Rocketdyne F-1: Difference between revisions

Magioladitis (talk | contribs) m clean up, replaced: |imsize → |image_size using AWB (9461) |

|||

| Line 48: | Line 48: | ||

A [[gas-generator cycle (rocket)|gas-generator]] was used to drive a [[turbine]] which in turn drove separate fuel and oxygen pumps, each feeding the thrust chamber assembly. The turbine was driven at 5,500 [[RPM]] by the gas generator, producing {{convert|55000|bhp|MW|disp=flip}}. The fuel pump produced {{convert|15,471|USgal|l|disp=flip}} of RP-1 per minute while the oxidizer pump delivered {{convert|24,811|USgal|disp=flip}} of liquid oxygen per minute. Environmentally, the turbopump was required to withstand temperatures ranging from input gas at {{convert|1500|°F|disp=flip}} to liquid oxygen at {{convert|−300|°F|disp=flip}}. Structurally, fuel was used to lubricate and cool the turbine [[Bearing (mechanical)|bearings]]. |

A [[gas-generator cycle (rocket)|gas-generator]] was used to drive a [[turbine]] which in turn drove separate fuel and oxygen pumps, each feeding the thrust chamber assembly. The turbine was driven at 5,500 [[RPM]] by the gas generator, producing {{convert|55000|bhp|MW|disp=flip}}. The fuel pump produced {{convert|15,471|USgal|l|disp=flip}} of RP-1 per minute while the oxidizer pump delivered {{convert|24,811|USgal|disp=flip}} of liquid oxygen per minute. Environmentally, the turbopump was required to withstand temperatures ranging from input gas at {{convert|1500|°F|disp=flip}} to liquid oxygen at {{convert|−300|°F|disp=flip}}. Structurally, fuel was used to lubricate and cool the turbine [[Bearing (mechanical)|bearings]]. |

||

[[Image:F-1 Engine Test Firing.jpg|right|thumb|Test Firing of an F-1 Engine at Edwards Air Force Base. In comparison to the hotter and therefore lighter colored inner portion, the darker more [[Air-fuel ration|fuel rich]] outer portion of the exhaust gases is clearly visible. This darker region or "curtain" was created by means of the flow of the [[gas generator]]s exhaust into the turbine exhaust manifold. Serving as a means to cool/protect the nozzle from the intense heat of the lighter colored near [[stoichiometric]] combustion products within.]] |

|||

[[Image:F-1 Engine Test Firing.jpg|right|thumb|Test Firing of an F-1 Engine at Edwards Air Force Base.]] |

|||

[[Image:F-1 Engines Being Installed.jpg|right|thumb|Installation of F-1 engines to the Saturn V S-IC Stage. The [[nozzle extension]] is absent from the engine being fitted.]] |

[[Image:F-1 Engines Being Installed.jpg|right|thumb|Installation of F-1 engines to the Saturn V S-IC Stage. The [[nozzle extension]] is absent from the engine being fitted.]] |

||

Below the thrust chamber was the [[nozzle extension]], roughly half the length of the engine. This extension increased the expansion ratio of the engine from 10:1 to 16:1. The exhaust from the turbopump was fed into the nozzle extension by a large, tapered manifold; this relatively cool gas formed a film which protected the nozzle extension from the hot ({{convert|5800|°F|disp=out|abbr=on}}) exhaust gas.<ref name=SVPressKit>{{Citation |

Below the thrust chamber was the [[nozzle extension]], roughly half the length of the engine. This extension increased the expansion ratio of the engine from 10:1 to 16:1. The exhaust from the turbopump was fed into the nozzle extension by a large, tapered manifold; this relatively cool gas formed a film which protected the nozzle extension from the hot ({{convert|5800|°F|disp=out|abbr=on}}) exhaust gas.<ref name=SVPressKit>{{Citation |

||

Revision as of 16:54, 10 September 2013

This article needs additional citations for verification. (July 2009) |

F-1 rocket engine specifications | |

| Country of origin | United States |

|---|---|

| Manufacturer | Rocketdyne |

| Liquid-fuel engine | |

| Propellant | LOX / RP-1 |

| Cycle | gas-generator |

| Performance | |

| Thrust, sea-level | 6.77 meganewtons (1,522,000 lbf) |

| Chamber pressure | 7.0 megapascals (70 bar) |

| Specific impulse, sea-level | 263 s (2.58 kN·s/kg) |

The F-1 is a gas-generator cycle rocket engine developed by Rocketdyne in the late 1950s and used in the Saturn V rocket in the 1960s and early 1970s. Five F-1 engines were used in the S-IC first stage of each Saturn V, which served as the main launch vehicle in the Apollo program. The F-1 is still the most powerful single-chamber liquid-fueled rocket engine ever developed.[1] The RD-170 has slightly more thrust, using a cluster of four smaller combustion chambers and nozzles.[2]

