Injection moulding: Difference between revisions

Pinethicket (talk | contribs) m Reverted edits by 119.82.65.226 (talk) to last version by 24.12.148.37 |

|||

| Line 7: | Line 7: | ||

* Utilizes a ram or screw-type plunger to force molten plastic material into a mold cavity |

* Utilizes a ram or screw-type plunger to force molten plastic material into a mold cavity |

||

* Produces a solid or open-ended shape that has conformed to the contour of the mold |

* Produces a solid or open-ended shape that has conformed to the contour of the mold |

||

* Uses thermoplastic or thermoset |

* Uses thermoplastic or thermoset material |

||

* The process usually begins with a conventional production mold. These tools can be multi-cavity and produce millions of parts <ref>http://prismier.com/injection-molding/</ref> |

* The process usually begins with a conventional production mold. These tools can be multi-cavity and produce millions of parts <ref>http://prismier.com/injection-molding/</ref> |

||

* A [[parting line]], [[Sprue (manufacturing)|sprue]], gate marks, and ejector pin marks are usually present. None of these features are typically desired. They are the results of the parting of the mold for ejection of the formed part. <ref name="ReferenceA">Manufacturing Processes Reference Guide pg. 240</ref> |

* A [[parting line]], [[Sprue (manufacturing)|sprue]], gate marks, and ejector pin marks are usually present. None of these features are typically desired. They are the results of the parting of the mold for ejection of the formed part. <ref name="ReferenceA">Manufacturing Processes Reference Guide pg. 240</ref> |

||

Revision as of 15:53, 6 June 2012

Injection molding (British English: moulding) is a manufacturing process for producing parts from both thermoplastic and thermosetting plastic materials. Material is fed into a heated barrel, mixed, and forced into a mold cavity where it cools and hardens to the configuration of the cavity.[1] After a product is designed, usually by an industrial designer or an engineer, molds are made by a moldmaker (or toolmaker) from metal, usually either steel or aluminum, and precision-machined to form the features of the desired part. Injection molding is widely used for manufacturing a variety of parts, from the smallest component to entire body panels of cars.

Process characteristics

- Utilizes a ram or screw-type plunger to force molten plastic material into a mold cavity

- Produces a solid or open-ended shape that has conformed to the contour of the mold

- Uses thermoplastic or thermoset material

- The process usually begins with a conventional production mold. These tools can be multi-cavity and produce millions of parts [2]

- A parting line, sprue, gate marks, and ejector pin marks are usually present. None of these features are typically desired. They are the results of the parting of the mold for ejection of the formed part. [3]

History

1847 Jons Jacob Berzelius produces first condensation polymer, polyester, from glycerin (propanetriol) and tartaric acid

Jons Jacob Berzelius is also credited with originating the chemical terms "catalysis," "polymer," "isomer," and "allotrope," although his original definitions differ dramatically from modern usage. For example, he coined the term "polymer" in 1833 to describe organic compounds which shared identical empirical formulas but which differed in overall molecular weight, the larger of the compounds being described as "polymers" of the smallest. According to this (now obsolete) definition, glucose (C6H12O6) would be a polymer of formaldehyde (CH2O).

The first man-made commercial plastic was invented in Britain in 1861 by Alexander Parkes. He publicly demonstrated it at the 1862 International Exhibition in London, calling the material he produced "Parkesine." Derived from cellulose, Parkesine could be heated, molded, and retain its shape when cooled. It was, however, expensive to produce, prone to cracking, and highly flammable.

In 1868, American inventor John Wesley Hyatt developed a plastic material he named Celluloid, improving on Parkes' invention so that it could be processed into finished form. Together with his brother Isaiah, Hyatt patented the first injection molding machine in 1872.[4] This machine was relatively simple compared to machines in use today. It worked like a large hypodermic needle, using a plunger to inject plastic through a heated cylinder into a mold. The industry progressed slowly over the years, producing products such as collar stays, buttons, and hair combs.

