Railway air brake: Difference between revisions

No edit summary |

|||

| Line 38: | Line 38: | ||

Unlike the straight air system, the Westinghouse system uses a ''reduction'' in air pressure in the train line to apply the brakes. When the engine operator applies the brake by operating the locomotive brake valve, the train line vents to atmosphere at a controlled rate, reducing the train line pressure and in turn triggering the triple valve on each car to feed air into its brake cylinder. When the engine operator releases the brake, the locomotive brake valve portal to atmosphere is closed, allowing the train line to be recharged by the compressor of the locomotive. The subsequent increase of train line pressure causes the triple valves on each car to discharge the contents of the brake cylinder to the atmosphere, releasing the brakes and recharging the reservoirs. |

Unlike the straight air system, the Westinghouse system uses a ''reduction'' in air pressure in the train line to apply the brakes. When the engine operator applies the brake by operating the locomotive brake valve, the train line vents to atmosphere at a controlled rate, reducing the train line pressure and in turn triggering the triple valve on each car to feed air into its brake cylinder. When the engine operator releases the brake, the locomotive brake valve portal to atmosphere is closed, allowing the train line to be recharged by the compressor of the locomotive. The subsequent increase of train line pressure causes the triple valves on each car to discharge the contents of the brake cylinder to the atmosphere, releasing the brakes and recharging the reservoirs. |

||

Under the Westinghouse system, therefore, brakes are applied by reducing train line pressure and released by increasing train line pressure. The Westinghouse system is thus [[fail safe]]—any failure in the train line, including a separation ("break-in-two") of the train, will cause a loss of train line pressure, causing the brakes to be applied and bringing the train to a stop, thus preventing a runaway train. |

Under the Westinghouse system, therefore, brakes are applied by reducing train line pressure and released by increasing train line pressure. The Westinghouse system is thus [[fail safe]]—any failure in the train line, including a separation ("break-in-two") of the train, will cause a loss of train line pressure, causing the brakes to be applied and bringing the train to a stop, thus preventing a runaway train. |

||

This system lets the break be activated from any car by venting the train line into the atmosphere to lower the pressure and activate the brakes. |

|||

===Modern systems=== |

===Modern systems=== |

||

Revision as of 13:03, 21 August 2015

This article includes a list of general references, but it lacks sufficient corresponding inline citations. (July 2013) |

A railway air brake is a railway brake power braking system with compressed air as the operating medium.[1] Modern trains rely upon a fail-safe air brake system that is based upon a design patented by George Westinghouse on March 5, 1868. The Westinghouse Air Brake Company (WABCO) was subsequently organized to manufacture and sell Westinghouse's invention. In various forms, it has been nearly universally adopted.

The Westinghouse system uses air pressure to charge air reservoirs (tanks) on each car. Full air pressure signals each car to release the brakes. A reduction or loss of air pressure signals each car to apply its brakes, using the compressed air in its reservoirs.[2]

Overview

Straight air brake

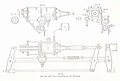

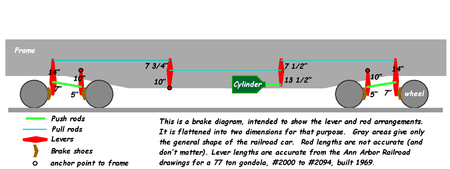

In the air brake's simplest form, called the straight air system, compressed air pushes on a piston in a cylinder. The piston is connected through mechanical linkage to brake shoes that can rub on the train wheels, using the resulting friction to slow the train. The mechanical linkage can become quite elaborate, as it evenly distributes force from one pressurized air cylinder to 8 or 12 wheels.

The pressurized air comes from an air compressor in the locomotive and is sent from car to car by a train line made up of pipes beneath each car and hoses between cars. The principal problem with the straight air braking system is that any separation between hoses and pipes causes loss of air pressure and hence the loss of the force applying the brakes. This could easily cause a runaway train. Straight air brakes are still used on locomotives, although as a dual circuit system, usually with each bogie (truck) having its own circuit.

