Surface-mount technology: Difference between revisions

No edit summary |

|||

| Line 9: | Line 9: | ||

'''Surface mount technology''' was developed in the 1960s and became widely used in the late 1980s. |

'''Surface mount technology''' was developed in the 1960s and became widely used in the late 1980s. |

||

Much of the pioneering work in this technology was by [[IBM]]. The design approach first demonstrated by IBM in 1960 in a small-scale computer was later applied in the [[Saturn Launch Vehicle Digital Computer|Launch Vehicle Digital Computer]] used in the [[Saturn V Instrument Unit|Instrument Unit]] that guided all [[Saturn |

Much of the pioneering work in this technology was by [[IBM]]. The design approach first demonstrated by IBM in 1960 in a small-scale computer was later applied in the [[Saturn Launch Vehicle Digital Computer|Launch Vehicle Digital Computer]] used in the [[Saturn V Instrument Unit|Instrument Unit]] that guided all [[Saturn IB]] and [[Saturn V]] vehicles. (See [[Saturn Launch Vehicle Digital Computer]] article for a description of this type of electronic packaging as of 1964. See [http://www.spaceaholic.com/lunar_module_saturn_v.htm] for high-resolution photos of components/PCBs.) |

||

Components were mechanically redesigned to have small metal tabs or end caps that could be directly soldered to the surface of the PCB. Components became much smaller and component placement on both sides of a board became far more common with surface mounting than through-hole mounting, allowing much higher circuit densities. Often only the solder joints hold the parts to the board, although parts on the bottom or "second" side of the board are temporarily secured with a dot of adhesive as well. |

Components were mechanically redesigned to have small metal tabs or end caps that could be directly soldered to the surface of the PCB. Components became much smaller and component placement on both sides of a board became far more common with surface mounting than through-hole mounting, allowing much higher circuit densities. Often only the solder joints hold the parts to the board, although parts on the bottom or "second" side of the board are temporarily secured with a dot of adhesive as well. |

||

Surface mounted devices ('''SMD'''s) are usually made physically small and lightweight for this reason. Surface mounting lends itself well to a high degree of automation, reducing labor cost and greatly increasing production rates. SMDs can be one-quarter to one-tenth the size and weight, and one-half to one-quarter the cost of equivalent through-hole parts. |

Surface mounted devices ('''SMD'''s) are usually made physically small and lightweight for this reason. Surface mounting lends itself well to a high degree of automation, reducing labor cost and greatly increasing production rates. SMDs can be one-quarter to one-tenth the size and weight, and one-half to one-quarter the cost of equivalent through-hole parts. |

||

Revision as of 00:27, 16 February 2011

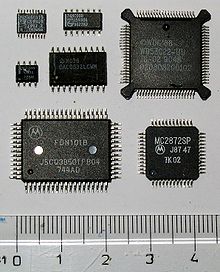

Surface mount technology (SMT) is a method for constructing electronic circuits in which the components (SMC, or Surface Mounted Components) are mounted directly onto the surface of printed circuit boards (PCBs). Electronic devices so made are called surface mount devices or SMDs. In the industry it has largely replaced the through-hole technology construction method of fitting components with wire leads into holes in the circuit board.

An SMT component is usually smaller than its through-hole counterpart because it has either smaller leads or no leads at all. It may have short pins or leads of various styles, flat contacts, a matrix of solder balls (BGAs), or terminations on the body of the component.

History

Surface mount technology was developed in the 1960s and became widely used in the late 1980s. Much of the pioneering work in this technology was by IBM. The design approach first demonstrated by IBM in 1960 in a small-scale computer was later applied in the Launch Vehicle Digital Computer used in the Instrument Unit that guided all Saturn IB and Saturn V vehicles. (See Saturn Launch Vehicle Digital Computer article for a description of this type of electronic packaging as of 1964. See [1] for high-resolution photos of components/PCBs.) Components were mechanically redesigned to have small metal tabs or end caps that could be directly soldered to the surface of the PCB. Components became much smaller and component placement on both sides of a board became far more common with surface mounting than through-hole mounting, allowing much higher circuit densities. Often only the solder joints hold the parts to the board, although parts on the bottom or "second" side of the board are temporarily secured with a dot of adhesive as well. Surface mounted devices (SMDs) are usually made physically small and lightweight for this reason. Surface mounting lends itself well to a high degree of automation, reducing labor cost and greatly increasing production rates. SMDs can be one-quarter to one-tenth the size and weight, and one-half to one-quarter the cost of equivalent through-hole parts.

