Heat pump

A heat pump is a machine or device that moves heat from one location (the 'source') to another location (the 'sink' or 'heat sink') using work. Most heat pump technology moves heat from a low temperature heat source to a higher temperature heat sink.[1] Common examples are food refrigerators and freezers, air conditioners, and reversible-cycle heat pumps for providing thermal comfort. Heat pumps can also operate in reverse, producing heat. This produces an efficient way of drying, and manufacturers such as AEG and Miele have released tumble dryers that utilise this method. It is claimed to be more energy saving and quicker than conventional drying.

Heat pumps can be thought of as a heat engine which is operating in reverse. One common type of heat pump works by exploiting the physical properties of an evaporating and condensing fluid known as a refrigerant. In heating, ventilation, and cooling (HVAC) applications, a heat pump normally refers to a vapor-compression refrigeration device that includes a reversing valve and optimized heat exchangers so that the direction of heat flow may be reversed. Most commonly, heat pumps draw heat from the air or from the ground. Air-source heat pumps with a coefficient of performance (COP) 3 are developed in Japan at −20 °C.

Operation

According to the second law of thermodynamics heat cannot spontaneously flow from a colder location to a hotter area; work is required to achieve this.[2] Heat pumps differ in how they apply this work to move heat, but they can essentially be thought of as heat engines operating in reverse. A heat engine allows energy to flow from a hot 'source' to a cold heat 'sink', extracting a fraction of it as work in the process. Conversely, a heat pump requires work to move thermal energy from a cold source to a warmer heat sink.

Since the heat pump uses a certain amount of work to move the heat, the amount of energy deposited at the hot side is greater than the energy taken from the cold side by an amount equal to the work required. Conversely, for a heat engine, the amount of energy taken from the hot side is greater than the amount of energy deposited in the cold heat sink since some of the heat has been converted to work.

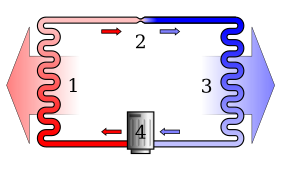

One common type of heat pump works by exploiting the physical properties of an evaporating and condensing fluid known as a refrigerant.

The working fluid, in its gaseous state, is pressurized and circulated through the system by a compressor. On the discharge side of the compressor, the now hot and highly pressurized gas is cooled in a heat exchanger, called a condenser, until it condenses into a high pressure, moderate temperature liquid. The condensed refrigerant then passes through a pressure-lowering device like an expansion valve, capillary tube, or possibly a work-extracting device such as a turbine. This device then passes the low pressure, (almost) liquid refrigerant to another heat exchanger, the evaporator where the refrigerant evaporates into a gas via heat absorption. The refrigerant then returns to the compressor and the cycle is repeated.

In such a system it is essential that the refrigerant reaches a sufficiently high temperature when compressed, since the second law of thermodynamics prevents heat from flowing from a cold fluid to a hot heat sink. Similarly, the fluid must reach a sufficiently low temperature when allowed to expand, or heat cannot flow from the cold region into the fluid. In particular, the pressure difference must be great enough for the fluid to condense at the hot side and still evaporate in the lower pressure region at the cold side. The greater the temperature difference, the greater the required pressure difference, and consequently more energy is needed to compress the fluid. Thus as with all heat pumps, the energy efficiency (amount of heat moved per unit of input work required) decreases with increasing temperature difference.

Due to the variations required in temperatures and pressures, many different refrigerants are available. Refrigerators, air conditioners, and some heating systems are common applications that use this technology.

In HVAC applications, a heat pump normally refers to a vapor-compression refrigeration device that includes a reversing valve and optimized heat exchangers so that the direction of heat flow may be reversed. The reversing valve switches the direction of refrigerant through the cycle and therefore the heat pump may deliver either heating or cooling to a building. In the cooler climates the default setting of the reversing valve is heating. The default setting in warmer climates is cooling. Because the two heat exchangers, the condenser and evaporator, must swap functions, they are optimized to perform adequately in both modes. As such, the efficiency of a reversible heat pump is typically slightly less than two separately-optimized machines.

