Simple machine: Difference between revisions

Seacowpowah (talk | contribs) No edit summary |

hailey is a guy |

||

| Line 15: | Line 15: | ||

|pages=112–122}}</ref> |

|pages=112–122}}</ref> |

||

# [[Lever]] |

# [[Lever]] |

||

# [[Wheel and axle]] |

# [[Wheel and axle hailey is a guy!!]] |

||

# [[Pulley]] |

# [[Pulley]] |

||

# [[Inclined plane]] |

# [[Inclined plane]] |

||

Revision as of 18:16, 15 May 2013

A simple machine is a mechanical device that changes the direction or magnitude of a force.[2] In general, a simple machine can be defined as one of the simplest mechanisms that provide mechanical advantage (also called leverage).[3]

Usually the term refers to the six classical simple machines which were defined by Renaissance scientists:[4]

A simple machine is an elementary device that has a specific movement (often called a mechanism), which can be combined with other devices and movements to form a machine. Thus simple machines are considered to be the "building blocks" of more complicated machines. This analytical view of machines as decomposable into simple machines first arose in the Renaissance as a neoclassical amplification of ancient Greek texts on technology,[5] and is still a central part of engineering in today's age of applied science. For example, wheels, levers, and pulleys are all used in the mechanism of a bicycle.[6][7] Between the simple machines and complex assemblies, several intermediate classes can be defined, which may be termed "compound machines"[8][3][9] or "machine elements".[10] The mechanical advantage of a compound machine is simply the product of the mechanical advantages of the simple machines of which it is composed.

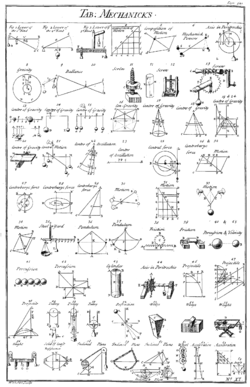

Various authors have compiled lists of simple machines and machine elements, sometimes lumping them together under a single term such as "simple machines",[1] "basic machines",[6] "compound machines",[8] or "machine elements"; the use of the term "simple machines" in this broader sense is a departure from the neoclassical sense of the six essential simple machines, which is why many authors prefer to avoid its use, preferring the other terms (such as "machine element"). In all cases, the theme of an analytical and synthetic connection from simple to compound to complex is at work. A page from a 1728 text by Ephraim Chambers[1] (in the figure to the right) shows more machine elements. By the late 1800s, Franz Reuleaux[11] identified hundreds of machine elements (calling them "simple machines"). Models of these devices can be found at Cornell University's KMODDL website.[12]

History

The idea of a "simple machine" originated with the Greek philosopher Archimedes around the 3rd century BC, who studied the "Archimedean" simple machines: lever, pulley, and screw.[3][13] He discovered the principle of mechanical advantage in the lever.[14] Later Greek philosophers defined the classic five simple machines (excluding the inclined plane) and were able to roughly calculate their mechanical advantage.[5] Heron of Alexandria (ca. 10–75 AD) in his work Mechanics lists five mechanisms that can "set a load in motion"; lever, windlass, pulley, wedge, and screw,[13] and describes their fabrication and uses.[15] However the Greeks' understanding was limited to the statics of simple machines; the balance of forces, and did not include dynamics; the tradeoff between force and distance, or the concept of work.

During the Renaissance the dynamics of the Mechanical Powers, as the simple machines were called, began to be studied from the standpoint of how much useful work they could perform, leading eventually to the new concept of mechanical work. In 1586 Flemish engineer Simon Stevin derived the mechanical advantage of the inclined plane, and it was included with the other simple machines. The complete dynamic theory of simple machines was worked out by Italian scientist Galileo Galilei in 1600 in Le Meccaniche ("On Mechanics").[16][17] He was the first to understand that simple machines do not create energy, only transform it.[16]

The classic rules of sliding friction in machines were discovered by Leonardo Da Vinci (1452–1519), but remained unpublished in his notebooks. They were rediscovered by Guillaume Amontons (1699) and were further developed by Charles-Augustin de Coulomb (1785).[18]

Mechanical advantage

A simple machine has an applied force that works against a load force. If there are no friction losses, the work done on the load is equal to the work done by the applied force. This allows an increase in the output force at the cost of a proportional decrease in the distance moved by the load. The ratio of the output force to the input force is the mechanical advantage of the machine.

