HEPA

This article's lead section may be too short to adequately summarize the key points. (November 2010) |

HEPA stands for "High-Efficiency Particulate Air" [1]. A HEPA filter is a type of air filter that satisfies certain standards of efficiency such as those set by the United States Department of Energy (DOE). By government standards, a HEPA air filter must remove 99.97% of all particles greater than 0.3 microns from the air that passes through.

Function

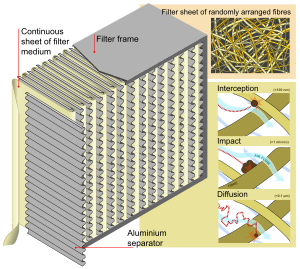

HEPA filters are composed of a mat of randomly arranged fibres. The fibres are typically composed of [fiberglass] and possess diameters between 0.5 and 2.0 micrometers. Key factors affecting function are fibre diameter, filter thickness, and face velocity. The air space between HEPA filter fibres is much greater than 0.3 μm. The common assumption that a HEPA filter acts like a sieve where particles smaller than the largest opening can pass through is incorrect. Unlike membrane filters, where particles as wide as the largest opening or distance between fibres cannot pass in between them at all, HEPA filters are designed to target much smaller pollutants and particles. These particles are trapped (they stick to a fibre) through a combination of the following three mechanisms:

- Interception, where particles following a line of flow in the air stream come within one radius of a fibre and adhere to it.

- Impaction, where larger particles are unable to avoid fibres by following the curving contours of the air stream and are forced to embed in one of them directly; this effect increases with diminishing fibre separation and higher air flow velocity.

- Diffusion, an enhancing mechanism is a result of the collision with gas molecules by the smallest particles, especially those below 0.1 µm in diameter, which are thereby impeded and delayed in their path through the filter; this behaviour is similar to Brownian motion and raises the probability that a particle will be stopped by either of the two mechanisms above; it becomes dominant at lower air flow velocities.

Diffusion predominates below the 0.1 μm diameter particle size. Impaction and interception predominate above 0.4 μm. In between, near the Most Penetrating Particle Size (MPPS) 0.3 μm, both diffusion and interception are comparatively inefficient. Therefore, the HEPA specifications use the retention of these particles to define the filter.

Specifications

HEPA filters, as defined by the DOE standard adopted by most American industries, remove at least 99.97% of airborne particles 0.3 micrometers (µm) in diameter. The filters maximum resistance to airflow, or pressure drop, is usually specified around 300 Pa at its nominal flow rate.

The specification usually used in the European Union is the European Norm EN 1822:2009. It defines several classes of HEPA filters by their retention at MPPS:

| HEPA class | retention (total) | retention (local) |

|---|---|---|

| E10 | > 85 % | --- |

| E11 | > 95 % | --- |

| E12 | > 99.5 % | --- |

| H13 | > 99.95 % | > 99.75 % |

| H14 | > 99.995 % | > 99.975 % |

| U15 | > 99.9995 % | > 99.9975 % |

| U16 | > 99.99995 % | > 99.99975 % |

| U17 | > 99.999995 % | > 99.9999 % |

The original HEPA filter was designed in the 1940s and was used in the Manhattan Project to prevent the spread of airborne radioactive contaminants. It was commercialized in the 1950s, and the original term became a registered trademark and a generic term for highly efficient filters. Over the decades filters have evolved to satisfy the higher and higher demands for air quality in various high technology industries, such as aerospace, pharmaceutical processing, hospitals, health care, nuclear fuels, nuclear power, and electronic microcircuitry (computer chips).

Today, a HEPA filter rating is applicable to any highly efficient air filter that can attain the same filter efficiency performance standards as a minimum and is equivalent to the more recent NIOSH N100 rating for respirator filters. The United States Department of Energy (DOE) has specific requirements for HEPA filters in DOE regulated applications. Products that claim to be "HEPA-type", "HEPA-like", or "99% HEPA" do not satisfy these requirements and may not have been tested in independent laboratories.

