Microstructure

This article needs additional citations for verification. (June 2007) |

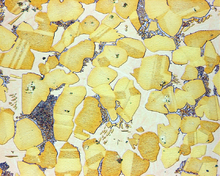

Microstructure is the small scale structure of a material, defined as the structure of a prepared surface of material as revealed by a microscope above 25× magnification.[1] The microstructure of a material (such as metals, polymers, ceramics or composites) can strongly influence physical properties such as strength, toughness, ductility, hardness, corrosion resistance, high/low temperature behavior or wear resistance. These properties in turn govern the application of these materials in industrial practice. Microstructure at scales smaller than can be viewed with optical microscopes is often called nanostructure, while the structure in which individual atoms are arranged is known as crystal structure. The nanostructure of biological specimens is referred to as ultrastructure.

Methods

The concept of microstructure is observable in macrostructural features in commonplace objects. Galvanized steel, such as the casing of a lamp post or road divider, exhibits a non-uniformly colored patchwork of interlocking polygons of different shades of grey or silver. Each polygon is a single crystal of zinc adhering to the surface of the steel beneath. Zinc and lead are two common metals which form large crystals (grains) visible to the naked eye. The atoms in each grain are organized into one of seven 3d stacking arrangements or crystal lattices (cubic, tetrahedral, hexagonal, monoclinic, triclinic, rhombohedral and orthorhombic). The direction of alignment of the matrices differ between adjacent crystals, leading to variance in the reflectivity of each presented face of the interlocked grains on the galvanized surface. The average grain size can be controlled by processing conditions and composition, and most alloys consist of much smaller grains not visible to the naked eye. This is to increase the strength of the material (see Hall-Petch Strengthening).

Microstructure Characterizations

To quantify microstructural features, both morphological and material property must be characterized. Image processing is a robust technique for determination of morphological features such as volume fraction,[2] inclusion morphology,[3] void and crystal orientations. To acquire micrographs, optical as well as electron microscopy are commonly used. To determine material property, Nanoindentation is a robust technique for determination of properties in micron and submicron level for which conventional testing are not feasible. Conventional mechanical testing such as tensile testing or dynamic mechanical analysis (DMA) can only return macroscopic properties without any indication of microstructural properties. However, nanoindentation can be used for determination of local microstructural properties of homogeneous as well as heterogeneous materials.[4]

Microscopy

Optical

When a polished flat sample reveals traces of its microstructure, it is normal to capture the image using macrophotography. More sophisticated microstructure examination involves higher powered instruments: optical microscopy, electron microscopy, X-ray diffraction and so on, some involving preparation of the material sample (cutting, microtomy, polishing, etching, vapor-deposition etc.). The methods are known collectively as metallography as applied to metals and alloys, and can be used in modified form for any other material, such as ceramics, glasses, composites, and polymers.

Two kinds of optical microscope are generally used to examine flat, polished and etched specimens: a reflection microscope and an inverted microscope. Recording the image is achieved using a digital camera working through the eyepiece.

X-Ray microtomographic

Nondestructive testing of microstructure for biological materials is a challenge and computer microtomography is the current solution. In fact, CMT can be used for the evaluation of microstructure of many other materials also. CMT can be very expensive though, and for research purposes, it is a necessity to generate a three-dimensional microstructure from two-dimensional cross-sectional images of the material. This is an area of active research and pursued by many scientists.

3D compositional microstructure

Microscopic distribution of material compositions in a material sample can be obtained using a data constrained modelling technique together with quantitative X-Ray computed tomography. A software implementation of the technique is available .[5]

Electron microscopy

For high-resolution information on metallurgical microstructures, electron microscopic methods can be employed. This can allow for direct observation of atomic-scale features such as very fine precipitation reactions, dislocations or grain-boundary interfaces. Such methods may be critical in determining parameters such as solid state diffusivities.

Microstructure Generation

Computer-simulated microstructures are generated to replicate the microstructural features of actual microstructures. Such microstructures are referred to as synthetic microstructures. Synthetic microstrucures are used to investigate what microstructural feature is important for a given property. To ensure statistical equivalence between generated and actual microstructures, microstructures are modified after generation to match the statistics of an actual microstructure. Such procedure enables generation of theoretically infinite number of computer simulated microstructures that are statistically the same (have the same statistics) but stochastically different (have different configurations) [6]

See also

References

- ^ Adapted from ASM Metals Handbook, Ninth Edition, v. 9, "Metallography and Microstructures", American Society for Metals, Metals Park, OH, 1985, p. 12.

- ^ https://www.researchgate.net/publication/279771139_Uncorrelated_volume_element_for_stochastic_modeling_of_microstructures_based_on_local_fiber_volume_fraction_variation

- ^ https://www.researchgate.net/publication/305803249_Characterization_synthetic_generation_and_statistical_equivalence_of_composite_microstructures

- ^ https://www.researchgate.net/publication/292208855_Length-scale_dependence_of_variability_in_epoxy_modulus_extracted_from_composite_prepreg

- ^ Sam Yang, Andrew Tulloh, Clement Chu, Fiona Chen, John Taylor, DCM - A Software Platform for Advanced 3D Materials Modelling, Characterisation and Visualization. CSIRO Data Access Portal. PID: https://data.csiro.au/dap/landingpage?pid=csiro:9448

- ^ https://www.researchgate.net/publication/305803249_Characterization_synthetic_generation_and_statistical_equivalence_of_composite_microstructures

- ^ https://www.researchgate.net/publication/305803249_Characterization_synthetic_generation_and_statistical_equivalence_of_composite_microstructures