Hydraulic drive system

A hydraulic or hydrostatic drivesystem or hydraulic power transmission is a drive- or transmission system that makes use of a hydraulic fluid under pressure to drive machinery.

Such a system basically consists of:

- Generator part of the transmission, in general a hydraulic pump, driven by an electric motor, a combustion engine or maybe a windmill.

- Valves, filters, piping etc. to guide and control the system

- Motor part of the transmission a hydraulic motor or hydraulic cylinder to drive the machinery.

Hydrostatic means that the energy comes from the flow and the pressure, but not from the kinetic energy of the flow

Principle of a hydraulic drive

Pascal's law is

the basis of hydraulic drive systems. As the pressure in the system is the same, the force that the fluid gives to the surroundings is therefore equal to pressure x area.

In such a way, a small piston feels a small force and a large piston feels a large force.

The same counts for a hydraulic pump with a small sweptvolume, that asks for a small torque, combined with a hydraulic motor with a large sweptvolume, that gives a large torque.

In such a way a transmission with a certain ratio can be built.

Most hydraulic drive systems make use of hydraulic cylinders. Here the same principle is used- a small torque can be transmitted in a large force.

By throttling the fluid between generator part and motor part, or by using hydraulic pumps and/or motors with adjustable swept volume, the ratio of the transmission can be changed easily. In case throttling is used, the efficiency of the transmission is limited; in case adjustable pumps and motors are used, the efficiency however is very large. In fact up to say 1980, a hydraulic drive system had hardly competition from other adjustable (electric) drive systems.

Nowadays electric drive systems using electric servo-motors can be controlled in an excellent way and can easily compete with rotating hydraulic drive systems.

Hydraulic cylinders are in fact without competition for linear (high) forces. For these cylinders anyway hydraulic systems will remain of interest and if such a system is available, it is easy and logical to use this system also for the rotating drives of the system.

Hydraulic pump

For a hydraulic pump it is of interest to know what pressures and sizes are available. The smallest gearpumps (except miniature ones) have a sweptvolume of 1 cm3 and the largest axial plungerpump that is available from stock will have a swept volume of 1000 cm3 (2000 cm3 might be possible for a special delivery). Other pumps are between these two figures. For continuous hydraulic drives, the maximum working pressure will be some 200 bars. The pumps may be used up to 450 bars, but at these pressures special components are required and pump life is limited. Low cost hydraulic drives on garbage trucks may use gearpumps with maybe 180 bars, depending on the number of working hours. Small pumps can rotate at high speeds of say 3000-5000 rpm, whereas large pumps only can rotate at 1200 or 1500 rpm. Sometimes it is important to use multiple pumps, so that each motor or cylinder within the hydraulic drive system can have his own pump. In case an adjustable speed is required, it is often better to use adjustable pumps in order to save energy (no throttling). For constant power or constant pressure systems also adjustable vanepumps are used. The simple control system decreases the swept volume automatically if the pressure that is asked for increases. Sometimes closed loop systems are used, in that case normally axial plunger-pumps are used (with separate leakage connection). These systems can cope with negative forces and because of the boost pressure, the pumps can be rotated at a higher speed.

Hydraulic motor

A hydraulic motor can in fact be a rotating hydraulic motor as well as a linear hydraulic motor (cylinder). Hydraulic cylinders are described here separately. In fact a hydraulic motor is more or less identical to a hydraulic pump. The main difference is that a hydraulic motor is designed for the working pressure at both sides of the motor, like a hydraulic pump for a closed loop system. Following types of hydraulic motors are available±

