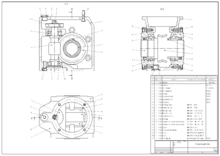

Bill of materials

A bill of materials (sometimes bill of material or BOM) is a list of the raw materials, sub-assemblies, intermediate assemblies, sub-components, parts and the quantities of each needed to manufacture an end product. No physical dimension is described in a BOM, however the rough outline should include:[1][2]

Creating a Bill of Materials should include:[3]

- BOM Level

- Part Number

- Part Name

- Phase

- Description

- Quantity

- Unit of Measure

- Procurement Type

- Reference Designators

- BOM Notes

When creating or using a BOM you should consider who will be using it. It may be used for communication between manufacturing partners, or confined to a single manufacturing plant.

A BOM can define products as they are designed (engineering bill of materials), as they are ordered (sales bill of materials), as they are built (manufacturing bill of materials), or as they are maintained (service bill of materials). The different types of BOMs depend on the business need and use for which they are intended. In process industries, the BOM is also known as the formula, recipe, or ingredients list. In electronics, the BOM represents the list of components used on the printed wiring board or printed circuit board. Once the design of the circuit is completed, the BOM list is passed on to the PCB layout engineer as well as component engineer who will procure the components required for the design.

BOMs are hierarchical in nature with the top level representing the finished product which may be a sub-assembly or a completed item. BOMs that describe the sub-assemblies are referred to as modular BOMs. An example of this is the NAAMS BOM that is used in the automotive industry to list all the components in an assembly line. The structure of the NAAMS BOM is System, Line, Tool, Unit and Detail.

The first hierarchical databases were developed for automating bills of materials for manufacturing organizations in the early 1960s. At present this BOM is used as a data base to identify the many parts and their codes in automobile manufacturing companies.[4]

A bill of materials "implosion" links component pieces to a major assembly, while a bill of materials "explosion" breaks apart each assembly or sub-assembly into its component parts.

A BOM can be displayed in the following formats:

- A single-level BOM that displays the assembly or sub-assembly with only one level of children. Thus it displays the components directly needed to make the assembly or sub-assembly.[5]

- An indented BOM that displays the highest-level item closest to the left margin and the components used in that item indented more to the right.[1]

- Modular (planning) BOM

A BOM can also be visually represented by a product structure tree, although they are rarely used in the workplace.[1]

Configurable BOM

A BOM, that is configurable, is called a super BOM or "Complex-BOM", if the product is configurable, i.e., can be produced in a large number of variations. In this case, the BOM lists all possible components, only a subset of which will be used in a specific variation.[6]

To decide, which varinat of the parts or components has to be choose, they are be attributed by the product options, that are the characteristics features of the product (business). If the options of the product built an ideal Boolean Algebra [7], it is possible to describe the connection between parts and product variants with an boolean expression, which refers to a subset of the set of products [8].

References

- ^ a b c

Reid, R. Dan (2002). Operations Management. John Wiley & Sons. pp. 457–458. ISBN 0-471-32011-0.

{{cite book}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^

Monk, Ellen (2007). Concepts in Enterprise Resource Planning. Course Technology Cengage Learning. pp. 97–98. ISBN 1-4239-0179-7.

{{cite book}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ "Creating a Bill of Materials". Arena Solutions. Retrieved January 16, 2013.

- ^ "Bill of Materials". The Free Dictionary. Retrieved September 28, 2008.

- ^ "Bill of Materials". Inventory Interface. Gerald Drouillard. December 28, 2001. Retrieved June 7, 2011.

- ^ "Super BOM". SAP ERP 6.0. SAP. 2012. Archived from the original on 2012-07-17. Retrieved 2012-07-17.

- ^ a b W. Herlyn (2012), PPS im Automobilbau – Produktionsprogrammplanung und -steuerung von Fahrzeugen und Aggregaten, München: Hanser Verlag, ISBN 978-3-446-41370-2

- ^ a b W. Herlyn (1990), Zur Problematik der Abbildung variantenreicher Erzeugnisse in der Automobilindustrie, Düsseldorf: VDI Verlag, ISBN 3-18-145216-5