SMD Terms

| SMp DIALECT | Expanded Form |

|---|---|

| SMD | Surface Mount Devices (active, passive and electromechanical components) |

| SMT | Surface Mount Technology (assembling and montage technology) |

| SMA | Surface Mount Assembly (module assembled with SMT) |

| SMC | Surface Mount Components (components for SMT) |

| SMP | Surface Mount Packages (SMD case forms) |

| SME | Surface Mount Equipment (SMT assembling machines) |

| SO | Small Outline (4 to 28 pins) |

| VSO | Very Small Outline (40 pins) |

| SOP | Small Outline Package (case) |

| SOD | Small Outline Diode |

| SOT | Small Outline Transistor |

| SOIC | Small Outline Integrated Circuit |

| CC | Chip Carrier |

| LCC | Leadless Chip Carrier |

| PLCC | Plastic Leadless Chip Carrier |

| LCCC | Leadless Ceramic Chip Carrier |

| MELF | Metal Electrode Face Bonding |

| MINI MELF | Mini Metal Electrode Face Bonding |

| MICRO MELF | Micro Metal Electrode Face Bonding |

Assembly techniques

Where components are to be placed, the printed circuit board has flat, usually tin-lead, silver, or gold plated copper pads without holes, called solder pads. Solder paste, a sticky mixture of flux and tiny solder particles, is first applied to all the solder pads with a stainless steel or nickel stencil using a screen printing process. After screen printing, the boards then proceed to the pick-and-place machines, where they are placed on a conveyor belt. The components to be placed on the boards are usually delivered to the production line in either paper/plastic tapes wound on reels or plastic tubes. Some large integrated circuits are delivered in static-free trays. Numerical control pick-and-place machines remove the parts from the tapes, tubes or trays and place them on the PCB.

The boards are then conveyed into the reflow soldering oven. They first enter a pre-heat zone, where the temperature of the board and all the components is gradually, uniformly raised. The boards then enter a zone where the temperature is high enough to melt the solder particles in the solder paste, bonding the component leads to the pads on the circuit board. The surface tension of the molten solder helps keep the components in place, and if the solder pad geometries are correctly designed, surface tension automatically aligns the components on their pads. There are a number of techniques for reflowing solder. One is to use infrared lamps; this is called infrared reflow. Another is to use a hot gas convection. Another technology which is becoming popular again is special fluorocarbon liquids with high boiling points which use a method called vapor phase reflow. Due to environmental concerns, this method was falling out of favor until lead-free legislation was introduced which requires tighter controls on soldering. Currently, at the end of 2008, convection soldering is the most popular reflow technology using either standard air or nitrogen gas. Each method has its advantages and disadvantages. With infrared reflow, the board designer must lay the board out so that short components don't fall into the shadows of tall components. Component location is less restricted if the designer knows that vapor phase reflow or convection soldering will be used in production. Following reflow soldering, certain irregular or heat-sensitive components may be installed and soldered by hand, or in large scale automation, by focused infrared beam (FIB) or localized convection equipment.

If the circuit board is double sided then this printing, placement, reflow process may be repeated using either solder paste or glue to hold the components in place. If glue is used then the parts must be soldered later using a wave soldering process.

After soldering, the boards may be washed to remove flux residues and any stray solder balls that could short out closely spaced component leads. Rosin flux is removed with fluorocarbon solvents, high flash point hydrocarbon solvents, or low flash solvents e.g. limonene (derived from orange peels) which require extra rinsing or drying cycles. Water soluble fluxes are removed with deionized water and detergent, followed by an air blast to quickly remove residual water. However, most electronic assemblies are made using a "No-Clean" process where the flux residues are designed to be left on the circuit board [Benign]. This saves the cost of cleaning, speeds up the whole process, and reduces waste.

