Rectifier

A rectifier is an electrical device that converts alternating current (AC), which periodically reverses direction, to direct current (DC), which flows in only one direction. The process is known as rectification. Physically, rectifiers take a number of forms, including vacuum tube diodes, mercury-arc valves, solid-state diodes, silicon-controlled rectifiers and other silicon-based semiconductor switches. Historically, even synchronous electromechanical switches and motors have been used. Early radio receivers, called crystal radios, used a "cat's whisker" of fine wire pressing on a crystal of galena (lead sulfide) to serve as a point-contact rectifier or "crystal detector".

Rectifiers have many uses, but are often found serving as components of DC power supplies and high-voltage direct current power transmission systems. Rectification may serve in roles other than to generate direct current for use as a source of power. As noted, detectors of radio signals serve as rectifiers. In gas heating systems flame rectification is used to detect presence of flame.

The simple process of rectification produces a type of DC characterized by pulsating voltages and currents (although still unidirectional). Depending upon the type of end-use, this type of DC current may then be further modified into the type of relatively constant voltage DC characteristically produced by such sources as batteries and solar cells.

A device which performs the opposite function (converting DC to AC) is known as an inverter.

Rectifier devices

Before the development of silicon semiconductor rectifiers, vacuum tube diodes and copper(I) oxide or selenium rectifier stacks were used. With the introduction of semiconductor electronics, vacuum tube rectifiers became obsolete, except for some enthusiasts of vacuum tube audio equipment. For power rectification from very low to very high current, semiconductor diodes of various types (junction diodes, Schottky diodes, etc.) are widely used. Other devices which have control electrodes as well as acting as unidirectional current valves are used where more than simple rectification is required, e.g., where variable output voltage is needed. High power rectifiers, such as are used in high-voltage direct current power transmission, employ silicon semiconductor devices of various types. These are thyristors or other controlled switching solid-state switches which effectively function as diodes to pass current in only one direction.

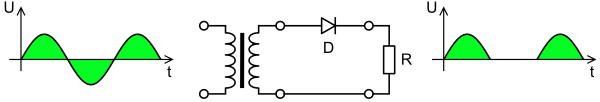

Half-wave rectification

In half wave rectification of a single-phase supply, either the positive or negative half of the AC wave is passed, while the other half is blocked. Because only one half of the input waveform reaches the output, mean voltage is lower. Half-wave rectification requires a single diode in a single-phase supply, or three in a three-phase supply. Rectifiers yield a unidirectional but pulsating direct current; half-wave rectifiers produce far more ripple than full-wave rectifiers, and much more filtering is needed to eliminate harmonics of the AC frequency from the output.

The output DC voltage of an ideal half wave rectifier is:[1]

A real rectifier will have a characteristic which drops part of the input voltage (a voltage drop, for silicon devices, of typically 0.7 volts plus an equivalent resistance, in general non-linear), and at high frequencies will distort waveforms in other ways; unlike an ideal rectifier, it will dissipate power.

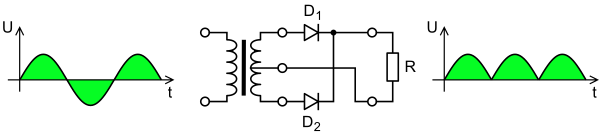

Full-wave rectification

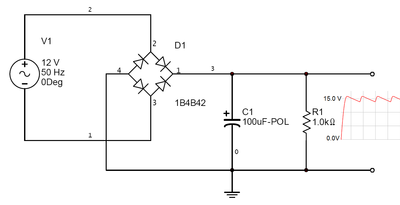

A full-wave rectifier converts the whole of the input waveform to one of constant polarity (positive or negative) at its output. Full-wave rectification converts both polarities of the input waveform to DC (direct current), and yields a higher mean output voltage. Two diodes and a center tapped transformer, or four diodes in a bridge configuration and any AC source (including a transformer without center tap), are needed. Single semiconductor diodes, double diodes with common cathode or common anode, and four-diode bridges, are manufactured as single components.

