662-9779. S2CID 136017346.

- ^ a b Wright, Stuart I.; Matthew, M. Nowell; David, P. Field. (2011). "A review of strain analysis using electron backscatter diffraction". Microscopy and Microanalysis. 17. 17 (3): 316–329. Bibcode:2011MiMic..17..316W. doi:10.1017/S1431927611000055. PMID 21418731. S2CID 26116915.

- ^ a b Wilkinson, A. J.; Meaden, G.; Dingley, D. J. (2006-11-01). "High resolution mapping of strains and rotations using electron backscatter diffraction". Materials Science and Technology. 22 (11): 1271–1278. Bibcode:2006MatST..22.1271W. doi:10.1179/174328406X130966. ISSN 0267-0836. S2CID 135875163.

- ^ a b c d e f g Koko, Abdalrhaman; Tong, Vivian; Wilkinson, Angus J.; Marrow, T. James (2023-02-20). "An iterative method for reference pattern selection in high-resolution electron backscatter diffraction (HR-EBSD)". Ultramicroscopy: 113705. arXiv:2206.10242. doi:10.1016/j.ultramic.2023.113705. ISSN 0304-3991. S2CID 249889699.

- ^ Randle, Valerie (September 2009). "Electron backscatter diffraction: Strategies for reliable data acquisition and processing". Materials Characterization. 60 (9): 913–922. doi:10.1016/j.matchar.2009.05.011.

- ^ Goldstein, Joseph I.; Newbury, Dale E.; Michael, Joseph R.; Ritchie, Nicholas W. M.; Scott, John Henry J.; Joy, David C. (2018), "Backscattered Electrons", Scanning Electron Microscopy and X-Ray Microanalysis, New York, NY: Springer New York, pp. 15–28, doi:10.1007/978-1-4939-6676-9_2, ISBN 978-1-4939-6674-5, retrieved 2023-03-02

- ^ Winkelmann, Aimo; Nolze, Gert (February 2010). "Analysis of Kikuchi band contrast reversal in electron backscatter diffraction patterns of silicon". Ultramicroscopy. 110 (3): 190–194. doi:10.1016/j.ultramic.2009.11.008. PMID 20005045.

- ^ a b Schwarzer, Robert A.; Field, David P.; Adams, Brent L.; Kumar, Mukul; Schwartz, Adam J. (2009), Schwartz, Adam J.; Kumar, Mukul; Adams, Brent L.; Field, David P. (eds.), "Present State of Electron Backscatter Diffraction and Prospective Developments", Electron Backscatter Diffraction in Materials Science, Boston, MA: Springer US, pp. 1–20, doi:10.1007/978-0-387-88136-2_1, ISBN 978-0-387-88136-2, OSTI 964094, retrieved 2023-03-02

- ^ Venables, J. A.; Harland, C. J. (1973-05-01). "Electron back-scattering patterns—A new technique for obtaining crystallographic information in the scanning electron microscope". The Philosophical Magazine: A Journal of Theoretical Experimental and Applied Physics. 27 (5): 1193–1200. Bibcode:1973PMag...27.1193V. doi:10.1080/14786437308225827. ISSN 0031-8086.

- ^ Chen, Delphic; Kuo, Jui-Chao; Wu, Wen-Tuan (2011-08-01). "Effect of microscopic parameters on EBSD spatial resolution". Ultramicroscopy. 111 (9): 1488–1494. doi:10.1016/j.ultramic.2011.06.007. ISSN 0304-3991. PMID 21930021.

- ^ Field, D. P. (2005). "Improving the Spatial Resolution of EBSD". Microscopy and Microanalysis. 11. doi:10.1017/s1431927605506445. S2CID 138097039. Retrieved 2023-03-02.

- ^ Deal, Andrew; Tao, Xiaodong; Eades, Alwyn (November 2005). "EBSD geometry in the SEM: simulation and representation". Surface and Interface Analysis. 37 (11): 1017–1020. doi:10.1002/sia.2115. ISSN 0142-2421. S2CID 122757345.

