Escapement

This article needs additional citations for verification. (November 2007) |

In mechanical watches and clocks, an escapement is a device which converts continuous rotational motion into an oscillating or back and forth motion. The term is also used in fisheries science to refer to that portion of the spawning stock surviving fishing pressures over a spawning cycle.

A mechanical escapement most usually drives a pendulum (or similar harmonic device) in a pendulum clock, usually from a gear train. The gear train is powered to provide energy into the pendulum, typically using springs or weights. Without the escapement the system would simply unwind continuously, but the escapement regulates this motion, controlled by the periodic swing of the pendulum. The pendulum moves the escapement back and forth, and makes it change from a "locked" state to a "drive" state for a short period that ends when the next tooth on the gear hits the locking surface on the escapement. It is this periodic release of energy and rapid stopping that makes a clock "tick;" it is the sound of the gear train suddenly stopping when the escapement locks again. An escapement is also found in a mechanical watch, powering and regulated by a balance wheel and hairspring instead of a pendulum.

History

The importance of the escapement in the history of technology is that it was the key invention that made the mechanical clock possible.[1][2] This initiated a change in timekeeping methods from continuous processes, such as the flow of water in water clocks, to repetitive oscillatory processes, such as the swing of pendulums, which could yield more accuracy.[2]

The first escapement originated in China with the Buddhist monk Yi Xing, who along with government official Liang Lingzan applied its use in 723 (or 725) to the workings of a water-powered armillary sphere and clock drive.[3] The Song Dynasty (960–1279) era horologists Zhang Sixun (fl. late 10th century) and Su Song (1020–1101) duly applied escapement devices for their astronomical clock towers.[4] These were not modern escapements, in the sense that they did not use an oscillating mass for timekeeping but instead used the flow of water into a container. The escapement's role was to tip the container over each time it reached a certain weight, thus advancing the clock's wheels each time an equal quantity of water was measured out.

The predecessor to the first escapement mechanism in Europe is still of unknown origin (perhaps derived from a device of Villard de Honnecourt in 1237).[5] It appeared in Europe sometime in the late 13th century to early 14th century, certainly before 1319 when Dante Alighieri made a reference to the gear work of striking clocks.[6]

Reliability

The reliability of an escapement depends on the quality of workmanship and the level of maintenance given. A poorly constructed or poorly maintained escapement will cause problems. The escapement must accurately convert the oscillations of the pendulum or balance wheel into rotation of the clock or watch gear train, and it must deliver enough energy to the pendulum or balance wheel to maintain its oscillation.

In many escapements, the unlocking of the escapement involves sliding motion; for example, in the animation shown above, the pallets of the anchor slide against the escapement wheel teeth as the pendulum swings. The pallets are often made of very hard materials such as polished stone (for example, artificial ruby), but even so they normally require lubrication. Since lubricating oil degrades over time, due to evaporation, dust, oxidation, etc., periodic re-lubrication is needed. If this is not done, the timepiece may work unreliably or stop altogether, and the escapement components may be subjected to rapid wear. The increased reliability of modern watches is due primarily to the higher-quality oils used for lubrication. Lubricant lifetimes can be greater than five years in a high-quality watch.

Some escapements avoid sliding friction; examples include the grasshopper escapement of John Harrison in the 18th century, and the co-axial escapement of Daniels in the 20th century. This may avoid the need for lubrication in the escapement (though that doesn't affect the requirement for lubrication of other parts of the gear train).

Accuracy

The accuracy of a mechanical clock is dependent on the accuracy of the timing device. If this is a pendulum, then the period of swing of the pendulum determines the accuracy. If the pendulum rod is made of metal it will expand and contract with heat, shortening or lengthening the pendulum; this changes the time taken for a swing. Special alloys are used in expensive pendulum-based clocks to minimize this distortion. Pendulum swings also vary according to how big the arc is; highly-accurate pendulum-based clocks have very small arcs. Pendulum-based clocks can achieve outstanding accuracy. Even into the 20th century, pendulum-based clocks were reference time pieces in laboratories, although at sea the natural motion of the vessel severely impairs the accuracy of a pendulum. Escapements play a big part in accuracy as well. The precise point in the pendulum's travel at which impulse is supplied, will determine how closely to time the pendulum will swing. Ideally, the impulse should be evenly distributed on either side of the lowest point of the pendulum's swing. This is because pushing a pendulum when it's moving towards mid-swing makes it gain, whereas pushing it while it's moving away from mid-swing makes it lose. If the impulse is evenly distributed then it gives energy to the pendulum without changing the time of its swing.[7]

