Yield surface

A yield surface is a five-dimensional surface in the six-dimensional space of stresses. The yield surface is usually convex and the state of stress of inside the yield surface is elastic. When the stress state lies on the surface the material is said to have reached its yield point and the material is said to have become plastic. Further deformation of the material causes the stress state to remain on the yield surface, even though the shape and size of the surface may change as the plastic deformation evolves. This is because stress states that lie outside the yield surface are non-permissible in rate-independent plasticity, though not in some models of viscoplasticity.[1]

The yield surface is usually expressed in terms of (and visualized in) a three-dimensional principal stress space (), a two- or three-dimensional space spanned by stress invariants () or a version of the three-dimensional Haigh–Westergaard stress space. Thus we may write the equation of the yield surface (that is, the yield function) in the forms:

- where are the principal stresses.

- where is the first principal invariant of the Cauchy stress and are the second and third principal invariants of the deviatoric part of the Cauchy stress.

- where are scaled versions of and and is a function of .

- where are scaled versions of and , and is the stress angle[2] or Lode angle[3]

Invariants used to describe yield surfaces

The first principal invariant () of the Cauchy stress (), and the second and third principal invariants () of the deviatoric part () of the Cauchy stress are defined as:

where () are the principal values of , () are the principal values of , and

where is the identity matrix.

A related set of quantities, (), are usually used to describe yield surfaces for cohesive frictional materials such as rocks, soils, and ceramics. These are defined as

where is the equivalent stress. However, the possibility of negative values of and the resulting imaginary makes the use of these quantities problematic in practice.

Another related set of widely used invariants is () which describe a cylindrical coordinate system (the Haigh–Westergaard coordinates). These are defined as:

The plane is also called the Rendulic plane. The angle is called stress angle, the value is sometimes called the Lode parameter[4][5][6] and the relation between and was first given by Novozhilov V.V. in 1951,[7] see also [8]

The principal stresses and the Haigh–Westergaard coordinates are related by

A different definition of the Lode angle can also be found in the literature:[9]

in which case the ordered principal stresses (where ) are related by[10]

Examples of yield surfaces

There are several different yield surfaces known in engineering, and those most popular are listed below.

Tresca yield surface

The Tresca yield criterion is taken to be the work of Henri Tresca.[11] It is also known as the maximum shear stress theory (MSST) and the Tresca–Guest[12] (TG) criterion. In terms of the principal stresses the Tresca criterion is expressed as

Where is the yield strength in shear, and is the tensile yield strength.

Figure 1 shows the Tresca–Guest yield surface in the three-dimensional space of principal stresses. It is a prism of six sides and having infinite length. This means that the material remains elastic when all three principal stresses are roughly equivalent (a hydrostatic pressure), no matter how much it is compressed or stretched. However, when one of the principal stresses becomes smaller (or larger) than the others the material is subject to shearing. In such situations, if the shear stress reaches the yield limit then the material enters the plastic domain. Figure 2 shows the Tresca–Guest yield surface in two-dimensional stress space, it is a cross section of the prism along the plane.

von Mises yield surface

The von Mises yield criterion is expressed in the principal stresses as

where is the yield strength in uniaxial tension.

Figure 3 shows the von Mises yield surface in the three-dimensional space of principal stresses. It is a circular cylinder of infinite length with its axis inclined at equal angles to the three principal stresses. Figure 4 shows the von Mises yield surface in two-dimensional space compared with Tresca–Guest criterion. A cross section of the von Mises cylinder on the plane of produces the elliptical shape of the yield surface.

Burzyński-Yagn criterion

represents the general equation of a second order surface of revolution about the hydrostatic axis. Some special case are:[15]

- cylinder (Maxwell (1865), Huber (1904), von Mises (1913), Hencky (1924)),

- cone (Botkin (1940), Drucker-Prager (1952), Mirolyubov (1953)),

- paraboloid (Burzyński (1928), Balandin (1937), Torre (1947)),

- ellipsoid centered of symmetry plane , (Beltrami (1885)),

- ellipsoid centered of symmetry plane with (Schleicher (1926)),

- hyperboloid of two sheets (Burzynski (1928), Yagn (1931)),

- hyperboloid of one sheet centered of symmetry plane , , (Kuhn (1980))

- hyperboloid of one sheet , (Filonenko-Boroditsch (1960), Gol’denblat-Kopnov (1968), Filin (1975)).