The industry expanded rapidly in the 1940s because World War II created a huge demand for inexpensive, mass-produced products. In 1946, American inventor James Watson Hendry built the first screw injection machine, which allowed much more precise control over the speed of injection and the quality of articles produced. This machine also allowed material to be mixed before injection, so that colored or recycled plastic could be added to virgin material and mixed thoroughly before being injected. Today screw injection machines account for the vast majority of all injection machines. In the 1970s, Hendry went on to develop the first gas-assisted injection molding process, which permitted the production of complex, hollow articles that cooled quickly. This greatly improved design flexibility as well as the strength and finish of manufactured parts while reducing production time, cost, weight and waste.

The plastic injection molding industry has evolved over the years from producing combs and buttons to producing a vast array of products for many industries including automotive, medical, aerospace, consumer products, toys, plumbing, packaging, and construction.[5]

Applications

Injection molding is used to create many things such as wire spools, packaging, bottle caps, automotive dashboards, pocket combs, some musical instruments (and parts of them), one-piece chairs and small tables, storage containers, mechanical parts (including gears), and most other plastic products available today. Injection molding is the most common method of part manufacturing. It is ideal for producing high volumes of the same object.[6] Some advantages of injection molding are high production rates, repeatable high tolerances, the ability to use a wide range of materials, low labor cost, minimal scrap losses, and little need to finish parts after molding. Some disadvantages of this process are expensive equipment investment, potentially high running costs, and the need to design moldable parts.

Examples of polymers best suited for the process

Most polymers, sometimes referred to as resins, may be used, including all thermoplastics, some thermosets, and some elastomers.[7] In 1995 there were approximately 18,000 different materials available for injection molding and that number was increasing at an average rate of 750 per year. The available materials are alloys or blends of previously developed materials meaning that product designers can choose from a vast selection of materials, one that has exactly the right properties. Materials are chosen based on the strength and function required for the final part, but also each material has different parameters for molding that must be taken into account.[8] Common polymers like epoxy and phenolic are examples of thermosetting plastics while nylon, polyethylene, and polystyrene are thermoplastic.[9] Until comparatively recently, plastic springs were not possible, but advances in polymer properties make them quite practical. Among such applications are buckles for anchoring and disconnecting outdoor-equipment webbing.

Equipment

Injection molding machines consist of a material hopper, an injection ram or screw-type plunger, and a heating unit.[3] They are also known as presses, they hold the molds in which the components are shaped. Presses are rated by tonnage, which expresses the amount of clamping force that the machine can exert. This force keeps the mold closed during the injection process. Tonnage can vary from less than 5 tons to over 9,000 tons, with the higher figures used in comparatively few manufacturing operations. The total clamp force needed is determined by the projected area of the part being molded. This projected area is multiplied by a clamp force of from 2 to 8 tons for each square inch of the projected areas. As a rule of thumb, 4 or 5 tons/in2 can be used for most products. If the plastic material is very stiff, it will require more injection pressure to fill the mold, thus more clamp tonnage to hold the mold closed.[10] The required force can also be determined by the material used and the size of the part, larger parts require higher clamping force.[11]

Mold

Mold or die are the common terms used to describe the tooling used to produce plastic parts in molding.

Since molds have been expensive to manufacture, they were usually only used in mass production where thousands of parts were being produced. Typical molds are constructed from hardened steel, pre-hardened steel, aluminum, and/or beryllium-copper alloy. The choice of material to build a mold from is primarily one of economics; in general, steel molds cost more to construct, but their longer lifespan will offset the higher initial cost over a higher number of parts made before wearing out. Pre-hardened steel molds are less wear-resistant and are used for lower volume requirements or larger components. The typical steel hardness is 38–45 on the Rockwell-C scale. Hardened steel molds are heat treated after machining. These are by far the superior in terms of wear resistance and lifespan. Typical hardness ranges between 50 and 60 Rockwell-C (HRC). Aluminum molds can cost substantially less, and, when designed and machined with modern computerized equipment, can be economical for molding tens or even hundreds of thousands of parts. Beryllium copper is used in areas of the mold that require fast heat removal or areas that see the most shear heat generated.[12] The molds can be manufactured either by CNC machining or by using electrical discharge machining processes.