For single-phase AC, if the transformer is center-tapped, then two diodes back-to-back (cathode-to-cathode or anode-to-anode, depending upon output polarity required) can form a full-wave rectifier. Twice as many turns are required on the transformer secondary to obtain the same output voltage than for a bridge rectifier, but the power rating is unchanged.

A very common double-diode rectifier tube contained a single common cathode and two anodes inside a single envelope, achieving full-wave rectification with positive output. The 5U4 and 5Y3 were popular examples of this configuration.

For three-phase AC, six diodes are used. Double diodes in series, with the anode of the first diode connected to the cathode of the second, are manufactured as a single component for this purpose. Some commercially available double diodes have all four terminals available so the user can configure them for single-phase split supply use, half a bridge, or three-phase rectifier.

|

|

Many devices that generate alternating current (some such devices are called alternators) generate three-phase AC. For example, an automobile alternator has six diodes inside it to function as a full-wave rectifier for battery charging applications.

The average and root-mean-square output voltages of an ideal single-phase full-wave rectifier are:

For a three-phase full-wave rectifier with ideal thyristors, the average output voltage is

Where:

- Vdc, Vav - the DC or average output voltage,

- Vpeak - the peak value of half wave,

- Vrms - the root-mean-square value of output voltage.

- π = ~ 3.14159

- α = firing angle of the thyristor (0 if diodes are used to perform rectification)

Peak loss

An aspect of most rectification is a loss from the peak input voltage to the peak output voltage, caused by the built-in voltage drop across the diodes (around 0.7 V for ordinary silicon p–n junction diodes and 0.3 V for Schottky diodes). Half-wave rectification and full-wave rectification using a center-tapped secondary will have a peak voltage loss of one diode drop. Bridge rectification will have a loss of two diode drops. This reduces output voltage, and limits the available output voltage if a very low alternating voltage must be rectified. As the diodes do not conduct below this voltage, the circuit only passes current through for a portion of each half-cycle, causing short segments of zero voltage (where instantaneous input voltage is below one or two diode drops) to appear between each "hump".

Rectifier output smoothing

While half-wave and full-wave rectification can deliver unidirectional current, neither produces a constant voltage. In order to produce steady DC from a rectified AC supply, a smoothing circuit or filter is required.[2] In its simplest form this can be just a reservoir capacitor or smoothing capacitor, placed at the DC output of the rectifier. There will still be an AC ripple voltage component at the power supply frequency for a half-wave rectifier, twice that for full-wave, where the voltage is not completely smoothed.

Sizing of the capacitor represents a tradeoff. For a given load, a larger capacitor will reduce ripple but will cost more and will create higher peak currents in the transformer secondary and in the supply feeding it. The peak current is set in principle by the rate of rise of the supply voltage on the rising edge of the incoming sine-wave, but in practice it is reduced by the resistance of the transformer windings. In extreme cases where many rectifiers are loaded onto a power distribution circuit, peak currents may cause difficulty in maintaining a correctly shaped sinusoidal voltage on the ac supply.

To limit ripple to a specified value the required capacitor size is proportional to the load current and inversely proportional to the supply frequency and the number of output peaks of the rectifier per input cycle. The load current and the supply frequency are generally outside the control of the designer of the rectifier system but the number of peaks per input cycle can be affected by the choice of rectifier design.

A half-wave rectifier will only give one peak per cycle and for this and other reasons is only used in very small power supplies. A full wave rectifier achieves two peaks per cycle, the best possible with a single-phase input. For three-phase inputs a three-phase bridge will give six peaks per cycle; higher numbers of peaks can be achieved by using transformer networks placed before the rectifier to convert to a higher phase order.