History

The F-1 was originally developed by Rocketdyne to meet a 1955 US Air Force requirement for a very large rocket engine. The eventual result of that requirement was two engines, the E-1 and the much larger F-1. The E-1, although successfully tested in static firing, was quickly seen as a technological dead-end, and was abandoned for the larger, more powerful F-1. The Air Force eventually halted development of the F-1 because of a lack of requirement for such a large engine. However, the recently created National Aeronautics and Space Administration appreciated the usefulness of an engine with so much power, and contracted Rocketdyne to complete its development. Test firings of F-1 components had been performed as early as 1957. The first static firing of a full-stage developmental F-1 was performed in March 1959. The first F-1 was delivered to MSFC in October 1963. In December 1964, the F-1 completed flight-rating tests. Testing continued at least through 1965.[3]

During seven years of development, F-1 tests revealed serious combustion instability problems which sometimes caused catastrophic failure.[4] Initially, progress on this problem was slow, as it was intermittent and unpredictable. Oscillations of 4 kHz with harmonics to 24 kHz were observed. Eventually, engineers developed a technique of detonating small explosive charges (which they called "bombs") outside the combustion chamber, through a tangential tube (RDX, C4 or black powder were used) while the engine was firing. This allowed them to determine exactly how the running chamber responded to variations in pressure, and to determine how to nullify these oscillations. The designers could then quickly experiment with different co-axial fuel-injector designs to obtain the one most resistant to instability. These problems were addressed from 1959 through 1961. Eventually, engine combustion was so stable, it would self-damp artificially induced instability within 1/10 of a second.

Design

The Rocketdyne-developed F-1 engine is the most powerful single-nozzle liquid-fueled rocket engine ever flown. The RD-170 produces 11% more thrust through a cluster of four combustion chambers and four nozzles. The M-1 rocket engine was designed to have more thrust, however it was only tested at the component level. The F-1 was a liquid-fueled rocket motor, burning RP-1 (kerosene) as fuel, and using liquid oxygen (LOX) as the oxidizer. A turbopump was used to inject fuel and oxygen into the combustion chamber.

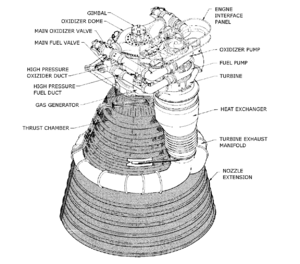

The heart of the engine was the thrust chamber, which mixed and burned the fuel and oxidizer to produce thrust. A domed chamber at the top of the engine served as a manifold supplying liquid oxygen to the injectors, and also served as a mount for the gimbal bearing which transmitted the thrust to the body of the rocket. Below this dome were the injectors, which directed fuel and oxidizer into the thrust chamber in a way designed to promote mixing and combustion. Fuel was supplied to the injectors from a separate manifold; some of the fuel first travelled in 178 tubes down the length of the thrust chamber—which formed approximately the upper half of the exhaust nozzle—and back, to cool the nozzle.

A gas-generator was used to drive a turbine which in turn drove separate fuel and oxygen pumps, each feeding the thrust chamber assembly. The turbine was driven at 5,500 RPM by the gas generator, producing 41 megawatts (55,000 bhp). The fuel pump produced 58,560 litres (15,471 US gal) of RP-1 per minute while the oxidizer pump delivered 93,920 litres; 20,659 imperial gallons (24,811 US gal) of liquid oxygen per minute. Environmentally, the turbopump was required to withstand temperatures ranging from input gas at 820 °C (1,500 °F) to liquid oxygen at −184.4 °C (−300 °F). Structurally, fuel was used to lubricate and cool the turbine bearings.

