Karrick process: Difference between revisions

Rmosler2100 (talk | contribs) |

responsible warning of politically incorrect content |

||

| Line 1: | Line 1: | ||

ADVISORY NOTICE of environmentally irresponsible and politically unapproved subject matter. This article contains unacceptable scientific references to fossil fuel products, processes and uses which are not deemed appropriate for family viewing and may constitute violations of Federal Energy Law under recent Cap and Trade legislation. |

|||

{{Refimprove|date=March 2008}} |

{{Refimprove|date=March 2008}} |

||

{{No footnotes|date=June 2009}} |

{{No footnotes|date=June 2009}} |

||

Revision as of 19:03, 3 July 2009

ADVISORY NOTICE of environmentally irresponsible and politically unapproved subject matter. This article contains unacceptable scientific references to fossil fuel products, processes and uses which are not deemed appropriate for family viewing and may constitute violations of Federal Energy Law under recent Cap and Trade legislation.

This article needs additional citations for verification. (March 2008) |

This article includes a list of references, related reading, or external links, but its sources remain unclear because it lacks inline citations. (June 2009) |

The Karrick process is a low-temperature carbonization (LTC) of coal, oil shale, lignite or any carbonaceous materials. These are heated at 680 °F (360 °C) to 1,380 °F (750 °C) in the absence of air to distill out oil and gas. The process was the work of oil shale technologist Lewis C. Karrick at the U.S. Bureau of Mines in the 1920s.

Process

Karrick processing of 1 short ton of coal yields up to 1 barrel of coal tars (12% by weight), richer in lighter hydrocarbons than normal coal tar and suitable for processing into fuels, plus 3,000 cubic feet (85 m3) of rich fuel gas plus 1500 pounds of solid smokeless char or semi-coke (for one metric ton, 0.175 m³ of coal tars, 95 m³ of gas, and 750 kg of semi-coke). Smokeless char can be used for utility boilers and cooking coal in steel smelters, yields more heat than raw coal and can be converted to water gas. Water gas can be converted to oil by the Fischer-Tropsch process. Coal gas from Karrick LTC yields greater energy content than natural gas. Phenolic wastes are used by the chemical industry as feedstock for plastics, etc. Electrical power can be cogenerated at nominal equipment cost.

The Karrick LTC process occurs in a sealed oxygen-free retort and generates no carbon dioxide. (See "Carbon/CO2 sequestration" in "See also" below).

History

Karrick did not invent coal LTC but perfected it in his now expired patents, issued from 1931 to 1942. Dozens of American facilities had previously produced oil, gas, grease and paraffin from coal, but by 1873, cheap petroleum caused the last coal oil plant to close. America is today experiencing a revival of the practice in response to crude oil prices of up to or exceeding $125(USD) per barrel, geopolitical and economic considerations. (See "Fischer-Tropsch process" below)

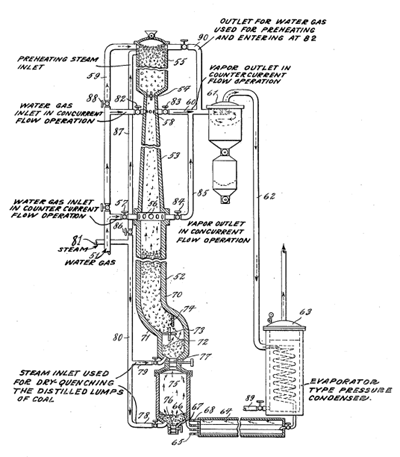

The Karrick low temperature carbonization process

Comparative

A Karrick LTC pilot plant was constructed at the University of Utah in the 1930s, and below are some findings:

- Bergius (HTC) liquefaction is too costly and approximately one-half of the thermal value of coal is destroyed.

- Bergius process requires substantial volumes of water.

- Karrick process, including conversion of the oil to motor fuel, destroys only 25% of the thermal value, or one-half that of the Bergius process.

Gasoline

- Gasoline obtained from coal LTC liquefaction is equal in quality to tetraethyl lead gasolines.

- More power is developed in internal combustion engines and an increase in fuel economy of approximately 20% is obtainable under identical operating conditions.

Byproducts / Yields

- Yields by volume of approximately 25% gasoline, 10% kerosene and 20% good quality fuel oil are obtainable from coal.

