Mineral wool

Mineral wool, means fibres made from minerals or metal oxides, be they synthetic or natural. In industry use, MMMF (man-made-mineral-fibres) generally refer to synthetic materials. This includes fibreglass, ceramic fibres and rock wool, also known as stone wool. Mineral wool is an inorganic substance used for insulation and filtering. A common mistake is to believe that fibreglass and ceramic fibres are NOT mineral wools, but they are by virtue of their consisting of minerals or metal oxides.

Manufacture of stone wool

Stone wool is a furnace product of molten stone, at a temperature of about 1600 °C, through which is blown a stream of air or steam. More high tech production techniques are based on spinning molten rock (lava) on high speed spinning wheels. (compare with candy floss) The final product is a mass of fine, intertwined fibres with a typical diameter of 6 to 10 micrometres. Mineral wool may contain a binder, often phenol formaldehyde resin, and an oil to reduce dusting and making it water repellent (hydrophobic).

Usage

The fibres themselves are excellent conductors of heat, but they package air so well, that when pressed into rolls and sheets, rockwool makes for an excellent and reliable insulator. Batts, sheets and roll made of rockwool are a poor conductor of heat and sound. Fire resistive properties for mineral wools is given here in ascending order, from lowest to highest:

- fiberglass,

- stone wool,

- ceramic fibres.

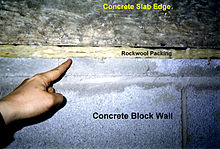

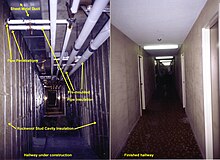

No conventional building materials, including mineral wool are immune to the effects of fire of sufficient duration or intensity. However, each of the aforementioned three wools make common components in passive fire protection systems, such as in spray fireproofing, stud cavities in drywall assemblies required to have a fire-resistance rating, packing materials in firestops and more.

Mineral wools are unattractive to rodents but will provide a structure for bacterial growth if allowed to become wet.

Other uses are in resin bonded panels, growth medium in hydroponics, filler in compounds for gaskets, brake pads, in plastics in the automotive industry and as a filtering medium.

Use in hydroponics

Mineral wool is used for its ability to hold large quantities of water and at the same time maintain a high percentage of air as well. This aids root growth and nutrient uptake. The fibrous nature of mineral wool also provides a good mechanical structure to hold the plant stable. Mineral wool has a high pH, which is unsuitable to plant growth. This requires correcting or conditioning. Conditioned mineral wool has a long, stable pH.

Safety of material

Precautions need to be taken when handling a fibre product as it can be absorbed into the body by inhalation. It can also irritate the eyes, skin and respiratory tract. Prolonged exposure could lead to long term effects and it is considered a possible carcinogen to humans. This effect may depend upon the fiber diameter and length, chemical composition and persistence within the body.

High bio soluble fibers (HT-fibers) are produced that do not cause damage to the human cell. IARC (the International Agency for Research on Cancer) has reviewed the carcinogenicity of man made mineral fibres in October 2002. These newer biosoluble materials have been tested for carcinogenicity and most are found to be non-carcinogenic, or to cause tumours in experimental animals only under very restricted conditions of exposure. The IARC Monographs working group concluded that only the more biopersistent materials remain classified by IARC as possible human carcinogens (Group 2B). These include refractory ceramic fibres, which are used industrially as insulation in high-temperature environments such as blast furnaces, and certain special-purpose glass wools not used as insulating materials. In contrast, the more commonly used vitreous fibre wools including insulation glass wool, rock (stone) wool and slag wool are considered not classifiable as to carcinogenicity to humans (Group 3).

The EU risk and safety phrases associated with this material in general are:

- R38 – Irritating to the skin

- R39 – Danger of very serious irreversible effects

- R40 – Possible risk of irreversible effects

- S36/37 – Wear suitable protective clothing and gloves.

All European produced rock (stone)wool and glass wool is bio soluble and R39 and R40 do not apply. For these products only the risk phrase R38 remains. This irritation to the skin however is not a chemical irritation but only a temporal mechanical irritation, comparable with exposure of the skin to straw, grass or hay.

Controversy exists over these rulings, as the majority of test results upon which they are based have typically been provided by the industry that makes the fibers. Test results that contravene such results were deemed inadmissible to IARC as submission by whistleblowers are not sanctioned by the party paying for the tests. Still by following common sense and industrial guidelines to prevent breathing of the fibers, it is possible to reduce the likelihood of pathology.