- Injection molding die with side pulls

-

"A" side of die for 25% glass-filled acetal with 2 side pulls.

-

Close up of removable insert in "A" side.

-

"B" side of die with side pull actuators.

-

Insert removed from die.

Mold design

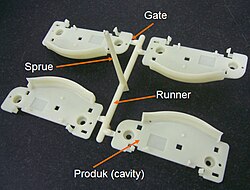

The mold consists of two primary components, the injection mold (A plate) and the ejector mold (B plate). Plastic resin enters the mold through a sprue in the injection mold; the sprue bushing is to seal tightly against the nozzle of the injection barrel of the molding machine and to allow molten plastic to flow from the barrel into the mold, also known as the cavity.[13] The sprue bushing directs the molten plastic to the cavity images through channels that are machined into the faces of the A and B plates. These channels allow plastic to run along them, so they are referred to as runners.[14] The molten plastic flows through the runner and enters one or more specialized gates and into the cavity[15] geometry to form the desired part.

The amount of resin required to fill the sprue, runner and cavities of a mold is a shot. Trapped air in the mold can escape through air vents that are ground into the parting line of the mold. If the trapped air is not allowed to escape, it is compressed by the pressure of the incoming material and is squeezed into the corners of the cavity, where it prevents filling and causes other defects as well. The air can become so compressed that it ignites and burns the surrounding plastic material.[16] To allow for removal of the molded part from the mold, the mold features must not overhang one another in the direction that the mold opens, unless parts of the mold are designed to move from between such overhangs when the mold opens (utilizing components called Lifters).

Sides of the part that appear parallel with the direction of draw (The axis of the cored position (hole) or insert is parallel to the up and down movement of the mold as it opens and closes)[17] are typically angled slightly (with draft) to ease release of the part from the mold. Insufficient draft can cause deformation or damage. The draft required for mold release is primarily dependent on the depth of the cavity: the deeper the cavity, the more draft necessary. Shrinkage must also be taken into account when determining the draft required.[18] If the skin is too thin, then the molded part will tend to shrink onto the cores that form them while cooling, and cling to those cores or part may warp, twist, blister or crack when the cavity is pulled away.[19] The mold is usually designed so that the molded part reliably remains on the ejector (B) side of the mold when it opens, and draws the runner and the sprue out of the (A) side along with the parts. The part then falls freely when ejected from the (B) side. Tunnel gates, also known as submarine or mold gates, are located below the parting line or mold surface. An opening is machined into the surface of the mold on the parting line. The molded part is cut (by the mold) from the runner system on ejection from the mold.[20] Ejector pins, also known as knockout pins, are circular pins placed in either half of the mold (usually the ejector half), which push the finished molded product, or runner system out of a mold.[21]

The standard method of cooling is passing a coolant (usually water) through a series of holes drilled through the mold plates and connected by hoses to form a continuous pathway. The coolant absorbs heat from the mold (which has absorbed heat from the hot plastic) and keeps the mold at a proper temperature to solidify the plastic at the most efficient rate.[22]

To ease maintenance and venting, cavities and cores are divided into pieces, called inserts, and sub-assemblies, also called inserts, blocks, or chase blocks. By substituting interchangeable inserts, one mold may make several variations of the same part.

More complex parts are formed using more complex molds. These may have sections called slides, that move into a cavity perpendicular to the draw direction, to form overhanging part features. When the mold is opened, the slides are pulled away from the plastic part by using stationary “angle pins” on the stationary mold half. These pins enter a slot in the slides and cause the slides to move backward when the moving half of the mold opens. The part is then ejected and the mold closes. The closing action of the mold causes the slides to move forward along the angle pins.[23]

Some molds allow previously molded parts to be reinserted to allow a new plastic layer to form around the first part. This is often referred to as overmolding. This system can allow for production of one-piece tires and wheels.

