Cyclopropene

| |||

| |||

| Names | |||

|---|---|---|---|

| IUPAC name

Cyclopropene

| |||

| Identifiers | |||

PubChem CID

|

|||

CompTox Dashboard (EPA)

|

|||

| Properties | |||

| C3H4 | |||

| Molar mass | 40.0646 g/mol | ||

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |||

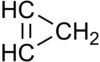

Cyclopropene is an organic compound with the formula Template:Carbon3Template:Hydrogen4. It is the simplest isolable cycloalkene. It has a triangular structure. Because the ring is highly strained, cyclopropene is both difficult to prepare and interesting to study.[1]

Synthesis of cyclopropene and derivatives

Early syntheses

The first confirmed synthesis of cyclopropene, carried out by Dem'yanov and Doyarenko, involved the thermal decomposition of trimethylcyclopropylammonium hydroxide over platinized clay at 320-330 °C under a CO2 atmosphere. This reaction produces mainly trimethylamine and dimethylcyclopropyl amine, together with about 5% of cyclopropene. Cyclopropene can also be obtained in about 1% yield by thermolysis of the adduct of cycloheptatriene and dimethyl acetylenedicarboxylate.

Modern syntheses from allyl chlorides

Allyl chloride undergoes dehydrohalogenation upon treatment with the base sodium amide at 80 °C to produce cyclopropene in ~10% yield.[2]

- CH2=CHCH2Cl + NaNH2 → C3H4 (cyclopropene) + NaCl + NH3

The major byproduct of the reaction is allyl amine. Adding allyl chloride to sodium bis(trimethylsilyl)amide in boiling toluene over a period of 45-60 min. produces the targeted compound in about 40% yield with an improvement in purity:[3]

- CH2=CHCH2Cl + NaN(TMS)2 → C3H4 (cyclopropene) + NaCl + NH(TMS)2

1-Methylcyclopropene is synthesized similarly but at room temperature from methallylchloride using phenyllithium as the base:[4]

- CH2=C(CH3)CH2Cl + LiC6H5 → CH3C3H3 (1-methylcylopropene) + LiCl + C6H6

Syntheses of derivative

Treatment of nitrocyclopropanes with sodium methoxide eliminates the nitrite, giving the respective cyclopropene derivative. The synthesis of purely aliphatic cyclopropenes was first illustrated by the following reaction. Using copper sulfate as the catalyst, the addition of carbenes derived from ethyl diazoacetate to acetylene yielded the appropriate cyclopropene. By this route, 1,2-dimethylcyclopropene was formed by addition of methylene to 2-butyne, and 1,2-dimethylcyclopropene-3-carboxylate was made by adding carbomethoxycarbene to 2-butyne. Copper has proved to be useful as a catalyst in a variety of cyclopropene syntheses. Copper sulfate and copper dust are among the more popular forms of copper used.

Chemical reactions of cyclopropene and its derivatives

Studies on cyclopropene mainly focus on the consequences of its high ring strain, and the release thereof. At 425 °C, cyclopropene isomerizes to methylacetylene.

- C3H4 → H3CC≡CH

Attempted fractional distillation of cyclopropene at -36 °C (its predicted boiling point) results in polymerization. The mechanism is assumed to be a free-radical chain reaction, and the product, based on NMR spectra, is thought to be polycyclopropane.

Cyclopropene undergoes the Diels-Alder reaction with cyclopentadiene to give endo-tricyclo[3.2.1.02,4]oct-6-ene. This reaction is commonly used to check for the presence of cyclopropene, following its synthesis.[3]

1-Methylcyclopropene

1-Methylcyclopropene (1-MCP) is used to desensitize fruits and flowers toward ethylene, particularly apples, thus slowing the process of ripening in fruits.[5] It works by inhibiting the perception of ethylene, which results in the reduction of respiration, aroma production, and softening, all signs of ripening and is used in the floral industry to inhibit floral senescence.[6][7] While simple exposure to 1-MCP is enough to begin the inhibiting process, optimal conditions found for apples call for air concentration of about 0.25 to 1 ppm, temperatures slightly above room temperature, and an exposure time of 12-16 h. SmartFresh is a product based on this cyclopropene and in use by the produce industry.

External links

References

- ^ Carter, F. L.; Frampton, V. L. "Review of the Chemistry of Cyclopropene Compounds." Chemical Reviews; 1964; Vol 64, 497-525.

- ^ Closs, G.L.; Krantz, K.D. "A Simple Synthesis of Cyclopropene." Journal of Organic Chemistry; 1966; Volume 31; 638.

- ^ a b Binger, P.; Wedermann, P.; Brinker, U. H. "Cyclopropene: A New Simple Synthesis and Its Diels-Alder reaction with Cyclopentadiene." Organic Syntheses; 2000; Vol 77; 254.

- ^ Clarke, T. C.; Duncan, C. D.; Magid, R. M. "An Efficient and Convenient Synthesis of 1-Methylcyclopropene." J. Org. Chem; 1971; Vol 39; 1320.

- ^ Beaudry, R.; Watkins, C. "Use of 1-MCP on Apples" Perishable Handling Quarterly; 2001;Issue 108; 12.

- ^ Serek, M.; Tamari, G.; Sisler, E.C.; Borochov, A. (1995) Inhibition of ethylene-induced cellular senescence symptoms by 1-methylcyclopropene, a new inhibitor of ethylene action. Physiol. Plant., 94: 229-232.

- ^ Sisler E.C., Serek M. (2003) Compounds interacting with the ethylene receptor in plants. Plant Biol 5:473–80.