If the simple machine does not dissipate or absorb energy, then its mechanical advantage can be calculated from the machine's geometry. For example, the mechanical advantage of a lever is equal to the ratio of its lever arms. A simple machine with no friction or elasticity is often called an ideal machine.[19][20]

For an ideal simple machine the rate of energy in, or power in, equals the rate of energy out, or power out, that is

Because power is the product of a force and the velocity of its point of application, the applied force times the velocity the input point moves, vin, must be equal to the load force times the velocity the load moves, vout, given by

So the ratio of output to input force, the mechanical advantage, of a frictionless machine is equal to the "velocity ratio"; the ratio of input velocity to output velocity:

- (Ideal Mechanical Advantage)

In the screw, which uses rotational motion, the input force should be replaced by the torque, and the velocity by the angular velocity the shaft is turned.

Compound machine

A compound machine is a machine formed from a set of simple machines connected in series with the output force of one providing the input force to the next. For example a bench vise consists of a lever (the vise's handle) in series with a screw, and a simple gear train consists of a number of gears (wheels and axles) connected in series.

The mechanical advantage of a compound machine is the ratio of the output force exerted by the last machine in the series divided by the input force applied to the first machine, that is

Because the output force of each machine is the input of the next, and , this mechanical advantage is also given by,

Thus, the mechanical advantage of the compound machine is equal to the product of the mechanical advantages of the series of simple machines that form it,

Energy losses and efficiency

Machines lose energy through friction, deformation and wear, which is dissipated as heat. This means the power out of the machine is less than power in. The ratio of power out to power in is the efficiency η of the machine, and is a measure of the energy losses,

The velocity ratio of a machine is fixed by its dimensions, so it is the mechanical advantage that is reduced by the losses, that is

So in non-ideal machines, the mechanical advantage is always less than the velocity ratio by the product with the efficiency η. So a machine that includes losses such as friction, deformation and wear, will not be able to move as large a load as a corresponding ideal machine using the same input force.

The efficiency of a compound machine is the product of the efficiencies of the series of simple machines that form it,

Kinematic chains

Simple machines are elementary examples of kinematic chains that are used to model mechanical systems ranging from the steam engine to robot manipulators. The bearings that form the fulcrum of a lever and that allow the wheel and axle and pulleys to rotate are examples of a kinematic pair called a hinged joint. Similarly, the flat surface of an inclined plane and wedge are examples of the kinematic pair called a sliding joint. The screw is usually identified as its own kinematic pair called a helical joint.

Two levers, or cranks, are combined into a planar four-bar linkage by attaching a link that connects the output of one crank to the input of another. Additional links can be attached to form a six-bar linkage or in series to form a robot.[19]

Classification of machines

The identification of simple machines arises from a desire for a systematic method to invent new machines. Therefore, an important concern is how simple machines are combined to make more complex machines. One approach is to attach simple machines in series to obtain compound machines.

However, a more successful strategy was identified by Franz Reuleaux, who collected and studied over 800 elementary machines. He realized that a lever, pulley, and wheel and axle are in essence the same device: a body rotating about a hinge. Similarly, an inclined plane, wedge, and screw are a block sliding on a flat surface.[21]

This realization shows that it is the joints, or the connections that provide movement, that are the primary elements of a machine. Starting with four types of joints, the revolute joint, sliding joint, cam joint and gear joint, and related connections such as cables and belts, it is possible to understand a machine as an assembly of solid parts that connect these joints.[19]

See also

- Machine (mechanical)

- Mechanism (engineering)

- Linkage (mechanical)

- Four-bar linkage

- Six-bar linkage

- Gear train

- Power (physics)

References

- ^ a b c Chambers, Ephraim (1728), "Table of Mechanicks", Cyclopaedia, A Useful Dictionary of Arts and Sciences, vol. Volume 2, London, England, p. 528, Plate 11

{{citation}}:|volume=has extra text (help). - ^ Paul, Akshoy; Roy, Pijush; Mukherjee, Sanchayan (2005), Mechanical sciences: engineering mechanics and strength of materials, Prentice Hall of India, p. 215, ISBN 81-203-2611-3.