The relations compression-tension and torsion-tension can be computed to

The Poisson's ratios at tension and compression are obtained using

For ductile materials the restriction

is important. The application of rotationally symmetric criteria for brittle failure with

has not been studied sufficiently.[16]

The Burzyński-Yagn criterion is well suited for academic purposes. For practical applications, the third invariant of the deviator in the odd and even power should be introduced in the equation, e.g.:[17]

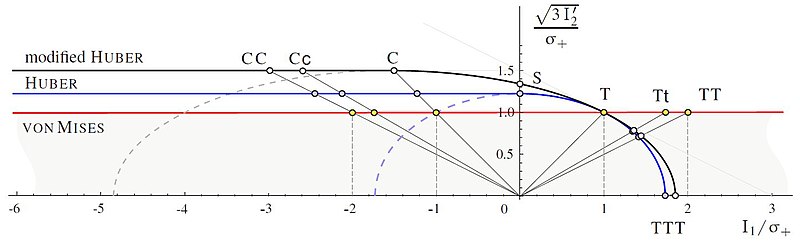

Huber criterion

The Huber criterion consists of the Beltrami ellipsoid and a scaled von Mises cylinder in the principal stress space,[18][19][20][21] see also[22][23]

with . The transition between the surfaces in the cross section is continuously differentiable. The criterion represents the "classical view" with respect to inelastic material behavior:

- pressure-sensitive material behavior for with and

- pressure-insensitive material behavior for with

The Huber criterion can be used as a yield surface with an empirical restriction for Poisson's ratio at tension , which leads to .

The modified Huber criterion,[24][23] see also [25]

consists of the Schleicher ellipsoid with the restriction of Poisson's ratio at compression

and a cylinder with the -transition in the cross section . The second setting for the parameters and follows with the compression / tension relation

The modified Huber criterion can be better fitted to the measured data as the Huber criterion. For setting it follows and .

The Huber criterion and the modified Huber criterion should be preferred to the von Mises criterion since one obtains safer results in the region . For practical applications the third invariant of the deviator should be considered in these criteria.[23]

Mohr–Coulomb yield surface

The Mohr–Coulomb yield (failure) criterion is similar to the Tresca criterion, with additional provisions for materials with different tensile and compressive yield strengths. This model is often used to model concrete, soil or granular materials. The Mohr–Coulomb yield criterion may be expressed as:

where

and the parameters and are the yield (failure) stresses of the material in uniaxial compression and tension, respectively. The formula reduces to the Tresca criterion if .

Figure 5 shows Mohr–Coulomb yield surface in the three-dimensional space of principal stresses. It is a conical prism and determines the inclination angle of conical surface. Figure 6 shows Mohr–Coulomb yield surface in two-dimensional stress space. In Figure 6 and is used for and , respectively, in the formula. It is a cross section of this conical prism on the plane of . In Figure 6 Rr and Rc are used for Syc and Syt, respectively, in the formula.

Drucker–Prager yield surface

The Drucker–Prager yield criterion is similar to the von Mises yield criterion, with provisions for handling materials with differing tensile and compressive yield strengths. This criterion is most often used for concrete where both normal and shear stresses can determine failure. The Drucker–Prager yield criterion may be expressed as

where

and , are the uniaxial yield stresses in compression and tension respectively. The formula reduces to the von Mises equation if .

Figure 7 shows Drucker–Prager yield surface in the three-dimensional space of principal stresses. It is a regular cone. Figure 8 shows Drucker–Prager yield surface in two-dimensional space. The elliptical elastic domain is a cross section of the cone on the plane of ; it can be chosen to intersect the Mohr–Coulomb yield surface in different number of vertices. One choice is to intersect the Mohr–Coulomb yield surface at three vertices on either side of the line, but usually selected by convention to be those in the compression regime.[26] Another choice is to intersect the Mohr–Coulomb yield surface at four vertices on both axes (uniaxial fit) or at two vertices on the diagonal (biaxial fit).[27] The Drucker-Prager yield criterion is also commonly expressed in terms of the material cohesion and friction angle.