In plumbing applications, a heat pump is sometimes used to heat or preheat water for swimming pools or domestic water heaters.

In somewhat rare applications, both the heat extraction and addition capabilities of a single heat pump can be useful, and typically results in very effective use of the input energy. For example, when an air cooling need can be matched to a water heating load, a single heat pump can serve two useful purposes. Unfortunately, these situations are rare because the demand profiles for heating and cooling are often significantly different.

Refrigerants

Until the 1990s, the refrigerants were often chlorofluorocarbons such as R-12 (dichlorodifluoromethane), one in a class of several refrigerants using the brand name Freon, a trademark of DuPont. Its manufacture was discontinued in 1995 because of the damage that CFCs cause to the ozone layer if released into the atmosphere. One widely-adopted replacement refrigerant is the hydrofluorocarbon (HFC) known as R-134a (1,1,1,2-tetrafluoroethane). R-134a is not as efficient as the R-12 it replaced (in automotive applications) and therefore, more energy is required to operate systems utilizing R-134a than those using R-12. Other substances such as liquid ammonia, or occasionally the less corrosive but flammable propane or butane, can also be used.

Since 2001, carbon dioxide, R-744, has increasingly been used, utilizing the transcritical cycle. In residential and commercial applications, the hydrochlorofluorocarbon (HCFC) R-22 is still widely used, however, HFC R-410a does not deplete the ozone layer and is being used more frequently. Hydrogen, helium, nitrogen, or plain air is used in the Stirling cycle, providing the maximum number of options in environmentally friendly gases. More newer refrigerators are now exploiting the R600A which is isobutane, and does not deplete the ozone and is friendly to the environment.

Efficiency

When comparing the performance of heat pumps, it is best to avoid the word "efficiency" which has a very specific thermodynamic definition. The term coefficient of performance (COP) is used to describe the ratio of useful heat movement to work input. Most vapor-compression heat pumps utilize electrically powered motors for their work input. However, in most vehicle applications shaft work, via their internal combustion engines, provide the needed work.

When used for heating a building on a mild day, a typical air-source heat pump has a COP of 3 - 4, whereas a typical electric resistance heater has a COP of 1.0. That is, one joule of electrical energy will cause a resistance heater to produce one joule of useful heat, while under ideal conditions, one joule of electrical energy can cause a heat pump to move much more than one joule of heat from a cooler place to a warmer place. Sometimes this is inappropriately expressed as an efficiency value greater than 100%, as in the statement, "XYZ brand heat pumps operate at up to 400% efficiency!" This is inaccurate, since the work does not make heat, but instead moves existing heat "upstream"; if the claim were true, this would be a perpetual-motion machine. The effective heating per watt of electric energy used can be up to 450% as much as resistance heating however, making this more an issue of semantics than science.

Note that when there is a wide temperature differential, e.g., when an air-source heat pump is used to heat a house on a very cold winter day, it takes more work to move the same amount of heat indoors than on a mild day. Ultimately, due to Carnot efficiency limits, the heat pump's performance will approach 1.0 as the outdoor-to-indoor temperature difference increases. This typically occurs around −18 °C (0 °F) outdoor temperature for air source heat pumps. Also, as the heat pump takes heat out of the air, some moisture in the outdoor air may condense and possibly freeze on the outdoor heat exchanger. The system must periodically melt this ice. In other words, when it is extremely cold outside, it is simpler, and wears the machine less, to heat using an electric-resistance heater than to strain an air-source heat pump. (Geothermal heat pumps are dependent upon the temperature underground, which is "mild" all year round. Their COP is therefore always in the range of 3.5-4.0).

In cooling mode a heat pump's operating performance is described as its energy efficiency ratio (EER) or seasonal energy efficiency ratio (SEER), and both measures have units of BTU/(h·W). A larger EER number indicates better performance. The manufacturer's literature should provide both a COP to describe performance in heating mode and an EER or SEER to describe performance in cooling mode. Actual performance varies, however, and depends on many factors such as installation, temperature differences, site elevation, and maintenance.