To further reduce ripple, a capacitor-input filter can be used. This complements the reservoir capacitor with a choke (inductor) and a second filter capacitor, so that a steadier DC output can be obtained across the terminals of the filter capacitor. The choke presents a high impedance to the ripple current.[2] For use at power-line frequencies inductors require cores of iron or other magnetic materials, and add weight and size. Their use in power supplies for electronic equipment has therefore dwindled in favour of semiconductor circuits such as voltage regulators.

A more usual alternative to a filter, and essential if the DC load requires very low ripple voltage, is to follow the reservoir capacitor with an active voltage regulator circuit. The reservoir capacitor needs to be large enough to prevent the troughs of the ripple dropping below the minimum voltage required by the regulator to produce the required output voltage. The regulator serves both to significantly reduce the ripple and to deal with variations in supply and load characteristics. It would be possible to use a smaller reservoir capacitor (these can be large on high-current power supplies) and then apply some filtering as well as the regulator, but this is not a common strategy. The extreme of this approach is to dispense with the reservoir capacitor altogether and put the rectified waveform straight into a choke-input filter. The advantage of this circuit is that the current waveform is smoother and consequently the rectifier no longer has to deal with the current as a large current pulse, but instead the current delivery is spread over the entire cycle. The disadvantage, apart from extra size and weight, is that the voltage output is much lower – approximately the average of an AC half-cycle rather than the peak.

Voltage-multiplying rectifiers

The simple half wave rectifier can be built in two electrical configurations with the diode pointing in opposite directions, one version connects the negative terminal of the output direct to the AC supply and the other connects the positive terminal of the output direct to the AC supply. By combining both of these with separate output smoothing it is possible to get an output voltage of nearly double the peak AC input voltage. This also provides a tap in the middle, which allows use of such a circuit as a split rail supply.

A variant of this is to use two capacitors in series for the output smoothing on a bridge rectifier then place a switch between the midpoint of those capacitors and one of the AC input terminals. With the switch open this circuit will act like a normal bridge rectifier: with it closed it will act like a voltage doubling rectifier. In other words this makes it easy to derive a voltage of roughly 320V (+/- around 15%) DC from any mains supply in the world, this can then be fed into a relatively simple switched-mode power supply.

Cascaded diode and capacitor stages can be added to make a voltage multiplier (Cockroft-Walton circuit). These circuits are capable of producing a DC output voltage potential tens of times that of the peak AC input voltage, but are limited in current capacity and regulation. Diode voltage multipliers, frequently used as a trailing boost stage or primary high voltage (HV) source, are used in HV laser power supplies, powering devices such as cathode ray tubes (CRT) (like those used in CRT based television, radar and sonar displays), photon amplifying devices found in image intensifying and photo multiplier tubes (PMT), and magnetron based radio frequency (RF) devices used in radar transmitters and microwave ovens. Before the introduction of semiconductor electronics, transformerless vacuum tube equipment powered directly from AC power sometimes used voltage doublers to generate about 170VDC from a 100-120V power line.

Applications

The primary application of rectifiers is to derive DC power from an AC supply. Virtually all electronic devices require DC, so rectifiers are used inside the power supplies of virtually all electronic equipment.

Converting DC power from one voltage to another is much more complicated. One method of DC-to-DC conversion first converts power to AC (using a device called an inverter), then use a transformer to change the voltage, and finally rectifies power back to DC. A frequency of typically several tens of kilohertz is used, as this requires much smaller inductance than at lower frequencies and obviates the use of heavy, bulky, and expensive iron-cored units.

Rectifiers are also used for detection of amplitude modulated radio signals. The signal may be amplified before detection. If not, a very low voltage drop diode or a diode biased with a fixed voltage must be used. When using a rectifier for demodulation the capacitor and load resistance must be carefully matched: too low a capacitance will result in the high frequency carrier passing to the output, and too high will result in the capacitor just charging and staying charged.

Rectifiers are used to supply polarised voltage for welding. In such circuits control of the output current is required; this is sometimes achieved by replacing some of the diodes in a bridge rectifier with thyristors, effectively diodes whose voltage output can be regulated by switching on and off with phase fired controllers.

