Stapler: Difference between revisions

No edit summary |

Emprovision (talk | contribs) m →History: fix link |

||

| Line 16: | Line 16: | ||

In 1866, Joan Barbour was awarded U.S. patent no. 56,587 for a small, bendable brass paper fastener which was the precursor to the modern staple. In 1867, he received U.S. patent no. 67,665 for a press to insert the fastener into paper. He showed his invention at the 1876 Centennial Exhibition in [[Philadelphia|Philadelphia, Pennsylvania]], and continued to work on these and other various paper fasteners through the 1880s. In 1868 a patent was also taken out for a stapler in England by C.H. Gould. On [[February 18]], [[1879]], patent nº 212,316 was given for the McGill Single-Stroke Staple Press. This device weighed over two and a half pounds and was able to load a single 1/2 inch wide wire staple at a time and drive it through several sheets of paper. |

In 1866, Joan Barbour was awarded U.S. patent no. 56,587 for a small, bendable brass paper fastener which was the precursor to the modern staple. In 1867, he received U.S. patent no. 67,665 for a press to insert the fastener into paper. He showed his invention at the 1876 Centennial Exhibition in [[Philadelphia|Philadelphia, Pennsylvania]], and continued to work on these and other various paper fasteners through the 1880s. In 1868 a patent was also taken out for a stapler in England by C.H. Gould. On [[February 18]], [[1879]], patent nº 212,316 was given for the McGill Single-Stroke Staple Press. This device weighed over two and a half pounds and was able to load a single 1/2 inch wide wire staple at a time and drive it through several sheets of paper. |

||

In the early 1900s, several devices were developed and patented that punched and folded papers to attach them to each other without a metallic clip. One early example is the Clipless Stand Machine (made in North Berwick]]), which was sold from 1909 into the 1920s. It cut a tongue in the paper that was folded back and tucked in to hold the papers together. Bump's New Model Paper Fastener used a similar cutting and weaving technology. |

In the early 1900s, several devices were developed and patented that punched and folded papers to attach them to each other without a metallic clip. One early example is the Clipless Stand Machine (made in [[North Berwick]]), which was sold from 1909 into the 1920s. It cut a tongue in the paper that was folded back and tucked in to hold the papers together. Bump's New Model Paper Fastener used a similar cutting and weaving technology. |

||

==Methods== |

==Methods== |

||

Revision as of 04:02, 22 March 2009

This article needs additional citations for verification. (July 2008) |

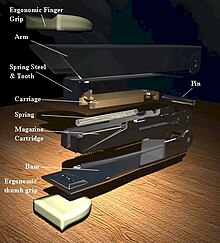

A stapler is a mechanical device that joins together sheets of paper or other similar materials by driving a thin metal staple through the sheets and folding over the ends to secure the paper. Staplers are widely used in government, business, offices and schools.

History

The first stapler was believed to be handmade in the 18th century in France for King Louis XV. Each staple was inscribed with the insignia of the royal court, as required.[1] The growing uses of paper in the 19th century created a demand for an efficient paper fastener.[2] On August 7, 1866, the Novelty Paper Fastener was patented by the Patent Novelty Mfg Co. It allowed a single staple to be loaded and was used to mainly bind papers or books, but also carpet, furniture or boxes. Staples for the fastener were manufactured by the P.N. Mfg Co. in several sizes.

In 1866, Joan Barbour was awarded U.S. patent no. 56,587 for a small, bendable brass paper fastener which was the precursor to the modern staple. In 1867, he received U.S. patent no. 67,665 for a press to insert the fastener into paper. He showed his invention at the 1876 Centennial Exhibition in Philadelphia, Pennsylvania, and continued to work on these and other various paper fasteners through the 1880s. In 1868 a patent was also taken out for a stapler in England by C.H. Gould. On February 18, 1879, patent nº 212,316 was given for the McGill Single-Stroke Staple Press. This device weighed over two and a half pounds and was able to load a single 1/2 inch wide wire staple at a time and drive it through several sheets of paper.

In the early 1900s, several devices were developed and patented that punched and folded papers to attach them to each other without a metallic clip. One early example is the Clipless Stand Machine (made in North Berwick), which was sold from 1909 into the 1920s. It cut a tongue in the paper that was folded back and tucked in to hold the papers together. Bump's New Model Paper Fastener used a similar cutting and weaving technology.

Methods

Permanent fastening is used for permanently binding items by driving the staple through and bending over the staple inwards to clinch it. Most modern staplers have a metal attachment that can be rotated to choose between inward stapling and outward stapling (in reference to the way the staple is folded). Clinches can be standard, squiggled, flat, or rounded with completely adjacent to the paper in order to stack documents more neatly.

A staple remover is a device that can remove staples fastened in this manner, by using a pair of interlocking curved claws that slide under the staple's bent-over ends and bend them back out.

Tacking is used for fastening objects to bulletin boards or walls. In order to use a stapler for tacking, the base hinge must allow the base to be folded out of the way so that staples can be driven directly into an object without use of the anvil. Heavy-duty tacking with larger staples, as in the case of affixing posters to a utility pole or wooden fence, is done using a staple gun.

Pinning is used to temporarily bind documents or other items, often cloth or clothing, for sewing. In order to pin using a stapler, the anvil must be shifted so that the staple bends outwards instead of inwards. The staple binds the item with relative security, but can be easily removed by pulling the staple along the plane of the paper. This method varies between staplers, as some anvils need to be simply pushed forward to allow pinning, while others must be rotated. Some staplers implement pinning by bending one leg of the staple inwards, while bending the other outwards. Some modern staplers, though, do not include support for pinning.

Saddle staplers have an inverted "V"-shaped saddle for stapling pre-fold sheets to make booklets.

Stapleless staplers are often presented as a more environmentally friendly means of stapling, and operate by punching out a small flap of paper and weaving it through a notch. Although invented first in 1910, the stapleless stapler has only recently acquired popularity. [1]

Surgical use

Surgical staplers are used as substitutes for sutures. These do not resemble standard staplers as they have no "jaw" or plate to bend the staple into shape. They may be used to close the skin, or during surgical anastomosis. Surgical staples are commonly preshaped into a "M". Pressing the stapler into the skin and applying pressure onto the handle bends the staple through the skin and into the fascia until the two ends almost meet in the middle forming a rectangle.

Staplers are commonly used intra-operatively during bowel resections in colorectal surgery. Often these staplers have an integral knife, so as the staples are deployed the knife cuts through the bowel, maintaining the aseptic field within the abdominal cavity. The staples, made from surgical steel, are typically supplied in disposable, pre-filled, pre-sterilized cartridges.

-

A long reach stapler is used to staple items such as booklets.

-

A booklet stapler that rotates 90 degrees for vertical or horizontal stapling.

-

Clipless Stand Machine.

-

Heavy-duty foot-activated electric stapler.

-

Skin stapler

-

Surgical stapler

See also

References

- ^ "The History of the Stapler". Retrieved 2006-03-10.

- ^ "Antique Staplers & Other Paper Fasteners". Retrieved 2006-03-10.