Photoelasticity: Difference between revisions

No edit summary |

No edit summary |

||

| Line 47: | Line 47: | ||

Photoelasticity has been used for a variety of stress analyses and even for routine use in design, particularly before the advent of numerical methods, such as for instance finite elements or boundary elements <ref>Frocht, M.M., 1965. ''Photoelasticity''. J. Wiley and Sons, London</ref>. |

Photoelasticity has been used for a variety of stress analyses and even for routine use in design, particularly before the advent of numerical methods, such as for instance finite elements or boundary elements <ref>Frocht, M.M., 1965. ''Photoelasticity''. J. Wiley and Sons, London</ref>. |

||

Photoelasticity can successfully be used to investigate the highly localized stress state within masonry<ref>[http://www.ing.unitn.it/~bigoni |

Photoelasticity can successfully be used to investigate the highly localized stress state within masonry<ref>[http://www.ing.unitn.it/~bigoni D. Bigoni and G. Noselli, Localized stress percolation through dry masonry walls. Part I - Experiments. ''European Journal of Mechanics A/Solids'', 2010, 29, 291-298.]</ref><ref>[http://www.ing.unitn.it/~bigoni D. Bigoni and G. Noselli, Localized stress percolation through dry masonry walls. Part II - Modelling. ''European Journal of Mechanics A/Solids'', 2010, 29, 299-307.]</ref> or in proximity of a rigid line inclusion (stiffener) embedded in an elastic medium<ref>[http://www.ing.unitn.it/~bigoni G. Noselli, F. Dal Corso and D. Bigoni, The stress intensity near a stiffener disclosed by photoelasticity. International Journal of Fracture, 2010, 166, 91–103.]</ref>. In the former case, the problem is nonlinear due to the contacts between bricks, while in the latter case the elastic solution is singular, so that numerical methods may fail to provide correct results. These can be obtained through photoelastic techniques. |

||

==See also== |

==See also== |

||

Revision as of 16:51, 19 November 2010

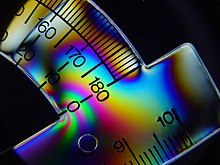

Photoelasticity is an experimental method to determine stress distribution in a material. The method is mostly used in cases where mathematical methods become quite cumbersome. Unlike the analytical methods of stress determination, photoelasticity gives a fairly accurate picture of stress distribution even around abrupt discontinuities in a material. The method serves as an important tool for determining the critical stress points in a material and is often used for determining stress concentration factors in irregular geometries.

History

The photoelastic phenomena was first described by the scottish physicist David Brewster[1] [2]. Photoelasticity developed at the beginning of the twentieth century with the works of E.G.Coker and L.N.G Filon of University of London. Their book Treatise on Photoelasticity published in 1930 by the Cambridge Press became a standard text on the subject. Between 1930 and 1940 many other books in Russian, German and French appeared on the subject.

At the same time lot of development was made in field. Great improvements were achieved in the technique and the equipment was simplified. With the improvement in technology the scope of photoelasticity was also extended to three dimensional state of stress. Many practical problems were solved using photoelasticity and it soon became very popular. A number of photoelastic laboratories were then setup in both educational institutions and industries.

With the advent of digital polariscope using LEDs, continuous monitoring of structures under load became possible. This led to the development of dynamic photoelasticity. Dynamic photoelasticity has contributed greatly to the study of complex phenomena of fracture of materials.

Principles

The method is based on the property of birefringence, which is exhibited by certain transparent materials. Birefringence is a property by virtue of which a ray of light passing through a birefringent material experiences two refractive indices. The property of birefringence or double refraction is exhibited by many optical crystals. But photoelastic materials exhibit the property of birefringence only on the application of stress and the magnitude of the refractive indices at each point in the material is directly related to the state of stress at that point. Thus, the first task is to develop a model made out of such materials. The model has a similar geometry to that of the structure on which stress analysis is to be performed. This ensures that the state of the stress in the model is similar to the state of the stress in the structure.

