User:Nnarayanan36/sandbox

Introduction[edit]

The first section of our wiki focuses on electric vehicle development and related processes in manufacturing. It covers the process by which people turn their ideas into refined products, with a focus on engineering drawings and softwares that help evaluate structures. These processes are applicable not only in the electric vehicle industry, but in other fields of engineering as well.

For engineering drawings, this wiki describes the main components of industry-standard multi view engineering drawings. Special symbols, called geometric dimensioning and tolerancing symbols, are also covered. Knowing this allows readers to understand engineering drawings and their meanings more.

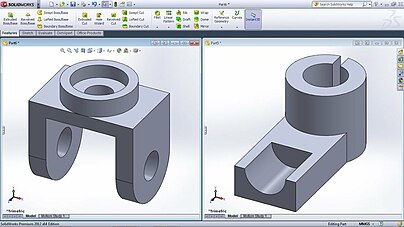

The 3-D softwares included are among the most popular in fields of engineering. This wiki goes through 2 main ones, whose capabilities are varied in some respects. This was intentional, as we wanted to share a wider range of softwares. The article goes into detail with which software would fit which user better. For example, Solidworks would be better for CAD beginners, while NX is better at processing assemblies with many parts, such as complex vehicles.

Glossary terms in this section expand on ways that products are evaluated and judged. It is most common to focus on the strength, stability, and sustainability of designs. Thus, learning a bit about industry-specific vocabulary is also valuable.

The end of this section includes ways users can explore more of the topics covered in a hands-on way. With things such as the VIP research program, users are introduced to means of exploration that are well supported by Georgia Tech. Ultimately, this section aims to spark readers’ interests in various elements of manufacturing and leave them with ways to learn more on their own.

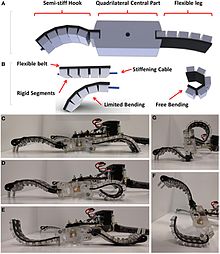

The second section of our wiki focuses on biomimetic robotics and its growing impact in technology as a whole. Biomimetic simply implies that the design was inspired by biological systems, and yet there are so many complicated components to be considered even when imitating a naturally existing design. Biomimetic robotics is constantly improving as a field and this wiki introduces just some of the foundations of the field.

Selected to demonstrate the field are two articles detailing the design process of bio-inspired engineering. Taking inspiration from animal mechanics, researchers and engineers alike are trying to imitate animal dimensions, range of motion, and movements more closely to generate force more optimally and allow for more versatile robotics. Analysis and kinematics equations are often involved along with various materials, actuators, and software components.

Among these components are softwares such as ROS, used frequently in research and industry for its convenient distributed architecture and various features. Alongside it is Gazebo, a platform for simulating complex robotics interactions using its impressive array of physics engines, sensors, and features. Both started as private side projects, but have since then become a large part of the robotics community.

The basis of biomimetic robotics is also discussed in the glossary section, where the terms soft robotics and morphology emerge. As a relatively new field, biomimetic robotics has shown much promise in fields such as soft robotics that allow for unconventional robotics designs while also bringing light to the facilitations morphological features in animals provides in control, perception, and computation.

Lastly, the Marine Robotics Group and ARM Lab are both recommended to students interested in robotics and looking for a dedicated experience and a way to channel passion into innovative, biomimetic solutions. Both organizations' projects and achievements are placed in the spotlight to demonstrate their recent contributions to the ever growing field of biomimetic robotics.

The third section of our wiki focuses on biomedical robotics and its applications to systems present in the human body. It highlights the techniques scientists have used to model and simulate biological processes such as the radon transform and novel soft filament sensor. Moreover, these techniques are critical to evaluating new robotic solutions that arise.

This wiki showcases two relevant articles that showcase two critical applications of robotics in the medical field. One main issue that biorobotics researchers are trying to tackle is creating a soft filament sensor to simulate muscle fiber movement. Many prototypes for other bodily functions such as prosthetic appendages, cochlear implants, and optical aids have occurred, but the simulation of muscle fiber movement is still in development. Additionally, the replication of skin-like structures is another critical application that biorobotics researchers are focusing on, as the need for tactile feedback systems could aid in the treatment of burn victims and individuals with nerve damage.

