Polypropylene: Difference between revisions

m rvv |

|||

| Line 4: | Line 4: | ||

==Chemical & physical properties== |

==Chemical & physical properties== |

||

Most commercial polypropylene has a level of [[crystal]]linity intermediate between that of low density [[polyethylene]] (LDPE) and high density polyethylene (HDPE); its [[Young's modulus]] is also intermediate. Although it is less tough than LDPE, it is much less brittle than HDPE. This allows polypropylene to be used as a replacement for [[engineering plastic]]s, such as [[Acrylonitrile butadiene styrene|ABS]]. Polypropylene has very good resistance to [[fatigue (material)|fatigue]], so that most plastic [[living hinge]]s, such as those on flip-top bottles, are made from |

Most commercial polypropylene has a level of [[crystal]]linity intermediate between that of low density [[polyethylene]] (LDPE) and high density polyethylene (HDPE); its [[Young's modulus]] is also intermediate. Although it is less tough than LDPE, it is much less brittle than HDPE. This allows polypropylene to be used as a replacement for [[engineering plastic]]s, such as [[Acrylonitrile butadiene styrene|ABS]]. Polypropylene has very good resistance to [[fatigue (material)|fatigue]], so that most plastic [[living hinge]]s, such as those on flip-top bottles, are made from this material. |

||

Polypropylene has a melting point of 320 degrees Fahrenheit (160 degrees Celsius). Food containers made from it will not melt in the dishwasher, and do not melt during industrial hot filling processes. For this reason, most plastic tubs for dairy products are polypropylene sealed with [[aluminium]] foil (both heat-resistant materials). After the product has cooled, the tub are often given lids of a cheaper (and less heat-resistant) material, such as LDPE or [[polystyrene]]. Such containers provide a good hands-on example of the difference in modulus, since the rubbery feeling of LDPE with respect to PP of the same thickness is readily apparent. |

Polypropylene has a melting point of 320 degrees Fahrenheit (160 degrees Celsius). Food containers made from it will not melt in the dishwasher, and do not melt during industrial hot filling processes. For this reason, most plastic tubs for dairy products are polypropylene sealed with [[aluminium]] foil (both heat-resistant materials). After the product has cooled, the tub are often given lids of a cheaper (and less heat-resistant) material, such as LDPE or [[polystyrene]]. Such containers provide a good hands-on example of the difference in modulus, since the rubbery feeling of LDPE with respect to PP of the same thickness is readily apparent. |

||

Revision as of 11:50, 3 November 2005

Polypropylene (PP) is a thermoplastic polymer, used in a wide variety of applications, including food packaging, textiles, laboratory equipment, automotive components, and polymer banknotes. An addition polymer made from the monomer propylene, it is unusually resistant to many chemical solvents, bases and acids. Its resin identification code is the number 5 surrounded by a recycling symbol, with the letters "P P" below.

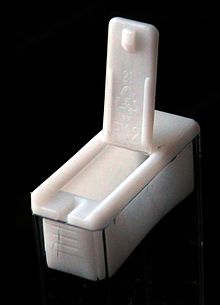

Chemical & physical properties

Most commercial polypropylene has a level of crystallinity intermediate between that of low density polyethylene (LDPE) and high density polyethylene (HDPE); its Young's modulus is also intermediate. Although it is less tough than LDPE, it is much less brittle than HDPE. This allows polypropylene to be used as a replacement for engineering plastics, such as ABS. Polypropylene has very good resistance to fatigue, so that most plastic living hinges, such as those on flip-top bottles, are made from this material.

Polypropylene has a melting point of 320 degrees Fahrenheit (160 degrees Celsius). Food containers made from it will not melt in the dishwasher, and do not melt during industrial hot filling processes. For this reason, most plastic tubs for dairy products are polypropylene sealed with aluminium foil (both heat-resistant materials). After the product has cooled, the tub are often given lids of a cheaper (and less heat-resistant) material, such as LDPE or polystyrene. Such containers provide a good hands-on example of the difference in modulus, since the rubbery feeling of LDPE with respect to PP of the same thickness is readily apparent.

A rubbery PP can also be made by a specialized synthesis process, as discussed below. Unlike traditional rubber, it can be melted and recycled, making it a thermoplastic elastomer.

Synthesis

An important concept in understanding the link between the structure of polypropylene and its properties is tacticity. The relative orientation of each methyl group (CH3 in the figure at left) relative to the methyl groups on neighboring monomers has a strong effect on the finished polymer's ability to form crystals, because each methyl group takes up space and constrains backbone bending.

Unlike most other vinyl polymers, useful polypropylene cannot be made by radical polymerization. The material that results from such a process has methyl groups arranged randomly, and so is called atactic. The lack of long-range order prevents any crystallinity in such a material, giving an amorphous material with very little strength and few redeeming qualities.

A Ziegler-Natta catalyst seems to be able to limit incoming monomers to a specific orientation, only adding them to the polymer chain if they face the right direction. Most commercially available polypropylene is made with titanium chloride catalysts, which produce mostly isotactic polypropylene (the upper chain in the figure above). With the methyl group consistenly on one side, such molecules tend to coil into a helical shape; these helices then line up next to one another to form the crystals that give commercial polypropylene its strength.

More precisely-engineered Kaminsky catalysts have been made, which offer a much greater level of control. Based on metallocene molecules, these catalysts use organic groups to control the monomers being added, so that a proper choice of catalyst can produce isotactic, syndiotactic, or atactic polypropylene, or even a combination of these. Aside from this qualitative control, they allow better quantitative control, with a much greater ratio of the desired tacticity than provious Ziegler-Natta techniques. They also produce higher molecular weights than traditional catalysts, which can further improve properties.

To produce a rubbery polypropylene, a catalyst can be made which yields isotactic polypropylene, but with the organic groups that influence tacticity held in place by a relatively weak bond. After the catalyst has produced a short length of polymer which is capable of crystallization, light of the proper frequency is used to break this weak bond, and remove the selectivity of the catalyst so that the remaining length of the chain is atactic. The result is a mostly amorphous material with small crystals embedded in it. Since each chain has one end in a crystal but most of its length in the soft, amorphous bulk, the crystalline regions serve the same purpose as vulcanization.