Two-shot or multi-shot molds are designed to "overmold" within a single molding cycle and must be processed on specialized injection molding machines with two or more injection units. This process is actually an injection molding process performed twice. In the first step, the base color material is molded into a basic shape, which contains spaces for the second shot. Then the second material, a different color, is injection-molded into those spaces. Pushbuttons and keys, for instance, made by this process have markings that cannot wear off, and remain legible with heavy use.[24]

A mold can produce several copies of the same parts in a single "shot". The number of "impressions" in the mold of that part is often incorrectly referred to as cavitation. A tool with one impression will often be called a single impression(cavity) mold.[25] A mold with 2 or more cavities of the same parts will likely be referred to as multiple impression (cavity) mold.[26] Some extremely high production volume molds (like those for bottle caps) can have over 128 cavities.

In some cases multiple cavity tooling will mold a series of different parts in the same tool. Some toolmakers call these molds family molds as all the parts are related. Examples include plastic model kits.[27]

Effects on the material properties

The mechanical properties of a part are usually little affected. Some parts can have internal stresses in them. This is one of the reasons why it is desirable to have uniform wall thickness when molding. One of the physical property changes is shrinkage. A permanent chemical property change takes place in thermoset polymers, which can't be remelted to be injected again.[28]

Tool materials

Tool steel or beryllium-copper are often used. Mild steel, aluminum, nickel or epoxy are suitable only for prototype or very short production runs.[29] Modern hard aluminum (7075 and 2024 alloys) with proper mold design, can easily make molds capable of 100,000 or more part life.[citation needed]

Geometrical possibilities

The most commonly used plastic molding process, injection molding, is used to create a large variety of products with different shapes and sizes. Most importantly, they can create products with complex geometry that many other processes cannot. There are a few precautions when designing something that will be made using this process to reduce the risk of weak spots. First, streamline the product or keep the thickness relatively uniform. Second, try to keep your product between 2 to 20 inches (5 to 50 cm), although larger products are possible in special cases: adult-size chairs cast in one piece are readily available.

The size of a part will depend on a number of factors (material, wall thickness, shape,process etc.). The initial raw material required may be measured in the form of granules, pellets or powders. Here are some ranges of the sizes:[29]

| Method | Raw materials | Maximum size | Minimum size |

|---|---|---|---|

| Injection molding (thermo-plastic) | Granules, pellets, powders | 700 oz. / 20 kg | Less than 1 oz. / 28 g |

| Injection molding (thermo-setting) | Granules, pellets, powders | 200 oz. / 5.5 kg | Less than 1 oz. / 28 g |

Machining

Molds are built through two main methods: standard machining and EDM. Standard machining, in its conventional form, has historically been the method of building injection molds. With technological development, CNC machining became the predominant means of making more complex molds with more accurate mold details in less time than traditional methods.

The electrical discharge machining (EDM) or spark erosion process has become widely used in mold making. As well as allowing the formation of shapes that are difficult to machine, the process allows pre-hardened molds to be shaped so that no heat treatment is required. Changes to a hardened mold by conventional drilling and milling normally require annealing to soften the mold, followed by heat treatment to harden it again. EDM is a simple process in which a shaped electrode, usually made of copper or graphite, is very slowly lowered onto the mold surface (over a period of many hours), which is immersed in paraffin oil (kerosene). A voltage applied between tool and mold causes spark erosion of the mold surface in the inverse shape of the electrode.[30]

Cost

The cost of manufacturing molds depends on a very large set of factors ranging from number of cavities, size of the parts (and therefore the mold), complexity of the pieces, expected tool longevity, surface finishes and many others. The initial cost is great, however the piece part cost is low, so with greater quantities the overall price decreases.

