Dowel: Difference between revisions

m Reverted edits by 86.0.117.97 to last revision by Wizard191 (HG) |

No edit summary |

||

| Line 73: | Line 73: | ||

[[nl:Plug (verbinding)]] |

[[nl:Plug (verbinding)]] |

||

[[ja:ダボ]] |

[[ja:ダボ]] |

||

[[pl:Kołek]] |

|||

[[pl:Kołek rozporowy]] |

[[pl:Kołek rozporowy]] |

||

[[ru:Дюбель]] |

[[ru:Дюбель]] |

||

Revision as of 15:16, 1 June 2009

A dowel is a solid cylindrical rod, usually made of wood, plastic or metal. In its original manufactured form, dowel is called dowel rod.

Dowel rod is employed in numerous, diverse applications. It is used to form axles in toys, as detents on gymnastics grips, as knitting needles and as structural reinforcement in cabinet making. Dowel rod is often cut into short lengths called dowel pins, which are used in various ways:

- As shelf supports in furniture.

- As moveable pieces (i.e., pegs) in games.

- As supports for hanging items such as keyrings and tools.

- To secure two objects together with precise alignment in a dowel joint: a hole is bored in both objects and the dowel pin is inserted into the aligned holes.

Wood dowel

Manufacturing process

For modest manufacturing volumes, wood dowel is typically manufactured on industrial dowel machines. Such machines employ interchangable cutting heads of varying diameters, thus enabling the machines to be quickly retooled to manufacture different diameters of dowel (e.g., 1/4", 1/2", 2", etc.). Each head consists of a hollow chuck with cutting knives protruding inward, through which the wood passes as the knives cut it into cylindrical shape. The mechanism is open-ended, with material guides at the machine's entry and exit to enable fabrication of continuous dowel rod of unlimited length. Some dowel machines have powered feed devices that automatically feed material into the machine, while others require hand feeding.

High volume dowel manufacturing is done on a wood shaper, which simultaneously forms multiple dowels from a single piece of rectangular stock (i.e., wood). These machines employ two wide, rotating cutting heads, one above the stock and one below it. The heads have nearly identical cutting profiles so that each will form an array of adjoined, side-by-side "half dowels." The heads are aligned to each other and one head is shaped to make deeper cuts along the dowel edges so as to part the stock into individual dowel rods, resulting in a group of dowel rods emerging in parallel at the machine's output.

Application

The wooden dowel rod used in woodworking applications is commonly cut into dowel pins, which are used to reinforce joints and support shelves and other components in cabinet making. Some woodworkers make their own dowel pins, while others purchase precut dowel pins that are typically available in assorted lengths and diameters. Various systems, such as Dowelmax, have been devised to aid in dowel joinery.

Dowel-based joinery typically employs fluted dowel pins. A fluted dowel pin has a series of parallel grooves cut along its length. The fluting provides channels through which excess glue—which is used to secure the dowel pin in its hole—can escape as the dowel is inserted, thereby relieving the hydraulic pressure that might otherwise split the timber when the mating pieces are clamped together.

Depending on the application, alternative joinery methods may be used in place of conventional dowel pins, including Miller dowels, biscuit joiners, and proprietary tools such as the Domino jointer.

Metal dowel

In stone masonry

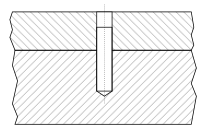

Steel dowels are commonly used in masonry to pin stone components together. Holes are bored in the stone and the steel dowels inserted to secure the components.

In machinery

Dowel pins are often used as precise locating devices in machinery. Steel dowel pins are machined to tight tolerances, as are the corresponding holes, which are typically reamed. A dowel pin may have a smaller diameter than its hole so that it freely slips in, or a larger diameter so that it must be pressed into its hole.

When designing mechanical components, engineers typically use dowel holes as reference points to control positioning variations and attain repeatable assembly quality. If no dowels are used for alignment (e.g., components are mated by bolts only), there can be significant variation, or "play," in component alignment. Typical drilling and milling operations, as well as manufacturing practices for bolt threads, introduce at least 0.2 mm (0.008 inches) play for bolts up to 10 mm (3/8 inches). If dowels are used in addition to bolts, the play is reduced to approximately 0.01 mm (0.0004 inches).[citation needed]

In automobiles, dowels are used when precise mating alignment is required, such as in differential gear casings, engines, and transmissions.

In woodworking

A cross dowel is a cylindrically shaped metal nut (i.e., a metal dowel) that is used to join two pieces of wood. Like other metal nuts, it has an inside threaded hole, although the hole is unusual in that it passes through the sides of the dowel.

In a cross dowel application, the two pieces of wood are aligned and a bolt hole is drilled through one piece of wood and into the other. A dowel hole is drill laterally across the bolt hole and the cross dowel is inserted into it. The end of the cross dowel is slotted so that a screwdriver can be inserted, thus providing a means for rotating the dowel so its threaded shaft aligns with the bolt hole. The bolt is then inserted into the bolt hole and screwed into the cross dowel until the wood pieces are held tightly together.

See also

- Dowel reinforced butt joint

- Rebar

- Dowelmax — a dowel joinery system