Mercury-arc valve: Difference between revisions

Add a new image |

That's too big! |

||

| Line 1: | Line 1: | ||

[[Image:Mercury Rectifier.JPG|A working demonstration from an old German broadcaster]] |

[[Image:Mercury Rectifier.JPG|thumb|A working demonstration from an old German broadcaster]] |

||

A '''mercury arc valve''' ('''mercury vapor rectifier''') is a type of electrical [[rectifier]] which converts alternating current into [[direct current]]. Rectifiers of this type were used in electric motor power supplies for industry, in [[Railway electrification system|electric railways]], |

A '''mercury arc valve''' ('''mercury vapor rectifier''') is a type of electrical [[rectifier]] which converts alternating current into [[direct current]]. Rectifiers of this type were used in electric motor power supplies for industry, in [[Railway electrification system|electric railways]], |

||

Revision as of 05:19, 23 November 2009

A mercury arc valve (mercury vapor rectifier) is a type of electrical rectifier which converts alternating current into direct current. Rectifiers of this type were used in electric motor power supplies for industry, in electric railways, streetcars and electric locomotives. They also found use in static inverter stations and as rectifiers for high-voltage direct current power transmission.

History

Mercury arc rectifiers were invented by Peter Cooper Hewitt in 1902 and further developed throughout the 1920s and 1930s by researchers in both Europe and North America. Before the advent of solid-state devices, mercury arc rectifiers were one of the more efficient rectifiers. Mercury arc rectifiers or "converters" were used for charging storage batteries, and in arc lighting systems where they were found to be more efficient than rotary converters.[1]

By 1975, high-voltage solid state devices such as the silicon diode and thyristor made the mercury arc rectifier obsolete even in high-voltage DC applications.

Applications

Mercury arc valves were widely used until the 1960s for the production of direct current. Applications included power supply for streetcars and electric railways, variable-voltage power supplies for large radio transmitters. Mercury arc stations were used to provide DC power to legacy Edison-style DC power grids in urban centers until the 1950s.

They are still used in some South African mines (2006), the Manx Electric Railway and until 21 September 2007, on Pole 1 of the HVDC Inter-Island link between the North and South Islands of New Zealand. Prior to this date, the original mercury arc rectifiers had seen over 40 years of near continuous service. Half of the original system, still using the original valves, may be brought back into action to secure the power supply into the North Island during winter months. Since being placed in standby, these valves have seen intermittent service, a situation that is expected to last until a replacement pole can be built and commissioned, which is likely to be around 2012/2013. By this time these valves will be close to 50 years old.

As of February, 2008, the only fully operational HVDC system using mercury arc valves is Pole 1 of the HVDC Vancouver Island link. Pole 1 of the Vancouver Island system went into service in early 1968, and is still providing reliable service. This pole is expected to be replaced with an AC undersea cable, removing the need for a HVDC system.

Design

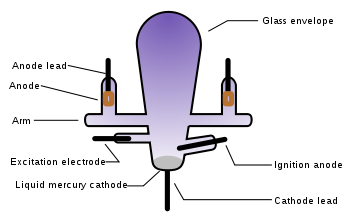

One type of mercury vapor electric rectifier consists of an evacuated glass bulb, with a pool of liquid mercury sitting in the bottom as the cathode.[2] Over it curves the glass bulb, which condenses mercury evaporated in the course of operation of the device. The glass envelope has one or more arms with graphite rods as anodes. Their number depends on the application. If direct current is to be produced from single-phase alternating current, then two anodes are used, each connected to the outer ends of a centre-tapped transformer secondary winding. With three-phase alternating current three or six anodes are used, to provide a smoother direct current. Six-phase operation can improve the efficiency of the transformer as well as providing smoother DC, by enabling two anodes to conduct simultaneously. During operation, the arc transfers to the anodes at the highest positive potential (with respect to the cathode). Design of the arms and envelope is intended to prevent an arc from forming between the anodes; such a condition is called "backfire" and is a critical factor in the design of mercury arc rectifiers.

Glass envelope rectifiers can produce hundreds of kilowatts of direct-current power in a single unit. A 6-phase rectifier rated 150 amperes has a glass envelope approximately 600 mm (24 inches) high by 300 mm (12 inches) outside diameter. These rectifiers will contain several pounds of liquid mercury. The large size of the envelope is required due to the low thermal conductivity of glass. Mercury vapor in the upper part of the envelope must give up heat through the glass envelope to condense and return to the cathode pool.

The current-carrying capacity of a rectifier is limited in part by the size of the wires fused into the glass envelope for connection of the anodes and cathode. Development of high-current rectifiers required leadwire materials and glass with very similar coefficients of thermal expansion in order to prevent leakage of air into the envelope.

For larger valves, a metal tank with ceramic insulators for the electrodes is used, with a vacuum pump system to counteract slight leakage of air into the tank around imperfect seals. The design patented by Uno Lamm of ASEA is one example of this type which includes grading electrodes between the anode and cathode to prevent backfire. Metal-tank rectifiers were built with ratings of 2000 A and 125 kV per unit.

Both glass and metal envelope rectifiers may have control grids inserted between the anode and cathode. This allows the conduction of the rectifier to be controlled, for example to delay the instant at which the arc transfers to the anode on the alternating current waveform, thereby giving control of the mean output voltage produced by the rectifier. Such grid-controlled valves are an essential part of a static inverter.

The temperature of the envelope must be carefully controlled, since the working pressure within the envelope is set by the coolest spot on the enclosure wall. A typical design maintains temperature at 40 degrees Celsius and a mercury vapor pressure of 7 millipascals.