Westinghouse air brake

In order to design a system without the shortcomings of the straight air system, Westinghouse invented a system wherein each piece of railroad rolling stock was equipped with an air reservoir and a triple valve, also known as a control valve.[3]

The triple valve is described as being so named as it performs three functions: Charging air into an air tank ready to be used, applying the brakes, and releasing them. In so doing, it supports certain other actions (i.e. it 'holds' or maintains the application and it permits the exhaust of brake cylinder pressure and the recharging of the reservoir during the release). In his patent application, Westinghouse refers to his 'triple-valve device' because of the three component valvular parts comprising it: the diaphragm-operated poppet valve feeding reservoir air to the brake cylinder, the reservoir charging valve, and the brake cylinder release valve. When he soon improved the device by removing the poppet valve action, these three components became the piston valve, the slide valve, and the graduating valve.

- If the pressure in the train line is lower than that of the reservoir, the brake cylinder exhaust portal is closed and air from the car's reservoir is fed into the brake cylinder to apply the brakes. This action continues until equilibrium between the brake pipe pressure and reservoir pressure is achieved. At that point, the airflow from the reservoir to the brake cylinder is lapped off and the cylinder is maintained at a constant pressure.

- If the pressure in the train line is higher than that of the reservoir, the triple valve connects the train line to the reservoir feed, causing the air pressure in the reservoir to increase. The triple valve also causes the brake cylinder to be exhausted to the atmosphere, releasing the brakes.

- As the pressure in the train line and that of the reservoir equalize, the triple valve closes, causing the air pressure in the reservoir and brake cylinder to be maintained at the current level.

Unlike the straight air system, the Westinghouse system uses a reduction in air pressure in the train line to apply the brakes. When the engine operator applies the brake by operating the locomotive brake valve, the train line vents to atmosphere at a controlled rate, reducing the train line pressure and in turn triggering the triple valve on each car to feed air into its brake cylinder. When the engine operator releases the brake, the locomotive brake valve portal to atmosphere is closed, allowing the train line to be recharged by the compressor of the locomotive. The subsequent increase of train line pressure causes the triple valves on each car to discharge the contents of the brake cylinder to the atmosphere, releasing the brakes and recharging the reservoirs.

Under the Westinghouse system, therefore, brakes are applied by reducing train line pressure and released by increasing train line pressure. The Westinghouse system is thus fail safe—any failure in the train line, including a separation ("break-in-two") of the train, will cause a loss of train line pressure, causing the brakes to be applied and bringing the train to a stop, thus preventing a runaway train.

This system lets the break be activated from any car by venting the train line into the atmosphere to lower the pressure and activate the brakes.

Modern systems

Modern air brake systems serve two functions:

- The service brake system, which applies and releases the brakes during normal operations, and

- The emergency brake system, which applies the brakes rapidly in the event of a brake pipe failure or an emergency application by the engine operator (generally referred to as the automatic brake).

When the train brakes are applied during normal operations, the engine operator makes a "service application" or a "service rate reduction”, which means that the train line pressure reduces at a controlled rate. It takes several seconds for the train line pressure to reduce and consequently takes several seconds for the brakes to apply throughout the train. In the event the train needs to make an emergency stop, the engine operator can make an "emergency application," which immediately and rapidly vents all of the train line pressure to atmosphere, resulting in a rapid application of the train's brakes. An emergency application also results when the train line comes apart or otherwise fails, as all air will also be immediately vented to atmosphere.

In addition, an emergency application brings in an additional component of each car's air brake system: the emergency portion. The triple valve is divided into two portions: the service portion, which contains the mechanism used during brake applications made during service reductions, and the emergency portion, which senses the immediate, rapid release of train line pressure. In addition, each car's air brake reservoir is divided into two portions—the service portion and the emergency portion—and is known as the "dual-compartment reservoir”. Normal service applications transfer air pressure from the service portion to the brake cylinder, while emergency applications cause the triple valve to direct all air in both the service portion and the emergency portion of the dual-compartment reservoir to the brake cylinder, resulting in a 20–30% stronger application.