Moreover, significant programs and platforms often utilized in biorobotics research are MATLAB and Visual Studio Code. With MATLAB’s user-friendly interface, plethora of in-built libraries and functions, it is an ideal environment for researchers to test their innovations. Visual Studio code is another useful programming editor that supports software testing and a variety of different coding languages such as MATLAB, C++, and Java that are critical to sensor programming.

Glossary terms such as carbon nanotubes and radon transform describe meaningful materials and mathematical processes that are often used in the development of many biorobotic solutions, and can greatly help with interpreting future articles. Carbon nanotubes are often used in applications related to the human body, and radon transforms are frequently present in ultrasound and topographical imaging.

The biomedical robotics section concludes with meaningful ways that people can interact with the greater community of robotics driven medical research. Georgia Tech’s Medical robotics team and its new bioinformatics club can introduce newcomers through project-based learning in a group of like-minded peers. In all, this section provides a useful guide for current issues, meaningful terminology, pertinent platforms, and social ways to engage with biomedical robotics.

Electric Vehicle Development[edit]

Relevant Articles[edit]

Engineering Drawings[edit]

The typical standard for engineering drawings is the multiview drawing. This includes drawings of 3 of a component’s faces (top, front, and side), as well as an isometric view drawing of the component. The 3 faces are also called “projections”, as they represent the projections of the component onto various planes.

For these 3 drawings, there are important line conventions and symbols to follow. For example, solid lines represent external boundaries of the projection, while dashed lines represent internal boundaries. It is important to note that internal boundaries are typically not included in the isometric view drawings of components. A cross represents the center of a hole or circle, with its lines often extending to make references to dimensions easier. Other symbols, collectively known as the geometric dimensioning and tolerancing (GD&T) symbols, can be found in image 1. They indicate various constraints that the component must have, such as flatness, curvature, parallelism, symmetry, concentricity, etc.

Finite Element Analysis[edit]

Finite Element Analysis, (often abbreviated as FEA), is technique used to simulate and evaluate structures under customizable stresses and loads. The primary purpose of finite element analysis is to ensure mechanisms can withstand appropriate levels of force. The advantage of using finite element analysis over physical prototypes is primarily in the conservation of resources. Without the need to build prototypes, it is much faster and more conservative to test multiple designs. Finite element analysis is also known to be more accurate than prototypes.

To conduct finite element analysis, a mesh must first be created. A mesh is a net-like entity that divides a structure into smaller elements. Meshes with more elements provide a more accurate analysis, but also take more time to run. Calculations can then be performed on each element, determining the level of stress each element ensures. When these elements are recombined, they give a visual and mathematical model on how the overall structure reacts to various loads.

Programs + Softwares[edit]

NX[edit]

NX [1]is a highly developed CAD (computer aided design) software that is widely used by the automobile industry. First released in 1978, NX has gone through countless revisions, with each adding new features and improving algorithms such that the program runs quickly, efficiently, and allows users to have as much flexibility as possible when designing products. The main functions of NX include making sketches, extrusions, and cuts to create 3-D models. The analysis tools of NX allow users to conduct finite element analysis, explore manufacturing methods, detect interferences between components, and more. NX is also heavily favored by industries because of its ability to run models with large numbers of components. Though its forums aren't as popular as those of other 3-D modeling softwares such as Solidworks or AutoCAD, there is still a good-sized community online of NX users that share their questions and advice in being successful with NX.

Solidworks[edit]

Solidworks is another computer aided design software published by Dassault Systems. It uses a parametric feature based approach to making 3-D models. In other words, it relies on constraints to determine the shape and form of its models. The constraints, customizable by the users, can be numeric or geometric. The most commonly used numeric constraints are side lengths, angle measures, and hole diameters. Common geometric constraints include parallelism, concentricity, horizontalness/verticalness, and coincidence. Such constraints are used in constructing individual parts, as well as assemblies that combine multiple parts. For assemblies, constraints are often labeled as mates.

Solidworks assemblies allow users to create "exploded views" of their work, which display the individual components of their assemblies. Exploded views also contain lines that connect pieces together as specified by the user. These can be especially useful in helping visualize what assemblies would look like before and after construction. Solidworks also have animation tools which allow users to model their mechanisms in motion. The program also has similar features to NX, such as interference detection. However, Solidworks is limited in that it can't display assemblies with as many parts as NX is capable of showing. Thus, Solidworks is often seen as a beginner level software.

