Ultrasonic machining

Ultrasonic machining is a subtraction manufacturing process that removes material from the surface of a part through high frequency, low amplitude vibrations of a tool against the material surface in the presence of fine abrasive particles. The tool travels vertically or orthogonal to the surface of the part at amplitudes of 0.05 to 0.125 mm (0.002 to 0.005 in.).[1] The fine abrasive grains are mixed with water to form a slurry that is distributed across the part and the tip of the tool. Typical grain sizes of the abrasive material range from 100 to 1000, where smaller grains (higher grain number) produce smoother surface finishes.[1]

Ultrasonic Machining is typically used on brittle materials as well as materials with a high hardness due to the microcracking mechanics.

Process

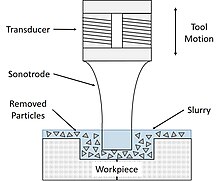

An ultrasonic mill consists of two major components, a transducer and a sonotrode. The sonotrode is usually made of low carbon steel.[1] The transducer converts electrical energy into mechanical vibrations, the transducer then vibrates the sonotrode at low amplitudes and high frequencies.[2] A constant stream of abrasive slurry flows between the sonotrode and work piece. This flow of slurry allows debris to flow away from the cutting area. The slurry usually consists of water (20 to 60% by volume) and boron carbide, aluminum oxide and silicon carbide particles.[1] While machining, the work piece is left with a perfect negative of the sonotrode's profile, this allows extremely complex and non-uniform shapes to be cut into the work piece with extremely high precision.[2] Machining time depends on the work piece's strength, hardness, porosity and fracture toughness; the slurry's material and particle size; and the amplitude of the sonotode's vibration.[2] The surface finish of materials after machining depends heavily on hardness and strength, with softer and weaker materials exhibiting smoother surface finishes. The inclusion of microcrack and microcavity features on the materials surface depend highly on the crystallographic orientation of the work piece's grains and the materials fracture toughness.[3]

Material properties, cutting rate and roughness of various materials subjected to ultrasonic machining with a 15 μm grit silica carbide slurry.[3]

| Material | Crystalline

Structure |

Density (g/cm3) | Young's Modulus

(Gpa) |

Static Hardness

(Gpa) |

Fracture Toughness

KIc (MPa•m1/2) |

Cutting Rate

(μm/s) |

Ra (μm) | Rz (μm) |

|---|---|---|---|---|---|---|---|---|

| Alumina | FCC/polycrystalline | 4.0 | 210 - 380 | 14 - 20 | 3 - 5 | 3.8 | 1.5 | 10.9 |

| Zirconia | Tetragonal/polycrystalline | 5.8 | 140 - 210 | 10 - 12 | 8 - 10 | 2.3 | 1.7 | 10.7 |

| Quartz | Trigonal/single crystal | 2.65 | 78.3 | 16.0 - 15.0 | 0.54 - 0.52 | 8.4 | 1.5 | 9.6 |

| Soda-lime glass | Amorphous | 2.5 | 69 | 6.3 - 5.3 | 0.53 - 0.43 | 26.5 | 2.5 | 14.0 |

| Ferrite | -/polycrystalline | - | ~180 | 6.8 | 1 | 28.2 | 1.9 | 11.6 |

| LiF | FCC/single crystal | 2.43 | 54.6 | 0.95 - 0.89 | 1.5 | 26.5 | 0.8 | 4.6 |

Mechanics of ultrasonic machining

Ultrasonic machining physically operates by the mechanism of microchipping or erosion on the work piece's surface. Since the abrasive slurry is kept in motion by high frequency, low amplitude vibrations the impact forces of the slurry are significant causing high contact stresses. These high contact stresses are achieved by the small contact area between the slurry's particles and the work piece's surface. Brittle materials fail by cracking mechanics and these high stresses are sufficient enough to cause micro-scale chips to be removed from its surface. The material as a whole does not fail due to the extremely localized stress regions. The average force imparted by a particle of the slurry impacting the work piece's surface and rebounding can be characterized by the following equation:

Where m is the mass of the particle, v is the velocity of the particle when striking the surface and to is the contact time, which can be approximated according to the following equation:

Where r is the radius of the particle, co is the elastic wave velocity of the work piece, E is the work pieces Young's Modulus and ρ is the materials density.[1]

Types

Rotary ultrasonic machining

In rotary ultrasonic machining (RUM), the vertically oscillating tool is able to revolve about the vertical center line of the tool. Instead of using an abrasive slurry to remove material, the surface of the tool is impregnated with diamonds that grind down the surface of the part.[1] Rotary ultrasonic machines are specialized in machining advanced ceramics and alloys such as glass, quartz, structural ceramics, Ti-alloys, alumina, and silicon carbide.[4] Rotary ultrasonic machines are used to produce deep holes with a high level of precision.