The emergency portion of each triple valve is activated by the extremely rapid rate of reduction of train line pressure. Due to the length of trains and the small diameter of the train line, the rate of reduction is high near the front of the train (in the case of an engine operator-initiated emergency application) or near the break in the train line (in the case of the train line coming apart). Farther away from the source of the emergency application, the rate of reduction can be reduced to the point where triple valves will not detect the application as an emergency reduction. To prevent this, each triple valve's emergency portion contains an auxiliary vent port, which, when activated by an emergency application, also locally vents the train line's pressure directly to atmosphere. This serves to propagate the emergency application rapidly along the entire length of the train.

Use of distributed power (i.e., remotely controlled locomotive units mid-train and/or at the rear end) mitigates somewhat the time-lag problem with long trains, because a telemetered radio signal from the engine operator in the front locomotive commands the distant units to initiate brake pressure reductions that propagate quickly through nearby cars.

Working pressures

The compressor on the locomotive charges the main reservoir with air at 125–140 psi (8.6–9.7 bar; 860–970 kPa). The train brakes are released by admitting air to the train pipe through the engineer's brake valve. A fully charged brake pipe is typically 70–90 psi (4.8–6.2 bar; 480–620 kPa) for freight trains and 110 psi (7.6 bar; 760 kPa) for passenger trains. The brakes are applied when the engineer moves the brake handle to the "service" position, which causes a reduction in pressure in the train pipe. In normal braking, the pressure in the train pipe does not reduce to zero. If it does fall to zero, (e.g., because of a broken brake hose) an emergency brake application will be made.[5]

Enhancements

Electro-pneumatic or EP brakes are a type of air brake that allows for immediate application of brakes throughout the train instead of the sequential application. EP brakes have been in British practice since 1949 and also used in German high-speed trains (most notably the ICE) since the late 1980s, they are fully described in Electro-pneumatic brake system on British railway trains. Electro-pneumatic brakes are currently in testing in North America and South Africa in captive service ore and coal trains.

Passenger trains have had for a long time a 3-wire version of the electro-pneumatic brake, which gives seven levels of braking force. In most cases the system is not fail-safe, with the wires being energized in sequence to apply the brakes, but the conventional automatic air brake is also provided to act as a fail safe, and in most cases can be used independently in the event of a failure of the EP brakes.

In North America, WABCO supplied HSC (High Speed Control) brake equipment for several post-World War II streamlined passenger trains. This was an electrically controlled overlay on conventional D-22 passenger and 24-RL locomotive brake equipment. On the conventional side, the control valve set a reference pressure in a volume, which set brake cylinder pressure via a relay valve. On the electric side, pressure from a second straight-air trainline controlled the relay valve via a two-way check valve. This "straight air" trainline was charged (from reservoirs on each car) and released by magnet valves on each car, controlled electrically by a 3 wire trainline, in turn controlled by an "electro-pneumatic master controller" in the controlling locomotive. This controller compared the pressure in the straight air trainline with that supplied by a self lapping portion of the engineers valve, signaling all of the "apply" or "release" magnets valves in the train to open simultaneously, changing the pressure in the "straight air" trainline much more rapidly and evenly than possible by simply supplying air directly from the locomotive. The relay valve was equipped with four diaphragms, magnet valves, electric control equipment, and an axle-mounted speed sensor, so that at speeds over 60 mph (97 km/h) full braking force was applied, and reduced in steps at 60 mph (97 km/h) 40 and 20 mph (64 and 32 km/h), bringing the train to a gentle stop. Each axle was also equipped with anti-lock brake equipment. The combination minimized braking distances, allowing more full-speed running between stops. The "straight air" (electro-pneumatic trainline), anti-lock, and speed graduating portions of the system were not dependent on each other in any way, and any or all of these options could be supplied separately.[6]

Later systems replace the automatic air brake with an electrical wire (in the UK, at least, known as a "round the train wire") that has to be kept energized to keep the brakes off.

More recent innovations are electronically controlled pneumatic brakes where the brakes of all the wagons (cars) and locomotives are connected by a kind of local area network, which allows individual control of the brakes on each wagon, and the reporting back of performance of each wagon's brakes.

Limitations

The Westinghouse air brake system is very trustworthy, but not infallible. Recall that the car reservoirs recharge only when the brake pipe pressure is higher than the reservoir pressure, and that the car reservoir pressure will rise only to the point of equilibrium. Fully recharging the reservoirs on a long train can require considerable time (8 to 10 minutes in some cases[7]), during which the brake pipe pressure will be lower than locomotive reservoir pressure.

