Power-to-gas

This article needs to be updated. (July 2020) |

Power-to-gas (often abbreviated P2G) is a technology that uses electric power to produce a gaseous fuel.[1] When using surplus power from wind generation, the concept is sometimes called windgas.[citation needed]

Most P2G systems use electrolysis to produce hydrogen. The hydrogen can be used directly,[2] or further steps (known as two-stage P2G systems) may convert the hydrogen into syngas, methane,[3] or LPG.[4] Single-stage P2G systems to produce methane also exist, such as reversible solid oxide cell (rSOC) technology.[5]

The gas may be used as chemical feedstock, or converted back into electricity using conventional generators such as gas turbines.[6] Power-to-gas allows energy from electricity to be stored and transported in the form of compressed gas, often using existing infrastructure for long-term transport and storage of natural gas. P2G is often considered the most promising technology for seasonal renewable energy storage.[7][8]

Energy storage and transport[edit]

Power-to-gas systems may be deployed as adjuncts to wind parks or solar power plants. The excess power or off-peak power generated by wind generators or solar arrays may then be used hours, days, or months later to produce electrical power for the electrical grid. In the case of Germany, before switching to natural gas, the gas networks were operated using towngas, which for 50–60 % consisted of hydrogen. The storage capacity of the German natural gas network is more than 200,000 GWh which is enough for several months of energy requirement. By comparison, the capacity of all German pumped-storage hydroelectricity plants amounts to only about 40 GWh.[citation needed] Natural gas storage is a mature industry that has been in existence since Victorian times. The storage/retrieval power rate requirement in Germany is estimated at 16 GW in 2023, 80 GW in 2033 and 130 GW in 2050.[9] The storage costs per kilowatt hour are estimated at €0.10 for hydrogen and €0.15 for methane.[10]

The existing natural gas transport infrastructure conveys massive amounts of gas for long distances profitably using pipelines. It is now profitable to ship natural gas between continents using LNG carriers. The transport of energy through a gas network is done with much less loss (<0.1%) than in an electrical transmission network (8%). This infrastructure can transport methane produced by P2G without modification. It is possible to use it for up to 20% hydrogen.[11] [12] The use of the existing natural gas pipelines for hydrogen was studied by the EU NaturalHy project[13] and the United States Department of Energy (DOE).[14] Blending technology is also used in HCNG.

Efficiency[edit]

In 2013, the round-trip efficiency of power-to-gas-storage was well below 50%, with the hydrogen path being able to reach a maximum efficiency of ~ 43% and methane of ~ 39% by using combined-cycle powerplants. If cogeneration plants are used that produce both electricity and heat, efficiency can be above 60%, but is still less than pumped hydro or battery storage.[15] However, there is potential to increase the efficiency of power-to-gas storage. In 2015 a study published in Energy and Environmental Science found that by using reversible solid oxide cells and recycling waste heat in the storage process, electricity-to-electricity round-trip efficiencies exceeding 70% can be reached at low cost.[16] In addition, a 2018 study using pressurized reversible solid oxide cells and a similar methodology found that round-trip efficiencies (power-to-power) of up to 80% might be feasible.[17]

| Fuel | Efficiency | Conditions |

|---|---|---|

| Pathway: Electricity→Gas | ||

| Hydrogen | 54–72 % | 200 bar compression |

| Methane (SNG) | 49–64 % | |

| Hydrogen | 57–73 % | 80 bar compression (Natural gas pipeline) |

| Methane (SNG) | 50–64 % | |

| Hydrogen | 64–77 % | without compression |

| Methane (SNG) | 51–65 % | |

| Pathway: Electricity→Gas→Electricity | ||

| Hydrogen | 34–44 % | 80 bar compression up to 60% back to electricity |

| Methane (SNG) | 30–38 % | |

| Pathway: Electricity→Gas→Electricity & heat (cogeneration) | ||

| Hydrogen | 48–62 % | 80 bar compression and electricity/heat for 40/45 % |

| Methane (SNG) | 43–54 % | |

Electrolysis technology[edit]

- Relative advantages and disadvantages of electrolysis technologies.[19]

| Advantage | Disadvantage |

|---|---|

| Commercial technology (high technology readiness level) | Limited cost reduction and efficiency improvement potential |

| Low investment electrolyser | High maintenance intensity |

| Large stack size | Modest reactivity, ramp rates and flexibility (minimal load 20%) |

| Extremely low hydrogen impurity (0.001%) | Stacks < 250 kW require unusual AC/DC converters |

| Corrosive electrolyte deteriorates when not operating nominally |

| Advantage | Disadvantage |

|---|---|

| Reliable technology (no kinetics) and simple, compact design | High investment costs (noble metals, membrane) |

| Very fast response time | Limited lifetime of membranes |

| Cost reduction potential (modular design) | Requires high water purity |

| Advantage | Disadvantage |

|---|---|

| Highest electrolysis efficiency | Very low technology readiness level (proof of concept) |

| Low capital costs | Poor lifetime because of high temperature and affected material stability |

| Possibilities for integration with chemical methanation (heat recycling) | Limited flexibility; constant load required |

Power-to-hydrogen[edit]

All current P2G systems start by using electricity to split water into hydrogen and oxygen by means of electrolysis. In a "power-to-hydrogen" system, the resulting hydrogen is injected into the natural gas grid or is used in transport or industry rather than being used to produce another gas type.[2]