Injection process

With injection molding, granular plastic is fed by gravity from a hopper into a heated barrel. As the granules are slowly moved forward by a screw-type plunger, the plastic is forced into a heated chamber, where it is melted. As the plunger advances, the melted plastic is forced through a nozzle that rests against the mold, allowing it to enter the mold cavity through a gate and runner system. The mold remains cold so the plastic solidifies almost as soon as the mold is filled.[31]

Injection molding cycle

The sequence of events during the injection mold of a plastic part is called the injection molding cycle. The cycle begins when the mold closes, followed by the injection of the polymer into the mold cavity. Once the cavity is filled, a holding pressure is maintained to compensate for material shrinkage. In the next step, the screw turns, feeding the next shot to the front screw.This causes the screw to retract as the next shot is prepared. Once the part is sufficiently cool, the mold opens and the part is ejected.[32]

Different types of injection molding processes

Although most injection molding processes are covered by the conventional process description above, there are several important molding variations including:

- Co-injection (sandwich) molding

- Fusible (lost, soluble) core injection molding

- Gas-assisted injection molding

- In-mold decoration and in mold lamination

- Injection-compression molding

- Insert and outsert molding

- Lamellar (microlayer) injection molding

- Low-pressure injection molding

- Metal injection molding

- Microinjection molding

- Microcellular molding

- Multicomponent injection molding

- Multiple live-feed injection molding

- Powder injection molding

- Push-Pull injection molding

- Reaction injection molding

- Resin transfer molding

- Rheomolding

- Structural foam injection molding

- Structural reaction injection molding

- Thin-wall molding

- Vibration gas injection molding

- Water assisted injection molding

- Rubber injection

- Injection molding of liquid silicone rubber[33]

For more details about the different types of injection processes, see [1]

Process troubleshooting

Optimal process settings are critical to influencing the cost, quality, and productivity of plastic injection molding. The main trouble in injection molding is to have a box of good plastics parts contaminated with scrap. For that reason process optimization studies have to be done and process monitoring has to take place. First article inspection of internal and external geometry including imperfections such as porosity can be completed using Industrial CT Scanning, a 3D x-ray technology. For external geometry verification only a Coordinate-measuring machine or white light scanner can be used.

To have a constant filling rate in the cavity, the switch over from injection phase to the holding phase can be made based on cavity pressure level.

Having a stable production window, the following issues are worth investigating:

- The Metering phase can be optimized by varying screw turns per minute and back pressure. Variation of time needed to reload the screw gives an indication of the stability of this phase.

- Injection speed can be optimized by pressure drop studies between pressure measured in the Nozzle (alternatively hydraulic pressure) and pressure measured in the cavity. Melted material with a lower viscosity has less pressure loss from nozzle to cavity than material with a higher viscosity. Varying the Injection speed changes the shear rate. Higher speed gives a higher shear rate and lower viscosity.

- Gate seal or gate freeze / sink mark / weight and geometry studies prevent sink marks and geometrical faults. Optimizing the height and duration of applied holding pressure based on cavity pressure curves is the appropriate way to go. The thicker the part, the longer the holding pressure should be applied.

- Cooling time starts once the injection phase is finished. The hotter the melted plastics, the longer the cooling time, and the thicker the part produced, the longer the cooling time.

Molding trial

When filling a new or unfamiliar mold for the first time, where shot size for that mold is unknown, a technician/tool setter usually starts with a small shot weight and fills gradually until the mold is 95 to 99% full. Once this is achieved, a small amount of holding pressure will be applied and holding time increased until gate freeze off (solidification time) has occurred. Gate freeze off time can be determined by increasing the hold time, and then weighing the part. When the weight of the part does not change, we then know that the gate has frozen and no more material is injected into the part. Gate solidification time is important, as it determines cycle time and the quality and consistency of the product, which itself is an important issue in the economics of the production process.[34] Holding pressure is increased until the parts are free of sinks and part weight has been achieved.

Once the parts are good enough and have passed any specific criteria, a setting sheet is produced for people to follow in the future. Setting up an unknown mold for the first time can be helped by installing cavity pressure sensors. Measuring the cavity pressure as a function of time can provide a good indication of the filling profile of the cavity. Once the equipment is set to successfully create the molded part, modern monitoring systems can save a reference curve of the cavity pressure. With that it is possible to reproduce the same part quality on another molding machine within a short setup time.