- Gear motor

- Vane motor

- Axial plungermotor bent axis

- Axial plungermotor Swash plate

- Radial plungermotor

Gear and vane motors are used in simple rotating systems that may be used now and then. If high quality rotating drive systems are used in general plungermotors are used. Whereas the speed of hydraulic pumps is mostly 1200 -1800 rpm, the machinery that should be driven by the motor asks for a much lower speed. This means that in case an axial plungermotor (swept volume maximum 2 litres) is used, mostly a gearbox is needed. Radial pistonmotors can be obtained with very large sweptvolumes. Sometimes because the total piston volume of the pump is large (sometimes up to 8-9 litres), sometimes because the pistons move more than one time each revolution(sometimes up to 250 (!) litres working sweptvolume). By decreasing the sweptvolume of the motor, the speed goes up and the maximum torque decreases. For a continuous adjustable swept volume, axial pistonmotors are used. Radial motors can get an adjustable sweptvolume by switching off a part of the plungers. Hydraulic motors have a leakage connection, this means that a hydraulic motor in a drive system can never hold the load, like a hydraulic cylinder can do. There is always a need for a brake or a locking device device. Hydraulic motors are used for winch and crane drives and as wheelmotors for military vehicles, self driving cranes and excavators.

Hydraulic cylinder

Hydraulic cylinder(also called linear hydraulic motors) are mechanical actuators that are used to give a linear force through a linear stroke. A hydraulic cylinder is without doubt the best known hydraulic component. Hydraulic cylinders are able to give pushing and pulling forces of millions of metric tons, with only a simple hydraulic system. Very simple hydraulic cylinders are used in presses; here the cylinder consists out of a volume in a piece of iron with a plunger pushed in it and sealed with a cover. By pumping hydraulic fluid in the volume, the plunger is pushed out with a force of plunger-area * pressure.

More sophisticated cylinders have a body with end cover, a piston-rod with piston and a cylinder-head. At one side the bottom is for instance connected to a single clevis, whereas at the other side, the piston rod also is foreseen with a single clevis. The cylinder shell normally has hydraulic connections at both sides. A connection at bottom side and one at cylinder head side. If oil is pushed under the piston, the piston-rod is pushed out and oil that was between the piston and the cylinder head is pushed back to the oil-tank again.

The pushing or pulling force of a hydraulic cylinder is:

F = Ab * pb - Ah * ph

F = Pushing Force in N

Ab = (π/4) * (Bottom-diameter)^2 [in m2]

Ah = (π/4) * ((Bottom-diameter)^2-(Piston-rod-diameter)^2)) [in m2]

pb = pressure at bottom side in [N/m2]

ph = pressure at cylinder head side in [N/m2]

Apart from miniature cylinders, in general, the smallest cylinder diameter is 32 mm and the smallest piston rod diameter is 16 mm.

Simple hydraulic cylinders have a maximum working pressure of say 70 bars, the next step is 140 bars, 210 bars. 320/350 bars and further, the cylinders are in general custom build. The stroke of a hydraulic cylinder is limited by the manufacturing process. The majority of hydraulic cylinders have a stroke between 0,3 and 5 metres, whereas 12-15 metre stroke is also possible, but for this length only a limited number of suppliers are on the market.

In case the retracted length of the cylinder is too long for the cylinder to be build in the structure. In this case telescopic cylinders can be used. One has to realize that for simple pushing applications telescopic cylinders might be available easily; for higher forces and/or double acting cylinders, they must be designed especially and are very expensive.

If hydraulic cylinders are only used for pushing and the piston rod is brought in again by other means, one can also use plunger cylinders. Plunger cylinders have no sealing over the piston, or the piston does not exist. This means that only one oil connection is necessary. In general the diameter of the plunger is rather large compared with a normal piston cylinder, because this large area is needed.

Whereas a hydraulic motor will always leak oil, a hydraulic cylinder does not have a leakage over the piston nor over the cylinder head sealing, so that there is no need for a mechanical brake.

Hydraulic valves

These valves are usually very heavy duty to stand up to high pressures. Some special valves can control the direction of the flow of fluid and act as a control unit for a system.

Hydraulic piping

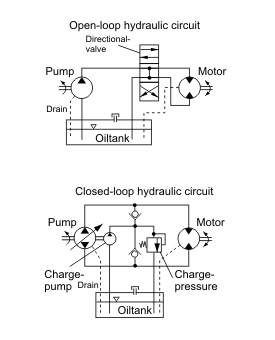

Open and closed loop system