Function

Principle

Operation of the rectifier relies on an electrical arc discharge between electrodes in a sealed envelope containing mercury vapor. A pool of liquid mercury acts as a self-renewing cathode that does not deteriorate with time. The mercury emits electrons freely, whereas the carbon anodes emit very few electrons even when heated, thus rectifying action occurs.

Once an arc is formed, electrons are emitted from the surface of the pool, causing ionization of mercury vapor along the path towards the anodes. The mercury ions are attracted towards the cathode, and the resulting ionic bombardment of the pool maintains the temperature of the 'emission spot', so long as a current of a few amperes continues.

The mercury ions emit light at characteristic wavelengths, the relative intensities of which are determined by the pressure of the vapor. At the low pressure within a rectifier, the light appears pale blue-violet and contains much ultraviolet light.

The cathode is connected to the DC load, which in turn is connected to the center tap of an AC transformer, which always remains at zero potential. For each AC phase, a wire from each of the two end taps is connected to an anode "arm" on the mercury arc rectifier. As the voltage on each anode goes positive, it will begin to conduct through the mercury vapor to the cathode. As the anodes of each AC phase are fed from opposite ends of the transformer winding, one will be positive, and the other negative, and thus a current will always be maintained from one or more positive anodes to the cathode.

Single-phase mercury arc rectifiers were infrequently used because every time the AC voltage dropped to zero the arc would be extinguished. The direct current produced by a single-phase rectifier contains a varying component (ripple) at twice the power supply frequency, which was undesirable in many applications for DC. The solution was to use 2, 3 or even 6 phase AC power supplies so that the rectified current would maintain a more constant voltage level. Polyphase rectifiers also balanced the load on the phases of a polyphase supply system, which is desirable for reasons of system performance and economy.

Starting

A conventional mercury arc rectifier is started by a brief high-voltage arc within the rectifier, between the cathode pool and a starting electrode. By one of a number of means, the starting electrode is brought into contact with the pool and allowed to pass current through an inductive circuit. The contact with the pool is then broken, resulting in a high emf.

The momentary contact between the starting electrode and the pool may be achieved by allowing an external electromagnet to pull the electrode into contact with the pool; the electromagnet can also serve as the starting inductance. Alternatively, the electromagnet may be arranged to tip the bulb of a small rectifier, just enough to allow mercury from the pool to reach the starting electrode. An alternative system provides a narrow neck of mercury between two pools, and by passing a very high current at negligible voltage through the neck, displaces it by magnetostriction, thus opening the circuit.

Excitation

Since momentary interruptions or reductions of output current may cause the cathode spot to extinguish, many rectifiers incorporate an additional electrode to maintain an arc whenever the plant is in use. Typically, a two or three phase supply of a few amperes passes through small 'excitation' anodes. A magnetically-shunted transformer of a few hundred VA rating is commonly used to provide this supply.

This excitation or keep-alive circuit was absolutely necessary for mercury arc rectifiers used in the high voltage supply of radiotelegraphy transmitters, as current flow was regularly interrupted every time the morse key was released.[3]

Control

Installation of a control grid between the anode and the pool cathode allows control of the conduction of the valve. Start of the current flow can be delayed past the point at which the arc would form in an uncontrolled valve. This allows the output voltage of a valve group to be adjusted by delaying the firing point, and allows controlled mercury arc valves to form the active switching elements in an inverter converting direct current into alternating current.

Others

The largest ever mercury arc rectifiers were used until 2004 at the Nelson River Bipole high-voltage DC power transmission project.

Special types of mercury arc rectifiers are the Ignitron and the Excitron.

In 1919 the book "Cyclopedia of Telephony & Telegraphy Vol. 1"[4] described an amplifier for telephone signals that used a magnetic field to modulate an arc in a mercury rectifier tube. This pre-dated the application of the vacuum tube to amplification of audio signals but was never commercially important.

Environmental hazard

Mercury compounds are toxic, highly persistent in the environment, and present a danger to humans and the environment. The use of large quantities of mercury in fragile glass envelopes presents a hazard of potential release of mercury to the environment should the glass bulb be broken. Some HVDC static inverter stations have required expensive clean-up to eliminate traces of mercury emitted from the station over its service life. Steel tank rectifiers frequently required vacuum pumps which continually emitted small amounts of mercury vapor.

See also

References

This article includes a list of references, related reading, or external links, but its sources remain unclear because it lacks inline citations. (April 2009) |

- ^ I.C.S. Reference Library volume 4B, International Textbook Company, Scranton PA 1908, section 53, page 34. Replacing rotary converters in one 6000 volt series lighting system increased efficiency from 62 per cent to 88 per cent. the system voltage was large compared to the fixed voltage drop across each rectifier.

- ^ Howatson A H (1965). "8". An Introduction to Gas Discharges. Oxford: Pergamon Press. ISBN 0080205755.

- ^ Francis Edward Handy (1926). The Radio Amateur's Handbook (1st ed.). Hartford, CT: American Radio Relay League. pp. 78–81.

- ^ * The Project Gutenberg EBook of Cyclopedia of Telephony & Telegraphy Vol. 1

Further reading

Media related to Mercury arc rectifiers at Wikimedia Commons

Media related to Mercury arc rectifiers at Wikimedia Commons- ABB page on the history of high voltage direct current transmission

- The Tube Collector Virtual Museum. Description of mercury arc rectifiers and further links, including photographs

- 1903 illustrated article - A Great Electrical Discovery

- H. Rissik, Mercury-Arc Current Converters, Pitman. 1941.