The crucial element in escapement design is to give just enough energy to the pendulum in order to keep it swinging, and to interfere with the free swinging of the pendulum as little as is possible. As the lubrication of the escapement ages, friction will increase, and less power will be transferred to the timing device (for example, the pendulum). If the timing device is a pendulum, this means the pendulum will swing a shorter and shorter arc. Contrary to popular opinion, the time taken for a pendulum swing is not constant regardless of the size of the swing; the swing time changes with the size of the swing. Therefore, a dirty escapement will cause inaccuracy because the arc of the pendulum swing becomes shorter (the clock will speed up). To minimize this effect, pendulum swings are kept as small as possible.

Wristwatches, and smaller clocks, do not use pendulums as the timing device. Instead, they use balance-springs; fine springs connected to a metal "balance wheel" (imagine a bicycle wheel without the tire). The balance wheel spins back and forward; a good Swiss watch has a frequency of 4 Hz (or 8 beats). Faster speeds are used in some watches. The balance-spring must also be temperature neutral. Very sophisticated alloys are used; in this area, watchmaking is still advancing. As with the pendulum, the escapement must provide a small kick each cycle to keep the balance-wheel spinning. Also, the same lubrication problem occurs over time; the watch will lose accuracy (typically it will speed up) when the escapement lubrication starts failing.

Pocket watches were the predecessor of modern wristwatches. Pocket watches, being in the pocket, were usually in a vertical orientation. Gravity causes some loss of accuracy as it magnifies over time any lack of symmetry in the balance mechanism. The 'tourbillon' was invented to minimize this: the balance spring is put in a cage which rotates (typically once a minute), smoothing gravitational distortions. This very clever and sophisticated clock-work is a prized 'complication' in wrist-watches, even though the natural movement of the wearer tends to smooth gravitational influences much more than for a pocketwatch.

The most accurate mechanical clocks ever made are those by W. H. Shortt in 1921 and the Littlemore Clock built by noted archaeologist E. T. Hall. In Hall's paper[8], he reports an error of 3 parts in 109 measured over 100 days (an error of about 0.02 seconds over that period). The article compares that with a number of other precision clocks; the next best reported accuracy is that of the Shortt clock, a factor of 10 less accurate (30 parts in 109). Both of these clocks are electromechanical clocks: they use a pendulum as the timekeeping element, but electrical power rather than a mechanical gear train to supply energy to the pendulum.

Mechanical escapements

Since 1658 when the introduction of the pendulum and balance spring made accurate timepieces possible, more than three hundred different mechanical escapements have been devised, but only about 10 have seen widespread use.[9] These are discribed below. In the 20th century, electric timekeeping methods replaced mechanical clocks and watches, so escapement design became a little known curiosity.

Verge escapement

The earliest escapement in Europe (from about 1275)[citation needed] is the verge escapement, also known as the crown-wheel-and-verge escapement. It pre-dates the pendulum and was originally controlled by a foliot, a horizontal bar with a weight at each end. A vertical shaft (verge) is attached to the middle of the foliot and carries two small plates (pallets) sticking out like flags from a flag pole. One pallet is near the top of the verge and one near the bottom and looking end-on down the verge the pallets are a little over ninety degrees apart. The escape wheel is shaped somewhat like a crown and turns about a horizontal axis. As the wheel tries to turn, one tooth of the wheel pushes against the upper pallet and starts the foliot moving. As the tooth pushes past the upper pallet, the lower pallet swings into the path of the escape wheel. The momentum of the moving foliot pushes the escape wheel backwards but eventually the system comes to rest. It is now the turn of the lower pallet to push the foliot and so on. The system has no natural frequency of oscillation - it is simply force pushing inertia around.