Molding defects

Injection molding is a complex technology with possible production problems. They can be caused either by defects in the molds, or more often by the molding process itself.

| Molding Defects | Alternative name | Descriptions | Causes |

|---|---|---|---|

| Blister | Blistering | Raised or layered zone on surface of the part | Tool or material is too hot, often caused by a lack of cooling around the tool or a faulty heater |

| Burn marks | Air burn/gas burn/dieseling | Black or brown burnt areas on the part located at furthest points from gate or where air is trapped | Tool lacks venting, injection speed is too high |

| Color streaks (US) | Colour streaks (UK) | Localized change of color/colour | Masterbatch isn't mixing properly, or the material has run out and it's starting to come through as natural only. Previous colored material "dragging" in nozzle or check valve. |

| Delamination | Thin mica like layers formed in part wall | Contamination of the material e.g. PP mixed with ABS, very dangerous if the part is being used for a safety critical application as the material has very little strength when delaminated as the materials cannot bond | |

| Flash | Burrs | Excess material in thin layer exceeding normal part geometry | Mold is over packed or parting line on the tool is damaged, too much injection speed/material injected, clamping force too low. Can also be caused by dirt and contaminants around tooling surfaces. |

| Embedded contaminates | Embedded particulates | Foreign particle (burnt material or other) embedded in the part | Particles on the tool surface, contaminated material or foreign debris in the barrel, or too much shear heat burning the material prior to injection |

| Flow marks | Flow lines | Directionally "off tone" wavy lines or patterns | Injection speeds too slow (the plastic has cooled down too much during injection, injection speeds should be set as fast as is appropriate for the process and material used) |

| Jetting | Part deformed by turbulent flow of material. | Poor tool design, gate position or runner. Injection speed set too high. | |

| Knit lines | Weld lines | Small lines on the backside of core pins or windows in parts that look like just lines. | Caused by the melt-front flowing around an object standing proud in a plastic part as well as at the end of fill where the melt-front comes together again. Can be minimized or eliminated with a mold-flow study when the mold is in design phase. Once the mold is made and the gate is placed, one can minimize this flaw only by changing the melt and the mold temperature. |

| Polymer degradation | Polymer breakdown from hydrolysis, oxidation etc. | Excess water in the granules, excessive temperatures in barrel, excessive screw speeds causing high shear heat, material being allowed to sit in the barrel for too long, too much regrind being used. | |

| Sink marks | [sinks] | Localized depression (In thicker zones) | Holding time/pressure too low, cooling time too short, with sprueless hot runners this can also be caused by the gate temperature being set too high. Excessive material or walls too thick. |

| Short shot | Non-fill / Short mold | Partial part | Lack of material, injection speed or pressure too low, mold too cold, lack of gas vents |

| Splay marks | Splash mark / Silver streaks | Circular pattern around gate caused by hot gas | Moisture in the material, usually when hygroscopic resins are dried improperly. Trapping of gas in "rib" areas due to excessive injection velocity in these areas. Material too hot. |

| Stringiness | Stringing | String like remnant from previous shot transfer in new shot | Nozzle temperature too high. Gate hasn't frozen off, no decompression of the screw, no sprue break, poor placement of the heater bands inside the tool. |

| Voids | Empty space within part (Air pocket is commonly used, correction: A void is absolute vacuum correction by JC Mora) | Lack of holding pressure (holding pressure is used to pack out the part during the holding time). Filling too fast, not allowing the edges of the part to set up. Also mold may be out of registration (when the two halves don't center properly and part walls are not the same thickness). The provided information is the commond understanding, Correction: The Lack of pack (not holding) pressure (pack pressure is used to pack out even though is the part during the holding time). Filling too fast does not cause this condition, as a void is a sink that did not have a place to happen. In other words as the part shrink the resin separated from it self as there was not sufficient resin in the cavity. The void could happened at any area or the part is not limited by the thickness but by the resin flow and thermal conductivity, but it is more likely to happened at thicker areas like ribs or bosses.Additional root causes for voids are un-melt on the melt pool. | |

| Weld line | Knit line / Meld line / Transfer line | Discolored line where two flow fronts meet | Mold/material temperatures set too low (the material is cold when they meet, so they don't bond). Time for transition between injection and transfer (to packing and holding) is too early. |

| Warping | Twisting | Distorted part | Cooling is too short, material is too hot, lack of cooling around the tool, incorrect water temperatures (the parts bow inwards towards the hot side of the tool) Uneven shrinking between areas of the part |

Methods such as industrial CT scanning can help with finding these defects externally as well as internally.