Bresler–Pister yield surface

The Bresler–Pister yield criterion is an extension of the Drucker Prager yield criterion that uses three parameters, and has additional terms for materials that yield under hydrostatic compression. In terms of the principal stresses, this yield criterion may be expressed as

where are material constants. The additional parameter gives the yield surface an ellipsoidal cross section when viewed from a direction perpendicular to its axis. If is the yield stress in uniaxial compression, is the yield stress in uniaxial tension, and is the yield stress in biaxial compression, the parameters can be expressed as

Willam–Warnke yield surface

The Willam–Warnke yield criterion is a three-parameter smoothed version of the Mohr–Coulomb yield criterion that has similarities in form to the Drucker–Prager and Bresler–Pister yield criteria.

The yield criterion has the functional form

However, it is more commonly expressed in Haigh–Westergaard coordinates as

The cross-section of the surface when viewed along its axis is a smoothed triangle (unlike Mohr–Coulomb). The Willam–Warnke yield surface is convex and has unique and well defined first and second derivatives on every point of its surface. Therefore, the Willam–Warnke model is computationally robust and has been used for a variety of cohesive-frictional materials.

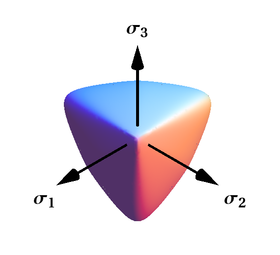

Podgórski and Rosendahl trigonometric yield surfaces

Normalized with respect to the uniaxial tensile stress , the Podgórski criterion [28] as function of the stress angle reads

with the shape function of trigonal symmetry in the -plane

It contains the criteria of von Mises (circle in the -plane, , ), Tresca (regular hexagon, , ), Mariotte (regular triangle, , ), Ivlev [29] (regular triangle, , ) and also the cubic criterion of Sayir [30] (the Ottosen criterion [31]) with and the isotoxal (equilateral) hexagons of the Capurso criterion[29][30][32] with . The von Mises - Tresca transition [33] follows with , . The isogonal (equiangular) hexagons of the Haythornthwaite criterion [23][34][35] containing the Schmidt-Ishlinsky criterion (regular hexagon) cannot be described with the Podgórski ctiterion.

The Rosendahl criterion [36][37] reads

with the shape function of hexagonal symmetry in the -plane

It contains the criteria of von Mises (circle, , ), Tresca (regular hexagon, , ), Schmidt—Ishlinsky (regular hexagon, , ), Sokolovsky (regular dodecagon, , ), and also the bicubic criterion [23][36][38][39] with or equally with and the isotoxal dodecagons of the unified yield criterion of Yu [40] with . The isogonal dodecagons of the multiplicative ansatz criterion of hexagonal symmetry [23] containing the Ishlinsky-Ivlev criterion (regular dodecagon) cannot be described by the Rosendahl criterion.

The criteria of Podgórski and Rosendahl describe single surfaces in principal stress space without any additional outer contours and plane intersections. Note that in order to avoid numerical issues the real part function can be introduced to the shape function: and . The generalization in the form [36] is relevant for theoretical investigations.

A pressure-sensitive extension of the criteria can be obtained with the linear -substitution [23]

which is sufficient for many applications, e.g. metals, cast iron, alloys, concrete, unreinforced polymers, etc.

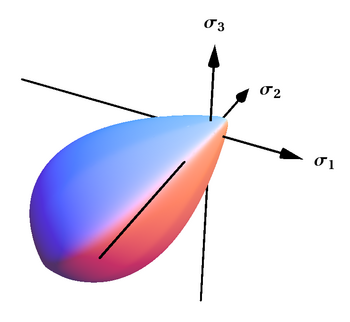

Bigoni–Piccolroaz yield surface

The Bigoni–Piccolroaz yield criterion [41][42] is a seven-parameter surface defined by

where is the "meridian" function

describing the pressure-sensitivity and is the "deviatoric" function [43]

describing the Lode-dependence of yielding. The seven, non-negative material parameters:

define the shape of the meridian and deviatoric sections.

