Rotary union

A rotary union is a union that allows for rotation of the united parts. It is thus a device that provides a seal between a stationary supply passage (such as pipe or tubing) and a rotating part (such as a drum, cylinder, or spindle) to permit the flow of a fluid into and/or out of the rotating part. Fluids typically used with rotary joints and rotating unions include various heat transfer media and fluid power media such as steam, water, thermal oil, hydraulic fluid, and coolants.[2] A rotary union is sometimes referred to as a rotating union, rotary valve, swivel union, rotorseal,[3]rotary couplings, rotary joint, rotating joints, hydraulic coupling, pneumatic rotary union, through bore rotary union, air rotary union, electrical rotary union, or vacuum rotary union[4]

Function

A rotary union will lock onto an input valve while rotating to meet an outlet. During this time the liquid and/or gas will flow into the rotary union from its source and will be held within the device during its movement. This liquid and/or gas will leave the union when the valve openings meet during rotation and more liquid and/or gas will flow into the union again for the next rotation. Often functioning under high pressure and constant movement a rotary union is designed to rotate around an axis. A rotary union’s design can be altered to change this or to increase the psi or rpm it needs to withstand as well as the number of valves required.

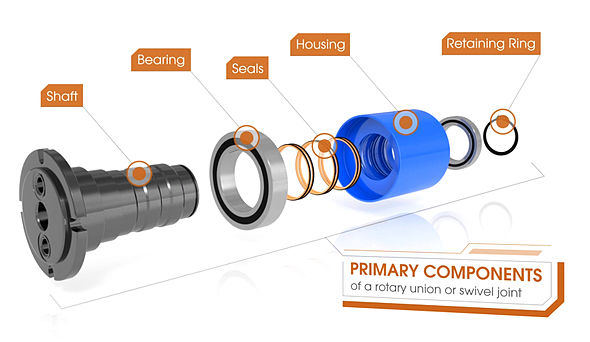

Composition

While rotary unions come in many shapes, sizes, and configurations, they always have the same four basic components: a housing unit, a shaft, a bearing (mechanical) (or bearings), and a seal. Rotary unions typically are constructed from stainless steel to resist rust and corrosion, but many other metals can be involved like aluminum.

Housing

The housing is the component that holds all of the other elements of the rotary union together. The housing has an inlet port, which is a threaded port to which the hose supplying the medium will be attached. The rotary union may also have an outlet port, if the same joint is being used both to supply fluid to a roll and to remove fluid from the roll. In smaller rotary unions the housing is stationary. In larger rotary unions the housing is usually bolted to the drum or roll using a flange. In these cases the housing rotates at the same speed as the drum

Shaft

The shaft is the component that carries the medium through the rotary union into the drum or roll. In many cases the shaft will turn with the drum or roll. In some cases, like in larger flanged rotary unions, the shaft may be stationary while the housing rotates. The bearings and seal are typically assembled around the shaft.

Bearing

The second most important part of the rotary union is the bearing. A rotary union may have only one bearing, but multiple bearing are much more common. Roller bearings; such as ball bearings and tapered roller bearings; or non-roller bearings, like graphite bearings and bronze brushings, may be used in a rotary union. The bearings are always used to allow a part of the joint, either the shaft or the housing, to rotate

The heart of the rotary union is the seal. The seal prevents the medium from leaking outside the rotary union while in operation. Seal types can vary from pusher-type end face mechanical seal, non-pusher type end face mechanical seal, lip seals, and o-ring seals. Most rotary unions have more than one seal. .[5]

Types of rotary unions

Many rotary unions incorporate multiple ports, some of which are designed to handle different types of material simultaneously. A rotary union with a straight port transfers the substance directly through the rotary union. Other designs include an elbow port, which causes the material to flow out at an angle, and multiple ports. A multiple port rotary union looks like a perforated cylinder. At the end of the cylinder is a threaded screw with seals that locks on to the output. The material being transferred flows into the cylinder and out of the input holes. In the case of a rotary union with multiple inputs, chambers separated by seals keep the materials from inadvertently mixing. This type of rotary union is often used in the manufacture of plastics and other petroleum products, for which multiple inputs may need to be streamlined, but kept separate.[citation needed]

Uses

Many assembly lines incorporate multiple rotary unions, because they are highly versatile and take up less space than other devices designed for a similar purpose. Rotary unions also appear in automobiles and other machines that require constant supplies of lubrication, air, or other liquids in order for moving parts to run smoothly. Brakes, for example, use rotary unions to maintain a constant supply of pressurized brake fluid. Rotary unions are also heavily used in crude oil processing, the chemical industry, commercial food production, and pharmaceutical applications.