Tolerances and surfaces

Molding tolerance is a specified allowance on the deviation in parameters such as dimensions, weights, shapes, or angles, etc. To maximize control in setting tolerances there is usually a minimum and maximum limit on thickness, based on the process used.[35] Injection molding typically is capable of tolerances equivalent to an IT Grade of about 9–14. The possible tolerance of a thermoplastic or a thermoset is ±0.008 to ±0.002 inches. Surface finishes of two to four microinches or better can be obtained. Rough or pebbled surfaces are also possible.

| Molding Type | Typical [in] | Possible [in] |

|---|---|---|

| Thermoplastic | ±0.008 | ±0.002 |

| Thermoset | ±0.008 | ±0.002 |

Lubrication and cooling

Obviously, the mold must be cooled in order for the production to take place. Because of the heat capacity, low cost, and availability of water, water is used as the primary cooling agent. To cool the mold, water can be channeled through the mold to account for quick cooling times. Usually a colder mold is more efficient because this allows for faster cycle times. However, this is not always true because crystalline materials require the opposite: a warmer mold and lengthier cycle time.[31]

Power requirements

The power required for this process of injection molding depends on many things and varies between materials used. Manufacturing Processes Reference Guide states that the power requirements depend on "a material's specific gravity, melting point, thermal conductivity, part size, and molding rate." Below is a table from page 243 of the same reference as previously mentioned that best illustrates the characteristics relevant to the power required for the most commonly used materials.

| Material | Specific gravity (g/cm3) | Melting point (°F) | Melting point (°C) |

|---|---|---|---|

| Epoxy | 1.12 to 1.24 | 248 | 120 |

| Phenolic | 1.34 to 1.95 | 248 | 120 |

| Nylon | 1.01 to 1.15 | 381 to 509 | 194 to 265 |

| Polyethylene | 0.91 to 0.965 | 230 to 243 | 110 to 117 |

| Polystyrene | 1.04 to 1.07 | 338 | 170 |

Inserts, and advantages of robotic parts handling

Metal inserts can also be injection molded into the workpiece. For parts made in large quantities, inserts are placed automatically into the mold. Automation means that the smaller size of parts permits a mobile inspection system to examine multiple parts more quickly. In addition to mounting inspection systems on automatic devices, multiple-axis robots can remove parts from the mold and position them for further processes.[36](Edited)

Specific instances include removing of parts from the mold immediately after the parts are created, as well as applying machine vision systems. A robot grips the part after the ejector pins have been extended to free the part from the mold. It then moves them into either a holding location or directly onto an inspection system. The choice depends upon the type of product, as well as the general layout of the manufacturing equipment. Vision systems mounted on robots have greatly enhanced quality control for insert molded parts. A mobile robot can more precisely determine the placement accuracy of the metal component, and inspect faster than a human can.[36](Edited)

Gallery

-

Lego injection mold, lower side

-

Lego injection mold, detail of lower side

-

Lego injection mold, upper side

-

Lego injection mold, detail of upper side

See also

Notes

- ^ Manufacturing Processes Reference Guide pg 240

- ^ http://prismier.com/injection-molding/

- ^ a b Manufacturing Processes Reference Guide pg. 240

- ^ U.S. patent #133229, dated 19 November 1872.

- ^ Douglas M. Bryce. Plastic Injection Molding: Manufacturing Process Fundamentals. SME, 1996. pg. 1–2

- ^ http://www.yaskawa.com/site/Industries.nsf/applicationDoc/appinjmold.html, 02/27/09

- ^ http://www.custompartnet.com/wu/InjectionMolding, 02/27/09.