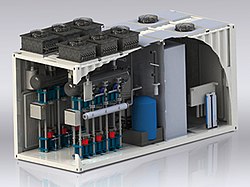

ITM Power won a tender in March 2013 for a Thüga Group project, to supply a 360 kW self-pressurising high-pressure electrolysis rapid response proton exchange membrane (PEM) electrolyser Rapid Response Electrolysis Power-to-Gas energy storage plant. The unit produces 125 kg/day of hydrogen gas and incorporates AEG power electronics. It will be situated at a Mainova AG site in the Schielestraße, Frankfurt in the state of Hessen. The operational data will be shared by the whole Thüga group – the largest network of energy companies in Germany with around 100 municipal utility members. The project partners include: badenova AG & Co. kg, Erdgas Mittelsachsen GmbH, Energieversorgung Mittelrhein GmbH, erdgas schwaben GmbH, Gasversorgung Westerwald GmbH, Mainova Aktiengesellschaft, Stadtwerke Ansbach GmbH, Stadtwerke Bad Hersfeld GmbH, Thüga Energienetze GmbH, WEMAG AG, e-rp GmbH, ESWE Versorgungs AG with Thüga Aktiengesellschaft as project coordinator. Scientific partners will participate in the operational phase.[20] It can produce 60 cubic metres of hydrogen per hour and feed 3,000 cubic metres of natural gas enriched with hydrogen into the grid per hour. An expansion of the pilot plant is planned from 2016, facilitating the full conversion of the hydrogen produced into methane to be directly injected into the natural gas grid.[21]

In December 2013, ITM Power, Mainova, and NRM Netzdienste Rhein-Main GmbH began injecting hydrogen into the German gas distribution network using ITM Power HGas, which is a rapid response proton exchange membrane electrolyser plant. The power consumption of the electrolyser is 315 kilowatts. It produces about 60 cubic meters per hour of hydrogen and thus in one hour can feed 3,000 cubic meters of hydrogen-enriched natural gas into the network.[22]

On August 28, 2013, E.ON Hanse, Solvicore, and Swissgas inaugurated a commercial power-to-gas unit in Falkenhagen, Germany. The unit, which has a capacity of two megawatts, can produce 360 cubic meters of hydrogen per hour.[23] The plant uses wind power and Hydrogenics[24] electrolysis equipment to transform water into hydrogen, which is then injected into the existing regional natural gas transmission system. Swissgas, which represents over 100 local natural gas utilities, is a partner in the project with a 20 percent capital stake and an agreement to purchase a portion of the gas produced. A second 800 kW power-to-gas project has been started in Hamburg/Reitbrook district[25] and is expected to open in 2015.[26]

In August 2013, a 140 MW wind park in Grapzow, Mecklenburg-Vorpommern owned by E.ON received an electrolyser. The hydrogen produced can be used in an internal combustion engine or can be injected into the local gas grid. The hydrogen compression and storage system stores up to 27 MWh of energy and increases the overall efficiency of the wind park by tapping into wind energy that otherwise would be wasted.[27] The electrolyser produces 210 Nm3/h of hydrogen and is operated by RH2-WKA.[28]

The INGRID project started in 2013 in Apulia, Italy. It is a four-year project with 39 MWh storage and a 1.2 MW electrolyser for smart grid monitoring and control.[29] The hydrogen is used for grid balancing, transport, industry, and injection into the gas network.[30]

The surplus energy from the 12 MW Prenzlau Windpark in Brandenburg, Germany[31] will be injected into the gas grid from 2014 on.

The 6 MW Energiepark Mainz[32] from Stadtwerke Mainz, RheinMain University of Applied Sciences, Linde and Siemens in Mainz (Germany) will open in 2015.

Power to gas and other energy storage schemes to store and utilize renewable energy are part of Germany's Energiewende (energy transition program).[33]

In France, the MINERVE demonstrator of AFUL Chantrerie (Federation of Local Utilities Association) aims to promote the development of energy solutions for the future with elected representatives, companies and more generally civil society. It aims to experiment with various reactors and catalysts. The synthetic methane produced by the MINERVE demonstrator (0.6 Nm3 / h of CH4) is recovered as CNG fuel, which is used in the boilers of the AFUL Chantrerie boiler plant. The installation was designed and built by the French SME Top Industrie, with the support of Leaf. In November 2017 it achieved the predicted performance, 93.3% of CH4. This project was supported by the ADEME and the ERDF-Pays de la Loire Region, as well as by several other partners: Conseil départemental de Loire -Atlantic, Engie-Cofely, GRDF, GRTGaz, Nantes-Metropolis, Sydela and Sydev.[34]

A full scale 1GW electrolyzer operated by EWE and Tree Energy Solutions is planned at the gas terminal in Wilhelmshaven, Germany. The first 500 MW is expected to begin operation in 2028. Wilhelmshaven can accommodate a second plant, bringing total potential capacity to 2GW.[35]

Grid injection without compression[edit]

The core of the system is a proton exchange membrane (PEM) electrolyser. The electrolyser converts electrical energy into chemical energy, which in turn facilitates the storage of electricity. A gas mixing plant ensures that the proportion of hydrogen in the natural gas stream does not exceed two per cent by volume, the technically permissible maximum value when a natural gas filling station is situated in the local distribution network. The electrolyser supplies the hydrogen-methane mixture at the same pressure as the gas distribution network, namely 3.5 bar. [36]

Power-to-methane[edit]