This criterion represents a smooth and convex surface, which is closed both in hydrostatic tension and compression and has a drop-like shape, particularly suited to describe frictional and granular materials. This criterion has also been generalized to the case of surfaces with corners.[44]

Cosine Ansatz (Altenbach-Bolchoun-Kolupaev)

For the formulation of the strength criteria the stress angle

can be used.

The following criterion of isotropic material behavior

contains a number of other well-known less general criteria, provided suitable parameter values are chosen.

Parameters and describe the geometry of the surface in the -plane. They are subject to the constraints

which follow from the convexity condition. A more precise formulation of the third constraints is proposed in.[45][46]

Parameters and describe the position of the intersection points of the yield surface with hydrostatic axis (space diagonal in the principal stress space). These intersections points are called hydrostatic nodes. In the case of materials which do not fail at hydrostatic pressure (steel, brass, etc.) one gets . Otherwise for materials which fail at hydrostatic pressure (hard foams, ceramics, sintered materials, etc.) it follows .

The integer powers and , describe the curvature of the meridian. The meridian with is a straight line and with – a parabola.

Barlat's Yield Surface

For the anisotropic materials, depending on the direction of the applied process (e.g., rolling) the mechanical properties vary and, therefore, using an anisotropic yield function is crucial. Since 1989 Frederic Barlat has developed a family of yield functions for constitutive modelling of plastic anisotropy. Among them, Yld2000-2D yield criteria has been applied for a wide range of sheet metals (e.g., aluminum alloys and advanced high-strength steels). The Yld2000-2D model is a non-quadratic type yield function based on two linear transformation of the stress tensor:

- :

The Yld2000-2D yield loci for a AA6022 T4 sheet. - where is the effective stress. and and are the transformed matrices (by linear transformation C or L):

- where s is the deviatoric stress tensor.

for principal values of X’ and X”, the model could be expressed as:

and:

where are eight parameters of the Barlat's Yld2000-2D model to be identified with a set of experiments.

See also

References

- ^ Simo, J. C. and Hughes, T,. J. R., (1998), Computational Inelasticity, Springer.

- ^ Yu, M.-H. (2004), Unified strength theory and its applications. Springer, Berlin

- ^ Zienkiewicz O.C., Pande, G.N. (1977), Some useful forms of isotropic yield surfaces for soil and rock mechanics. In: Gudehus, G. (ed.) Finite Elements in Geomechanics. Wiley, New York, pp. 179–198

- ^ Lode, W. (1925). Versuche über den Einfluß der mittleren Hauptspannug auf die Fließgrenze. ZAMM 5(2), pp. 142–144

- ^ Lode, W. (1926). Versuche über den Einfuss der mittleren Hauptspannung auf das Fliessen der Metalle Eisen Kupfer und Nickel. Zeitung Phys., vol. 36, pp. 913–939.

- ^ Lode, W. (1928). Der Einfluß der mittleren Hauptspannung auf das Fließen der Metalle. Dissertation, Universität zu Göttingen. Forschungsarbeiten auf dem Gebiete des Ingenieurwesens, Heft 303, VDI, Berlin

- ^ Novozhilov, V.V. (1951). On the principles of the statical analysis of the experimental results for isotropic materials (in Russ.: O prinzipakh obrabotki rezultatov staticheskikh ispytanij izotropnykh materialov). Prikladnaja Matematika i Mekhanika, XV(6):709–722.

- ^ Nayak, G. C. and Zienkiewicz, O.C. (1972). Convenient forms of stress invariants for plasticity. Proceedings of the ASCE Journal of the Structural Division, vol. 98, no. ST4, pp. 949–954.

- ^ Chakrabarty, J., 2006, Theory of Plasticity: Third edition, Elsevier, Amsterdam.