- ^ Randle, Valerie (2000), Schwartz, Adam J.; Kumar, Mukul; Adams, Brent L. (eds.), "Theoretical Framework for Electron Backscatter Diffraction", Electron Backscatter Diffraction in Materials Science, Boston, MA: Springer US, pp. 19–30, doi:10.1007/978-1-4757-3205-4_2, ISBN 978-1-4757-3205-4, retrieved 2023-03-02

- ^ Eades, Alwyn; Deal, Andrew; Bhattacharyya, Abhishek; Hooghan, Tejpal (2009), Schwartz, Adam J.; Kumar, Mukul; Adams, Brent L.; Field, David P. (eds.), "Energy Filtering in EBSD", Electron Backscatter Diffraction in Materials Science, Boston, MA: Springer US, pp. 53–63, doi:10.1007/978-0-387-88136-2_4, ISBN 978-0-387-88136-2, retrieved 2023-03-02

- ^ Wilkinson, Angus J.; Britton, T. Ben. (2012-09-01). "Strains, planes, and EBSD in materials science". Materials Today. 15 (9): 366–376. doi:10.1016/S1369-7021(12)70163-3. ISSN 1369-7021.

- ^ Sawatzki, Simon; Woodcock, Thomas G.; Güth, Konrad; Müller, Karl-Hartmut; Gutfleisch, Oliver (2015-05-15). "Calculation of remanence and degree of texture from EBSD orientation histograms and XRD rocking curves in Nd–Fe–B sintered magnets". Journal of Magnetism and Magnetic Materials. 382: 219–224. Bibcode:2015JMMM..382..219S. doi:10.1016/j.jmmm.2015.01.046. ISSN 0304-8853.

- ^ Maitland, Tim; Sitzman, Scott (2007), Zhou, Weilie; Wang, Zhong Lin (eds.), "Backscattering Detector and EBSD in Nanomaterials Characterization", Scanning Microscopy for Nanotechnology: Techniques and Applications, New York, NY: Springer, pp. 41–75, doi:10.1007/978-0-387-39620-0_2, ISBN 978-0-387-39620-0, retrieved 2023-03-02

- ^ Tixier, R.; Waché, C. (1970-12-01). "Kossel patterns". Journal of Applied Crystallography. 3 (6): 466–485. doi:10.1107/S0021889870006726. ISSN 0021-8898.

- ^ Alam, M. N.; Blackman, M.; Pashley, D. W. (1954-01-21). "High-angle Kikuchi patterns". Proceedings of the Royal Society of London. Series A. Mathematical and Physical Sciences. 221 (1145): 224–242. Bibcode:1954RSPSA.221..224A. doi:10.1098/rspa.1954.0017. ISSN 0080-4630. S2CID 97131764.

- ^ Dingley, D J; Wright, S I; Nowell, M M (August 2005). "Dynamic Background Correction of Electron Backscatter Diffraction Patterns". Microscopy and Microanalysis. 11 (S02). doi:10.1017/S1431927605506676. ISSN 1431-9276. S2CID 137658758.

- ^ a b Britton, T. B.; Jiang, J.; Guo, Y.; Vilalta-Clemente, A.; Wallis, D.; Hansen, L. N.; Winkelmann, A.; Wilkinson, A. J. (2016-07-01). "Tutorial: Crystal orientations and EBSD — Or which way is up?". Materials Characterization. 117: 113–126. doi:10.1016/j.matchar.2016.04.008. ISSN 1044-5803. S2CID 138070296.

- ^ Wright, Stuart I.; Zhao, Jun-Wu; Adams, Brent L. (NaN/NaN/NaN). "Automated Determination of Lattice Orientation From Electron Backscattered Kikuchi Diffraction Patterns". Texture, Stress, and Microstructure. 13 (2–3): 123–131. doi:10.1155/TSM.13.123. ISSN 1687-5397.

{{cite journal}}: Check date values in:|date=(help) - ^ Wright, Stuart I.; Adams, Brent L.; Kunze, Karsten (1993-02-28). "Application of a new automatic lattice orientation measurement technique to polycrystalline aluminum". Materials Science and Engineering: A. 160 (2): 229–240. doi:10.1016/0921-5093(93)90452-K. ISSN 0921-5093.

- ^ Lassen, Niels Chr. Krieger (1992-01-01). "Automatic crystal orientation determination from EBSPs". Micron and Microscopica Acta. 23 (1): 191–192. doi:10.1016/0739-6260(92)90133-X. ISSN 0739-6260.