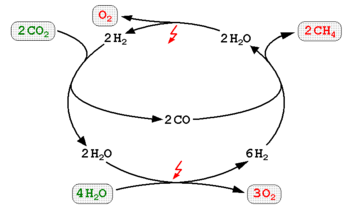

A power-to-methane system combines hydrogen from a power-to-hydrogen system with carbon dioxide to produce methane[37] (see natural gas) using a methanation reaction such as the Sabatier reaction or biological methanation resulting in an extra energy conversion loss of 8%,[citation needed] the methane may then be fed into the natural gas grid if the purity requirement is reached.[38]

ZSW (Center for Solar Energy and Hydrogen Research) and SolarFuel GmbH (now ETOGAS GmbH) realized a demonstration project with 250 kW electrical input power in Stuttgart, Germany.[39] The plant was put into operation on October 30, 2012.[40]

The first industry-scale Power-to-Methane plant was realized by ETOGAS for Audi AG in Werlte, Germany. The plant with 6 MW electrical input power is using CO2 from a waste-biogas plant and intermittent renewable power to produce synthetic natural gas (SNG) which is directly fed into the local gas grid (which is operated by EWE).[41] The plant is part of the Audi e-fuels program. The produced synthetic natural gas, named Audi e-gas, enables CO2-neutral mobility with standard CNG vehicles. Currently it is available to customers of Audi's first CNG car, the Audi A3 g-tron.[42]

In April 2014 the European Union's co-financed and from the KIT coordinated[43] HELMETH[44] (Integrated High-Temperature ELectrolysis and METHanation for Effective Power to Gas Conversion) research project started.[45] The objective of the project is the proof of concept of a highly efficient Power-to-Gas technology by thermally integrating high temperature electrolysis (SOEC technology) with CO2-methanation. Through the thermal integration of exothermal methanation and steam generation for the high temperature steam electrolysis conversion efficiency > 85% (higher heating value of produced methane per used electrical energy) are theoretically possible. The process consists of a pressurized high-temperature steam electrolysis and a pressurized CO2-methanation module. The project was completed in 2017 and achieved an efficiency of 76% for the prototype with an indicated growth potential of 80% for industrial scale plants.[46] The operating conditions of the CO2-methanation are a gas pressure of 10 - 30 bar, a SNG production of 1 - 5.4 m3/h (NTP) and a reactant conversion that produces SNG with H2 < 2 vol.-% resp. CH4 > 97 vol.-%.[47] Thus, the generated substitute natural gas can be injected in the entire German natural gas network without limitations.[48] As a cooling medium for the exothermic reaction boiling water is used at up to 300 °C, which corresponds to a water vapour pressure of about 87 bar. The SOEC works with a pressure of up to 15 bar, steam conversions of up to 90% and generates one standard cubic meter of hydrogen from 3.37 kWh of electricity as feed for the methanation.

The technological maturity of Power to Gas is evaluated in the European 27 partner project STORE&GO, which has started in March 2016 with a runtime of four years.[49] Three different technological concepts are demonstrated in three different European countries (Falkenhagen/Germany, Solothurn/Switzerland, Troia/Italy). The technologies involved include biological and chemical methanation, direct capture of CO2 from atmosphere, liquefaction of the synthesized methane to bio-LNG, and direct injection into the gas grid. The overall goal of the project is to assess those technologies and various usage paths under technical,[50] economic,[51] and legal [52] aspects to identify business cases on the short and on the long term. The project is co-funded by the European Union's Horizon 2020 research and innovation programme (18 million euro) and the Swiss government (6 million euro), with another 4 million euro coming from participating industrial partners.[53] The coordinator of the overall project is the research center of the DVGW[54] located at the KIT.

Microbial methanation[edit]

The biological methanation combines both processes, the electrolysis of water to form hydrogen and the subsequent CO2 reduction to methane using this hydrogen. During this process, methane forming microorganisms (methanogenic archaea or methanogens) release enzymes that reduce the overpotential of a non-catalytic electrode (the cathode) so that it can produce hydrogen.[55][56] This microbial power-to-gas reaction occurs at ambient conditions, i.e. room temperature and pH 7, at efficiencies that routinely reach 80-100%.[57][58] However, methane is formed more slowly than in the Sabatier reaction due to the lower temperatures. A direct conversion of CO2 to methane has also been postulated, circumventing the need for hydrogen production.[59] Microorganisms involved in the microbial power-to-gas reaction are typically members of the order Methanobacteriales. Genera that were shown to catalyze this reaction are Methanobacterium,[60][61] Methanobrevibacter,[62] and Methanothermobacter (thermophile).[63]

LPG production[edit]

Methane can be used to produce LPG by synthesising SNG with partial reverse hydrogenation at high pressure and low temperature. LPG in turn can be converted into alkylate which is a premium gasoline blending stock because it has exceptional antiknock properties and gives clean burning.[4]

Power to food[edit]

The synthetic methane generated from electricity can also be used for generating protein rich feed for cattle, poultry and fish economically by cultivating Methylococcus capsulatus bacteria culture with tiny land and water footprint.[64][65][66][need quotation to verify]The carbon dioxide gas produced as by-product from these plants can be recycled in the generation of synthetic methane (SNG). Similarly, oxygen gas produced as by product from the electrolysis of water and the methanation process can be consumed in the cultivation of bacteria culture. With these integrated plants, the abundant renewable solar and wind power potential can be converted into high value food products without any water pollution or greenhouse gas (GHG) emissions.[67]