- ^ Brannon, R.M., 2009, KAYENTA: Theory and User's Guide, Sandia National Laboratories, Albuquerque, New Mexico.

- ^ Tresca, H. (1864). Mémoire sur l'écoulement des corps solides soumis à de fortes pressions. C. R. Acad. Sci. Paris, vol. 59, p. 754.

- ^ Guest

- ^ Burzyński, W. (1929). Über die Anstrengungshypothesen. Schweizerische Bauzeitung, 94 (21), pp. 259–262.

- ^ Yagn, Yu. I. (1931). New methods of strength prediction (in Russ.: Novye metody pascheta na prochnost'). Vestnik inzhenerov i tekhnikov, 6, pp. 237–244.

- ^ Altenbach, H., Kolupaev, V.A. (2014) Classical and Non-Classical Failure Criteria, in Altenbach, H., Sadowski, Th., eds., Failure and Damage Analysis of Advanced Materials, in press, Springer, Heidelberg (2014), pp. 1–66

- ^ Beljaev, N. M. (1979). Strength of Materials. Mir Publ., Moscow

- ^ Bolchoun, A., Kolupaev, V. A., Altenbach, H. (2011) Convex and non-convex yield surfaces (in German: Konvexe und nichtkonvexe Fließflächen), Forschung im Ingenieurwesen, 75 (2), pp. 73–92

- ^ Huber, M. T. (1904). Specific strain work as a measure of material effort (in Polish: Właściwa praca odkształcenia jako miara wytężenia materyału), Czasopismo Techniczne, Lwów, Organ Towarzystwa Politechnicznego we Lwowie, v. 22. pp. 34-40, 49-50, 61-62, 80-81

- ^ Föppl, A., Föppl, L. (1920). Drang und Zwang: eine höhere Festigkeitslehre für Ingenieure. R. Oldenbourg, München

- ^ Burzyński, W. (1929). Über die Anstrengungshypothesen. Schweizerische Bauzeitung 94(21):259–262

- ^ Kuhn, P. (1980). Grundzüge einer allgemeinen Festigkeitshypothese, Auszug aus Antrittsvorlesung des Verfassers vom 11. Juli, 1980 Vom Konstrukteur und den Festigkeitshypothesen. Inst. für Maschinenkonstruktionslehre, Karlsruhe

- ^ Kolupaev, V.A., Moneke M., Becker F. (2004). Stress appearance during creep. Calculation of plastic parts (in German: Spannungsausprägung beim Kriechen: Berechnung von Kunststoffbauteilen). Kunststoffe 94(11):79–82

- ^ a b c d e f g Kolupaev, V.A. (2018). Equivalent Stress Concept for Limit State Analysis, Springer, Cham.

- ^ Kolupaev, V. A., (2006). 3D-Creep Behaviour of Parts Made of Non-Reinforced Thermoplastics (in German: Dreidimensionales Kriechverhalten von Bauteilen aus unverstärkten Thermoplasten), Diss., Martin-Luther-Universität Halle-Wittenberg, Halle-Saale

- ^ Memhard, D,., Andrieux, F., Sun, D.-Z., Häcker, R. (2011) Development and verification of a material model for prediction of containment safety of exhaust turbochargers, 8th European LS-DYNA Users Conference, Strasbourg, May 2011, 11 p.

- ^ Khan and Huang. (1995), Continuum Theory of Plasticity. J.Wiley.

- ^ Neto, Periç, Owen. (2008), The mathematical Theory of Plasticity. J.Wiley.

- ^ Podgórski, J. (1984). Limit state condition and the dissipation function for isotropic materials, Archives of Mechanics 36(3), pp. 323-342.

- ^ a b Ivlev, D. D. (1959). The theory of fracture of solids (in Russ.: K teorii razrusheniia tverdykh tel), J. of Applied Mathematics and Mechanics, 23(3), pp. 884-895.

- ^ a b Sayir, M. (1970). Zur Fließbedingung der Plastizitätstheorie, Ingenieur-Archiv 39(6), pp. 414-432.