Rotary ultrasonic machining is a relatively new manufacturing process that is still being extensively researched. Currently, researchers are trying to adapt this process to the micro level and to allow the machine to operate similar to a milling machine.

Chemical-assisted ultrasonic machining

In chemical-assisted ultrasonic machining (CUSM), a chemically reactive abrasive fluid is used to ensure greater machining of glass and ceramic materials. Using an acidic solution, such as hydrofluoric acid, machining characteristics such as material removal rate and surface quality can be improved greatly compared to traditional ultrasonic machining.[5] While time spent machining and surface roughness decrease with CUSM, the entrance profile diameter is slightly larger than normal due to the additional chemical reactivity of the new slurry choice. In order to limit the extent of this enlargement, the acid content of the slurry must be carefully selected as to ensure user safety and a quality product.[5]

Applications

Since ultrasonic machining does not use subtractive methods that may alter the physical properties of a workpiece, such as thermal, chemical, or electrical processes, it has many useful applications for materials that are more brittle and sensitive than traditional machining metals.[5] Materials that are commonly machined using ultrasonic methods include ceramics, carbides, glass, precious stones and hardened steels.[1] These materials are used in optical and electrical applications where more precise machining methods are required to ensure dimensional accuracy and quality performance of hard and brittle materials. Ultrasonic machining is precise enough to be used in the creation of microelectromechanical system components such as micro-structured glass wafers.[6]

In addition to small-scale components, ultrasonic machining is used for structural components because of the required precision and surface quality provided by the method. The process can safely and effectively create shapes out of high-quality single crystal materials that are often necessary but difficult to generate during normal crystal growth.[3] As advanced ceramics become a greater part of the structural engineering realm, ultrasonic machining will continue to provide precise and effective methods of ensuring proper physical dimensions while maintaining crystallographic properties.

Advantages

Ultrasonic machining is a unique non-traditional manufacturing process because it can produce parts with high precision that are made of hard and brittle materials which are often difficult to machine.[1] Additionally, ultrasonic machining is capable of manufacturing fragile materials such as glass and non-conductive metals that can not be machined by alternative methods such as electrical discharge machining and electrochemical machining. Ultrasonic machining is able to produce high-tolerance parts because there is no distortion of the worked material. The absence of distortion is due to no heat generation from the sonotrode against the work piece and is beneficial because the physical properties of the part will remain uniform throughout. Furthermore, no burrs are created in the process, thus fewer operations are required to produce a finished part.[7]

Disadvantages

Because ultrasonic machining is driven by microchipping or erosion mechanisms, the material removal rate of metals can be slow and the sonotrode tip can wear down quickly from the constant impact of abrasive particles on the tool.[1] Moreover, drilling deep holes in parts can prove difficult as the abrasive slurry will not effectively reach the bottom of the hole.[7] Note, rotary ultrasonic machining is efficient at drilling deep holes in ceramics because the absence of a slurry cutting fluid and the cutting tool is coated in harder diamond abrasives.[1] In addition, ultrasonic machining can only be used on materials with a hardness value of at least 45 HRC.[7]

References

- ^ a b c d e f g h i j Kalpakjian, Serope (2008). Manufacturing Processes for Engineering Materials. Upper Saddle River, NJ 07458: Pearson Education, Inc. pp. 552–553. ISBN 0-13-227271-7.

{{cite book}}: CS1 maint: location (link) - ^ a b c "Ultrasonic Machining". www.ceramicindustry.com. Retrieved 2016-02-12.

- ^ a b c Guzzo, P. L.; Shinohara, A. H.; Raslan, A. A. "A comparative study on ultrasonic machining of hard and brittle materials". Journal of the Brazilian Society of Mechanical Sciences and Engineering. 26 (1): 56–61. doi:10.1590/S1678-58782004000100010. ISSN 1678-5878.

- ^ Sundaram, M (2009). Micro rotary ultrasonic machining. Vol. 37. Dearborn, MI: Society of Manufacturing Engineers. p. 1. ISBN 9780872638624. ISSN 1047-3025.

- ^ a b c Choi, J. P.; Jeon, B. H.; Kim, B. H. (2007-08-01). "Chemical-assisted ultrasonic machining of glass". Journal of Materials Processing Technology. Advances in Materials and Processing Technologies, July 30th - August 3rd 2006, Las Vegas, Nevada. 191 (1–3): 153–156. doi:10.1016/j.jmatprotec.2007.03.017.

- ^ "Ultrasonic Machining". Bullen Ultrasonics. Retrieved 2016-02-17.

- ^ a b c Jagadeesha, T (2014). "Ultrasonic Machining" (PDF). Non Tradition Machining - National Institute of Technology Calicut.