Biogas-upgrading to biomethane[edit]

In the third method the carbon dioxide in the output of a wood gas generator or a biogas plant after the biogas upgrader is mixed with the produced hydrogen from the electrolyzer to produce methane. The free heat coming from the electrolyzer is used to cut heating costs in the biogas plant. The impurities carbon dioxide, water, hydrogen sulfide, and particulates must be removed from the biogas if the gas is used for pipeline storage to prevent damage.[3]

2014-Avedøre wastewater Services in Avedøre, Kopenhagen (Denmark) is adding a 1 MW electrolyzer plant to upgrade the anaerobic digestion biogas from sewage sludge.[68] The produced hydrogen is used with the carbon dioxide from the biogas in a Sabatier reaction to produce methane. Electrochaea[69] is testing another project outside P2G BioCat with biocatalytic methanation. The company uses an adapted strain of the thermophilic methanogen Methanothermobacter thermautotrophicus and has demonstrated its technology at laboratory-scale in an industrial environment.[70] A pre-commercial demonstration project with a 10,000-liter reactor vessel was executed between January and November 2013 in Foulum, Denmark.[71]

In 2016 Torrgas, Siemens, Stedin, Gasunie, A.Hak, Hanzehogeschool/EnTranCe and Energy Valley intend to open a 12 MW Power to Gas facility in Delfzijl (The Netherlands) where biogas from Torrgas (biocoal) will be upgraded with hydrogen from electrolysis and delivered to nearby industrial consumers.[72]

Power-to-syngas[edit]

| Water | CO2 | ||||||||||||||||||||

| Electrolysis of Water | |||||||||||||||||||||

| Oxygen | Hydrogen | ||||||||||||||||||||

| Conversion Reactor | |||||||||||||||||||||

| Water | Hydrogen | CO | |||||||||||||||||||

Syngas is a mixture of hydrogen and carbon monoxide. It has been used since Victorian times, when it was produced from coal and known as "towngas". A power-to-syngas system uses hydrogen from a power-to-hydrogen system to produce syngas.

- 1st step: Electrolysis of Water (SOEC) −water is split into hydrogen and oxygen.

- 2nd step: Conversion Reactor (RWGSR) −hydrogen and carbon dioxide are inputs to the Conversion Reactor that outputs hydrogen, carbon monoxide, and water. 3H2 + CO2 → (2H2 + CO)syngas + H2O

- Syngas is used to produce synfuels.

Initiatives[edit]

Other initiatives to create syngas from carbon dioxide and water may use different water splitting methods.

- CSP

- HTE / Alkaline water electrolysis

- 2004 Syntrolysis Fuels —Idaho National Laboratory and Ceramatec, Inc. (US).[88][89][90][91][92][93]

- 2008 WindFuels —Doty Energy (US).[94][95]

- 2012 Air Fuel Synthesis —Air Fuel Synthesis Ltd (UK).[96][97][98][99][100] Air Fuel Synthesis Ltd have become insolvent.[101]

- 2013 Green Feed —BGU and Israel Strategic Alternative Energy Foundation (I-SAEF).[102][103][104][105]

- 2014 E-diesel —Sunfire, a clean technology company and Audi.[106][107][108]

The US Naval Research Laboratory (NRL) is designing a power-to-liquids system using the Fischer-Tropsch Process to create fuel on board a ship at sea,[109] with the base products carbon dioxide (CO2) and water (H2O) being derived from sea water via "An Electrochemical Module Configuration For The Continuous Acidification Of Alkaline Water Sources And Recovery Of CO2 With Continuous Hydrogen Gas Production".[110][111]

See also[edit]

- Carbon-neutral fuel

- Electromethanogenesis

- Electrofuel

- Electrohydrogenesis

- Grid energy storage

- Hydrogen economy

- Methanation

- List of energy storage power plants

- Power-to-X

- Renewable natural gas

- Timeline of hydrogen technologies

Notes[edit]

- ^ Bünger, U.; Landinger, H.; Pschorr-Schoberer, E.; Schmidt, P.; Weindorf, W.; Jöhrens, J.; Lambrecht, U.; Naumann, K.; Lischke, A. (11 June 2014). Power to gas in transport-Status quo and perspectives for development (PDF) (Report). Federal Ministry of Transport and Digital Infrastructure (BMVI), Germany. Retrieved 3 June 2021.

- ^ a b Eberle, Ulrich; Mueller, Bernd; von Helmolt, Rittmar (2012). "Fuel cell electric vehicles and hydrogen infrastructure: status 2012". Energy & Environmental Science. 5 (10): 8780. doi:10.1039/C2EE22596D. Archived from the original on 2014-02-09. Retrieved 2014-12-16.

- ^ a b Melaina, M. W.; Antonia, O.; Penev, M. (March 2013). Blending hydrogen into natural gas pipeline networks: A review of key issues (PDF) (Report). National Renewable Energy Laboratory. Archived (pdf) from the original on 2022-12-23. Retrieved 2022-12-24.

- ^ a b "BPN Butane – Propane news". Archived from the original on 30 December 2017. Retrieved 10 April 2017.