- ^ Ottosen, N. S. (1975). Failure and Elasticity of Concrete, Danish Atomic Energy Commission, Research Establishment Risö, Engineering Department, Report Risö-M-1801, Roskilde.

- ^ Capurso, M. (1967). Yield conditions for incompressible isotropic and orthotropic materials with different yield stress in tension and compression, Meccanica 2(2), pp. 118--125.

- ^ Lemaitre J., Chaboche J.L. (1990). Mechanics of Solid Materials, Cambridge University Press, Cambridge.

- ^ Candland C.T. (1975). Implications of macroscopic failure criteria which are independent of hydrostatic stress, Int. J. Fracture 11(3), pp. 540–543.

- ^ Haythornthwaite R.M. (1961). Range of yield condition in ideal plasticity, Proc ASCE J Eng Mech Div, EM6, 87, pp. 117–133.

- ^ a b c Rosendahl, P. L., Kolupaev, V A., Altenbach, H. (2019). Extreme Yield Figures for Universal Strength Criteria, in Altenbach, H., Öchsner, A., eds., State of the Art and Future Trends in Material Modeling, Advanced Structured Materials STRUCTMAT, Springer, Cham, pp. 259-324.

- ^ Rosendahl, P. L. (2020). From bulk to structural failure: Fracture of hyperelastic materials, Diss., Technische Universität Darmstadt.

- ^ Szwed, A. (2000). Strength Hypotheses and Constitutive Relations of Materials Including Degradation Effects, (in Polish: Hipotezy Wytężeniowe i Relacje Konstytutywne Materiałów z Uwzględnieniem Efektów Degradacji), Praca Doctorska, Wydział Inąynierii Lądowej Politechniki Warszawskiej, Warszawa.

- ^ Lagzdin, A. (1997). Smooth convex limit surfaces in the space of symmetric second-rank tensors, Mechanics of Composite Materials, 3(2), 119-127.

- ^ Yu M.-H. (2002). Advances in strength theories for materials under complex stress state in the 20th century, Applied Mechanics Reviews, 55(5), pp. 169-218.

- ^ Bigoni, D. Nonlinear Solid Mechanics: Bifurcation Theory and Material Instability. Cambridge University Press, 2012 . ISBN 9781107025417.

- ^ Bigoni, D. and Piccolroaz, A., (2004), Yield criteria for quasibrittle and frictional materials, International Journal of Solids and Structures 41, 2855–2878.

- ^ Podgórski, J. (1984). Limit state condition and the dissipation function for isotropic materials. Archives of Mechanics, 36 (3), pp. 323–342.

- ^ Piccolroaz, A. and Bigoni, D. (2009), Yield criteria for quasibrittle and frictional materials: a generalization to surfaces with corners, International Journal of Solids and Structures 46, 3587–3596.

- ^ Altenbach, H., Bolchoun, A., Kolupaev, V.A. (2013). Phenomenological Yield and Failure Criteria, in Altenbach, H., Öchsner, A., eds., Plasticity of Pressure-Sensitive Materials, Serie ASM, Springer, Heidelberg, pp. 49–152.

- ^ Kolupaev, V.A. (2018). Equivalent Stress Concept for Limit State Analysis, Springer, Cham.

![{\displaystyle {\begin{aligned}I_{1}&={\text{Tr}}({\boldsymbol {\sigma }})=\sigma _{1}+\sigma _{2}+\sigma _{3}\\J_{2}&={\tfrac {1}{2}}{\boldsymbol {s}}:{\boldsymbol {s}}={\tfrac {1}{6}}\left[(\sigma _{1}-\sigma _{2})^{2}+(\sigma _{2}-\sigma _{3})^{2}+(\sigma _{3}-\sigma _{1})^{2}\right]\\J_{3}&=\det({\boldsymbol {s}})={\tfrac {1}{3}}({\boldsymbol {s}}\cdot {\boldsymbol {s}}):{\boldsymbol {s}}=s_{1}s_{2}s_{3}\end{aligned}}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/2367aae106ad4915a3c05e829c4d06e62ee17c18)