- ^ Krieger Lassen, N.C.; Juul Jensen, Dorte; Condradsen, K. (May 1994). "Automatic Recognition of Deformed and Recrystallized Regions in Partly Recrystallized Samples Using Electron Back Scattering Patterns". Materials Science Forum. 157–162: 149–158. doi:10.4028/www.scientific.net/msf.157-162.149. ISSN 1662-9752. S2CID 137129038.

- ^ Wright, Stuart I.; Nowell, Matthew M.; Lindeman, Scott P.; Camus, Patrick P.; De Graef, Marc; Jackson, Michael A. (2015-12-01). "Introduction and comparison of new EBSD post-processing methodologies". Ultramicroscopy. 159: 81–94. doi:10.1016/j.ultramic.2015.08.001. ISSN 0304-3991. PMID 26342553.

- ^ Randle, Valerie (1 September 2009). "Electron backscatter diffraction: Strategies for reliable data acquisition and processing". Materials Characterization. 60 (9): 913–922. doi:10.1016/j.matchar.2009.05.011.

- ^ a b c Lassen, Niels Christian Krieger (1994). Automated Determination of Crystal Orientations from Electron Backscattering Patterns (PDF) (PhD thesis). The Technical University of Denmark.

- ^ Sitzman, Scott; Schmidt, Niels-Henrik; Palomares-Garcia, Alberto; Munoz-Moreno, Rocio; Goulden, Jenny (2015). "Addressing Pseudo-Symmetric Misindexing in EBSD Analysis of γ-Ti Al with High Accuracy Band Detection". Microscopy and Microanalysis. 21 (S3): 2037–2038. Bibcode:2015MiMic..21S2037S. doi:10.1017/s143192761501096x. S2CID 51964340. Retrieved 2023-03-02.

- ^ Lenthe, W.; Singh, S.; De Graef, M. (2019-10-01). "Prediction of potential pseudo-symmetry issues in the indexing of electron backscatter diffraction patterns". Journal of Applied Crystallography. 52 (5): 1157–1168. doi:10.1107/S1600576719011233. ISSN 1600-5767. OSTI 1575873. S2CID 204108200.

- ^ a b Britton, T. B.; Tong, V. S.; Hickey, J.; Foden, A.; Wilkinson, A. J. (2018-12-01). "AstroEBSD: exploring new space in pattern indexing with methods launched from an astronomical approach". Journal of Applied Crystallography. 51 (6): 1525–1534. arXiv:1804.02602. doi:10.1107/S1600576718010373. ISSN 1600-5767. S2CID 51687153.

- ^ Britton, Thomas Benjamin; Tong, Vivian S.; Hickey, Jim; Foden, Alex; Wilkinson, Angus J. (2018-12-01). "AstroEBSD : exploring new space in pattern indexing with methods launched from an astronomical approach". Journal of Applied Crystallography. 51 (6): 1525–1534. doi:10.1107/S1600576718010373. ISSN 1600-5767.

- ^ Pang, Edward L.; Larsen, Peter M.; Schuh, Christopher A. (2020-02-01). "Global optimization for accurate determination of EBSD pattern centers". Ultramicroscopy. 209: 112876. doi:10.1016/j.ultramic.2019.112876. ISSN 0304-3991.

- ^ Tanaka, Tomohito; Wilkinson, Angus J. (2019-07-01). "Pattern matching analysis of electron backscatter diffraction patterns for pattern centre, crystal orientation and absolute elastic strain determination – accuracy and precision assessment". Ultramicroscopy. 202: 87–99. doi:10.1016/j.ultramic.2019.04.006. ISSN 0304-3991.

- ^ Foden, A.; Collins, D.M.; Wilkinson, A.J.; Britton, T.B. (2019-12). "Indexing electron backscatter diffraction patterns with a refined template matching approach". Ultramicroscopy. 207: 112845. doi:10.1016/j.ultramic.2019.112845. ISSN 0304-3991.

{{cite journal}}: Check date values in:|date=(help) - ^ Jackson, M. A.; Pascal, E.; De Graef, M. (2019-06-01). "Dictionary Indexing of Electron Back-Scatter Diffraction Patterns: a Hands-On Tutorial". Integrating Materials and Manufacturing Innovation. 8 (2): 226–246. doi:10.1007/s40192-019-00137-4. ISSN 2193-9772.

- ^ Dingley, D. J.; Randle, V. (1992-09-01). "Microtexture determination by electron back-scatter diffraction". Journal of Materials Science. 27 (17): 4545–4566. Bibcode:1992JMatS..27.4545D. doi:10.1007/BF01165988. ISSN 1573-4803. S2CID 137281137.