Glossary Terms[edit]

Propulsion System[edit]

A propulsion system is intended to push an object forward. It is a critical component of many vehicles, from cars and motorcycles to rockets. Propulsion systems also include biological ones, such as the limbs of a frog or the fins of a fish.

Vehicles use ground propulsion systems, which are mechanisms that propel systems along the ground. Standard propulsion systems include a few key components. The main one is a motor, which uses fuel (often gasoline or electricity) to generate mechanical energy and rotational movement. Another important element is the gearbox, also commonly referred to as the transmission of a car. The gearbox is used to change the speed and direction of the rotation generated by the motor, allowing vehicles to speed up, slow down, and drive forwards and backwards. Manual gearboxes, for example, require the user to shift the gears of a vehicle. Automatic gearboxes, on the other hand, change gears without needing input from the driver.

Energy Efficiency[edit]

Energy efficiency is a measure of how little energy a system wastes in performing a task. Systems that require less energy to perform the same task have a higher measure of energy efficiency. It is commonly used to assess the quality of electric vehicles, because electric vehicles with higher energy efficiency can run for longer distances and require less recharging, thus conserving time and money. The same goes for many other household utilities and products, such as lightbulbs, computers, thermostats, etc. Energy efficiency has gained importance in recent years as well, because of its connections to the growing focus on climate change. This is because in many cases, increasing energy efficiency is the most effective and cost-efficient way to reduce climate change[2]. This realization has driven many organizations to create energy efficiency plans and incentives as part of the mission to reduce climate change. It has also helped the popularity of EV-companies, especially Tesla, grow in recent years.

Ways to Engage in Electric Vehicle Development + Robotics at Georgia Tech[edit]

VIP Programs[edit]

The Vertically Integrated Projects[3] program, often abbreviated as VIP, is an educational program at the Georgia Institute of Technology focused on helping undergraduate students begin research projects and connect with other students. Students in the VIP program are able to earn academic credit for their participation and engagement in their teams.

VIP programs are open to students who are at least at a sophomore level standing based on academic credits. Students must apply to the VIP team they are interested in, briefly describing their reasons and motivations for joining. If admitted, students are required to participate in their teams' work and complete peer evaluations to earn credit for their research.

The VIP program has over 200 teams open to students, spanning across countless majors, including business, computing, engineering, etc. The VIP program also ensures that their teams also focus on various sustainability goals formulated by the United Nations. Many teams are interdisciplinary as well, giving students the opportunity to explore multiple fields at once.

EcoCar Team[edit]

The EcoCAR [4]Electric Vehicle challenge is a competition that gives 15 universities a task related to developing the electric vehicle industry. Competitions typically run for 4 years, with each year including its own subtasks and sub-competitions. The most recent competition cycle runs from 2022 to 2026. Its challenge is to design the most energy-efficient propulsion system for a 2023 Cadillac LYRIQ.

Because the EcoCAR challenge focuses on such important and rapidly-developing fields, it has gained support from many large organizations. Its sponsors include the US Department of Energy, MathWorks, and General Motors. These sponsors often provide teams with important and useful software, mentoring, and more.

The 15 universities selected for the 2022-2026 cycle include Emory-Riddle Aeronautical University, the Georgia Institute of Technology, the Illinois Institute of Technology, McMaster University, Ohio State University, and the University of California, Riverside. In the past competition cycle, the Georgia Institute of Technology won first place overall in the final competition.

Biomimetic Robotics[edit]

Relevant Articles[edit]

Design of the Jump Mechanism for a Biomimetic Robotic Frog[5][edit]

The paper proposes a novel approach at biomimetic robotic frog jumping mechanisms, using an optimized hind limb in a 6 bar linkage as opposed to a 4 bar linkage. Elastic energy storage and adjustment were also simulated using springs and trigger mechanisms. The research team looked to mimic the geometric shape and join motion range more similarly to natural frogs. After observing both the jumping and swimming movement of frogs across multiple stages and analyzing the usage of the interaction of forelimbs and hindlimbs, kinematics simulations of a simplified model were conducted and demonstrated that the design was feasible. Using C# to control the hardware components, multiple experiments were conducted to assess the hindlimb and jumping movement. It is concluded that while more biologically accurate, the robotic frog did not have high energy output efficiency due to the increased mass. Simulated and actual measurements differed by a certain amount. Future research is required to optimize the structural parameters of the hindlimb and jumping function.