![{\displaystyle \gamma _{1}=\gamma _{2}\in ]0,1[}](https://wikimedia.org/api/rest_v1/media/math/render/svg/66ab6f7a14a52c2042d17030aa16705df21f1541)

![{\displaystyle \gamma _{1}\in ]0,1[,\gamma _{2}=0}](https://wikimedia.org/api/rest_v1/media/math/render/svg/ab67fc470c16fd7d16b50462f9c9d7af9b70f566)

![{\displaystyle \gamma _{1}=-\gamma _{2}\in ]0,1[}](https://wikimedia.org/api/rest_v1/media/math/render/svg/19f234ad4d2cddbc2eb4b2b5c0dfcb2a128c275b)

![{\displaystyle \gamma _{1}\in ]0,1[,\gamma _{2}<0}](https://wikimedia.org/api/rest_v1/media/math/render/svg/cc95c96fba08cb97251ef453346323702300f9ab)

![{\displaystyle \gamma _{1}\in ]0,1[,\gamma _{2}\in ]0,\gamma _{1}[}](https://wikimedia.org/api/rest_v1/media/math/render/svg/7bdf157e5b65de316f3462bcb5e2de9d10cda1cb)

![{\displaystyle \nu _{+}^{\mathrm {in} }\in {\bigg [}\,0.48,\,{\frac {1}{2}}\,{\bigg ]}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/4b7c270b90d3c766fd6ecd9b7204e1622d9f7722)

![{\displaystyle \nu _{+}^{\mathrm {in} }\in ]-1,~\nu _{+}^{\mathrm {el} }\,]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/690096f2ce81fb70324e3cebefabb993721ed772)

![{\displaystyle 3\,I_{2}'=\left\{{\begin{array}{ll}\displaystyle {\frac {\sigma _{\mathrm {eq} }-\gamma _{1}\,I_{1}}{1-\gamma _{1}}}\,{\frac {\sigma _{\mathrm {eq} }+\gamma _{1}\,I_{1}}{1+\gamma _{1}}},&I_{1}>0\\[1em]\displaystyle {\frac {\sigma _{\mathrm {eq} }}{1-\gamma _{1}}}\,{\frac {\sigma _{\mathrm {eq} }}{1+\gamma _{1}}},&I_{1}\leq 0\end{array}}\right.}](https://wikimedia.org/api/rest_v1/media/math/render/svg/84e5badc1256fedb02c6e3bb4e32c3c04f455c74)

![{\displaystyle \nu _{+}^{\mathrm {in} }\in \left]-1,\,1/2\right]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/b0492b09eaa5450be7f96f4a04b025a37ef0a620)

![{\displaystyle \nu _{+}^{\mathrm {in} }\in [0.48,1/2]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/95b2a945c4242aba4b539c51f5dc7441fceda3b9)

![{\displaystyle \gamma _{1}\in [0,0.1155]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/bee6b21ec154dddb4479a8f5fc3321c72ec824f4)

![{\displaystyle 3\,I_{2}'=\left\{{\begin{array}{ll}\displaystyle {\frac {\sigma _{\mathrm {eq} }-\gamma _{1}\,I_{1}}{1-\gamma _{1}}}\,{\frac {\sigma _{\mathrm {eq} }-\gamma _{2}\,I_{1}}{1-\gamma _{2}}},&I_{1}>-d\,\sigma _{\mathrm {+} }\\[1em]\displaystyle {\frac {\sigma _{\mathrm {eq} }^{2}}{(1-\gamma _{1}-\gamma _{2})^{2}}},&I_{1}\leq -d\,\sigma _{\mathrm {+} }\end{array}}\right.}](https://wikimedia.org/api/rest_v1/media/math/render/svg/7665d54a30d98465586f222a2ad1cf088bfd4d2a)

![{\displaystyle S_{yc}={\tfrac {1}{\sqrt {2}}}\left[(\sigma _{1}-\sigma _{2})^{2}+(\sigma _{2}-\sigma _{3})^{2}+(\sigma _{3}-\sigma _{1})^{2}\right]^{1/2}-c_{0}-c_{1}~(\sigma _{1}+\sigma _{2}+\sigma _{3})-c_{2}~(\sigma _{1}+\sigma _{2}+\sigma _{3})^{2}}](https://wikimedia.org/api/rest_v1/media/math/render/svg/168ce31fef86a9a05a75721a81e088c69edcf24f)

