Concrete saw: Difference between revisions

m Replace template per TFD outcome; no change in content |

→Dust control: Added image |

||

| Line 44: | Line 44: | ||

==Dust control== |

==Dust control== |

||

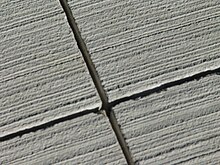

[[File:Highway work dust.jpg|thumb|right|Highway road workers using concrete saws and generating dust.]] |

|||

Stones, rocks, sands and clays can contain large amounts of crystalline silica and are used to make kerbs, flags, bricks, tiles and concrete. Cutting these materials produces airborne dust containing very fine respirable crystalline silica (RCS) particles. These particles are small and it is not always possible to see the RCS dust in normal lighting.<ref>[http://www.hse.gov.uk/pubns/cis54.pdf Dust Control on Cut-off Saws Used for Stone or Concrete Cutting]</ref> |

Stones, rocks, sands and clays can contain large amounts of crystalline silica and are used to make kerbs, flags, bricks, tiles and concrete. Cutting these materials produces airborne dust containing very fine respirable crystalline silica (RCS) particles. These particles are small and it is not always possible to see the RCS dust in normal lighting.<ref>[http://www.hse.gov.uk/pubns/cis54.pdf Dust Control on Cut-off Saws Used for Stone or Concrete Cutting]</ref> |

||

Revision as of 15:53, 6 December 2013

This article needs additional citations for verification. (December 2009) |

A concrete saw (often known as a consaw or road saw) is a power tool used for cutting concrete, masonry, brick, asphalt, tile, and other solid materials. It can be a small hand-held cut-off saw, a big walk-behind saw or other styles, and it may be powered by gasoline, hydraulic or pneumatic pressure, or electric motors. The saw blades used on concrete saws are often diamond saw blades to cut concrete, asphalt, stone, etc. Abrasive cut-off wheels can also be used on cut-off saws to cut stone and steel. The significant friction generated in cutting hard substances like concrete usually requires the blades to be cooled to prolong their life and reduce dust.

Operation

Before a concrete saw is operated, its operation manual should be read and understood, for serious safety issues may happen if the concrete saw is used improperly.

The operator then should inspect the saw machine to see if it is in good condition, and do some cleaning work.

Next, the operator should check the diamond saw blade. Below is the check list:[1]

- Drive pin hole. There should be no distortion of the pin hole.

- Gullets. Check the steel core of the blade for cracks that may have propagated from the gullets. Cracks indicate extreme fatigue failure and if sawing continues, catastrophic failure will occur.

- Edge of the steel core. Check the diameter edge for discoloration (blue oxidation) indicating an overheating condition caused by insufficient cooling water/air. Overheating of blades may lead to loss of core tension and/or increase the possibility for blade failure. Check to make sure the steel core's width is uniform about the rim of the blade, and not succumbing to an "under cutting" condition brought about by highly abrasive material or improper under cutting core protection.

- Directional arrow. Check to ensure that the blade is oriented properly. Reference the directional arrow on the blade and place it so the direction of rotation "downcuts" with the turn of the shaft.

- Diamond segments or rim. Ensure there are no cracks, dings, or missing portions of the diamond segments or rim. DO NOT use a blade that is missing a segment or a portion of the rim. Damaged and/or missing segments/rims may cause damage to the saw, and injury to the operator or others in the operating area.

- Features and specifications. Ensure that the blade' features and specifications properly match the sawing operation. Wet blades must have water to act as a coolant. Utilizing a diamond blade not matched properly to the task may result in poor performance and/or blade damage.

- Arbor hole. It is essential that the diameter of arbor hole matches the blade, and that it is free from distortions. Correct blade flanges (collars) must be used. The inside face of the flanges must be clean and free of debris. An out of round arbor condition will cause damage to the blade and the saw.

- Maximal RPM. This RPM reference is the maximum safe operating speed for the blade selected. Exceeding the max RPM of the diamond blade is dangerous, and may cause poor performance and may damage the blade.

