Air source heat pump

This article is written like a personal reflection, personal essay, or argumentative essay that states a Wikipedia editor's personal feelings or presents an original argument about a topic. (August 2010) |

This article is written like a debate. (January 2011) |

An air source heat pump uses outside air as a heat source or heat sink. A compressor, condenser and refrigerant system is used to absorb heat at one place and release it at another.

General

Outside air, at any temperature above absolute zero, contains some heat. An air-source heat pump moves ("pumps") some of this heat to provide hot water or space heating. This can be done in either direction, to cool or heat the interior of a building.

The main components of an air-source heat pump are:

- a heat exchanger, over which outside air is blown, to extract the heat from the air

- a compressor, which acts like a refrigerator but in reverse and raises the temperature from the outside air

- a way to transfer the heat into a hot water tank or heating system, such as radiators or under-floor heating circuits

How air source heat pumps work

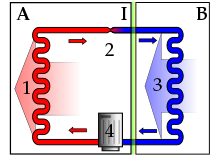

Heating and cooling is accomplished by moving a refrigerant through the heat pump's various indoor and outdoor coils and components. A compressor, condenser, expansion valve and evaporator are used to change states of the refrigerant from a liquid to hot gas and from a gas to a cold liquid. The refrigerant is used to heat or cool coils in a building or room and fans pull the room air over the coils. An external heat exchanger is used to heat or cool the refrigerant using ambient air. An air source heat pump works on the principles of vapor compression refrigeration.

When the liquid refrigerant at a low temperature passes through the outdoor evaporator coils, the temperature of the outside air causes the liquid to boil. This change of state from liquid to a vapor requires a considerable amount of energy or "latent heat" which is provided by outside air passing over the coils.

This vapor is then drawn into the compressor where the temperature of the vapor is boosted to well over 100 degrees Celsius. At this point we have used heat from the outside air to change the liquid refrigerant to a gas and added an amount of compression "work" to raise the temperature of the vapor. The vapor now enters the condenser heat exchanger coils where it begins to transfer heat to the air being drawn across the coils. As the vapor cools, it condenses back to a liquid and in doing so releases latent heat to the air passing over the condenser unit.

At this stage the very cold liquid refrigerant is under high pressure. The refrigerant is then passed through an expansion valve which releases the pressure, draws in heat and allows the refrigerant to re-enter the evaporator to begin a new cycle.

The heat pump can also operate in a cooling mode where the cold refrigerant is moved through the indoor coils to cool the room air.

Efficiency

The 'Efficiency' of air source heat pumps is measured by the Coefficient of performance (COP). A COP of 3 means the heat pump produces 3 units of heat energy for every 1 unit of electricity it consumes. In mild weather, the COP of an air source heat pump can be up to 4. However, on a very cold winter day, it takes more work to move the same amount of heat indoors than on a mild day. The heat pump's performance is limited by the Carnot cycle and will approach 1.0 as the outdoor-to-indoor temperature difference increases (around −18 °C / 0 °F) outdoor temperature for air source heat pumps). Within most normal temperature ranges of say -3°C to 10°C heat pump performance and thus the COP for many machines is fairly stable at 3-3.5. However, heat pump construction methods that enable use of carbon dioxide refrigerant extend the figure downward to -30 °C (-22 °F). A ground source heat pump has less change in COP as the ground temperature from which they extract heat is more constant than outdoor air temperature.

Seasonally adjusted heating and cooling efficiencies are given by the heating seasonal performance factor (HSPF) and seasonal energy efficiency ratio (SEER) respectively.

The specific design of a heat pump has a considerable impact on its efficiency. Many air source heat pumps began life as air conditioning units, designed for summer temperatures. In designing a heat pump as a heat pump from inception significant COPs and life cycles can be attained. The principal changes are in the scale and type of compressor and evaporator to allow COP]of greater than 2 even down to -20°C.

Advantages and disadvantages

Advantages

- Typically draws approximately 1/3 to 1/4 of the electricity of a standard resistance heater for the same amount of heating, reducing utility bills.[1] This typical efficiency compares to 70-95% for a fossil fuel-powered boiler[citation needed].

- Few moving parts, reducing maintenance requirements. However, it should be ensured that the outdoor heat exchanger and fan is kept free from leaves and debris. Moreover, it must be borne in mind that a heat pump will have significantly more moving parts than an equivalent electric resistance heater or fuel burning heater.

- As an electric system, no flammable or potentially asphyxiating fuel is used at the point of heating, reducing the potential danger to users, and removing the need to obtain gas or fuel supplies (except for electricity).

- May be used to heat air, or water.

- The same system may be used for air conditioning in summer, as well as a heating system in winter.

- Lower running costs, the compressor being the device that uses most power - when in comparison with traditional electrical resistance heaters.[citation needed].

