Ishikawa diagram: Difference between revisions

m WikiCleaner 0.98 - Repairing link to disambiguation page - You can help! |

|||

| Line 43: | Line 43: | ||

*Money Power |

*Money Power |

||

*Management |

*Management |

||

*Apple |

|||

*Fur-Haan |

|||

*FhaQ |

|||

===The 8 P's (Used In Service Industry)=== |

===The 8 P's (Used In Service Industry)=== |

||

Revision as of 13:37, 21 October 2009

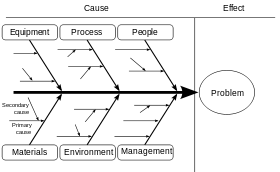

Ishikawa diagrams (also called fishbone diagrams or cause-and-effect diagrams) are diagrams that show the causes of a certain event. Common uses of the Ishikawa diagram are product design and quality defect prevention, to identify potential factors causing an overall effect. Each cause or reason for imperfection is a source of variation. Causes are usually grouped into major categories to identify these sources of variation. The categories typically include:

- People: Anyone involved with the process - Methods: How the process is performed and the specific requirements for doing it, such as policies, procedures, rules, regulations and laws - Machines: Any equipment, computers, tools etc. required to accomplish the job - Materials: Raw materials, parts, pens, paper, etc. used to produce the final product - Measurements: Data generated from the process that are used to evaluate its quality - Environment: The conditions, such as location, time, temperature, and culture in which the process operates

Overview

Ishikawa diagrams were proposed by Kaoru Ishikawa[1] in the 1960s, who pioneered quality management processes in the Kawasaki shipyards, and in the process became one of the founding fathers of modern management.

It was first used in the 1960s, and is considered one of the seven basic tools of quality management, along with the histogram, Pareto chart, check sheet, control chart, flowchart, and scatter diagram. It is known as a fishbone diagram because of its shape, similar to the side view of a fish skeleton.

Mazda Motors famously used an Ishikawa diagram in the development of the Miata sports car, where the required result was "Jinba Ittai" or "Horse and Rider as One". The main causes included such aspects as "touch" and "braking" with the lesser causes including highly granular factors such as "50/50 weight distribution" and "able to rest elbow on top of driver's door". Every factor identified in the diagram was included in the final design.

Causes

Causes in the diagram are often categorized, such as to the 4 M's, described below. Cause-and-effect diagrams can reveal key relationships among various variables, and the possible causes provide additional insight into process behavior.

Causes can be derived from brainstorming sessions. Successively sorted through affinity-grouping to collect similar ideas together. These groups can then be labeled as categories of the fishbone. They will typically be one of the traditional categories mentioned above but may be something unique to the application in a specific case. Causes can be traced back to root causes with the 5 Whys technique.

Typical categories are:

The original 4 M's

- Machine (Equipment)

- Method (Process/Inspection)

- Material (Raw,Consumables etc.)

- Man power

More categories

- Mother Nature (Environment)

- Man Power (physical work)

- Mind Power (Brain Work): Kaizens, Suggestions

- Measurement (Inspection)

- Maintenance

- Money Power

- Management

The 8 P's (Used In Service Industry)

- People

- Process

- Policies

- Procedures

- Price

- Promotion

- Place/Plant

- Product

The 4 S's (Used In Service Industry)

- Surroundings

- Suppliers

- Systems

- Skills

References

- ^ Hankins, Judy (2001). Infusion Therapy in Clinical Practice. p. 42.

Further reading

- Ishikawa, Kaoru (1990); (Translator: J. H. Loftus); Introduction to Quality Control; 448 p; ISBN 4-906224-61-X OCLC 61341428

- Dale, Barrie G. et al (2007); Managing Quality 5th ed; ISBN: 978-1-4051-4279-3 OCLC 288977828