- The smokeless fuel, when burned in an open grate or in boilers, delivers 20% to 25% more heat than raw coal.

- The oil can be converted to liquid fuels while the smokeless fuel is excellent for steam boilers.

- The coal gas should deliver more heat than natural gas per heat unit contained due to the greater quantity of combined carbon and lower dilution of the combustion gases with water vapor.

- The cheapest liquid fuel from coal will come when processed by LTC for both liquid fuels and electric power, which should yield the least expensive electricity.

- The gasoline, fuel oil, and other oil products would be a small percentage of imported petroleum products and should therefore find a ready and enthusiastic market.

Thermals / Electrical

- As a tertiary product of the coal distilling process, electrical energy can be generated at a minimum equipment cost.

- A Karrick LTC plant with 1 kiloton of daily coal capacity produces sufficient steam to generate 100,000 kilowatt hours of electrical power at no extra cost excepting capital investment for electrical equipment and loss of steam temperature passing through turbines.

- The process steam cost could be low since this steam could be derived from off-peak boiler capacity or from turbines in central electric stations. Fuel for steam and superheating would subsequently be reduced in cost.

Viability

- No difficulties whatsoever were encountered during the successful operation of the plant.

- A 30 ton plant and oil refinery will show a profit over and above all operating and capital costs and the products will sell at attractive prices for equivalent products.

- The private sector should require no subsidies, but not in competition with those who skim off the oil from coal and sell the residual smokeless fuel to power plants.

Criticisms

- Commercial Karrick LTC process plants would fail due to mechanical problems, a postulation based on previous failures of other plants using different processes under different conditions.

- Markets for the described coal products are limited, making such a venture economically unsound.

Coal reserves

The United States has 26% of Earth's known coal reserves. This is sufficient to last hundreds of years by the lowest estimates and accounts for 90% of U.S. energy reserves. Coal is, of course, a fossil fuel and as such is therefore subject to possible depletion within a few hundred years. In terms of energy obtained, coal peaked in 1998 and though production volumes have increased, the net energy has not, which could be explained by decreasing production of high quality coal, such as bituminous and anthracite. U.S. reserves are approximately 45% bituminous and anthracite.

The energy value of all the world's known recoverable coal is 27 zettajoules, which is expected to last 164 years. (See "Coal")

Of that, U.S. reserves alone comprise 7.02 zettajoules. The U.S. DOE estimates coal reserves at 1,081,279 million short tons (9.81 × 1014 kg), or about 4,786 billion (4.7 trillion) barrels of oil equivalent. The amount of coal burned during 2001 was calculated as 2.337 gigatonnes of oil equivalent, or about 46 million barrels (7,300,000 m3) of oil equivalent per day. Were consumption to continue at that rate, those reserves would last about 285 years.

Production of synthetic fuels from U.S. coal assets represents an effective means towards decreasing U.S. reliance on imported oil, reducing trade deficits and providing more economical energy than current markets offer. (See "Princeton University: Increased Automobile Fuel Efficiency and Synthetic Fuels; Alternatives for Reducing Oil Imports" below)

Economic viability

Oils, including petroleum, have long been extracted from coal. Production plants were merely shut down in the 1880s because crude oil became cheaper than coal liquefaction. The capability itself, however, has never disappeared. Eight years of pilot plant tests by Karrick attest that states, cities or even smaller towns, could make their own gas and generate their own electricity.

John Winslow, Laboratories Technology Manager for Coal Fuels at the U.S. DOE National Energy Technology Laboratory (NETL), estimates that a plant producing 30,000 barrels (4,800 m3) of liquid coal per day (4,800 m³/d) can keep costs to $35–$40 per barrel. This finding was presented at the Coal Utilization Technologies Workshop, September 22 2004, at the National Research Center for Coal & Energy, Morgantown, WV. This meeting was part of the Energy Roadmap Workshop Series commissioned by West Virginia Governor Bob Wise.

Potential market size is substantial, U.S. importation of petroleum products alone for 2005 being $251.6 Billion, $302.5 Billion for 2006, $331.2 Billion for 2007 and $386.3 Billion for 2008, all records, for a 4-year total of $1.27 Trillion. (See "U.S. Census Bureau 2008 Foreign Trade Statistics" below).