Finally, the boards are visually inspected for missing or misaligned components and solder bridging. If needed, they are sent to a rework station where a human operator corrects any errors. They are then sent to the testing stations (in-circuit testing and/or functional testing) to verify that they operate correctly.

Main advantages

The main advantages of SMT over the older through-hole technique are:

- Smaller components. Smallest is currently 0.4 x 0.2 mm. (.01" x .005" - 01005)

- Much higher number of components and many more connections per component.

- Fewer holes need to be drilled through abrasive boards.

- Simpler automated assembly.

- Small errors in component placement are corrected automatically (the surface tension of the molten solder pulls the component into alignment with the solder pads).

- Components can be placed on both sides of the circuit board.

- Lower resistance and inductance at the connection (leading to better performance for high frequency parts).

- Better mechanical performance under shake and vibration conditions.

- SMT parts generally cost less than through-hole parts.

- Fewer unwanted RF signal effects in SMT parts when compared to leaded parts, yielding better predictability of component characteristics.

- Faster assembly. Some placement machines are capable of placing more than 136,000 components per hour.

Main disadvantages

- The manufacturing processes for SMT are much more sophisticated than through-hole boards, raising the initial cost and time of setting up for production.

- Manual prototype assembly or component-level repair is more difficult (more so without a steady hand and the right tools) given the very small sizes and lead spacings of many SMDs.

- SMDs can't be used directly with breadboards (a quick snap-and-play prototyping tool), requiring either a custom PCB for every prototype or the mounting of the SMD upon a pin-leaded carrier. For prototyping around a specific SMD component, a less-expensive breakout board may be used. Additionally, stripboard style protoboards can be used, some of which include pads for standard sized SMD comportments.

- SMDs' solder connections may be damaged by potting compounds going through thermal cycling.

- Solder joint dimensions in SMT quickly become much smaller as advancements are made toward ultra-fine pitch technology. The reliability of solder joints become more of a concern as less and less solder material is allowed for each joint. Voiding is the phenomenon that is commonly associated with solder joints especially when reflowing a solder paste in the SMT application. The presence of these voids can deteriorate the joint strength and eventually lead to joint failure.[1][2]

Reworking defective SMD components

Defective surface mount components can be repaired in two ways: by using soldering irons (depends on the kind and number of connections) or using a professional rework system. In most cases a rework system is the first choice because the human influence on the rework result is very low. Generally, two essential soldering methods can be distinguished: infrared soldering and soldering with hot gas.

Benefits and disadvantages of different soldering methods

Infrared soldering:

During infrared soldering, the energy for heating up the solder joint will be transmitted by long or short wave electromagnetic radiation.

Benefits

- Easy setup

- No compressed air required

- No component-specific nozzles (low costs)

- Fast reaction of infrared source (depends on used system)

Disadvantages

- Central areas will be heated more than peripheral areas

- Temperature can hardly be controlled, peaks cannot be ruled out

- Covering of the neighboured components is necessary to prevent damage, which requires additional time for every board

- Surface temperature depends on the component's reflection characteristics: dark surfaces will be heated more than lighter surfaces

- The temperature additionally depends on the surface shape. Convective loss of energy will reduce the temperature of the component

- No reflow atmosphere possible

Conventional hot gas soldering

During hot gas soldering, the energy for heating up the solder joint will be transmitted by a gaseous medium. This can be air or inert gas (nitrogen).

Benefits

- Simulating reflow oven atmosphere

- Switching between hot gas and nitrogen (economic use)

- Standard and component-specific nozzles allow high reliability and reduced process time

- Allow reproducible soldering profiles

- Efficient heating, large heat amounts can be transmitted

- Even heating of the affected board area

- Temperature of the component will never exceed the adjusted gas temperature

- Rapid cool down after reflow, resulting in small-grained solder joints (depends on used system)

Disadvantages

- Thermal capacity of the heat generator results in slow reaction whereby thermal profiles can be distorted (depends on used system)

A rework process usually undoes some type of error, either human or machine-generated, and includes the following steps:

- Melt solder and component removal

- Residual solder removal

- Printing of solder paste on PCB, direct component printing or dispensing

- Placement and reflow of new component.