Heat pumps are more effective for heating than for cooling if the temperature difference is held equal. This is because the compressor's input energy is largely converted to useful heat when in heating mode, and is discharged along with the moved heat via the condenser. But for cooling, the condenser is normally outdoors, and the compressor's dissipated work is rejected rather than put to a useful purpose.

For the same reason, opening a food refrigerator or freezer heats up the kitchen rather than cooling it because its refrigeration cycle rejects heat to the indoor air. This heat includes the compressor's dissipated work as well as the heat removed from the inside of the appliance.

The COP for a heat pump in a heating or cooling application, with steady-state operation, is:

where

- is the amount of heat extracted from a cold reservoir at temperature ,

- is the amount of heat delivered to a hot reservoir at temperature ,

- is the compressor's dissipated work.

CoP and Lift

The CoP increases as the temperature difference, or "Lift", decreases between heat source and destination. The CoP can be maximised at design time by choosing a heating system requiring only a low final water temperature (e.g. underfloor heating), and by chosing a heat source with a high average temperature (e.g. the ground). Domestic Hot Water (DHW) and radiators require high water temperatures, affecting the choice of heat pump technology.

| Pump type and source | Typical use case | CoP variation with Output Temperature | |||||

|---|---|---|---|---|---|---|---|

| 35°C (e.g. heated screed floor) |

45°C (e.g. heated screed floor) |

55°C (e.g. heated timber floor) |

65°C (e.g. radiator or DHW) |

75°C (e.g. radiator & DHW) |

85°C (e.g. radiator & DHW) | ||

| High Efficiency ASHP air at -20°C[3] | 2.2 | 2.0 | - | - | - | - | |

| Two Stage ASHP air at -20°C[4] | Low source temp. | 2.4 | 2.2 | 1.9 | - | - | - |

| High Efficiency ASHP air at 0°C[3] | Low output temp. | 3.8 | 2.8 | 2.2 | 2.0 | - | - |

| Prototype Transcritical CO 2 (R744) Heat Pump with Tripartite Gas Cooler, source at 0°C[5] |

High output temp. | 3.3 | - | - | 4.2 | - | 3.0 |

| GSHP water at 0°C[3] | 5.0 | 3.7 | 2.9 | 2.4 | - | - | |

| GSHP ground at 10°C[3] | Low output temp. | 7.2 | 5.0 | 3.7 | 2.9 | 2.4 | - |

| Theoretical Carnot cycle limit, source -20°C | 5.6 | 4.9 | 4.4 | 4.0 | 3.7 | 3.4 | |

| Theoretical Carnot cycle limit, source 0°C | 8.8 | 7.1 | 6.0 | 5.2 | 4.6 | 4.2 | |

| Theoretical Lorentz Cycle limit (CO 2 pump), return fluid 25°C, source 0°C[5] |

10.1 | 8.8 | 7.9 | 7.1 | 6.5 | 6.1 | |

| Theoretical Carnot cycle limit, source 10°C | 12.3 | 9.1 | 7.3 | 6.1 | 5.4 | 4.8 | |

Heat sources

Most commonly, heat pumps draw heat from the air (outside or inside air) or from the ground (groundwater or soil) [6]. The heat drawn from the ground is in most cases stored solar heat, and it should not be confused with geothermal heat, though the latter will contribute in some small measure to all heat in the ground. Other heat sources include water; nearby streams and other natural water bodies have been used, and sometimes domestic waste water which is often warmer than the ambient temperature.

Types of heat pumps

A number of sources have been used for the heat source for heating private and communal buildings [7]. The two main types of heat pumps are compression heat pumps and absorption heat pumps. Compression heat pumps always operate on mechanical energy (through electricity), while absorption heat pumps may also run on heat as an energy source (through electricity or burnable fuels). [8]

Air-source heat pumps

Air source heat pumps are relatively easy (and inexpensive) to install and have therefore historically been the most widely used heat pump type. However, they suffer limitations due to their use of the outside air as a heat source or sink. The higher temperature differential during periods of extreme cold or heat leads to a lower efficiency, as explained above. In mild weather, COP may be around 3.5, while at temperatures below around −5°C (23°F) an air-source heat pump's COP will drop below 2. But Air-source heat pumps with a COP 3 are developed in Japan at −20 °C. The average COP over seasonal variation is typically 2.5-2.8,high efficiency model in Japan over 6.0(2.8kW).[9][10]