Thyristors are used in various classes of railway rolling stock systems so that fine control of the traction motors can be achieved. Gate turn-off thyristors are used to produce alternating current from a DC supply, for example on the Eurostar Trains to power the three-phase traction motors.[3]

Rectification technologies

Electromechanical

Early power conversion systems were purely electro-mechanical in design, since electronic devices were not available to handle significant power. Mechanical rectification systems usually use some form of rotation or resonant vibration (e.g. vibrators) in order to move quickly enough to follow the frequency of the input power source, and cannot operate beyond several thousand cycles per second.

Due to reliance on fast-moving parts of mechanical systems, they needed a high level of maintenance to keep operating correctly. Moving parts will have friction, which requires lubrication and replacement due to wear. Opening mechanical contacts under load results in electrical arcs and sparks that heat and erode the contacts.

Synchronous rectifier

To convert alternating into direct current in electric locomotives, a synchronous rectifier may be used [citation needed]. It consists of a synchronous motor driving a set of heavy-duty electrical contacts. The motor spins in time with the AC frequency and periodically reverses the connections to the load at an instant when the sinusoidal current goes through a zero-crossing. The contacts do not have to switch a large current, but they need to be able to carry a large current to supply the locomotive's DC traction motors.

Vibrator

Vibrators used to generate AC from DC in pre-semiconductor battery-to-high-voltage-DC power supplies often contained a second set of contacts that performed synchronous mechanical rectification of the stepped-up voltage.

Motor-generator set

A motor-generator set, or the similar rotary converter, is not strictly a rectifier as it does not actually rectify current, but rather generates DC from an AC source. In an "M-G set", the shaft of an AC motor is mechanically coupled to that of a DC generator. The DC generator produces multiphase alternating currents in its armature windings, which a commutator on the armature shaft converts into a direct current output; or a homopolar generator produces a direct current without the need for a commutator. M-G sets are useful for producing DC for railway traction motors, industrial motors and other high-current applications, and were common in many high power D.C. uses (for example, carbon-arc lamp projectors for outdoor theaters) before high-power semiconductors became widely available.

Electrolytic

The electrolytic rectifier[4] was a device from the early twentieth century that is no longer used. A home-made version is illustrated in the 1913 book The Boy Mechanic [5] but it would only be suitable for use at very low voltages because of the low breakdown voltage and the risk of electric shock. A more complex device of this kind was patented by G. W. Carpenter in 1928 (US Patent 1671970).[6]

When two different metals are suspended in an electrolyte solution, direct current flowing one way through the solution sees less resistance than in the other direction. Electrolytic rectifiers most commonly used an aluminum anode and a lead or steel cathode, suspended in a solution of tri-ammonium ortho-phosphate.

The rectification action is due to a thin coating of aluminum hydroxide on the aluminum electrode, formed by first applying a strong current to the cell to build up the coating. The rectification process is temperature-sensitive, and for best efficiency should not operate above 86 °F (30 °C). There is also a breakdown voltage where the coating is penetrated and the cell is short-circuited. Electrochemical methods are often more fragile than mechanical methods, and can be sensitive to usage variations which can drastically change or completely disrupt the rectification processes.

Similar electrolytic devices were used as lightning arresters around the same era by suspending many aluminium cones in a tank of tri-ammomium ortho-phosphate solution. Unlike the rectifier above, only aluminium electrodes were used, and used on A.C., there was no polarization and thus no rectifier action, but the chemistry was similar.[7]

The modern electrolytic capacitor, an essential component of most rectifier circuit configurations was also developed from the electrolytic rectifier.

