Switched reluctance motor

The switched reluctance motor (SRM) is a type of a stepper motor, an electric motor that runs by reluctance torque. Unlike common DC motor types, power is delivered to windings in the stator (case) rather than the rotor. This greatly simplifies mechanical design as power does not have to be delivered to a moving part, but it complicates the electrical design as some sort of switching system needs to be used to deliver power to the different windings. With modern electronic devices this is not a problem, and the SRM is a popular design for modern motors. Its main drawback is torque ripple.

Operating principle

The SRM has wound field coils as in a DC motor for the stator windings. The rotor however has no magnets or coils attached. It is a solid salient-pole rotor (having projecting magnetic poles) made of soft magnetic material (laminated-steel). When power is applied to the stator windings, the rotor's magnetic reluctance creates a force that attempts to align the rotor pole with the nearest stator pole. In order to maintain rotation, an electronic control system switches on the windings of successive stator poles in sequence so that the magnetic field of the stator "leads" the rotor pole, pulling it forward. Rather than using a troublesome high-maintenance mechanical commutator to switch the winding current as in traditional motors, the switched-reluctance motor uses an electronic position sensor to determine the angle of the rotor shaft and solid state electronics to switch the stator windings, which also offers the opportunity for dynamic control of pulse timing and shaping.

Simple switching

If the poles A0 and A1 are energized then the rotor will align itself with these poles. Once this has occurred it is possible for the stator poles to be de-energised before the stator poles of B0 and B1 are energized. The rotor is now positioned at the stator poles b. This sequence continues through c before arriving back at the start. This sequence can also be reversed to achieve motion in the opposite direction. This sequence can be found to be unstable[clarification needed] while in operation.

Improved sequence

A much more stable system can be found by using the following "quadrature" sequence. First, stator poles A0 and A1 are energized. Then stator poles of B0 and B1 are energized which pulls the rotor so that it is aligned in between the stator poles of A and B. Following this the stator poles of A are de-energized and the rotor continues on to be aligned with the stator poles of B, this sequence continues through BC, C and CA before a full rotation has occurred. This sequence can also be reversed to achieve motion in the opposite direction.

In addition to more stable operation, this approach provides a well-timed sequence as the timings of the phase being both on and off are equal, rather than being at a 1:2 ratio as in the simpler sequence.

Control

The control system is responsible for giving the required sequential pulses to the power circuitry in order to activate the phases as required. While it is possible to do this using electro-mechanical means such as commutators or simple analog or digital timing circuits, more control is possible with more advanced methods.

Many controllers in use incorporate programmable logic controllers (PLCs) rather than electromechanical components in their implementation. A microcontroller is also ideal for this kind of application since it enables a very precise control of the phase activation timings. It also gives the possibility of implementing a soft start function in software form, in order to reduce the amount of hardware required.

Power circuitry

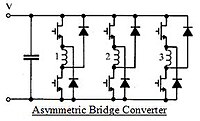

The most common approach to the powering of a switched reluctance motor is to use an asymmetric bridge converter.

There are 3 phases in an asymmetric bridge converter corresponding to the phases of the switched reluctance motor. If both of the power switches on either side of the phase are turned on, then that corresponding phase shall be actuated. Once the current has risen above the set value, the switch shall turn off. The energy now stored within the motor winding shall now maintain the current in the same direction until that energy is depleted.

This basic circuitry may be altered so that fewer components are required although the circuit shall perform the same action. This efficient circuit is known as the (n+1) switch and diode configuration.

A capacitor, in either configuration, is used to suppress electrical and acoustic noise by limiting fluctuations in the supply voltage.