Then the operator should be sure that all blade guards of the saw are in place and functioning properly. He should never operate the saw without blade guards and covers in place, and should not operate with the front of the blade guard raised. The blade exposure cannot exceed 180 degrees during operations.

Before beginning sawing, the operator should wear the appropriate protective equipment and clothing.

To make a straight cut, the operator can use a chalk line to mark a straight line on the concrete, and put a straight wood board along the line. Then he can do a shallow cut (about 1/4" deep) along the wood board. With this shallow cut, the operator can cut straight in further cuttings along it.[2]

Before starting the engine/motor of the saw, the operator should raise the saw blade clear of the working surface, and then allow it to reach operating speed. Then the blade can be lowered to the slab surface to cut. The maximum cutting depth of the diamond blade should not be exceeded, and the arbor flanges should not contact the slab surface. The saw blade cutting should remain straight, and the saw blade should not be twisted and/or forced.[3]

To finish the cutting, the operator should raise the saw blade out of the cut high enough to clear the slab surface, and then turn off the engine/motor.

Choosing diamond saw blades

Choosing a proper diamond saw blade for the concrete saw is a necessary condition to perform a cutting task well. Apart from some basic aspects, for example, what diameters of diamond saw blades the concrete saw can accommodate, its arbor size and the blade's quality, there are some other important aspects which should also be considered:[4]

- The match of the diamond saw blade's features and the concrete/asphalt's type. For example, some concretes have steel bars in them (reinforced concrete) and some do not have. Some concretes' stone aggregate is pebbles and some is crushed rocks. Some concretes' curing time is long (cured concrete) and some is short (green concrete). The diamond saw blades should have different design to fit these concrete and asphalt.

- Diamond saw blades for concrete are usually for wet cutting. Though diamond saw blades for concrete are usually laser welded, they are normally designed to fit wet cutting because the concrete to be cut is often very hard or abrasive. If the blades are used without adequate water, the diamond segment itself may break or the steel core below the segment may wear and break, and then the segment may fly out and may hurt the operator or people nearby. If you have to perform dry cutting for some reason (e.g., there is no water source near your work area), you can choose sharper diamond blades, and the dry cutting should be intermittent and shallow (you can do several passes of shallow cuttings to gain a deep cut) to keep the diamond blade cool.

- Whether faster cutting or longer lifespan is needed. The basic cutting speed of the diamond saw blades should be first ensured. On this basis, blade which has faster cutting speed or longer lifespan can be selected.

- The horsepower of the concrete saw. If the concrete saw's horsepower is big, the diamonds on the saw blade will receive bigger impact when cutting is performed. In this case, the diamond concentration of the diamond saw blade should be higher, or its bond should be harder. While if the saw machine's horsepower is small, the diamond concentration should be lower or the bond should be softer to make the blade become sharper to ensure the cutting speed needed.

Dust control

Stones, rocks, sands and clays can contain large amounts of crystalline silica and are used to make kerbs, flags, bricks, tiles and concrete. Cutting these materials produces airborne dust containing very fine respirable crystalline silica (RCS) particles. These particles are small and it is not always possible to see the RCS dust in normal lighting.[5]

Serious health effects, such as lung cancer or silicosis, can result from exposure to RCS. This is because fine RCS particles can penetrate deep into the lungs.

There are following ways to reduce or control the dust:

- Wet cutting with adequate water supply.

- If possible, use diamond saw blades instead of abrasive wheels to cut. Diamond saw blades normally cut more quickly than abrasive wheels, and need less water.

- The concrete saw should have a local exhaust ventilation (LEV) system, which can capture the majority of dust emitted during the cutting operation.

- When operating, the operator should always wear the personal protective equipment.

There are some other risks during the cutting process which will also need to be controlled to protect the operator and the passers-by, for example, noise, flying debris, hand-arm vibration, manual handling, electricity and refueling.