- ^ Mogensen MB, Chen M, Frandsen HL, Graves C, Hansen JB, Hansen KV, Hauch A, Jacobsen T, Jensen SH, Skafte TL, Sun X (September 2019). "Reversible solid-oxide cells for clean and sustainable energy". Clean Energy. 3 (3): 175–201. doi:10.1093/ce/zkz023.

over 100 times more solar photovoltaic energy than necessary is readily accessible and that practically available wind alone may deliver sufficient energy supply to the world. Due to the intermittency of these sources, effective and inexpensive energy-conversion and storage technology is needed. Motivation for the possible electrolysis application of reversible solid-oxide cells (RSOCs), including a comparison of power-to-fuel/fuel-to-power to other energy-conversion and storage technologies is presented.

- ^ "EUTurbines". www.poertheeu.eu. EUTurbines.

- ^ Andrews, John; Shabani, Bahman (January 2012). "Re-envisioning the role of hydrogen in a sustainable energy economy". International Journal of Hydrogen Energy. 37 (2): 1184–1203. doi:10.1016/j.ijhydene.2011.09.137.

- ^ Staffell, Iain; Scamman, Daniel; Velazquez Abad, Anthony; Balcombe, Paul; Dodds, Paul E.; Ekins, Paul; Shah, Nilay; Ward, Kate R. (2019). "The role of hydrogen and fuel cells in the global energy system". Energy & Environmental Science. 12 (2): 463–491. doi:10.1039/C8EE01157E. hdl:10044/1/65315.

- ^ Electricity storage in the German energy transition (PDF) (Report). Agora Energiewende. December 2014. Retrieved 2020-02-11.

- ^ "Wind power to hydrogen". hi!tech. Siemens. Archived from the original on 2014-07-14. Retrieved 2014-06-21.

- ^ Millard, Rachel (2023-02-13). "Hydrogen to be pumped into main gas pipeline by 2025". The Telegraph. ISSN 0307-1235. Retrieved 2023-04-30.

- ^ "Why is the hydrogen level set at a maximum of 20%?". HyDeploy. Retrieved 2023-04-30.

- ^ NaturalHY Project. "Using the Existing Natural Gas System for Hydrogen". EXERGIA. Archived from the original on 2014-10-29. Retrieved 2014-06-21.

- ^ NREL - Blending hydrogen into natural gas pipeline networks A review of key issues

- ^ Volker Quaschning, Regenerative Energiesysteme. Technologie - Berechnung - Simulation, Hanser 2013, p 373.

- ^ Jensen; et al. (2015). "Large-scale electricity storage utilizing reversible solid oxide cells combined with underground storage of CO

2 and CH

4". Energy and Environmental Science. 8 (8): 2471–2479. doi:10.1039/c5ee01485a. S2CID 93334230. - ^ Butera, Giacomo; et al. (2019). "A novel system for large-scale storage of electricity as synthetic natural gas using reversible pressurized solid oxide cells" (PDF). Energy. 166: 738–754. doi:10.1016/j.energy.2018.10.079. S2CID 116315454.

- ^ (German) Fraunhofer -Energiewirtschaftliche und ökologische Bewertung eines Windgas-Angebotes, p. 18

- ^ Grond, Lukas; Holstein, Johan (February 2014). "Power-to-gas: Climbing the technology readiness ladder" (PDF). Archived (PDF) from the original on 3 March 2020. Retrieved 3 March 2020.

- ^ "First Sale of 'Power-to-Gas' Plant in Germany –". Archived from the original on 2013-05-02. Retrieved 2013-05-17.

- ^ Ground broken at ITM Power power-to-gas pilot plant in Frankfurt Archived 2013-11-11 at the Wayback Machine

- ^ "Injection of Hydrogen into the German Gas Distribution Grid –". Archived from the original on 2014-03-08. Retrieved 2013-12-05.

- ^ "E.ON inaugurates power-to-gas unit in Falkenhagen in eastern Germany". e·on (Press release). 2013-08-28. Archived from the original on 2013-09-11.

- ^ "Hydrogenics and Enbridge to develop utility-scale energy storage". Archived from the original on 2013-11-11. Retrieved 2013-11-11.

- ^ "E.on Hanse starts construction of power-to-gas facility in Hamburg". Archived from the original on 2014-03-15. Retrieved 2013-11-19.

- ^ "E.ON power-to-gas pilot unit in Falkenhagen first year of operation". Archived from the original on 2014-11-11. Retrieved 2014-11-10.

- ^ "German wind park with 1 MW Hydrogenics electrolyser for Power-to-Gas energy storage". Renewable Energy Focus. 17 October 2013. Archived from the original on 1 June 2017. Retrieved 21 July 2017.

- ^ "RH2-WKA". Archived from the original on 2013-11-24. Retrieved 2013-11-11.

- ^ "INGRID Project to Launch 1.2 MW Electrolyser with 1 Ton of Storage for Smart Grid Balancing in Italy". Archived from the original on 2013-11-11. Retrieved 2013-11-11.

- ^ "Grid balancing, Power to Gas (PtG)" (PDF). Archived (PDF) from the original on 2013-11-11. Retrieved 2013-11-11.

- ^ Prenzlau Windpark (Germany)

- ^ Energiepark Mainz

- ^ Schiermeier, Quirin (April 10, 2013). "Renewable power: Germany's energy gamble: An ambitious plan to slash greenhouse-gas emissions must clear some high technical and economic hurdles". Nature. Archived from the original on April 13, 2013. Retrieved April 10, 2013.

- ^ "Un démonstrateur Power to gas en service à Nantes". Lemoniteur.fr (in French). 2018. Retrieved 9 February 2018..