When a ray of plane polarised light is passed through a photoelastic material, it gets resolved along the two principal stress directions and each of these components experiences different refractive indices. The difference in the refractive indices leads to a relative phase retardation between the two component waves. The magnitude of the relative retardation is given by the stress optic law:

where R is the induced retardation, C is the stress optic coefficient, t is the specimen thickness, σ11 is the first principal stress, and σ22 is the second principal stress.

The two waves are then brought together in a polariscope. The phenomena of optical interference takes place and we get a fringe pattern, which depends on relative retardation. Thus studying the fringe pattern one can determine the state of stress at various points in the material.

Isoclinics and isochromatics

Isoclinics are the locus of the points in the specimen along which the principal stresses are in the same direction.

Isochromatics are the locus of the points along which the difference in the first and second principal stress remains the same. Thus they are the lines which join the points with equal maximum shear stress magnitude.

Two-dimensional photoelasticity

Photoelasticity can be applied both to three dimensional and two dimensional state of stress. But the application of photoelasticty to the three dimensional state of stress is more involved as compared to the state of two dimensional / plane stress system. So the present section deals with application of photoelasticity in investigation of a plane stress system. This condition is achieved when the thickness of the prototype is much smaller as compared to dimensions in the plane. Thus one is only concerned with stresses acting parallel to the plane of the model, as other stress components are zero.

The experimental setup varies from experiment to experiment. The two basic kinds of setup used are plane polariscope and circular polariscope.

Plane polariscope

The setup consists of two linear polarizers and a light source. The light source can either emit monochromatic light or white light depending upon the experiment. First the light is passed through the first polarizer which converts the light into plane polarized light. The apparatus is set up in such a way that this plane polarized light then passes through the stressed specimen. This light then follows, at each point of the specimen, the direction of principal stress at that point. The light is then made to pass through the analyzer and we finally get the fringe pattern.

The fringe pattern in a plane polariscope setup consists of both the isochromatics and the isoclinics. The isoclinics change with the orientation of the polariscope while there is no change in the isochromatics.

The same device functions as a plane polariscoe when quarter wave plates are taken aside or rotated so their axes parallel to polarization axes

Circular polariscope

In a circular polariscope setup two quarter-wave plates are added to the experimental setup of the plane polariscope. The first quarter-wave plate is placed in between the polariser and the specimen and the second quarter-wave plate is placed between the specimen and the analyser. The effect of adding the quarter-wave plates is that we get circularly polarised light.

The basic advantage of a circular polariscope over a plane polariscope is that in a circular polariscope setup we only get the isochromatics and not the isoclinics. This eliminates the problem of differentiating between the isoclinics and the isochromatics.

Applications

Photoelasticity has been used for a variety of stress analyses and even for routine use in design, particularly before the advent of numerical methods, such as for instance finite elements or boundary elements [3].

Photoelasticity can successfully be used to investigate the highly localized stress state within masonry[4][5] or in proximity of a rigid line inclusion (stiffener) embedded in an elastic medium[6]. In the former case, the problem is nonlinear due to the contacts between bricks, while in the latter case the elastic solution is singular, so that numerical methods may fail to provide correct results. These can be obtained through photoelastic techniques.

See also

Notes

- ^ D. Brewster, Experiments on the depolarization of light as exhibited by various mineral, animal and vegetable bodies with a reference of the phenomena to the general principle of polarization, Phil. Tras. 1815, pp.29-53.

- ^ D. Brewster, On the communication of the structure of doubly-refracting crystals to glass, murite of soda, flour spar, and other substances by mechanical compression and dilation, Phil. Tras. 1816, pp.156-178.

- ^ Frocht, M.M., 1965. Photoelasticity. J. Wiley and Sons, London

- ^ D. Bigoni and G. Noselli, Localized stress percolation through dry masonry walls. Part I - Experiments. European Journal of Mechanics A/Solids, 2010, 29, 291-298.

- ^ D. Bigoni and G. Noselli, Localized stress percolation through dry masonry walls. Part II - Modelling. European Journal of Mechanics A/Solids, 2010, 29, 299-307.

- ^ G. Noselli, F. Dal Corso and D. Bigoni, The stress intensity near a stiffener disclosed by photoelasticity. International Journal of Fracture, 2010, 166, 91–103.