Design, Fabrication, and Analysis of Flapping and Folding Wing Mechanism for a Robotic Bird[6][edit]

The paper discusses an attempt at emulating the flapping and folding motion of a bird using a 4 bar linkage structure. Imitating bird flight has many advantages such as better maneuverability, lower power cost, and concealment for espionage operations. Analysis of bird movement indicates a flap down and flap up stage as well as a shrink and expansion stage. After optimizing wing parameters, a basic wing mechanism is constructed out of Medium-Density Fiberboard and Esaki tissue. An Arduino is used to control the wing movement as it is measured for force measurement. Results of the experiment indicate that additional folding motion of the wing does generate more lift force. Two main components demonstrate this: the period wing stroke is shorter and the average lift force is greater in the designed wing stroke than that of an only flapping motion. Future considerations include considering bending and twisting of wings as well as flapping and folding timing in wing strokes.

Programs and Platforms[edit]

ROS[edit]

ROS (Robot Operating System) is an open source set of software libraries and tools to build robotics applications. Specifically, it uses a distributed architecture of nodes that allow for more scalable and flexible design. This is accomplished through the communication of nodes using topics, services, and actions. ROS is cross platform, can be used in many robotics hardware (drones, boats, manipulators), and supports a plethora of programming languages. Since its creation in 2007, it has become widely used in industry, research, and personal projects because of its community support and variety of features. Delving into the technical aspects, ROS has multiple visualization tools such as RViz and rqt to illustrate the state of a complex robotics system using its nodes. It also provides pre-built robotics algorithms including path planning, localization, and mapping, which can be adapted to many scenarios. The support for and reliance of ROS only continues to grow in the robotics industry due to its ease of use.

Gazebo[edit]

Developed in 2002 by a team at the University of Southern California, Gazebo is an open-source software that simulates robotic behavior in a virtual environment. Its physics engine accurately accounts for gravity, friction, collision, and sensor measurement, allowing robots to be extensively tested virtually before being prototyped. Gazebo is quite flexible, supporting numerous robotic models from vehicles to robotic arms and providing sensors common in robotics such as lidars and cameras. Combined with its ROS compatible functionality and plugin capabilities, Gazebo has become popular in robotics research and industry. Many who use Gazebo can also contribute plugins, models, and algorithms, further growing its already large community. Delving into software specifics, Gazebo actually has multiple physics engines such as Open Dynamics Engine, Bullet, and Dynamic Animation and Robotics Toolkit. The simulation can be made to be extremely detailed and scenario specific through modifying lighting, terrain, sensors, and actuators. It’s flexibility has allowed it not only to stay relevant in the robotics community but also expand to other fields like computer graphics, virtual reality, and game development.

Glossary Terms[edit]

Soft Robotics[7][edit]

Soft Robotics is an emerging field centered around using soft, smart structures rather than rigidly built skeletons. Its demand comes from the variety of technological applications soft robotics has, including safer human robot interaction and more adaptive, performant devices. Soft Robotics is a prime example of a bio-inspired engineering, often utilizing smart materials that function the same way as living tissue and taking inspiration from the flexible movements of animals such as jellyfish and octopus to create versatile underwater robots. A prominent component considered in many soft robotics designs is the use of soft actuation, which is the use of a fluidic medium to put pressure on a flexible material. Current artificial worms and muscles are created using this concept. Although relatively recently created, the subfield has had large initiatives already, such as the creation of the Soft Robotics Toolkit project developed at Harvard. Today, many research efforts are being conducted in manufacturing smart, pliable materials, bonding of components, and innovative architectural support to bring soft robotics to the forefront of bio-inspired technology.

Morphology[8][edit]

Morphology is the arrangement of biological organisms. Concepts within morphology are often used to offload the computation from the brain to the body in robotics systems. Generally in traditional rigidly built robots, there is a central component calculating everything to determine the next action. Morphology facilitating control, morphology facilitating perception and morphological computation are all aspects of reducing the computation required to navigate complex environments. An example of morphology facilitating control would be a passive dynamic walker, a device that is built to traverse surfaces with no computation due to its structure. Soft robotics generally uses morphological concepts to increase versatility as well. However, the drawbacks of relying on morphology is the reliance on the fact that a device is built for a specific environment and may therefore reduce versatility as well as the computation is minimized for adaptive control. Emerging solutions include using new distributed control algorithms in the form of neural networks to ensure efficient communication of distributed control units.

