Isogrid: Difference between revisions

→Manufacturing: Add photo Tags: Mobile edit Mobile web edit |

Swap photos |

||

| Line 3: | Line 3: | ||

[[File:Isogrid topview.png|thumb|Border|right|baseline||link=|alt=|Topview of isogrid panel]] |

[[File:Isogrid topview.png|thumb|Border|right|baseline||link=|alt=|Topview of isogrid panel]] |

||

[[File:Isogrid flange.png|thumb|Border|right|baseline|link=|alt=|Cross-section of isogrid flange stiffner<ref name="composite_iso">{{cite patent |

[[File:Isogrid flange.png|thumb|Border|right|baseline|link=|alt=|Cross-section of isogrid flange stiffner<ref name="composite_iso">{{cite patent |

||

| country = US |

| country = US |

||

| Line 47: | Line 46: | ||

== Manufacturing == |

== Manufacturing == |

||

| ⚫ | |||

| ⚫ | |||

The stiffeners of an isogrid are generally machined from a single sheet of material with a milling machine, but a thickness less than 0.040 in. (1.0 [[millimeter]]) requires chemical milling processes.<ref name="theisogrid">{{cite web |

The stiffeners of an isogrid are generally machined from a single sheet of material with a milling machine, but a thickness less than 0.040 in. (1.0 [[millimeter]]) requires chemical milling processes.<ref name="theisogrid">{{cite web |

||

| url = http://www.isogrid-sst.com/machine%20design.htm |

| url = http://www.isogrid-sst.com/machine%20design.htm |

||

| Line 60: | Line 59: | ||

| last = Huybrechts |

| last = Huybrechts |

||

| first = Steven |

| first = Steven |

||

|author2=Troy E. Meink |author3=Peter M. Wegner |

|author2=Troy E. Meink |author3=Peter M. Wegner |

||

|author4=Jeff M. Ganley |

|||

| title = Manufacturing theory for advanced grid stiffened structures |

|||

| journal = Composites Part A: applied science and manufacturing |

| journal = Composites Part A: applied science and manufacturing |

||

| volume = 33 |

| volume = 33 |

||

| Line 84: | Line 84: | ||

== Uses == |

== Uses == |

||

| ⚫ | |||

| ⚫ | |||

Isogrid panels form self-stiffened structures where low weight, stiffness, strength and damage tolerance are important, such as in aircraft or space vehicles. |

Isogrid panels form self-stiffened structures where low weight, stiffness, strength and damage tolerance are important, such as in aircraft or space vehicles. |

||

Aerospace isogrid structures include payload shrouds, and boosters which must support the full weight of upper stages and payloads under high G loads. Their open configuration with a single, sealed sheet facing the outside makes them especially useful for propellant tanks for rockets, where sealing the propellant in but allowing it to drain in use or maintenance are necessary features. |

Aerospace isogrid structures include payload shrouds, and boosters which must support the full weight of upper stages and payloads under high G loads. Their open configuration with a single, sealed sheet facing the outside makes them especially useful for propellant tanks for rockets, where sealing the propellant in but allowing it to drain in use or maintenance are necessary features. |

||

Revision as of 03:45, 22 July 2015

This article includes a list of general references, but it lacks sufficient corresponding inline citations. (December 2010) |

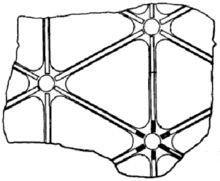

An isogrid is a type of partially hollowed-out structure formed usually from a single metal plate (or face sheet) with triangular integral stiffening ribs (often called stringers). It is extremely light and stiff.

Theory and design

Isogrid structures are related to Sandwich-structured composite panels; both can be modeled using Sandwich theory, which describes structures with separated, stiff face sheets and a lighter interconnecting layer. Isogrids are manufactured from single sheets of material and with large-scale triangular openings, and an open pattern to the flanges, compared to closed sheets and foam or honeycomb structures for the sandwich-composite structures.

The triangular pattern is very efficient because it retains rigidity while saving material and therefore weight. The term isogrid is used because the structure acts like an isotropic material, with equal properties measured in any direction, and grid, referring to the sheet and stiffeners structure.

A similar variant is the Orthogrid which uses rectangular rather than triangular openings. This is not isotropic (has different properties from different angles) but matches many use cases well and is easier to manufacture.

Traditionally, the equilateral triangle pattern was used because it was amenable to simplified analysis.[2] Since the equilateral triangle pattern has isotropic strength characteristics (no preferential direction), it was named isogrid.[citation needed]

Manufacturing

The stiffeners of an isogrid are generally machined from a single sheet of material with a milling machine, but a thickness less than 0.040 in. (1.0 millimeter) requires chemical milling processes.[3]

Metal isogrids (often aluminum), are constructed by milling material from one face of a sheet or plate. Composite isogrids are rib-skin[clarification needed] configurations formed by various manual or automated processes[4] , and can give extremely high strength-weight ratios.[5]

Uses

Isogrid panels form self-stiffened structures where low weight, stiffness, strength and damage tolerance are important, such as in aircraft or space vehicles. Aerospace isogrid structures include payload shrouds, and boosters which must support the full weight of upper stages and payloads under high G loads. Their open configuration with a single, sealed sheet facing the outside makes them especially useful for propellant tanks for rockets, where sealing the propellant in but allowing it to drain in use or maintenance are necessary features.

Some spacecraft and launch vehicles which use isogrid structures include:

References

- ^ US patent 4012549, Paul Slysh, "High strength composite structure", published Oct 10, 1974, issued Mar 15, 1977

- ^ a b c Meyer, R. R; Harwood, O. P. (Oct 1, 1973) [1973]. Isogrid design handbook. Marshall Space Flight Center. 19730000395. Archived from the original (PDF) on Sep 30, 2010.

- ^ Slysh, Paul. "The Isogrid". Retrieved May 27, 2011.

- ^ Huybrechts, Steven; Troy E. Meink; Peter M. Wegner; Jeff M. Ganley (2002). "Manufacturing theory for advanced grid stiffened structures". Composites Part A: applied science and manufacturing. 33. Elsevier: 155–161. Retrieved 26 May 2012.

- ^ Wegner, Peter M.; Higgins, John E.; VanWest, Barry P. (2002). "Application of Advanced Grid-Stiffened Structures Technology to the Minotaur Payload Fairing". 43rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference. Denver, CO.

{{cite conference}}: Unknown parameter|booktitle=ignored (|book-title=suggested) (help) - ^ Knighton, D. J., D.J. (Sep 1, 1972) [1972], Delta launch vehicle isogrid structure NASTRAN analysis, Goddard Space Flight Center, hdl:2060/19720025227, archived from the original on Jun 11, 2007