- ^ "TES and EWE to Build 500MW Electrolyser at Wilhelmshaven Green Energy Hub". 25 November 2022. Retrieved 20 December 2022..

- ^ "Energiewende & Dekarbonisierung Archive". Archived from the original on 2013-12-05. Retrieved 2013-12-05.

- ^ "DNV-Kema Systems analyses power to gas" (PDF). Archived from the original (PDF) on 2015-01-24. Retrieved 2014-08-21.

- ^ Ghaib, Karim; Ben-Fares, Fatima-Zahrae (2018). "Power-to-Methane: A state-of-the-art review" (PDF). Renewable and Sustainable Energy Reviews. 81: 433–446. doi:10.1016/j.rser.2017.08.004. Retrieved 1 May 2018.

- ^ "German network companies join up to build power-to-gas plant". Reuters. 2018-10-16. Archived from the original on 16 October 2018. Retrieved 17 October 2018.

- ^ "Weltweit größte Power-to-Gas-Anlage zur Methan-Erzeugung geht in Betrieb". ZSW-BW.de (in German). Archived from the original on 2012-11-07. Retrieved 2017-12-01.

- ^ "Energy turnaround in the tank". Audi.com. Archived from the original on 2014-06-06. Retrieved 2014-06-03.

- ^ "Company". Audi.com. Archived from the original on 2014-06-06. Retrieved 2014-06-04.

- ^ "Engler-Bunte-Institute Division of Combustion Technology - Project HELMETH". Retrieved 2014-10-31.

- ^ "Project homepage - HELMETH". Retrieved 2014-10-31.

- ^ "Karlsruhe Institute of Technology - Press Release 044/2014". Retrieved 2014-10-31.

- ^ "Karlsruhe Institute of Technology - Press Release 009/2018". Retrieved 2018-02-21.

- ^ "Project homepage - HELMETH". Retrieved 2018-02-21.

- ^ DIN EN 16723-2:2017-10 - Erdgas und Biomethan zur Verwendung im Transportwesen und Biomethan zur Einspeisung ins Erdgasnetz

- ^ "Deutscher Verein des Gas und Wasserfaches e.V.: Press release - Project Store&Go". Archived from the original on 2016-08-01. Retrieved 2016-12-12.

- ^ "Watt d'Or 4 all: "Store&Go" – Erdgasnetz als Riesen-Batterie". Archived from the original on 2017-02-21. Retrieved 2016-12-12.

- ^ "Store&Go, Innovative large-scale energy STORagE technologies AND Power-to-Gas concepts after Optimisation". Archived from the original on 2016-11-24. Retrieved 2016-12-12.

- ^ "Het juridische effect van innovatieve energieconversie en –opslag". Retrieved 2016-12-12.

- ^ "Project homepage - STORE&GO". Retrieved 2016-12-12.

- ^ "Deutscher Verein des Gas und Wasserfaches e.V.: Press release - Innovative 28 million E project STORE&GO started to show large scale energy storage by Power-to-Gas is already possible today" (PDF). Retrieved 2016-12-12.

- ^ Deutzmann, Jörg S.; Sahin, Merve; Spormann, Alfred M. (2015). "Deutzmann, J. S.; Sahin, M.; Spormann, A. M., Extracellular enzymes facilitate electron uptake in biocorrosion and bioelectrosynthesis". mBio. 6 (2). doi:10.1128/mBio.00496-15. PMC 4453541. PMID 25900658.

- ^ Yates, Matthew D.; Siegert, Michael; Logan, Bruce E. (2014). "Hydrogen evolution catalyzed by viable and non-viable cells on biocathodes". International Journal of Hydrogen Energy. 39 (30): 16841–16851. doi:10.1016/j.ijhydene.2014.08.015.

- ^ Marshall, C. W.; Ross, D. E.; Fichot, E. B.; Norman, R. S.; May, H. D. (2012). "Electrosynthesis of commodity chemicals by an autotrophic microbial community". Appl. Environ. Microbiol. 78 (23): 8412–8420. Bibcode:2012ApEnM..78.8412M. doi:10.1128/aem.02401-12. PMC 3497389. PMID 23001672.

- ^ Siegert, Michael; Yates, Matthew D.; Call, Douglas F.; Zhu, Xiuping; Spormann, Alfred; Logan, Bruce E. (2014). "Comparison of Nonprecious Metal Cathode Materials for Methane Production by Electromethanogenesis". ACS Sustainable Chemistry & Engineering. 2 (4): 910–917. doi:10.1021/sc400520x. PMC 3982937. PMID 24741468.

- ^ Cheng, Shaoan; Xing, Defeng; Call, Douglas F.; Logan, Bruce E. (2009). "Direct biological conversion of electric current into methane by electromethanogenesis". Environmental Science. 43 (10): 3953–3958. Bibcode:2009EnST...43.3953C. doi:10.1021/es803531g. PMID 19544913.

- ^ Beese-Vasbender, Pascal F.; Grote, Jan-Philipp; Garrelfs, Julia; Stratmann, Martin; Mayrhofer, Karl J.J. (2015). "Selective microbial electrosynthesis of methane by a pure culture of a marine lithoautotrophic archaeon". Bioelectrochemistry. 102: 50–5. doi:10.1016/j.bioelechem.2014.11.004. PMID 25486337.