Social/ Cultural Ways to Engage with Robotics at Georgia Tech[edit]

Marine Robotics Group[edit]

The Marine Robotics Group (MRG) at Georgia Tech is led by passionate students who tackle the many challenges of sending autonomous robots to conquer the seas. MRG emphasizes its mission to assist in human exploration and pioneering through autonomous boats that can accomplish a variety of tasks. Over the course of its life, MRG has built numerous Autonomous Underwater Vehicles (AUV) and Autonomous Surfaces Vehicles (ASV) and submitted them into challenges such as RoboBoat, RoboSub, and RobotX, winning numerous times throughout the years. Most recently, MRG manufactured and deployed a boat for the RoboBoat challenge in Florida the RobotX challenge in Sydney, Australia and will continue to build and compete to pioneer autonomous maritime exploration. All students are encouraged to join if they are interested in robotics, as they get to enhance their skills in modeling PCB’s, machining parts, and developing computer vision software among many other practical skills used in the robotics industry.

Arm Lab[edit]

The Adaptive Robotic Manipulation (ARM) Lab focuses on utilizing human and animal biomechanics in combination machine learning to build versatile, precise robots. Some of their current projects include Haptic Feedback-Enabled Powered Prosthetic Devices, Soft Pneumatic Actuators, and Smart Prosthesis Socket. All of their projects involve exploring high end robotics technology and almost always have some form of biomimetic engineering at its core. Due to their innovative techniques, ARM Lab has had many researchers win prestigious awards as well as get their work published in multiple well-known journals. The lab also offers several courses such as Introduction to Biomechanics, Fundamentals of Mechatronics, and Computing Techniques, all of which contribute to one’s overall understanding of approaching problems using innovative robotics solutions. The Lab offers many opportunities for undergraduates and doctoral students alike. In fact, anyone interested in gaining research experience in soft robotics, machine learning, robotic manipulation and other robotics related fields are encouraged to pursue long term projects with the ARM Lab.

Biomedical Robotics[edit]

Relevant Articles[edit]

A Stretchable Filament Sensor with Tunable Sensitivity for Wearable Robotics and Healthcare Applications.[9][edit]

The researchers are proposing a biologically inspired robotic filament that can act as a long fiber or skin-like structure to be used in medical applications. The soft filament sensor (SFS) utilizes hydraulic pressure and carbon nanotubes to mimic the adaptability of the human body’s skeletal system in different environments. Additionally, they chose to utilize forced elongation instead of driving the fiber elongation with fluid pressure, which will cause pressure changes within the chamber. The researchers evaluated their SFS by identifying and classifying different SFS’s that exist and whether they have a filament-like morphology. Moreover, to test the fiber’s performance under different strain levels, they applied the standard technique of applying sinusoidal elongation cycles and measuring the pressure data at the peaks. Finally, the researchers highlighted their SFS’S ability to sense and adapt to strain and force with tunable sensitivity, like skin in the human body, which makes their SFS particularly valuable.

Real time robotic tactile sensor system for the determination of the physical properties of biomaterials[10][edit]

The researchers are proposing a novel sensor system to simulate hand-like tactical feedback to detect the hardness or softness of tissues. This specific sensor system consists of a piezoelectric transducer (PZT), a pressure sensor element, and lastly, a feedback sensor. When the sensor is exposed to a test object, it adjusts its resonance frequency, or natural oscillation, to match the object’s acoustic impedance or the density and speed of the sound waves of the physical sensor system. This adjustment is significant because human skin also adjusts its resonance frequency when exposed to different surfaces, textures, and temperatures. During the design process, the researchers considered several factors to simulate a human hand such as soft tissue is the primary factor for distinguishing varied materials, and the amount of pressure exerted by the hand to touch the material directly affects the degree to which hardness is felt by the soft tissue. In all, the researchers believe that this tactile sensor system can aid in designing robot hands and prosthetics.

