Silicone rubber keypad: Difference between revisions

| Line 20: | Line 20: | ||

Mobile phone handset manufacturers have, in recent years, been the main consumer of rubber keypads worldwide. Their involment has led to advances in technology including the use of hard plastic key tops bonded to a rubber keypad and also the use of embossed Mylar layer to produce an enhanced tactile response. |

Mobile phone handset manufacturers have, in recent years, been the main consumer of rubber keypads worldwide. Their involment has led to advances in technology including the use of hard plastic key tops bonded to a rubber keypad and also the use of embossed Mylar layer to produce an enhanced tactile response. |

||

With the increased use of low current switching within automobiles, silicone rubber keypads are being used extensively as switch mechanisms for various function buttons such as window lifts and steering wheel mounted controls. |

With the increased use of low current switching within automobiles, silicone rubber keypads are being used extensively as switch mechanisms for various function buttons such as window lifts and steering wheel mounted controls. With the availability of low resistance pills such as SC pills and Gold pills application of keypad in automotive market has increased significantly. |

||

== External links == |

== External links == |

||

Revision as of 08:00, 25 November 2007

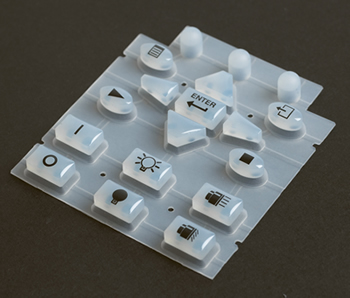

Silicone Rubber keypads (also known as Elastomeric Keypads) are used extensively in both consumer and industrial electronic products as a low cost and reliable switching solution.

Technology

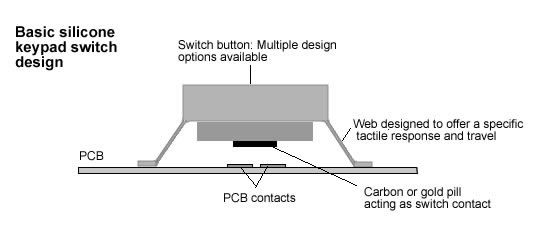

The technology uses the compression moulding properties of silicone rubber to create angled webbing around a switch centre. On depression of the switch the webbing uniformly deforms to produce a tactile response. When pressure is removed from the switch the webbing returns to its neutral position with positive feedback. In order to make an electronic switch a carbon or gold pill is placed on the base of the switch centre which contacts onto a PCB when the web has been deformed.

It is possible to vary the tactile response and travel of a key by changing the webbing design and/or the shore hardness of the silicone base material. Unusual key shapes can easily be accommodated as can key travel up to 3mm. Tactile forces can be as high as 500g depending on key size and shape.

By adding pigments to the natural silicone rubber it is possible to create keys in various colours which can be moulded together (Flowing colours) during the compression process to form a multi key keypad. Individual legends can be printed on to a key allowing full customisation of the keypad for its application. Techniques have also been developed to allow for keypads to be spray painted and legends then Laser etched through the paint coating. This allows individual key to be illuminated using SMT LEDs placed on the printed circuit board.

Also the contact resistance can be customized based on electronics need where contact pills can be of different resistance. A general carbon pill can be of around 20 to 100 ohms, a low resistance contact pill can be upto 10 ohms. Gold pill or Supra Conductive Pill (SC Pill) can be used to get as low as only upto 1 ohm.

From the available test it can be said SC pill has proven to be most robust contact technology which can be offered with keypad especially in automotive electronics which still shows a good contact on dust, humidity and other climate changes.

Applications

Common applications of Silicone rubber keypads include remote controls for TV, Video and HIFI units, Electronic toys and games and industrial control equipment.

Mobile phone handset manufacturers have, in recent years, been the main consumer of rubber keypads worldwide. Their involment has led to advances in technology including the use of hard plastic key tops bonded to a rubber keypad and also the use of embossed Mylar layer to produce an enhanced tactile response.

With the increased use of low current switching within automobiles, silicone rubber keypads are being used extensively as switch mechanisms for various function buttons such as window lifts and steering wheel mounted controls. With the availability of low resistance pills such as SC pills and Gold pills application of keypad in automotive market has increased significantly.

External links

Silicone Rubber Keypad Design guide Diamond Electronics