- ^ Siegert, Michael; Yates, Matthew D.; Spormann, Alfred M.; Logan, Bruce E. (2015). "Methanobacterium dominates biocathodic archaeal communities in methanogenic microbial electrolysis cells". ACS Sustainable Chemistry & Engineering. 3 (7): 1668−1676. doi:10.1021/acssuschemeng.5b00367.

- ^ Siegert, Michael; Li, Xiu-Fen; Yates, Matthew D.; Logan, Bruce E. (2015). "The presence of hydrogenotrophic methanogens in the inoculum improves methane gas production in microbial electrolysis cells". Frontiers in Microbiology. 5: 778. doi:10.3389/fmicb.2014.00778. PMC 4295556. PMID 25642216.

- ^ Sato, Kozo; Kawaguchi, Hideo; Kobayashi, Hajime (2013). "Bio-electrochemical conversion of carbon dioxide to methane in geological storage reservoirs". Energy Conversion and Management. 66: 343. doi:10.1016/j.enconman.2012.12.008.

- ^ "BioProtein Production" (PDF). Archived from the original (PDF) on 10 May 2017. Retrieved 31 January 2018.

- ^ "Food made from natural gas will soon feed farm animals – and us". Archived from the original on 12 December 2019. Retrieved 31 January 2018.

- ^ "New venture selects Cargill's Tennessee site to produce Calysta FeedKind Protein". Archived from the original on 30 December 2019. Retrieved 31 January 2018.

- ^ "Assessment of environmental impact of FeedKind protein" (PDF). Archived from the original (PDF) on 2 August 2019. Retrieved 20 June 2017.

- ^ "Excess wind power is turned into green gas in Avedøre". Archived from the original on 2014-05-31. Retrieved 2014-05-30.

- ^ "Electrochaea". Archived from the original on 2014-01-12. Retrieved 2014-01-12.

- ^ Martin, Matthew R.; Fornero, Jeffrey J.; Stark, Rebecca; Mets, Laurens; Angenent, Largus T. (2013). "A Single-Culture Bioprocess of Methanothermobacter thermautotrophicus to Upgrade Digester Biogas by CO

2-to-CH

4 Conversion with H

2". Archaea. 2013: 157529. doi:10.1155/2013/157529. PMC 3806361. PMID 24194675. Article ID 157529. - ^ "Power-to-Gas Energy Storage - Technology Description". Electrochaea.com. Archived from the original on 2014-01-12. Retrieved 2014-01-12.

- ^ "Power-to-Gas plant for Delfzijl". Archived from the original on 2014-05-31. Retrieved 2014-05-30.

- ^ "Sunshine to Petrol". Sandia National Laboratories. United States Department of Energy (DOE). Retrieved 15 May 2015.

- ^ SNL: Sunshine to Petrol - Solar Recycling of Carbon Dioxide into Hydrocarbon Fuels

- ^ "Sandia and Sunshine-to-Petrol: Renewable Drop-in Transportation Fuels". Federal Business Opportunities. U.S. Federal Government. Oct 29, 2013. Retrieved 15 May 2015.

- ^ Biello, David (September 23, 2010). "Reverse Combustion: Can CO2 Be Turned Back into Fuel?". Scientific American - Energy & Sustainability. Archived from the original on 16 May 2015. Retrieved 17 May 2015.

- ^ Lavelle, Marianne (August 11, 2011). "Carbon Recycling: Mining the Air for Fuel". National Geographic - News. National Geographic Society. Archived from the original on 20 May 2015. Retrieved 19 May 2015.

- ^ "Bright Way to Convert Greenhouse Gas to Biofuel". Weizmann UK. Weizmann UK. Registered Charity No. 232666. 18 December 2012. Retrieved 19 May 2015.[permanent dead link]

- ^ "CO

2 and H

2O Dissociation Process". NCF - Technology Process. New CO2 Fuels Ltd. Retrieved 19 May 2015. - ^ "Newsletter NewCO2Fuels, Issue 1" (PDF). September 2012.

- ^ "From challenge to opportunity New CO

2 Fuels: An Introduction..." (PDF). Archived (PDF) from the original on 2015-05-30. Retrieved 2015-05-30. - ^ "SOLAR-JET Project". SOLAR-JET. SOLAR-JET Project Office: ARTTIC. Archived from the original on 18 May 2015. Retrieved 15 May 2015.

- ^ "Sunlight to jet fuel". The ETH Zurich. Eidgenössische Technische Hochschule Zürich. Archived from the original on 10 September 2014. Retrieved 15 May 2015.

- ^ Alexander, Meg (May 1, 2014). ""Solar" jet fuel created from water and carbon dioxide". Gizmag. Gizmag. Archived from the original on 18 May 2015. Retrieved 15 May 2015.

- ^ "SOLARJET demonstrates full process for thermochemical production of renewable jet fuel from H2O & CO2". Green Car Congress. BioAge Group, LLC. 28 April 2015. Archived from the original on 18 May 2015. Retrieved 15 May 2015.

- ^ "Aldo Steinfeld - Solar Syngas". Solve For <X>. Google Inc.[permanent dead link]

- ^ "Brewing fuels in a solar furnace" (PDF). Archived (PDF) from the original on 2015-05-19. Retrieved 2015-05-30.

- ^ "Syntrolysis, Synthetic Fuels from Carbon Dioxide, Electricity and Steam" (PDF). Archived from the original (PDF) on 2015-05-21. Retrieved 2015-05-30.

- ^ "Synthetic Fuel (syntrolysis)". Thoughtware.TV. Thoughtware.TV. June 17, 2008. Retrieved 20 May 2015.