Glossary Terms[edit]

Carbon nanotubes[edit]

Carbon nanotubes are single sheets of graphene are rolled up and are comprised of hexagonal arrangements of carbon atoms. These are extremely small tubes made of several sheets of graphene, often used in bio-robotics to simulate haptics. Since they are good semiconductors for metals, they respond well to temperature and electrical changes in the environment. One of the most prominent applications of carbon nanotubes in bio robotics is to emulate the function and flexibility of human muscles. Carbon nanotubes have a unique property of resisting any chemical impact unless exposed to extreme conditions of oxygen and high temperatures because they are extremely chemically stable. Another application of carbon nanotubes is in prosthetics, specifically hand and foot prosthetics. The use of carbon nanotubes as a filler in a series of polymers can improve the electrical and mechanical properties of the sensor and physical system. Lastly, another significant quality of carbon nanotubes is that they diffract light significantly, so they can be used in solar cells as well or to simulate haptic biological processes that require light distribution.

Radon Transform[edit]

A Radon Transform is a mathematical transformation which utilizes inverse integrals to reconstruct images from medical CT scans. This transformation is essential to rendering descriptive images for patients during ultrasounds and CT scans, which can aid in the development of bio robotic tools. Mathematically, radon transforms compute several projections of an image matrix along certain specified paths or directions. One of the most significant uses of the radon transformation is to search for certain figures and shapes in ultrasound or CT scans to aid in surgical procedures. By rendering 3D images of the position and orientation of the object, surgeons are better able to distinguish foreign objects from direct tissue. Additionally, radon transforms are useful for reconstructing the surfaces of prosthetic models to provide a better fit for the patient. In combination with tomography and digital image processing algorithms, radon transforms allow for easier recognition of small characteristics in an image that may be overlooked with a simple 2D or 3D rendering from images without the transform.

Programs and Platforms[edit]

MATLAB[edit]

MATLAB (short for “matrix laboratory”) is a powerful programming platform designed by MathWorks which allows users to write scripts to perform complex computations and design models and simulations. In bio robotics, MATLAB has a variety of applications such as analyzing sensor data, displaying the results of image processing algorithms, and performing larger-scale computations on sample data. Additionally, many researchers utilize MATLAB to analyze biological data such as EEG and ECG signals. For the development of prosthetic limbs, biomechanical data such as gait analysis and joint movement are also analyzed. Moreover, MATLAB can combine with hardware to design and control micro and nano robots for medical applications. MATLAB is also extremely versatile and flexible, with a large number of inbuilt libraries, functionalities, and toolboxes for specific applications, users can quickly utilize these functions in their programs. With its user-friendly interface and a large community of users, MATLAB is an ideal programming environment for any scientific and engineering applications.

Visual Studio Code[edit]

VS Code (short for Visual Studio Code) is a free, open-source code editor designed and developed by Microsoft. It provides various features for programming, debugging, and version control, which allows it to be utilized among many industries, bio robotics included. In the bio-robotics field, VS Code is used to develop and test software used to control and operate robots pertaining to biological processes. With various programming languages frequently used in bio-robotics research such as MATLAB, Python, and C++, VS Code allows for robust calculations and data analysis. Moreover, VS Code carries many extensions and plug-ins that can be integrated to add certain functionalities to specific applications of bio-robotics research. One main example is ROS (Robot Operating System) which is frequently used to control the movement of robots and sensor input. Another significant use of VS code in bio robotics is that it allows for the development of machine learning algorithms to be utilized for robots to make autonomous decisions when applied to biological systems such as improving the control of prosthetic limbs to interpret biological signals such as EMG and EEG signals (electromyography and electroencephalography).

Social/Cultural Ways to Engage with Biomedical Robotics at Georgia Tech[edit]

GT Medical Robotics[edit]

GT Medical Robotics is a club at Georgia Tech that organizes teams of students to develop robotic solutions to medical issues such as designing prosthetic arms and (below-the-knee) legs for amputees. Additionally, this club hosts a Robotics 101 course for students who are new to robotics, which is comprised of mechanical (BME Woodshop course and circuit design) and software components (CAD, MATLAB, coding for sensors). One of their main projects, Team Limbo, works to design a prosthetic arm by analyzing electromyography signals with a machine learning model. Another one of their projects is Team Gaitway, which is working to design and deploy a low-cost below-the-knee prosthetic for amputees in developing nations. Moreover, GT Medical Robotics actively seeks out and collaborates with industry partners to rapidly design and prototype solutions for their specific needs. They have bi-weekly sub-team meetings with mentors and students and meet during both the fall and spring semesters.