If the brakes must be applied before recharging has been completed, a larger brake pipe reduction will be required in order to achieve the desired amount of braking effort, as the system is starting out at a lower point of equilibrium (lower overall pressure). If many brake pipe reductions are made in short succession ("fanning the brake" in railroad slang), a point may be reached where car reservoir pressure will be severely depleted, resulting in substantially reduced brake cylinder piston force, causing the brakes to fail. On a descending grade, the unfortunate result will be a runaway.

In the event of a loss of braking due to reservoir depletion, the engine driver may be able to regain control with an emergency brake application, as the emergency portion of each car's dual-compartment reservoir should be fully charged—it is not affected by normal service reductions. The triple valves detect an emergency reduction based on the rate of brake pipe pressure reduction. Therefore, as long as a sufficient volume of air can be rapidly vented from the brake pipe, each car's triple valve will cause an emergency brake application. However, if the brake pipe pressure is too low due to an excessive number of brake applications, an emergency application will not produce a large enough volume of air flow to trip the triple valves, leaving the engine driver with no means to stop the train.

Solutions

Dynamic brake

To prevent a runaway due to loss of brake pressure, dynamic (rheostatic) braking can be utilized so the locomotive(s) will assist in retarding the train. Often, blended braking, the simultaneous application of dynamic and train brakes, will be used to maintain a safe speed and keep the slack bunched on descending grades. Care would then be given when releasing the service and dynamic brakes to prevent draw-gear damage caused by a sudden run out of the train's slack.

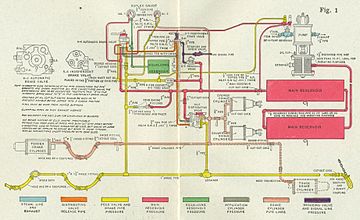

Two-pipe air brake

Another solution to loss of brake pressure is the two-pipe system, fitted on most modern passenger stock and many freight wagons. In addition to the traditional brake pipe, this enhancement adds the main reservoir pipe, which is continuously charged with air directly from the locomotive's main reservoir. The main reservoir is where the locomotive's air compressor output is stored, and is ultimately the source of compressed air for all systems that use it.

Since the main reservoir pipe is kept constantly pressurized by the locomotive, the car reservoirs can be charged independently of the brake pipe, this being accomplished via a check valve to prevent backfeeding into the pipe. This arrangement helps to reduce the above described pressure loss problems, and also reduces the time required for the brakes to release, since the brake pipe only has to recharge itself.

Main reservoir pipe pressure can also be used to supply air for auxiliary systems such as pneumatic door operators or air suspension. Nearly all passenger trains (all in the UK and USA), and many freights, now have the two-pipe system.

Accidents

The air brake can fail if one of the cocks where the pipes of each carriage are joined together is accidentally closed. In this case, the brakes on the wagons behind the closed cock will fail to respond to the driver's command. This happened in the 1953 Pennsylvania Railroad train wreck to the Federal Express, a Pennsylvania Railroad train which became runaway while heading into Washington DC's Union Station, causing the train to crash into the passenger concourse and fall through the floor. Similarly, in the Gare de Lyon train accident, a valve was accidentally closed by the crew, reducing braking power.

There are a number of safeguards that are usually taken to prevent this sort of accident happening. Railroads have strict government-approved procedures for testing the air brake systems when making up trains in a yard or picking up cars en route. These generally involve connecting the air brake hoses, charging up the brake system, setting the brakes and manually inspecting the cars to ensure the brakes are applied, and then releasing the brakes and manually inspecting the cars to ensure the brakes are released. Particular attention is usually paid to the rearmost car of the train, either by manual inspection or via an automated end-of-train device, to ensure that brake pipe continuity exists throughout the entire train. When brake pipe continuity exists throughout the train, failure of the brakes to apply or release on one or more cars is an indication that the cars' triple valves are malfunctioning. Depending on the location of the air test, the repair facilities available, and regulations governing the number of inoperative brakes permitted in a train, the car may be set out for repair or taken to the next terminal where it can be repaired.