![{\displaystyle \Omega _{3}(\theta ,\beta _{3},\chi _{3})=\cos \left[\displaystyle {\frac {1}{3}}\left(\pi \beta _{3}-\arccos[\,\sin(\chi _{3}\,{\frac {\pi }{2}})\,\!\cos 3\,\theta \,]\right)\right],\qquad \beta _{3}\in [0,\,1],\quad \chi _{3}\in [-1,\,1].}](https://wikimedia.org/api/rest_v1/media/math/render/svg/31655f9e540e841ea6d966f7a0bdbe1fd6304b4a)

![{\displaystyle \beta _{3}=[0,\,1]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/20634c0926a05259beda78f4e18b1ea6d38621be)

![{\displaystyle \chi _{3}=[0,1]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/6b4456eca66f88480bde86583de8ac126d973ac4)

![{\displaystyle \Omega _{6}(\theta ,\beta _{6},\chi _{6})=\cos \left[\displaystyle {\frac {1}{6}}\left(\pi \beta _{6}-\arccos[\,\sin(\chi _{6}\,{\frac {\pi }{2}})\,\!\cos 6\,\theta \,]\right)\right],\qquad \beta _{6}\in [0,\,1],\quad \chi _{6}\in [-1,\,1].}](https://wikimedia.org/api/rest_v1/media/math/render/svg/e980c867fa1766fcc5a741ecf363e19c05a8bfe8)

![{\displaystyle \beta _{6}=[0,\,1]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/61f7b566943062df913486ad99edfa445fbb58a1)

![{\displaystyle F(p)=\left\{{\begin{array}{ll}-Mp_{c}{\sqrt {(\phi -\phi ^{m})[2(1-\alpha )\phi +\alpha ]}},&\phi \in [0,1],\\+\infty ,&\phi \notin [0,1],\end{array}}\right.}](https://wikimedia.org/api/rest_v1/media/math/render/svg/9948aa54df1e39ab115e425b19f088dff39beadc)

![{\displaystyle g(\theta )={\frac {1}{\cos[\beta {\frac {\pi }{6}}-{\frac {1}{3}}\cos ^{-1}(\gamma \cos 3\theta )]}},}](https://wikimedia.org/api/rest_v1/media/math/render/svg/dba97f3c7548243d55f4c6736d862e34b31b04cb)

![{\displaystyle \left[{\begin{array}{*{20}{c}}{{L'}_{11}}\\{{L'}_{12}}\\{{L'}_{21}}\\{{L'}_{22}}\\{{L'}_{66}}\end{array}}\right]=\left[{\begin{array}{*{20}{c}}{2/3}&0&0\\{-1/3}&0&0\\0&{-1/3}&0\\0&{-2/3}&0\\0&0&1\end{array}}\right]\left[{\begin{array}{*{20}{c}}{\alpha _{1}}\\{\alpha _{2}}\\{\alpha _{7}}\end{array}}\right],\left[{\begin{array}{*{20}{c}}{{L''}_{11}}\\{{L''}_{12}}\\{{L''}_{21}}\\{{L''}_{22}}\\{{L''}_{66}}\end{array}}\right]=\left[{\begin{array}{*{20}{c}}{-2}&2&8&{-2}&0\\1&{-4}&{-4}&4&0\\4&{-4}&{-4}&4&0\\{-2}&8&2&{-2}&0\\0&0&0&0&1\end{array}}\right]\left[{\begin{array}{*{20}{c}}{\alpha _{3}}\\{\alpha _{4}}\\{\alpha _{5}}\\{\alpha _{6}}\\{\alpha _{8}}\end{array}}\right]}](https://wikimedia.org/api/rest_v1/media/math/render/svg/4ad31d6027e7e5da286c1ec7579505cffa4c919c)