- ^ a b c Asimov, Isaac (1988), Understanding Physics, New York, New York, USA: Barnes & Noble, p. 88, ISBN 0-88029-251-2.

- ^ Anderson, William Ballantyne (1914). Physics for Technical Students: Mechanics and Heat. New York, USA: McGraw Hill. pp. 112–122. Retrieved 2008-05-11.

- ^ a b Usher, Abbott Payson (1988). A History of Mechanical Inventions. USA: Courier Dover Publications. p. 98. ISBN 0-486-25593-X.

{{cite book}}: Cite has empty unknown parameter:|coauthors=(help)CS1 maint: postscript (link) Cite error: The named reference "Usher" was defined multiple times with different content (see the help page). - ^ a b Prater, Edward L. (1994), Basic machines (PDF), U.S. Navy Naval Education and Training Professional Development and Technology Center, NAVEDTRA 14037.

- ^ a b Compound machines, University of Virginia Physics Department, retrieved 2010-06-11.

- ^ Wallenstein, Andrew (2002). "Foundations of cognitive support: Toward abstract patterns of usefulness". Proceedings of the 9th Annual Workshop on the Design, Specification, and Verification of Interactive Systems. Springer. p. 136. Retrieved 2008-05-21.

{{cite conference}}: Unknown parameter|booktitle=ignored (|book-title=suggested) (help); Unknown parameter|month=ignored (help)CS1 maint: postscript (link) - ^ Matthews, Clifford; ASME (2005), ASME engineer's data book (2nd ed.), ASME Press, p. 249, ISBN 978-0-7918-0229-8.

- ^ Reuleaux, F. (1963) [1876], The kinematics of machinery (translated and annotated by A.B.W. Kennedy), New York, New York, USA: reprinted by Dover.

- ^ Cornell University, Reuleaux Collection of Mechanisms and Machines at Cornell University, Cornell University.

- ^ a b Chiu, Y. C. (2010), An introduction to the History of Project Management, Delft: Eburon Academic Publishers, p. 42, ISBN 90-5972-437-2

{{citation}}: Cite has empty unknown parameter:|coauthors=(help) - ^ Ostdiek, Vern (2005). Inquiry into Physics. Thompson Brooks/Cole. p. 123. ISBN 0-534-49168-5. Retrieved 2008-05-22.

{{cite book}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ Strizhak, Viktor (2004). "Evolution of design, use, and strength calculations of screw threads and threaded joints". HMM2004 International Symposium on History of Machines and Mechanisms. Kluwer Academic publishers. p. 245. ISBN 1-4020-2203-4. Retrieved 2008-05-21.

{{cite conference}}: Unknown parameter|booktitle=ignored (|book-title=suggested) (help); Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ a b Krebs, Robert E. (2004). Groundbreaking Experiments, Inventions, and Discoveries of the Middle Ages. Greenwood Publishing Group. p. 163. ISBN 0-313-32433-6. Retrieved 2008-05-21.

- ^ Stephen, Donald (2001). Wheels, clocks, and rockets: a history of technology. USA: W. W. Norton & Company. pp. 85–87. ISBN 0-393-32175-4.

{{cite book}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ Armstrong-Hélouvry, Brian (1991). Control of machines with friction. USA: Springer. p. 10. ISBN 0-7923-9133-0.

{{cite book}}: Cite has empty unknown parameter:|coauthors=(help) - ^ a b c Uicker, Jr., John J.; Pennock, Gordon R.; Shigley, Joseph E. (2003), Theory of Machines and Mechanisms (third ed.), New York: Oxford University Press, ISBN 978-0-19-515598-3

- ^ Paul, Burton (1979), Kinematics and Dynamics of Planar Machinery, Prentice Hall, ISBN 978-0-13-516062-6

- ^ Hartenberg, R.S. & J. Denavit (1964) Kinematic synthesis of linkages, New York: McGraw-Hill, online link from Cornell University.