The next stage of development was to use the same idea but attach it to a pendulum. The axis of the verge became horizontal, one half of the foliot disappeared and the crown wheel rotated about a vertical axis. On a much smaller scale the same escapement was used for watches with a balance wheel and spring replacing the pendulum. John Harrison's first marine chronometer used a heavily-modified verge escapement and demonstrated that the verge could be capable of good timekeeping.

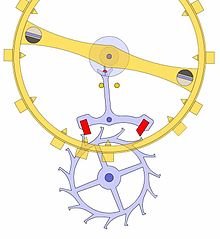

Anchor escapement

Invented around 1660 by Robert Hooke, the anchor quickly superseded the verge to become the standard escapement used in pendulum clocks through the 19th century. Its advantage was that it reduced the wide pendulum swing angles of the verge to 3°-6°, making the pendulum isochronous, and allowing the use of longer, slower moving pendulums, which used less energy. It is responsible for the long narrow shape of most pendulum clocks, particularly grandfather clocks.

It consists of an escape wheel with pointed, backward slanted teeth, and an 'anchor' shaped piece pivoted above it which rocks from side to side, attached to the pendulum. The anchor has slanted pallets on the arms which alternately catch on the teeth of the escape wheel, receiving impulses. Mechanically its operation has similarities to the verge escapement, and it has two of the verge's disadvantages: (1) The pendulum is constantly being pushed by an escape wheel tooth throughout its cycle, and is never allowed to swing freely, which disturbs its isochronism, and (2) it is a recoil escapement; the anchor pushes the escape wheel backward during part of its cycle. This causes backlash, increased wear in the clocks gears, and inaccuracy. These problems were eliminated in the deadbeat escapement, which slowly replaced the anchor in precision clocks.

Deadbeat escapement

A clock with a deadbeat escapement was made by Thomas Tompion to a design by Richard Towneley in 1675[11][citation needed] although it was left to Tompion's successor George Graham, to make it widely known around 1715.[12] It was an improved version of the anchor escapement. A pendulum continues to swing even after the teeth have locked, and with the verge and the anchor, this reverses the direction of the gear train. The traditional form of gears in clocks only works well going forwards so the recoil introduces high loads into the system, leading to friction and wear.

In Graham's escapement the pallets are curved about the same axis that they turn on: there is no recoil, so the locking face of the pallets provide no impulse. The impulse is provided by putting an angled plane surface on the end of the pallet so that as the escape wheel is released its tooth pushes along this wedge, impulsing the pendulum. This was the first escapement to separate the locking and impulse actions of the escapement.[citation needed] The escapement was adopted widely for precision and high-quality clocks and led to a number of later escapements which share its lack of recoil.[7]

Lever escapement

The lever escapement has been used by the vast majority of watches since the 1800s. It is accurate and reasonably easy to manufacture. It is a self-starting escapement, so if the watch is shaken so that the balance wheel stops, it will automatically start again. There are several forms of the lever escapement. The original form was the rack lever, in which the lever and the balance wheel were always in contact via a gear-like connection. Later, it was realized that all the teeth from the gears could be removed except one, and this created the detached lever escapement. Not only was the detached escapement easier to make and simpler, it was substantially more accurate. The lever could be configured so that it was at a right angle to the escape wheel, which was the common preference for British watchmakers. Or, the lever could be configured to be inline with the balance wheel and the escape wheel, which was the common preference for Swiss and American watchmakers. Finally, in the days of the "dollar watches", a very primitive form of the lever escapement was used, called the "pin-pallet".

Chronometer escapement

The detent or chronometer escapement was most commonly used on marine chronometers, although some precision watches during the 1800s also used it.[13] It was invented in 1783 by Thomas Earnshaw (John Arnold created a variant, patented in 1779, but the Earnshaw design was the one generally adopted)[14] and used until mechanical chronometers became obsolete in the 1970s. They could be made far more accurate than lever escapements,[15] due to the virtual absence of sliding friction between the escape tooth and the pallet during impulse. Yet they were more fragile, were not self-starting, and harder to manufacture in volume. Unlike the lever escapement, the impulse to the balance occurs at every other swing. Usually a balance making 4 swings per second with a helical balance spring was used.