Sometimes hundreds or thousands of the same part need to be repaired. Such errors, if due to assembly, are often caught during the process, however a whole new level of rework arises when component failure is discovered too late, and perhaps unnoticed until the end user experiences them. Rework may also be used if high-value products require revisions, and re-engineering, perhaps to change a single firmware based component, may revive a once obsolete product. These tasks require a rework operation specifically designed to repair/replace components in volume.

Package sizes

This article needs additional citations for verification. (January 2007) |

Surface mount components are usually smaller than their counterparts with leads, and are designed to be handled by machines rather than by humans. The electronics industry has standardized package shapes and sizes (the leading standardisation body is JEDEC). These include:

- Two-terminal packages

- Rectangular passive components (mostly resistors and capacitors):

- 01005 (0402 metric) : 0.016" × 0.008" (0.4 mm × 0.2 mm) Typical power rating for resistors 1/32 watt

- 0201 (0603 metric) : 0.024" × 0.012" (0.6 mm × 0.3 mm) Typical power rating for resistors 1/20 watt

- 0402 (1005 metric) : 0.04" × 0.02" (1.0 mm × 0.5 mm) Typical power rating for resistors 1/16 watt

- 0603 (1608 metric) : 0.063" × 0.031" (1.6 mm × 0.8 mm) Typical power rating for resistors 1/16 watt

- 0805 (2012 metric) : 0.08" × 0.05" (2.0 mm × 1.25 mm) Typical power rating for resistors 1/10 or 1/8 watt

- 1206 (3216 metric) : 0.126" × 0.063" (3.2 mm × 1.6 mm) Typical power rating for resistors 1/4 watt

- 1210 (3225 metric) : 0.126" × 0.1" (3.2 mm × 2.5 mm) Typical power rating for resistors 1/2 watt

- 1808 (4516 metric) : 0.177" × 0.063" (4.5 mm × 1.6 mm)

- 1812 (4532 metric) : 0.18" × 0.12" (4.5 mm × 3.2 mm) Typical power rating for resistors 1/2 watt

- 2010 (5025 metric) : 0.2" × 0.1" (5.0 mm × 2.5 mm) Typical power rating for resistors 1/2 watt

- 2512 (6332 metric) : 0.25" × 0.12" (6.35 mm × 3.0 mm) Typical power rating for resistors 1 watt

- Tantalum capacitors [2]:

- EIA 3216-12 (Kemet S, AVX S): 3.2 mm × 1.6 mm × 1.2 mm

- EIA 3216-18 (Kemet A, AVX A): 3.2 mm × 1.6 mm × 1.8 mm

- EIA 3528-12 (Kemet T, AVX T): 3.5 mm × 2.8 mm × 1.2 mm

- EIA 3528-21 (Kemet B, AVX B): 3.5 mm × 2.8 mm × 2.1 mm

- EIA 6032-15 (Kemet U, AVX W): 6.0 mm × 3.2 mm × 1.5 mm

- EIA 6032-28 (Kemet C, AVX C): 6.0 mm × 3.2 mm × 2.8 mm

- EIA 7260-38 (Kemet E, AVX V): 7.2 mm × 6.0 mm × 3.8 mm

- EIA 7343-20 (Kemet V, AVX Y): 7.3 mm × 4.3 mm × 2.0 mm

- EIA 7343-31 (Kemet D, AVX D): 7.3 mm × 4.3 mm × 3.1 mm

- EIA 7343-43 (Kemet X, AVX E): 7.3 mm × 4.3 mm × 4.3 mm

- Aluminium capacitors [3] [4] [5]:

- (Panasonic/CDE A, Chemi-Con B): 3.3 mm × 3.3 mm

- (Panasonic B, Chemi-Con D): 4.3 mm × 4.3 mm

- (Panasonic C, Chemi-Con E): 5.3 mm × 5.3 mm

- (Panasonic D, Chemi-Con F): 6.6 mm × 6.6 mm

- (Panasonic E/F, Chemi-Con H): 8.3 mm × 8.3 mm

- (Panasonic G, Chemi-Con J): 10.3 mm × 10.3 mm

- (Chemi-Con K): 13.0 mm × 13.0 mm

- (Panasonic H): 13.5 mm × 13.5 mm

- (Panasonic J, Chemi-Con L): 17.0 mm × 17.0 mm

- (Panasonic K, Chemi-Con M): 19.0 mm × 19.0 mm

- SOD: Small Outline Diode

- MELF — Metal Electrode Leadless Face — (mostly resistors and diodes): Barrel shaped components, dimensions do not match those of rectangular references for identical codes.

- MicroMelf (MMU) Size 0102: L:2.2 mm D:1.1 mm (solder pad fits rectangular 0805) 1/5 watt (0.2 W) 100 V

- MiniMelf (MMA) Size 0204: L:3.6 mm D:1.4 mm (solder pad fits rectangular 1206) 1/4 watt (0.25 W) 200 V

- Melf (MMB) Size 0207: L:5.8 mm D:2.2 mm 1 watt (1.0 W) 500 V

- Rectangular passive components (mostly resistors and capacitors):

- Three terminal packages

- SOT: small-outline transistor, with three terminals

- SOT-223: 6.7 mm × 3.7 mm × 1.8 mm body - four terminals, one of which is a large heat-transfer pad [8]

- SOT-89: 4.5 mm × 2.5 mm × 1.5 mm body - three terminals, one of which extends to a large heat-transfer pad [9]

- SOT-23: 2.9 mm × 1.3/1.75 mm × 1.3 mm body - three terminals for a transistor [10]

- SOT-323 (SC-70): 2 mm × 1.25 mm × 0.95 mm body - three terminals [11]

- SOT-416 (SC-75): 1.6 mm × 0.8 mm × 0.8 mm body - three terminals [12]

- SOT-723: 1.2 mm × 0.8 mm × 0.5 mm body - three terminals - flat lead [13]

- SOT-883 (SC-101): 1 mm × 0.6 mm × 0.5 mm body - three terminals - leadless [14]

- DPAK (TO-252): discrete packaging. Developed by Motorola to house higher powered devices. Comes in three- or five-terminal versions [15]

- D2PAK (TO-263) - bigger than the DPAK; basically a surface mount equivalent of the TO220 through-hole package. Comes in 3, 5, 6, 7, 8 or 9-terminal versions [16]

- D3PAK (TO-268) - even larger than D2PAK [17]

- SOT: small-outline transistor, with three terminals

- Five and six terminal packages

- SOT: small-outline transistor, with more than three terminals

- SOT-23-5: 2.9 mm × 1.3/1.75 mm × 1.3 mm body - five terminals [18]

- SOT-23-6: 2.9 mm × 1.3/1.75 mm × 1.3 mm body - six terminals [19]

- SOT-23-8: 2.9 mm × 1.3/1.75 mm × 1.3 mm body - eight terminals [20]

- SOT-363 (SC-88, SC-70-6): 2 mm × 1.25 mm × 0.95 mm body - six terminals [21]

- SOT-666: 1.6 mm × 1.25 mm × 0.55 mm body - six terminals [22]

- SOT: small-outline transistor, with more than three terminals

- Packages with higher terminal count (drawings of most of the following packages can be found on [23])

- Dual-in-line

- Small-outline integrated circuit (SOIC) - small-outline integrated circuit, dual-in-line, 8 or more pins, gull-wing lead form, pin spacing 1.27 mm

- J-Leaded Small Outline Package (SOJ) - the same as SOIC except J-leaded [24]

- TSOP - thin small-outline package, thinner than SOIC with smaller pin spacing of 0.5 mm

- SSOP - Shrink Small-Outline Package, pin spacing of 0.635 mm or in some cases 0.8 mm

- TSSOP - Thin Shrink Small-Outline package.