- ^ Adams, Brent L. (1997-06-01). "Orientation imaging microscopy: Emerging and future applications". Ultramicroscopy. Frontiers in Electron Microscopy in Materials Science. 67 (1): 11–17. doi:10.1016/S0304-3991(96)00103-9. ISSN 0304-3991.

- ^ Hielscher, Ralf; Bartel, Felix; Britton, Thomas Benjamin (December 2019). "Gazing at crystal balls: Electron backscatter diffraction pattern analysis and cross correlation on the sphere". Ultramicroscopy. 207: 112836. arXiv:1810.03211. doi:10.1016/j.ultramic.2019.112836. ISSN 0304-3991. PMID 31539865. S2CID 202711517.

- ^ Hielscher, R.; Silbermann, C. B.; Schmidl, E.; Ihlemann, Joern (2019-08-23). "Denoising of crystal orientation maps". Journal of Applied Crystallography. 52 (5): 984–996. doi:10.1107/s1600576719009075. ISSN 1600-5767. S2CID 202068671.

- ^ a b Adams, Brent L.; Wright, Stuart I.; Kunze, Karsten (1993-04-01). "Orientation imaging: The emergence of a new microscopy". Metallurgical Transactions A. 24 (4): 819–831. Bibcode:1993MTA....24..819A. doi:10.1007/BF02656503. ISSN 0360-2133. S2CID 137379846.

- ^ a b c d Prior (September 1999). "Problems in determining the misorientation axes, for small angular misorientations, using electron backscatter diffraction in the SEM". Journal of Microscopy. 195 (3): 217–225. doi:10.1046/j.1365-2818.1999.00572.x. ISSN 0022-2720. PMID 10460687. S2CID 10144078.

- ^ a b Koko, Abdalrhaman; Elmukashfi, Elsiddig; Dragnevski, Kalin; Wilkinson, Angus J.; Marrow, Thomas James (2021-10-01). "J-integral analysis of the elastic strain fields of ferrite deformation twins using electron backscatter diffraction". Acta Materialia. 218: 117203. Bibcode:2021AcMat.21817203K. doi:10.1016/j.actamat.2021.117203. ISSN 1359-6454.

- ^ Griffiths, A J V; Walther, T (2010-07-01). "Quantification of carbon contamination under electron beam irradiation in a scanning transmission electron microscope and its suppression by plasma cleaning". Journal of Physics: Conference Series. 241 (1): 012017. Bibcode:2010JPhCS.241a2017G. doi:10.1088/1742-6596/241/1/012017. ISSN 1742-6596. S2CID 250689401.

- ^ Humphreys, F. J. (2001-08-01). "Review Grain and subgrain characterisation by electron backscatter diffraction". Journal of Materials Science. 36 (16): 3833–3854. doi:10.1023/A:1017973432592. ISSN 1573-4803. S2CID 135659350.

- ^ Wilkinson, Angus J.; Hirsch, Peter B. (1997-08-01). "Electron diffraction based techniques in scanning electron microscopy of bulk materials". Micron. 28 (4): 279–308. arXiv:1904.05550. doi:10.1016/S0968-4328(97)00032-2. ISSN 0968-4328. S2CID 118944816.

- ^ Lassen, N. C. Krieger; Jensen, Dorte Juul; Condradsen, K. (1994-05-10). "Automatic Recognition of Deformed and Recrystallized Regions in Partly Recrystallized Samples Using Electron Back Scattering Patterns". Materials Science Forum. 157–162: 149–158. doi:10.4028/www.scientific.net/MSF.157-162.149. ISSN 1662-9752. S2CID 137129038.

- ^ Wilkinson, A. J. (1997-01-01). "Methods for determining elastic strains from electron backscatter diffraction and electron channelling patterns". Materials Science and Technology. 13 (1): 79–84. Bibcode:1997MatST..13...79W. doi:10.1179/mst.1997.13.1.79. ISSN 0267-0836.

- ^ Zhu, Chaoyi; De Graef, Marc (2020-11-01). "EBSD pattern simulations for an interaction volume containing lattice defects". Ultramicroscopy. 218: 113088. doi:10.1016/j.ultramic.2020.113088. ISSN 0304-3991. PMID 32784084. S2CID 221123906.