- ^ Stoots, C.M.; O'Brien, J.T.; Hartvigsen, J. (2007). "Carbon Neutral Production of Syngas via High Temperature Electrolytic Reduction of Steam and CO

2" (PDF). ASME 2007 International Mechanical Engineering Congress and Exposition. 2007 ASME International Mechanical Engineering Congress and Exposition, November 11–15, 2007, Seattle, Washington, USA. Vol. 15: Sustainable Products and Processes. pp. 185–194. doi:10.1115/IMECE2007-43667. ISBN 978-0-7918-4309-3. Archived from the original (PDF) on May 21, 2015. Retrieved May 30, 2015. - ^ Nuclear Hydrogen Initiative Overview

- ^ Nuclear Hydrogen Production Technology

- ^ Electrolysis For Synthetic Fuel Production Archived 2015-05-30 at the Wayback Machine

- ^ "The WindFuels Primer - Basic Explanation for the Non-scientist". Doty Energy. Doty Energy. Archived from the original on 16 May 2015. Retrieved 16 May 2015.

- ^ "Securing Our Energy Future by Efficiently Recycling CO

2 into Transportation Fuels" (PDF). Archived (PDF) from the original on 2016-03-04. Retrieved 2015-05-30. - ^ "The AFS Process - turning air into a sustainable fuel". Air Fuel Synthesis - Technical Review. Air Fuel Synthesis Limited. Archived from the original on 3 April 2015. Retrieved 19 May 2015.

- ^ Case Study: AFS demonstrator unit[permanent dead link]

- ^ "Cars Fueled by Air?". PlanetForward.org. Planet Forward. Retrieved 20 May 2015.

- ^ Rapier, Robert (October 31, 2012). "Investors Beware of Fuel from Thin Air". Investing Daily. Archived from the original on 18 May 2015. Retrieved 17 May 2015.

- ^ Williams, K.R.; van Lookeren Campagne, N. Synthetic Fuels From Atmospheric Carbon Dioxide (PDF) (Report). Archived from the original (PDF) on 2013-03-04.

- ^ "Air Fuel Synthesis Limited". www.thegazette.co.uk. The Gazette. Retrieved 19 October 2018.

- ^ "BGU Researchers invent Green Alternative to Crude Oil". Ben-Gurion University of the Negev. Ben-Gurion University of the Negev. 13 November 2013. Retrieved 17 May 2015.

- ^ "Recent Success Story: Converting carbon dioxide, a damaging greenhouse gas, into fuel that may be used for transportation". I-SAEF. Israel Strategic Alternative Energy Foundation. Retrieved 15 May 2015.

- ^ "BGU Researchers Develop New Type of Crude Oil Using Carbon Dioxide and Hydrogen". American Associates (Ben-Gurion University of the Negev). American Associates (AABGU). Archived from the original on 18 May 2015. Retrieved 15 May 2015.

- ^ "BGU researchers developing more efficient process for hydrogenation of CO2 to synthetic crude". Green Car Congress. BioAge Group, LLC. 21 November 2013. Archived from the original on 4 August 2015. Retrieved 15 May 2015.

- ^ "Fuel of the future: Research facility in Dresden produces first batch of Audi e-diesel". Audi MediaServices - Press release. Ingolstadt/Berlin: AUDI AG. 2015-04-21. Archived from the original on 19 May 2015. Retrieved 23 May 2015.

- ^ Rapier, Robert. "Is Audi's Carbon-Neutral Diesel a Game-Changer?". Energy Trends Insider. Energy Trends Insider. Archived from the original on 18 May 2015. Retrieved 15 May 2015.

- ^ Novella, Steven (28 April 2015). "Apr 28 2015 Audi's E-Diesel". The NeuroLogicaBlog - Technology. Steven Novella, MD. Archived from the original on 30 May 2015. Retrieved 24 May 2015.

- ^ "How the United States Navy Plans to Turn Seawater into Jet Fuel". Alternative Energy. altenergy.org. Retrieved 8 May 2015.

- ^ "Patent: US 20140238869 A1". Google Patents. Archived from the original on 18 May 2015. Retrieved 8 May 2015.

- ^ The total carbon content of the world's oceans is roughly 38,000 GtC. Over 95% of this carbon is in the form of dissolved bicarbonate ion (HCO3 −). Cline, William (1992). The Economics of Global Warming. Washington D.C.: Institute for International Economics.

The dissolved bicarbonate and carbonate of the ocean is essentially bound CO2 and the sum of these species along with gaseous CO2, shown in the following equation, represents the total carbon dioxide concentration [CO2]T, of the world's oceans. Σ[CO2]T=[CO2(g)]l+[HCO3 −]+[CO3 2−]

[verification needed]

Further reading[edit]

- Götz, Manuel; Lefebvre, Jonathan; Mörs, Friedemann; McDaniel Koch, Amy; Graf, Frank; Bajohr, Siegfried; Reimert, Rainer; Kolb, Thomas (2016). "Renewable Power-to-Gas: A technological and economic review". Renewable Energy. 85: 1371–1390. doi:10.1016/j.renene.2015.07.066.

- Méziane Boudellal. "Power-to-Gas. Renewable Hydrogen Economy for the Energy Transition". Second edition. 249 pages. English edition. Editor: de Gruyter, March 2023. https://www.degruyter.com/document/doi/10.1515/9783110781892/html