Standardisation

The modern air brake is not identical with the original airbrake as there have been slight changes in the design of the triple valve, which are not completely compatible between versions, and which must therefore be introduced in phases. However, the basic air brakes used on railways worldwide are remarkably compatible.

European systems

European railway air brakes include the Kunze-Knorr brake (invented by Georg Knorr and manufactured by Knorr-Bremse)[8] and the Oerlikon. The working principle is the same as for the Westinghouse air brake. In the steam era, Britain's railways were divided - some using vacuum brakes and some using air brakes - but there was a gradual standardization on the vacuum brake. Some locomotives, e.g. on the London, Brighton and South Coast Railway, were dual-fitted so that they could work with either vacuum or air braked trains. In the diesel era, the process was reversed and British Railways switched from vacuum braked to air braked rolling stock in the 1960s.[9]

-

Kunze-Knorr goods train brake (diagram)

-

Oerlikon brake valve

-

ČD brake controller and brake valve (Czech Republic)

-

London, Brighton and South Coast Railway locomotive. Note the three pipes, one for vacuum brake, one for air brake and one for steam heat

Vacuum brakes

The main competitor to the air brake is the vacuum brake, which operates on negative pressure. The vacuum brake is a little simpler than the air brake, with an ejector with no moving parts on steam engines or a mechanical or electrical "exhauster" on a diesel or electric locomotive replacing the air compressor. Disconnection taps at the ends of cars are not required as the loose hoses are sucked onto a mounting block.

However, the maximum pressure is limited to atmospheric pressure, so that all the equipment has to be much larger and heavier to compensate. This disadvantage is made worse at high altitude. The vacuum brake is also considerably slower acting in both applying and releasing the brake; this requires a greater level of skill and anticipation from the driver. Conversely, the vacuum brake had the advantage of gradual release long before the Westinghouse automatic air brake, which was originally only available in the direct-release form still common in freight service. A primary fault of vacuum brakes is the inability to easily find leaks. In a positive air system, a leak is quickly found due to the escaping pressurized air; discovering a vacuum leak is more difficult, although it is easier to repair when found because a piece of rubber (for example) can just be tied around the leak and will be firmly held there by the vacuum.

Electro-vacuum brakes have also been used with considerable success on South African electric multiple unit trains. Despite requiring larger and heavier equipment as stated above, the performance of the electro-vacuum brake approached that of contemporary electro-pneumatic brakes. However, their use has not been repeated.

See also

References

- ^ Wood, W.W. (1920) [first published 1909]. Wood's Westinghouse E-T Air Brake Instruction Pocket Book (second ed.). New York: The Norman W. Henley Publishing Co.

- ^ "SDRM Train Air Brake Description and History". Sdrm.org. Retrieved 2013-07-14.

- ^ The new Westinghouse brakes were explained to the railroad workers in many books. See, for example, A Textbook on the Westinghouse Air Brake (Scranton: International Textbook School, 1900).

- ^ "Welcome to Saskrailmuseum.org". Contact Us. September 11, 2008. Retrieved 2008-10-03.

{{cite web}}: Cite has empty unknown parameter:|coauthors=(help) - ^ "The Automatic Air Brake". Sdrm.org. Retrieved 2013-07-14.

- ^ Westinghouse 24RL air brake manual

- ^ EMD Enginemen's Operating Manual

- ^ "Knorr-Bremse - 100 years of experience in braking technology". Knorr-bremse.ch. Retrieved 2013-07-14.

- ^ Mike Smith. "British Railway Air braked wagon development". Myweb.tiscali.co.uk. Retrieved 2013-07-14.

- Air Brake and Train Handling Manual. Copyright 2006 Alaska Railroad Corporation

- Air Brake and Train Handling Manual. Copyright 2003 BNSF Railway Company

- AAR wheel dynamometer - braking: [1]

- Compressed Air Operations manual, ISBN 0-07-147526-5, McGraw Hill Book Company

External links

Information

- Railway-Technical: Air Brakes

- George Westinghouse Air Brake Patents and inventions

- How Your Train Stops, by Bill Reiche 1951 article with illustration that deals with the basics in way a layman would understand

Patents