Below the thrust chamber was the nozzle extension, roughly half the length of the engine. This extension increased the expansion ratio of the engine from 10:1 to 16:1. The exhaust from the turbopump was fed into the nozzle extension by a large, tapered manifold; this relatively cool gas formed a film which protected the nozzle extension from the hot (3,200 °C) exhaust gas.[5]

The F-1 burned 1,789 kilograms (3,945 lb) of liquid oxygen and 788 kilograms (1,738 lb) of RP-1 each second, generating 6.7 meganewtons (1,500,000 lbf) of thrust. This equated to a flow rate of 1,565 litres (413.5 US gal) of LOX and 976 litres (257.9 US gal) RP-1 per second. During their two and a half minutes of operation, the five F-1s propelled the Saturn V vehicle to a height of 68 kilometres (42 mi) and a speed of 9,920 km/h (6,164 mph). The combined propellant flow rate of the five F-1s in the Saturn V was 12,710 litres (3,357 US gal) per second.[5] Each F-1 engine had more thrust than three Space Shuttle Main Engines combined.[6]

Designer of the pump for the E-1/F-1 for Rocketdyne was Ernest A. Lamont. His hand written original calculations are part of the family archives and available for display. He stated that the design of the rocket engine hinged on the question of whether the pump design was viable.[citation needed]

Specifications

| Apollo 4, 6, and 8 | Apollo 9 on | |

|---|---|---|

| Thrust (sea level): | 6.7 meganewtons (1,500,000 lbf) | 6.77 meganewtons (1,522,000 lbf) |

| Burn time: | 150 s | 165s |

| Specific impulse: | 260 s (2.55 kN·s/kg) | 263 s (2.58 kN·s/kg) |

| Chamber pressure: | 7.0 megapascals (70 bar) | 7.0 megapascals (70 bar) |

| Engine weight dry: | 8,353 kilograms (18,416 lb) | 8,400 kilograms (18,500 lb) |

| Engine weight burnout: | 9,115 kilograms (20,096 lb) | 9,150 kilograms (20,180 lb) |

| Height: | 5.8 metres (19 ft) | |

| Diameter: | 3.7 metres (12.3 ft) | |

| Exit to throat ratio: | 16 to 1 | |

| Propellants: | LOX & RP-1 | |

| Mixture ratio: | 2.27:1 oxidizer to fuel | |

| Contractor: | NAA/Rocketdyne | |

| Vehicle application: | Saturn V / S-IC 1st stage - 5-engines | |

Improvements to F-1

F-1 thrust and efficiency were improved between Apollo 8 (SA-503) and Apollo 17 (SA-512). This was necessary for Saturn V payload capacity to meet the increasing demands of the later Apollo missions. There were small performance variations between engines on a given mission, and variations in average thrust between missions. For Apollo 15, F-1 performance was:

- Thrust (average, per engine, sea level liftoff): 6.909 meganewtons (1,553,200 lbf)

- Burn time: 159 s

- Specific impulse: 264.72 s

- Mixture ratio: 2.2674

- S-IC total sea level liftoff thrust: 34.54 meganewtons (7,766,000 lbf)

Measuring and making comparisons of rocket engine thrust is more complicated than it first appears. Based on actual measurement the liftoff thrust of Apollo 15 was 34.80 MN (7,823,000 lbf), which equates to an average F-1 thrust of 6.96 MN (1,565,000 lbf) - significantly more than the specified value. For more information, see S-IC thrust comparisons

F-1A After Apollo

There was an uprating redevelopment of the F-1 undertaken by Rocketdyne during the 1960s which resulted in a new engine specification known as the F-1A. While outwardly very similar to the F-1, the F-1A was lighter yet 33% more powerful [citation needed] and would have been used on future Saturn V vehicles in the post-Apollo era. However, the Saturn V production line was closed prior to the end of Project Apollo and no F-1A engine ever flew on a launch vehicle.[8]

There were proposals to use eight F-1 engines on the first stage of the Nova rocket. Numerous proposals have been made from the 1970s on[citation needed] to the present day to develop new expendable boosters based around the F-1 engine design, including one in 2013,[8] but none have proceeded beyond the initial study phase.

The F-1 remained the most powerful liquid-fuel rocket engine at 6.7 MN of thrust at sea level until overshadowed by the RD-170 from the Soviet Union. The RD-170 is actually a cluster of four separate combustion chambers and nozzles driven by a single turbopump. It visually appears to be and is considered by some a cluster of four engines, not a single engine. Viewed as a single engine it is the most powerful liquid-fuel rocket engine ever flown. The F-1 still holds the crown of largest single-chamber, single-nozzle liquid fuel engine flown. However among solid-fuel engines, more powerful engines exist, such as the Space Shuttle Solid Rocket Booster, with a sea-level liftoff thrust of 12.45 MN.