Congressional funding

In 1980, the U.S. Congress approved a $20 billion synfuel program authorizing an Energy Mobilization Board to expedite high priority projects such as facilities to produce oil from coal and shale.

However, the DOE placed great emphasis on the Bergius process of direct liquefaction of coal by hydrogenation to produce synfuel. The Bergius process combines coal with heated hydrogen at 3000-5000 psi (20 to 35 MPa) to produce oil. Synthesis requires 7,000 cubic feet (200 m3) of hydrogen per barrel of oil produced plus 1,500 cubic feet (42 m3) of hydrogen per 1,000 cubic feet (28 m3) of synfuel produced. The Bergius process has been criticized both economically and ecologically as untenable, and given the shortcomings of the Bergius process, the prudence of that Congressional funding allocation has been questioned.

Patents

Patents issued to L.C. Karrick

- U.S. patent 1,835,878 U.S. patent 1,894,691 U.S. patent 1,899,154

- U.S. patent 1,901,169 U.S. patent 1,901,170 U.S. patent 1,906,755

- U.S. patent 1,913,395 U.S. patent 1,919,636 U.S. patent 1,923,213

- U.S. patent 1,938,596 U.S. patent 1,942,650 U.S. patent 1,945,530

- U.S. patent 1,950,558 U.S. patent 1,958,918 U.S. patent 2,011,054

- U.S. patent 2,268,989 U.S. patent 2,283,556

CO2-Related/Sequestration Patents

- US 2007217981 US 2007051615 US 2007081924

- US 2007144747 US 2007261947 US 2007253886

- US 2005180910 US 2005169825 US 2005180910

- US 2004200393 US 7043920 US 2004161364

- US 6945029 US 6667022 US 6976362

- US 7132090 US 6598398 US 6667171

- US 6763886 US 6736215 US 6871707

- US 2001015061 US 6648949 US 6447437

- US 6115672 US 6148602 US 6190301

- US 6170264 US 2007028848 US 2002035307

- WO 2005108297 WO 0198313 WO 2007106372

- WO 2007077139 WO 2007106883 WO 2007071633

- WO 2007077137 WO 2007003013 WO 2007015689

- WO 03103805 WO 0175277 WO 2007106372

- WO 2007077138 CA 2122200 CA 2541681

- CA 2507946 CA 2537383 CA 2523135

- CA 2503655 CA 2531181 FR 2872566

- KR 20030011693 MXPA 06008537 EP 1801346

- EP 1350766 CN 1898010 CN 1884140

- AU 2003235033 JP 62081478

See also

- Bergius process

- Fischer-Tropsch process

- Coal

- Coal liquefication

- Coal oil

- Carbon sequestration

- CO2 sequestration

- Carbon capture and storage

- Destructive distillation

- Major coal producing regions

- Pyrolysis

- Pyrolysis oil

- Synthetic Liquid Fuels Program

- Synthetic fuel

- Synthetic oil

- Syngas

- Unconventional oil

External links

- New Fuel Cell Cleans Up (Coal) Pollution And Produces Electricity

- Methanol-to-Gasoline (MTG) for Coal-to-Liquids Project

- World's first coal-to-oil mass converter due to start operation this year (Xinhua, China, June 22, 2007)

- A magic way to make billions (TIME Magazine, February 2006)

- Development of the modern Fischer-Tropsch process (1958-1999)

- German Synthetic Fuels Scientists

- Koppers-Totzek process

- Lurgi process

- Learn about Coal

- China to Invest $128 Billion to Develop Coal-Based Synthetic Fuels

- Military's push to turn coal into fuel picking up speed (Associated Press)

- Princeton University: Increased Automobile Fuel Efficiency and Synthetic Fuels; Alternatives for Reducing Oil Imports (PDF)

- Sandia National Laboratory: Coal- The fuel of the future?

- Sasol

- Shell

- The Bureau of Mines Synthetic Liquid Fuels Program 1944-55 Part 1 Oil From Coal

- The Early Days of Coal Research at the U.S. Department of Energy site.

- USPTO Patent Number Search

- Google Patent Search

- U.S. Census Bureau 2007 Foreign Trade Statistics

- U.S. Department of Energy estimates of worldwide coal reserves