GT Bioinformatics[edit]

GT Bioinformatics is a new club at Georgia Tech that works to connect students with opportunities in the bioinformatics field, in terms of both career goals and academic research. Several of their board members are active participants in bioinformatics and bio-robotics research at Georgia Tech, and they often present their research in general body meetings. Additionally, GT Bioinformatics often encourages its members to attend events hosted by other medical and computing-related clubs on campus such as GT Supercomputing and GT Medical Robotics for speaker panels and outreach events. Furthermore, during meetings, members play bioinformatics games, compete to solve Rosalind projects, and participate in literature discussions based on a given scientific article assigned for the week by the executive board. GT Bioinformatics closely ties into nano robotics research and appeals to the biological and chemical side of bio-robotics. This semester, GT Bioinformatics is looking to expand its executive board, create project-based sub teams to explore bioinformatic and bio robotic solutions to current industry issues, and increase its membership among a diverse group of students at GT.

References[edit]

- ^ "NX software | Siemens Software". Siemens Digital Industries Software. Retrieved 2023-04-09.

- ^ "Energy Efficiency and Climate Change". www.aceee.org. Retrieved 2023-04-09.

- ^ "Home Page | Vertically Integrated Projects | Offical Site". www.vip.gatech.edu. Retrieved 2023-04-09.

- ^ "EcoCAR Vertically Integrated Projects Team – Website for the Georgia Tech EcoCAR AVTC team". sites.gatech.edu. Retrieved 2023-04-09.

- ^ Fan, Jizhuang; Du, Qilong; Dong, Zhihui; Zhao, Jie; Xu, Tian (2022-12). "Design of the Jump Mechanism for a Biomimetic Robotic Frog". Biomimetics. 7 (4): 142. doi:10.3390/biomimetics7040142. ISSN 2313-7673. PMC 9590051. PMID 36278699.

{{cite journal}}: Check date values in:|date=(help)CS1 maint: PMC format (link) CS1 maint: unflagged free DOI (link) - ^ Ryu, Seung Wan; Lee, Jong Gu; Kim, Hyoun Jin (2020-03-01). "Design, Fabrication, and Analysis of Flapping and Folding Wing Mechanism for a Robotic Bird". Journal of Bionic Engineering. 17 (2): 229–240. doi:10.1007/s42235-020-0018-3. ISSN 2543-2141.

- ^ Schmitt, François; Piccin, Olivier; Barbé, Laurent; Bayle, Bernard (2018). "Soft Robots Manufacturing: A Review". Frontiers in Robotics and AI. 5. doi:10.3389/frobt.2018.00084. ISSN 2296-9144. PMC 7805834. PMID 33500963.

{{cite journal}}: CS1 maint: PMC format (link) CS1 maint: unflagged free DOI (link) - ^ Müller, Vincent C.; Hoffmann, Matej (2017-02). "What Is Morphological Computation? On How the Body Contributes to Cognition and Control". Artificial Life. 23 (1): 1–24. doi:10.1162/artl_a_00219. ISSN 1064-5462.

{{cite journal}}: Check date values in:|date=(help) - ^ Davies, James; Thai, Mai Thanh; Hoang, Trung Thien; Nguyen, Chi Cong; Phan, Phuoc Thien; Phan, Hoang‐Phuong; Lovell, Nigel H.; Do, Thanh Nho (2023-03). "A Stretchable Filament Sensor with Tunable Sensitivity for Wearable Robotics and Healthcare Applications". Advanced Materials Technologies. 8 (6): 2201453. doi:10.1002/admt.202201453. ISSN 2365-709X.

{{cite journal}}: Check date values in:|date=(help) - ^ Omata, Sadao; Murayama, Yoshinobu; Constantinou, Christos E. (2004-05-01). "Real time robotic tactile sensor system for the determination of the physical properties of biomaterials". Sensors and Actuators A: Physical. 112 (2): 278–285. doi:10.1016/j.sna.2004.01.038. ISSN 0924-4247.