Pre and post ignition procedures

During static test firing, the kerosene based RP-1 fuel would leave hydrocarbon deposits and vapors in the engine post test firing. These vapors and deposits had to be removed from the engine to avoid problems during engine handling and future firing. To this effect, the solvent Trichloroethylene(TCE) was used to clean the engine's fuel system immediately before and after each test firing. The cleaning procedure involved pumping TCE through the engine's fuel system and letting the solvent overflow for a period ranging from several seconds to 30–35 minutes, depending upon the engine and the severity of the deposits. For some engines, the engine's gas generator and LOX dome were also flushed with TCE prior to test firing.[9][10] The F-1 rocket engine had its LOX dome, gas generator, and thrust chamber fuel jacket flushed with TCE during launch preparations.[10]

Current locations

Sixty-five F-1 engines were launched aboard thirteen Saturn Vs, and each first stage landed in the Atlantic ocean after about two and a half minutes of flight. Ten of these followed approximately the same flight azimuth of 72 degrees, but Apollo 15 and Apollo 17 followed significantly more southerly azimuths (80.088 degrees and 91.503 degrees, respectively). The Skylab launch vehicle flew at a more northerly azimuth to reach a higher inclination orbit (50 degrees versus the usual 32.5 degrees).[11]

Ten F-1 engines were installed on two Saturn Vs that never flew. The first stage from SA-514 is on display at the Johnson Space Center in Houston, Texas and the first stage from SA-515 is on display at the Michoud Assembly Facility in New Orleans, Louisiana.

On March 28, 2012, a team funded by Jeff Bezos, founder of Amazon.com, reported that they had located the F-1 rocket engines from an Apollo mission using sonar equipment.[12] Bezos stated he planned to raise at least one of the engines, which rest at a depth of 4,300 metres (14,000 ft), about 640 kilometres (400 mi) east of Cape Canaveral, Florida; however, the condition of the engines, which have been submerged for more than 40 years, was unknown.[13] NASA Administrator Charles Bolden released a statement congratulating Bezos and his team for their find and wished them success. He also affirmed NASA's position that any recovered artifacts would remain property of the agency, but that they would likely be offered to the Smithsonian Institution and other museums, depending on the number recovered.[14] On March 20, 2013, Bezos announced he had succeeded in bringing parts of an F-1 engine to the surface, and released photographs. Bezos noted, "Many of the original serial numbers are missing or partially missing, which is going to make mission identification difficult. We might see more during restoration." [15]

The recovered parts are currently at the Kansas Cosmosphere and Space Center in Hutchinson, Kansas for the process of conservation.[16]

On July 19, 2013, Bezos revealed that the serial number of the recovered engine is Rocketdyne serial number 2044 (equating to NASA number 6044), the #5 (center) engine that helped Neil Armstrong, Buzz Aldrin and Michael Collins to reach the Moon with the Apollo 11 mission.[16]

F-1B booster for the Space Launch System

In 2012, PWR proposed using a derivative of the F-1 engine in NASA's Advanced Booster Competition for the Space Launch System(SLS), a competition which is anticipated to end in 2015, with the selection of a winning booster configuration.[17][18] In 2013, engineers at the Marshall Space Flight Center began tests with an original F-1, serial number F-6049, an engine which was removed from Apollo 11 due to a glitch and never used; for many years it was at the Smithsonian Institute. The tests are designed to refamiliarize NASA with the design and propellants in light of interest in using an evolved version of the F-1 in future deep space flight applications.[19]

Pratt and Whitney, Rocketdyne and Dynetics, Inc. have presented a competitor to the 5 segment Space Shuttle Solid Rocket Booster intended for the Space Launch System, using two increased thrust and heavily modified F-1B engines. In 2012 it was noted that, due to the engines potential advantage in terms of specific impulse(a unit analogous to car fuel efficiency), if this F-1B configuration was integrated in the SLS Block II, the overall vehicle would have a payload lift capability of 150 metric tons to low earth orbit, 20 metric tons higher than what is achievable with the currently planned solid boosters.[20]