Plasma type

Mercury arc

A rectifier used in high-voltage direct current (HVDC) power transmission systems and industrial processing between about 1909 to 1975 is a mercury arc rectifier or mercury arc valve. The device is enclosed in a bulbous glass vessel or large metal tub. One electrode, the cathode, is submerged in a pool of liquid mercury at the bottom of the vessel and one or more high purity graphite electrodes, called anodes, are suspended above the pool. There may be several auxiliary electrodes to aid in starting and maintaining the arc. When an electric arc is established between the cathode pool and suspended anodes, a stream of electrons flows from the cathode to the anodes through the ionized mercury, but not the other way (in principle, this is a higher-power counterpart to flame rectification, which uses the same one-way current transmission properties of the plasma naturally present in a flame).

These devices can be used at power levels of hundreds of kilowatts, and may be built to handle one to six phases of AC current. Mercury arc rectifiers have been replaced by silicon semiconductor rectifiers and high power thyristor circuits in the mid 1970s. The most powerful mercury arc rectifiers ever built were installed in the Manitoba Hydro Nelson River Bipole HVDC project, with a combined rating of more than 1 GW and 450 kV.[8][9]

Argon gas electron tube

The General Electric Tungar rectifier was an argon gas-filled electron tube device with a tungsten filament cathode and a carbon button anode. It was used for battery chargers and similar applications from the 1920s until lower-cost metal rectifiers, and later semiconductor diodes, supplanted it. These were made up to a few hundred volts and a few amperes rating, and in some sizes strongly resembled an incandescent lamp with an additional electrode.

The 0Z4 was a gas-filled rectifier tube commonly used in vacuum tube car radios in the 1940s and 1950s. It was a conventional full-wave rectifier tube with two anodes and one cathode, but was unique in that it had no filament (thus the "0" in its type number). The electrodes were shaped such that the reverse breakdown voltage was much higher than the forward breakdown voltage. Once the breakdown voltage was exceeded, the 0Z4 switched to a low-resistance state with a forward voltage drop of about 24 V.

Vacuum tube (valve)

Since the discovery of the Edison effect or thermionic emission, various vacuum tube devices were developed to rectify alternating currents. The simplest is the simple vacuum diode (the term "valve" came into use for vacuum tubes in general due to this unidirectional property, by analogy with a unidirectional fluid flow valve). Low-current devices were used as signal detectors, first used in radio by Fleming in 1904. Many vacuum-tube devices also used vacuum diode rectifiers in their power supplies, for example the All American Five radio receiver. Vacuum rectifiers were made for very high voltages, such as the high voltage power supply for the cathode ray tube of television receivers, and the kenotron used for power supply in X-ray equipment. However, vacuum rectifiers generally had current capacity rarely exceeding 250 mA owing to the maximum current density that could be obtained by electrodes heated to temperatures compatible with long life. Another limitation of the vacuum tube rectifier was that the heater power supply often required special arrangements to insulate it from the high voltages of the rectifier circuit.

Solid state

Crystal detector

The cat's-whisker detector, typically using a crystal of galena, was the earliest type of semiconductor diode, though not recognised as such at the time.

Selenium and copper oxide rectifiers

Once common until replaced by more compact and less costly silicon solid-state rectifiers, these units used stacks of metal plates and took advantage of the semiconductor properties of selenium or copper oxide.[10] While selenium rectifiers were lighter in weight and used less power than comparable vacuum tube rectifiers, they had the disadvantage of finite life expectancy, increasing resistance with age, and were only suitable to use at low frequencies. Both selenium and copper oxide rectifiers have somewhat better tolerance of momentary voltage transients than silicon rectifiers.

Typically these rectifiers were made up of stacks of metal plates or washers, held together by a central bolt, with the number of stacks determined by voltage; each cell was rated for about 20 V. An automotive battery charger rectifier might have only one cell: the high-voltage power supply for a vacuum tube might have dozens of stacked plates. Current density in an air-cooled selenium stack was about 600 mA per square inch of active area (about 90 mA per square centimeter).

Silicon and germanium diodes

In the modern world, silicon diodes are the most widely used rectifiers for lower voltages and powers, and have largely replaced earlier germanium diodes. For very high voltages and powers, the added need for controllability has in practice caused simple silicon diodes to be replaced by high-power thyristors (see below) and their newer actively-gate-controlled cousins.