Biomedical applications

HEPA filters are critical in the prevention of the spread of airborne bacterial and viral organisms and, therefore, infection. Typically, medical-use HEPA filtration systems also incorporate high-energy ultra-violet light units to kill off the live bacteria and viruses trapped by the filter media. Some of the best-rated HEPA units have an efficiency rating of 99.995%, which assures a very high level of protection against airborne disease transmission.

Vacuum cleaners

Many vacuum cleaners also use HEPA filters as part of their filtration systems. This is beneficial for asthma and allergy sufferers, because the HEPA filter traps the fine particles (such as pollen and dust mite feces) which trigger allergy and asthma symptoms. For a HEPA filter in a vacuum cleaner to be effective, the vacuum cleaner must be designed so that all the air drawn into the machine is expelled through the filter, with none of the air leaking past it. This is often referred to as "Sealed HEPA" or sometimes the more vague "True HEPA." Vacuum cleaners simply labeled HEPA have a HEPA filter, but not all air necessarily passes through it. Finally, vacuum cleaner filters marketed as "HEPA-like" will typically use a filter of a similar construction to HEPA, but without the filtering efficiency. Because of the extra density of a HEPA filter, HEPA vacuum cleaners require more powerful motors to provide adequate cleaning power.

Newer models claim to be better than the first models because of being "washable". Generally washable filters are expensive. Some manufacturers claim filter standards such as "HEPA 4", without explaining the meaning behind them. It refers to their Minimum Efficiency Reporting Value (MERV) rating. These ratings are used to rate the ability of an air cleaner filter to remove dust from the air as it passes through the filter. MERV is a standard used to measure the overall efficiency of a filter. The MERV scale ranges from 1 to 20, and measures a filter's ability to remove particles from 10 to 0.3 micrometre in size. Filters with higher ratings not only remove more particles from the air, they also remove smaller particles.

Vehicle use

Cars

Some new model cars have a HEPA filter for the driver and passengers.

Airlines

Modern airliners use HEPA filters to reduce the spread of airborne pathogens in recirculated air. Test results from a Department of Transportation (DOT) study conducted on 92 randomly selected flights showed that bacteria and fungi levels measured in the airplane cabin are similar to or lower than those found in the common home. These very low microbial contaminant levels are due to the complete exchange of inside cabin air 10 to 15 times per hour and the high filtration capability of the recirculation system. The filters used on current airliners are similar to HEPA filters used in industrial “clean rooms” and in critical wards of hospitals, such as organ transplant and burn units. By comparison, the filtration systems in typical buildings are not capable of removing microbial contaminants including bacteria and viruses.[2]

See also

- Air purifier

- Electrostatic precipitator - trap particles with high voltage

- HEGA - carbon cloth filter developed by the British military against chemical warfare

- Hypoallergenic vacuum cleaner - vacuum cleaner with high efficiency air filter

- Respirator

- ULPA - Removes 99.999% of dust, pollen, mold, bacteria and particles larger than 120 nm

References

Footnotes

- ^ Originally 'High Efficiency Particulate Arrestment - see thefreedictionary.com

- ^ Boeing Facts on Cabin Air Systems in Commercial Airplanes

General references

External links

- HEPA filters and clean room supplies

- US Department of Energy HEPA website

- US Department of Energy Specification for HEPA Filters Used by DOE Contractors, 1997 Edition Warning: 100k PDF

- DOE HDBK-1169-2003; DOE Handbook Nuclear Air Cleaning Handbook

- Nuclear Air Cleaning Conference Proceedings

- ASME AG-1, Section FK, Special HEPA Filters

- DOE-STD-3020, 2005 Edition

- American Society of Heating, Refrigerating and Air-Conditioning Engineers

- IEST Recommended Practice on HEPA and ULPA Filters

- How HEPA filters work