Compact controller

This article needs additional citations for verification. (October 2019) |

A compact controller is a generic name given to a small autonomous controller which can control one or several control loops. They are also known as panel mounted, discrete or dedicated controllers.[1] The controllers can be easily configured and to control most types of control loop. Simple versions have a numerical display of the process values. Compact controllers in high-end equipment are available with touchscreen and graphical representation of the control loop or the system.[1]

In addition to the actual control loop, compact controllers can also take over control tasks and thus control the process sequence or parts thereof independently. Compact controllers can be found in almost all industries. For example, the program controller function is often used in the food industry, or in hardening to define specific temperature profiles.[2]

Construction

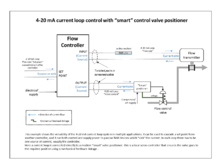

Compact controllers are either fixed or modular and can therefore be extended. The inputs for the actual value are often universal and can be configured for different types of sensors and signals.[3] Digital inputs are also available for the detection of switching operations. Various binary switching elements are available as outputs, such as relay, semiconductor relay, logic and MosFET outputs, and are used either for controlling binary actuators or for control signals. The analog outputs can be configured as voltage or current output, e.g. 4 ... 20 mA / 0 ... 10 V and are used for the continuous control of analog actuators such as, for example, control valves, thyristor power controllers or frequency converters.[4]

The operation, parameterization and configuration can be carried out via the device front, in addition, configuration programs are supplied in which the settings for the user can be clearly arranged. The connection between PC and controller can be established via USB, TCP / IP or serial interfaces.[5]

References

- ^ a b "How to choose an industrial automation controller". Control Engineering. Retrieved 20 April 2019.

- ^ Pannocchia, Gabriele (2015). "Whither Discrete Time Model Predictive Control?". IEEE Transactions on Automatic Control. 60 (1): 246–252. doi:10.1109/TAC.2014.2324131.

- ^ Higuera, J. E, and Polo, J (2011). "IEEE 1451 Standard in 6LoWPAN Sensor Networks Using a Compact Physical-Layer Transducer Electronic Datasheet". IEEE Transactions on Instrumentation and Measurement. 60 (8): 2751–2758. doi:10.1109/TIM.2011.2129990.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ "Electrical Relay". ElectronicsTutorials. Retrieved 20 April 2019.

- ^ "Ethernet Based Application Layer Protocol for Industrial Automation". Real Time Automation. Retrieved 20 April 2019.