Geothermal heat pumps

Geothermal heat pumps typically have higher efficiencies than air-source heat pumps. This is because they draw heat from the ground or groundwater which is at a relatively constant temperature all year round below a depth of about eight feet (2.5 m). This means that the temperature differential is lower, leading to higher efficiency. Ground-source heat pumps typically have COPs of 3.5-4.0 with little seasonal variation. The tradeoff for this improved performance is that a ground-source heat pump is more expensive to install due to the need for the digging of wells or trenches in which to place the pipes that carry the heat exchange fluid. When compared versus each other, groundwater heat pumps are generally more efficient than heat pumps using heat from the soil.

Solid state heat pumps

In 1881, the German physicist Emil Warburg put a block of iron into a strong magnetic field and found that it increased very slightly in temperature. Some commercial ventures to implement this technology are underway, claiming to cut energy consumption by 40% compared to current domestic refrigerators.[11] The process works as follows: Powdered gadolinium is moved into a magnetic field, heating the material by 2 to 5 °C. The heat is removed by a circulating fluid. The material is then moved out of the magnetic field, reducing its temperature below its starting temperature.

History

This section needs expansion. You can help by adding to it. (June 2008) |

Milestones:

- 1834 – Jacob Perkins built refrigerator with diethyl ether;

- 1852 – Lord Kelvin built first heat pump.

References

- ^ The Systems and Equipment volume of the ASHRAE Handbook, ASHRAE, Inc., Atlanta, GA, 2004

- ^ Fundamentals of Engineering Thermodynamics, by Howell and Buckius, McGraw-Hill, New York, 1987

- ^ a b c d The Canadian Renewable Energy Network 'Commercial Earth Energy Systems', Figure 29. (URL accessed Mar 26, 2008)

- ^ Technical Institute of Physics and Chemistry, Chinese Academy of Sciences 'State of the Art of Air-source Heat Pump for Cold Region', Figure 5. (URL accessed Apr 19, 2008)

- ^ a b SINTEF Energy Research 'Integrated CO2 Heat Pump Systems for Space Heating and DHW in low-energy and passive houses', J. Steen, Table 3.1, Table 3.3. (URL accessed Apr 19, 2008)

- ^ Heat pumps sources including groundwater, soil, outside and inside air)

- ^ Homeowners using heat pump systems

- ^ Types of heat pumps (see page 8)

- ^ Carrier web site: Heat Pumps

- ^ Heat Pumps Long Awaited Way out of the Global Warming

- ^ Guardian Unlimited, December 2006 'A cool new idea from British scientists: the magnetic fridge'

See also

- Flash evaporation

- Geothermal heat pump

- Geothermal exchange heat pump

- Geothermal Systems

- Renewable heat

- Thermoelectric heat pumps that use the Peltier effect

- Vapor-compression refrigeration

- Vortex tube

- IEA-ECBCS Annex 48 : Heat Pumping and Reversible Air Conditioning

External links

- Heat Pumps Long Awaited Way out of the Global Warming - Information from Heat Pump & Thermal Storage Technology Center of Japan

- Practical information on setting up heat pump systems at home

- Pictures on private/communal heat pump installations

- International Energy Agency Heat Pump Programme, Information site for heat pumping technology

- (Dutch) Useful publication called ""Warmtepompen voor woningverwarming". Info on heat pump systems with drawings, schematics and explications of practically set-up systems).

- (Dutch) Useful publication called "Warmtepompen - De natuur als bron van verwarming". Info on heat pump systems with drawings, schematics and explications.

- Road Energy Systems: Heat from the Street Article on heat pump systems installed in roads and parking lots. Allianz Knowledge, June 2008

- Heating and Cooling with a Heat pump - Information from the Canadian Government's Natural Resources Department, Office of Energy Efficiency