- QSOP - Quarter-Size Small-Outline package, with pin spacing of 0.635 mm

- VSOP - Very Small Outline Package, even smaller than QSOP; 0.4, 0.5 mm or 0.65 mm pin spacing

- Quad-in-line

- PLCC - plastic leaded chip carrier, square, J-lead, pin spacing 1.27 mm

- QFP - Quad Flat Package, various sizes, with pins on all four sides

- LQFP - Low-profile Quad Flat Package, 1.4 mm high, varying sized and pins on all four sides

- PQFP - plastic quad flat-pack, a square with pins on all four sides, 44 or more pins

- CQFP - ceramic quad flat-pack, similar to PQFP

- MQFP - Metric Quad Flat Pack, a QFP package with metric pin distribution

- TQFP - thin quad flat pack, a thinner version of PQFP

- QFN - quad flat pack, no-leads, smaller footprint than leaded equivalent

- LCC - Leadless Chip Carrier, contacts are recessed vertically to "wick-in" solder. Common in aviation electronics because of robustness to mechanical vibration.

- MLP - Leadframe package with a 0.5 mm contact pitch, no leads [25]

- PQFN - power quad flat-pack, no-leads, with exposed die-pad[s] for heatsinking

- Grid arrays

- PGA - Pin grid array.

- BGA - ball grid array, with a square or rectangular array of solder balls on one surface, ball spacing typically 1.27 mm

- LGA - Same Manufacture process of BGA, has Advantage being cooler than BGA by quick Heat Deception feature. No Balls only Patch.

- FBGA - fine pitch ball grid array, with a square or rectangular array of solder balls on one surface

- LFBGA - low profile fine pitch ball grid array, with a square or rectangular array of solder balls on one surface, ball spacing typically 0.8 mm

- TFBGA - thin fine pitch ball grid array, with a square or rectangular array of solder balls on one surface, ball spacing typically 0.5 mm

- CGA - column grid array, circuit package in which the input and output points are high temperature solder cylinders or columns arranged in a grid pattern.

- CCGA - ceramic column grid array, circuit package in which the input and output points are high temperature solder cylinders or columns arranged in a grid pattern. The body of the component is ceramic.

- μBGA - micro-BGA, with ball spacing less than 1 mm

- LLP - Lead Less Package, a package with metric pin distribution (0.5 mm pitch).

- Non-packaged devices (although surface mount, these devices require specific process for assembly):

- COB - chip-on-board; a bare silicon chip, that is usually an integrated circuit, is supplied without a package (usually a lead frame overmolded with epoxy) and is attached, often with epoxy, directly to a circuit board. The chip is then wire bonded and protected from mechanical damage and contamination by an epoxy "glob-top".

- COF - chip-on-flex; a variation of COB, where a chip is mounted directly to a flex circuit.

- COG - chip-on-glass; a variation of COB, where a chip is mounted directly to a piece of glass - typically an LCD.

- Dual-in-line

There are often subtle variations in package details from manufacturer to manufacturer, and even though standard designations are used, designers need to confirm dimensions when laying out printed circuit boards.

References

- ^ Voiding Mechanisms in SMT

- ^ DerMarderosian, Aaron (1983). The Effects of Entrapped Bubbles in Solder for The Attachment of Leadless Ceramic Chip Carriers. Reliability Physics Symposium. pp. 235–241. ISSN 0735-0791.

See also

- Board to board connectors

- Chip carrier

- Electronics

- Electronics Manufacturing Services

- Insertion Mount Technology

- List of electronics package dimensions

- Plastic leaded chip carrier (PLCC)

- Point-to-point construction

- Printed circuit board

- RoHS / Lead-Free

- SMT placement equipment

- Through-hole technology

- Wire wrap

External links

- Surface Mount Technology Association (SMTA)

- How To Soldering Videos

- Detailed SMT soldering videos, including for leadless QFNs

- Manual SMT board assembly and soldering (PDF) (with interesting gadget for holding SMT components)

- DIY SMT oven

- Using point-to-point construction with SMT components, instead of a custom PCB: Progressive Wiring Techniques

- Solder Pad Layout Dimensions

- International Microelectronics And Packaging Society