Agriculture

Equipment used in grain harvesting including combines, tractors, grain carts and threshers employ rotary unions. Once harvested, many crops will be processed with equipment that uses rotary unions. Food processing equipment that use rotary unions include cooling conveyors, flaking mills, shredders, steam cookers, starch dryers, rotary cutters and roll-forming.

Automotive

Auto manufacturing is a diverse user of rotary unions for a broad range of parts or components and materials, whether machined steel, iron or aluminum, stampings, plastics, glass or paperboard. Rotary unions are used for operations that require coolant, lubricant or hydraulics.

Car washes

There are two kinds of car wash facilities that use unions: the automatic and the hand operated. Most manufacturers of automatic systems have several revolving brushes which use 55 series to introduce low pressure detergent water through the supporting shaft to the brushes. In addition, automatic car washes have spinners that require rotary unions to transmit high-pressure water into the spinning mechanisms.

Converting

Downstream processing of paper, plastic film, foil and related substrate materials into finished, printed packaging such as bags, pouches, labels, tags, folding cartons and corrugated shipping cases is called converting. Rotary unions are used in all types of converting for water, steam, thermal oil, air or hydraulics.

Machine tools

Rotary unions may be used to transmit coolant, cutting oil, MQL, pressurized air in a bearingless or bearing supported configuration. Besides coolant delivery, rotary unions are used for chucking, tool sensing, rotary index table and other machine tool applications.

Mining

Electro-hydraulic equipment used in mining operations employ rotary unions including shuttle cars and coal cars, drill heads, backhoes, clam shell cranes and drag lines. In addition, boom hoists, retrieving drums and bucket drum clutches each require rotary unions.

Oil and gas

Drilling rigs (oil or gas) use air clutches and brakes that require rotary unions. Water unions are used to flush mud from the drill tip, and must withstand shock and vibration in this severe application. Oil and petrochemical refineries use batch mixers, flaking mills, blenders and drying rolls that each require rotary unions.

Paper

Paper applications span the supply chain from the raw pulp and paper mills, to the downstream paper converters. Mills use steam joint and siphon systems and water unions for heating and cooling. Converters use rotary unions for heating and cooling rolls, as well as winders with air clutches and brakes.

Plastics

The manufacturing of plastic materials encompasses a wide variety of applications including cast film, blown film, foam, flexible and rigid sheet extrusion, single and multi-layer co-extrusion, blow molding, thermoforming, pelletizing, wire and cable, injection molding and winding. Rotary unions are used for heating or cooling the many processing rolls throughout the wide variety of applications. In addition, rotary unions for air and hydraulic service are used in winding and injection molding applications. Many of today’s modern winding applications will also utilize electrical slip rings.

Printing

Printing on flexible rolls of paper or plastic films requires rotary unions for air or hydraulics, as well as chill rolls for temperature control. Web offset and sheet printing equipment use many rotary unions on the ink vibrator and chill rolls.

Rubber

Rubber is compounded on big industrial mixers which use rotary unions for water cooled rolls. Rubber extrusion is similar to plastic extrusion, with rotary unions used to cool the extruder screw.

Steel

The steel industry is one of the largest users of rotary unions primarily for continuous casting machines (CCM) which use rotary unions to cool the numerous rolls that support molten slabs as it moves by gravity through various segments onto a run-out table to downstream annealing and heat treating. The slab is formed into coil or sheet. Coil is further converted in processing centers that require hydraulic unions for actuation of mandrels.

Textiles

The textile industry is a large user of water, steam and hot oil unions. Weaving, dyeing and finishing processes are the largest users of rotary unions.

Tires

Rubber tire plants use industrial mixers, extruders, calendar train cooling stacks and rayon slashers to make tire cord. Rotary unions are used in every process for temperature control.[6]

References

- ^ "DSTI - Dynamic Sealing Technologies, Inc".

{{cite web}}: Cite has empty unknown parameter:|dead-url=(help) - ^ [1], Kadant Inc., retrieved 1/14/2013.

- ^ http://www.eaton.com/Eaton/ProductsServices/ProductsbyName/Airflex/Rotorseals/index.htm

- ^ [2], Rotary Systems Inc., retrieved 1/22/2013.

- ^ [3], Duff Norton, retrieved 1/15/2013.

- ^ "Industries". Deublin Company. Retrieved 5 November 2013.