High power: thyristors (SCRs) and newer silicon-based voltage sourced converters

In high power applications, from 1975–2000, most mercury valve arc-rectifiers were replaced by stacks of very high power thyristors, silicon devices with two extra layers of semiconductor, in comparison to a simple diode.

In medium power-transmission applications, even more complex and sophisticated voltage sourced converter (VSC) silicon semiconductor rectifier systems, such as insulated gate bipolar transistors (IGBT) and gate turn-off thyristors (GTO), have made smaller high voltage DC power transmission systems economical. All of these devices function as rectifiers.

As of 2009[update] it was expected that these high-power silicon "self-commutating switches," in particular IGBTs and a variant thyristor (related to the GTO) called the integrated gate-commutated thyristor (IGCT), would be scaled-up in power rating to the point that they would eventually replace simple thyristor-based AC rectification systems for the highest power-transmission DC applications.[11]

Early 21st century developments

High-speed rectifiers

Researchers at Idaho National Laboratory (INL) have proposed high-speed rectifiers that would sit at the center of spiral nanoantennas and convert infrared frequency electricity from AC to DC.[12] Infrared frequencies range from 0.3 to 400 terahertz.

Unimolecular rectifiers

A Unimolecular rectifier is a single organic molecule which functions as a rectifier, in the experimental stage as of 2012[update].

See also

- AC adapter

- Active rectification

- Capacitor

- Diode

- Direct current

- High-voltage direct current

- Inverter

- Ripple

- Synchronous rectification

References

- ^ Cyril W. Lander, ,Power Electronics third edition, McGraw Hill, 1993 ISBN 0-07-707714-8 chapter 2 Rectifying Circuits

- ^ a b [1][dead link]

- ^ Mansell, A.D.; Shen, J. (6 August 2002). "Power Engineering Journal". IEEE: 183–187. ISSN 0950-3366.

{{cite journal}}:|contribution=ignored (help); Check date values in:|year=/|date=mismatch (help); Cite journal requires|journal=(help)[clarification needed] - ^ Hawkins Electrical Guide, 1917, Chapter 54: Rectifiers

- ^ "How To Make An Electrolytic Rectifier". Chestofbooks.com. Retrieved 15 March 2012.

- ^ http://www.google.com/patents/US1671970.pdf

- ^ Cyclopedia of Applied Electricity, Vol-II, American Technical Society, Chicargo, 1924, Page 487: Alternating Current Machinery

- ^ Pictures of a mercury arc rectifier in operation can be seen here: Belsize Park deep shelter rectifier 1, Belsize Park deep shelter rectifier 2

- ^ Vijay K. Sood. HVDC and FACTS Controllers: Applications Of Static Converters In Power Systems. Springer-Verlag. p. 1. ISBN 978-1-4020-7890-3.

The first 25 years of HVDC transmission were sustained by converters having mercury arc valves till the mid-1970s. The next 25 years till the year 2000 were sustained by line-commutated converters using thyristor valves. It is predicted that the next 25 years will be dominated by force-commutated converters [4]. Initially, this new force-commutated era has commenced with Capacitor Commutated Converters (CCC) eventually to be replaced by self-commutated converters due to the economic availability of high power switching devices with their superior characteristics.

- ^ H. P. Westman et al., (ed), Reference Data for Radio Engineers, Fifth Edition, 1968, Howard W. Sams and Co., no ISBN, Library of Congress Card No. 43-14665 chapter 13

- ^ For review see: Self-Commutating Converters for High Power Applications Jos Arrillaga, Yonghe H. Liu, Neville R. Watson, Nicholas J. Murray. (Wiley IEEE Press, 2009) ISBN 978-0-470-74682-0

- ^ Harvesting the sun's energy with antennas (2007). Idaho National Laboratory. Accessed on 3 October 2008.