- When correctly specified an ASHP can offer a full central heating solution. Some systems can also offer domestic hot water up to 80°C [2]. This can in theory be down to well below -10°C if the unit is large enough.

Disadvantages

The following disadvantages are associated with all air source heat pump designs:

- Air source heat pumps require electricity for operation. Electricity generation accounts for a significant amount of emissions pollutants and greenhouse gases.

- External space needs to be found for the outside condenser unit which can be somewhat noisy(comparable to an air conditioner unit) [citation needed] and possibly unsightly.

- The cost of installation is high (though less than a Ground Source heat pump because a ground source heat pump requires installation of a ground loop).

- The outdoor section on some units may "frost up" when outdoor temperatures are between 0°C and 5°C (between 32°F and 41°F respectively) and there is sufficient moisture in the air[citation needed] which causes restriction of air flow across the outdoor coil. These units employ a time/delay or demand defrost cycle where the system a) switches to "A/C" mode for up to 10 minutes or more to move heat from the home to the outdoor section to melt the ice and b) turns on the supplemental heater (resistance electric, gas, etc.) in the indoor section to temper the cold air being distributed. The defrost cycle reduces the efficiency of the heat pump significantly, although the newer (demand) systems are more intelligent and need to defrost less. As temperatures drop below freezing the tendency for frosting of the outdoor section decreases due to reduced humidity in the air. An air source heat pump switching out of defrost mode in normal operation emits a characteristic "whoosh" sound from the outdoor section.[citation needed].

- Air source heat pumps lose their efficiency as the external temperatures fall below 5 degrees Celsius (about 41 degrees Fahrenheit). In colder climates, the system needs to be installed with an auxiliary source of heat to supplement the heat pump in extremely cold temperatures or when it is simply too cold for the heat pump to work at all. A "standard" air sourced heat pump found in most homes can extract useful heat down to about -5F or 0F; at colder outdoor temperatures it is just as well to turn off the heat pump and run only on supplemental heat (aka Emergency Heat) if the supplemental heat is sized large enough. Note there are specially designed heat pumps that, while giving up some performance in a/c mode, will provide useful heat extraction to even lower outdoor temperatures. An air source heat pump designed specifically for very cold climates can extract useful heat from ambient air as cold as -20F or even -25F, but these are uncommon in most homes. The Auxiliary Heat/Emergency Heat can also be used if the heat pump is malfunctioning and/or being repaired. In Northern climates, split-system heat pumps matched with gas or oil furnaces will work just fine in extremely cold temperatures. However, all-electric heat pump systems in colder Northern climates can be considerably more expensive to operate when the system is operating solely on the electric heat. All-electric heat pump systems have an electric furnace or electric resistance heat, or strip heat, which typically consists of rows of electric coils that heat up. A fan blows over the heated coils and circulates warm air throughout the home. This serves as an adequate heating source, but as temperatures go down, the utility bill will go up. As mentioned above, the gas, oil, or electric heating system will also kick in when the heat pump is defrosting. In milder climates, and regions where heat is rarely needed, an all-electric system is usually all that is needed. Some homes in regions where heat is rarely needed (like South Florida) do not even have heat pumps, and instead have cool-only central air-conditioners with electric strip/resistance heat.

- Retrofit is difficult when used with conventional heating systems using radiators, hot water baseboard heaters, or radiant panels. The lower Heat Pump output temperatures would mean radiators would have to be increased in size or a low temperature underfloor heating system be installed instead.

The following disadvantages are associated with units charged with HFC refrigerants:

- Usually marketed as low energy or a sustainable technology, the HFCs have the potential to contribute to global warming[citation needed]. The effect the refrigerant could have is measured in global warming potential (GWP) and ozone depletion potential (ODP). However, recent government mandates have seen the phase-out of R-22 refrigerant and its replacement with more environmentally sound R410a refrigerant.

- The COP is reduced when heat pumps are used to reach over 60°C for heating domestic water or in conventional central heating systems using radiators to distribute heat (instead of an underfloor heating array).

Conclusions

Air source heat pumps can provide fairly low cost space heating. A high efficiency heat pump can provide four times the heat compared to an electric heater.[3]

Air source heat pumps can heat water up to 70°C without difficulty when the air temperature is 5°C or greater. To minimize the risk from Legionellosis it is advised that hot water is heated to above 60°C.

The overall lifetime costs for using air source heat pumps should be considered carefully as gas (where available) may be cheaper than electricity (although it may produce higher carbon emissions depending upon how electricity is generated in your area).

Air source heat pumps should last for over 20 years with low maintenance requirements.[4][5] There are numerous heat pumps from the 1970s and 1980s that are still in service as of 2011, even in places where winters are extremely cold.

References

Literature

Summer, John A. (1976). Domestic Heat Pumps. PRISM Press. ISBN 0-904727-10-6.

External links

- The basics of air source heat pumps

- Discussion on changes to COP of a heat pump depending on input and output temperatures