In 2013, it was reported that the F-1B engine in development has the design goal of being at least as powerful as the un-flight tested F-1A, while also being more cost effective; incorporating a greatly simplified combustion chamber, and a reduced number of engine parts, including the removal of the previously mentioned F-1 exhaust recycling system, that is, the removal of the turbopump exhaust mid-nozzle, "curtain" cooling manifold. The resulting F-1B configuration is intended to result in each engine producing 8.0 MN (1,800,000 lbf) of thrust at sea level, an increase over the approximate 6.9 MN (1,550,000 lbf) of thrust that the mature Apollo 15 F-1 engines produced.[17]

See also

References

- Notes

- ^ W. David Woods, How Apollo Flew to the Moon, Springer, 2008, ISBN 978-0-387-71675-6, p. 19

- ^ RD-170 Rocket Engine, Aerospaceguide.net

- ^ NASA Rocketdyne document

- ^ Ellison, Renea; Moser, Marlow, Combustion Instability Analysis and the Effects of Drop Size on Acoustic Driving Rocket Flow (PDF), Huntsville, Alabama: Propulsion Research Center, University of Alabama in Huntsville

- ^ a b c Saturn V News Reference: F-1 Engine Fact Sheet (PDF), National Aeronautics and Space Administration, December 1968, pp. 3–3, 3–4, retrieved 2008-06-01

- ^ NSTS 1988 News Reference Manual, NASA, retrieved 2008-07-03

- ^ F-1 Engine (chart), NASA Marshall Space Flight Center, MSFC-9801771, retrieved 2008-06-01

- ^ a b Hutchinson, Lee (2013-04-14). "New F-1B rocket engine upgrades Apollo-era design with 1.8M lbs of thrust". ARS technica. Retrieved 2013-04-15.

- ^ The Use of Trichloroethylene at NASA’s SSFL Sites

- ^ a b F-1 Rocket Engine Operating Instructions

- ^ Orloff, Richard (September 2004). NASA, Apollo By the Numbers, "Earth Orbit Data"

- ^ Kluger, Jeffrey (April 29, 2012). "Has Bezos Really Found the Apollo 11 Engines?". Time.com. Archived from the original on May 3, 2012.

{{cite news}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help) - ^ Clark, Stephen (April 29, 2012). "NASA sees no problem recovering Apollo engines". Spaceflight Now. Archived from the original on May 3, 2012.

{{cite news}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help) - ^ Weaver, David (April 30, 2012). "NASA Administrator Supports Apollo Engine Recovery". NASA.gov. Release 12-102. Archived from the original on May 3, 2012.

{{cite news}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help) - ^ Walker, Brian (March 20, 2013). "Apollo Mission Rocket Engines Recovered", CNN Light Years blog

- ^ a b Updates: 19 July 2013, Bezos Expeditions, 19 July 2013, accessed 21 July 2013

- ^ a b Lee Hutchinson (2013-04-15). "New F-1B rocket engine upgrades Apollo-era design with 1.8M lbs of thrust". Ars Technica. Retrieved 2013-04-15.

- ^ "Rocket companies hope to repurpose Saturn 5 engines".

- ^ Jay Reeves (2013-01-24). "NASA testing vintage engine from Apollo 11 rocket". Associated Press. Retrieved 2013-01-24.

- ^ http://www.nasaspaceflight.com/2012/11/dynetics-pwr-liquidize-sls-booster-competition-f-1-power/

- Bibliography

- Apollo 15 Press Kit

- Saturn V Launch Vehicle, Flight Evaluation Report, AS-510, MPR-SAT-FE-71-2, October 28, 1971.

External links

- E-1 at the Encyclopedia Astronautica

- F-1 at the Encyclopedia Astronautica

- F-1A at the Encyclopedia Astronautica

- NASA SP-4206 Stages to Saturn - the official NASA history of the Saturn launch vehicle

- F-1 Engine Operating Instructions (310MB)

- The Saturn V F-1 Engine: Powering Apollo into History at Springer.com

- Remembering The Giants: Apollo Rocket Propulsion Development, 2009, John C. Stennis Space Center. Monograph in Aerospace History No. 45 NASA

- How NASA brought the monstrous F-1 “moon rocket” engine back to life

- New F-1B rocket engine upgrades Apollo-era design with 1.8M lbs of thrust