- ^ Douglas M. Bryce. Plastic Injection Molding: Manufacturing Process Fundamentals. SME, 1996. pg.6

- ^ Manufacturing Processes Reference Guide pg. 242

- ^ Douglas M. Bryce. Plastic Injection Molding: Manufacturing Process Fundamentals. SME, 1996. pg. 43–44

- ^ http://www.custompartnet.com/wu/InjectionMolding

- ^ Donald V. Rosato, Marlene G. Rosato. Concise Encyclopedia of Plastics. Springer, 2000. pg.176

- ^ Douglas M. Bryce. Plastic Injection Molding: Manufacturing Process Fundamentals. SME, 1996. pg.141

- ^ Douglas M. Bryce. Plastic Injection Molding: Manufacturing Process Fundamentals. SME, 1996. pg.142

- ^ Rosato Dominick , Rosato Marlene, and Rosato Donald Injection Molding Handbook 3rd Ed. Kluwer Academic Publishers, 2000. pg.15

- ^ Douglas M. Bryce. Plastic Injection Molding: Manufacturing Process Fundamentals. SME, 1996. pg.147

- ^ Rosato Dominick , Rosato Marlene, and Rosato Donald Injection Molding Handbook 3rd Ed. Kluwer Academic Publishers, 2000. pg.406

- ^ Rosato Dominick , Rosato Marlene, and Rosato Donald Injection Molding Handbook 3rd Ed. Kluwer Academic Publishers, 2000. pg.332

- ^ Douglas M. Bryce. Plastic Injection Molding: Manufacturing Process Fundamentals. SME, 1996. pg.47

- ^ Rosato Dominick , Rosato Marlene, and Rosato Donald Injection Molding Handbook 3rd Ed. Kluwer Academic Publishers, 2000. pg.288

- ^ Douglas M. Bryce. Plastic Injection Molding: Manufacturing Process Fundamentals. SME, 1996. pg.143

- ^ Douglas M. Bryce. Plastic Injection Molding: Manufacturing Process Fundamentals. SME, 1996. pg.86

- ^ Douglas M. Bryce. Plastic Injection Molding: Manufacturing Process Fundamentals. SME, 1996. pg.268

- ^ Douglas M. Bryce. Plastic Injection Molding: Manufacturing Process Fundamentals. SME, 1996. pg.174

- ^ Tony Whelan. Polymer Technology Dictionary Springer, 1994. pg.398

- ^ Tony Whelan. Polymer Technology Dictionary Springer, 1994. pg.262

- ^ Rees, Herbert; Catoen, Selecting Injection Molds – Weighing Cost versus Productivity Hanser Publishers, 2006. pg.114

- ^ Robert H. Todd, Dell K. Allen, Leo Alting. Manufacturing Processes Reference Guide Industrial Press Inc., 1994. pg. 243

- ^ a b Todd, R. H., Allen, D. K., & Alting, L. (1994). Manufacturing Processes Reference Guide. New York, NY: Industrial Press Inc.

- ^ http://advantagetool.us/mats/die_casting/

- ^ a b Manufacturing Processes Reference Guide

- ^ Injection Molding Handbook 2nd Ed pg 13

- ^ Injection Molding Handbook 2nd Ed pg 17–18

- ^ R Pantani, F De Santis, V Brucato, G Titomanlio Analysis of Gate Freeze-Off Time in Injection Molding. Polymer Engineering and Science, 2004

- ^ Rosato 2000, p. 439.

- ^ a b Callister

References

- Bryce, Douglas M. Plastic Injection Molding: Manufacturing Process Fundamentals. SME, 1996.

- Brydson, J, Plastics Materials, Butterworths 9th Ed (1999).

- Callister, William D, Materials Science and Engineering: An Introduction, John Wiley and Sons

- HI *Whelan, Tony. Polymer Technology Dictionary Springer, 1994.

- Mora, JC; Polymers Product Manufacturing; Part Design, Mold Design, Process, Production Controls, & Facilities

External links

- Injection molding cost estimator

- Injection molding cost estimator (detailed)

- Shrinkage & warpage

- Injection molding interactive animation

- Manufacturing engineering and mechanical properties of plastic parts - INTEMA (Research Institute), Universidad Nacional de Mar del Plata - CONICET