Cylinder escapement

The cylinder escapement was an improvement over the verge escapement in terms of time keeping abilities, but it was not easy to manufacture, was somewhat fragile and the escape wheel was in constant contact with the balance which caused it to need regular cleaning due to wear. It was commonly used by the French watchmakers, although the Swiss also used it quite a bit.

Duplex escapement

The duplex watch escapement was invented by Robert Hooke around 1700, improved by Jean Baptiste Dutertre and Pierre Le Roy, and put in final form by Thomas Tryer, who patented it in 1782.[16] It was used in quality English pocketwatches from about 1790 to 1860[17][18] [19], and in the Waterbury, a cheap American 'everyman's' watch, during 1880-1898.[20] [21] In the duplex, as in the chronometer escapement to which it has similarities, the balance wheel only receives an impulse during one of the two swings in its cycle.[17] The escape wheel has two sets of teeth (hence the name 'duplex'); long locking teeth project from the side of the wheel, and short impulse teeth stick up axially from the top. The cycle starts with a locking tooth resting against the ruby disk. As the balance wheel swings counterclockwise through its center position, the notch in the ruby disk releases the tooth. As the escape wheel turns, the pallet is in just the right position to receive a push from an impulse tooth. Then the next locking tooth drops onto the ruby roller and stays there while the balance wheel completes its cycle and swings back clockwise (CW), and the process repeats. During the CW swing, the impulse tooth falls momentarily into the ruby roller notch again, but isn't released.

The duplex is a frictional rest escapement; the balance is never totally free from the escapement because of the tooth resting against the roller.[17][22] As in the chronometer, there is little sliding friction during impulse since pallet and impulse tooth are moving almost parallel, so little lubrication is needed. The duplex is capable of accuracy at least equal to the lever escapement, and perhaps approaching the chronometer.[23] However it lost favor to the lever; its tight tolerances and sensitivity to shock made duplex watches unsuitable for active people. Like the chronometer, it is not self-starting and is vulnerable to "setting;" if a sudden jar stops the balance during its CW swing, it can't get started again.

Co-axial escapement

Invented around 1974[24] and patented 1980[25] by George Daniels, the co-axial escapement is one of the only new watch escapements adopted commercially in modern times. It is a modification of the lever that has some features of the chronometer escapement. Its main advantage is that through a complicated system of 3 pallets that separates the locking function from the impulse, it is able to avoid the sliding friction of the lever escapement, making lubrication of the pallets unnecessary.[26][27] Since mechanical watches no longer sell because of their accuracy or reliability as timepieces, watch manufacturers had little interest in investing in the tooling required, although finally Omega adopted it in 1990.[27] While low-friction escapements existed already, they were too large for small "movements" (as clock-work is referred to).[citation needed]

Grasshopper escapement

A rare but interesting mechanical escapement is John Harrison's grasshopper escapement. In this escapement, the pendulum is driven by two hinged arms (pallets). As the pendulum swings, the end of one arm catches on the escape wheel and drives it slightly backwards; this releases the other arm which moves out of the way to allow the escape wheel to pass. When the pendulum swings back again, the other arm catches the wheel, pushes it back and releases the first arm and so on. The grasshopper escapement is more difficult to manufacture than other escapements and is something of a rarity. Grasshopper escapements made by Harrison in the 18th century are still operating. Most escapements wear far more quickly, and waste far more energy.

Gravity escapement

A gravity escapement uses a small weight or a weak spring to give an impulse directly to the pendulum. The earliest form consisted of two arms which were pivoted very close to the suspension spring of the pendulum with one arm on each side of the pendulum. Each arm carried a small dead beat pallet with an angled plane leading to it. When the pendulum lifted one arm far enough its pallet would release the escape wheel. Almost immediately another tooth on the escape wheel would start to slide up the angle face on the other arm thereby lifting the arm. It would reach the pallet and stop. The other arm meanwhile was still in contact with pendulum and coming down again to a point lower than it had started from. This lowering of the arm provides the impulse to the pendulum. The design was developed steadily from the middle of the 18th century to the middle of the 19th century. It eventually became the escapement of choice for turret clocks and has recently been perfected in the inertially-detached gravity escapement invented by James Arnfield. This frees the pendulum from any part in unlocking the clock train; all it does is lift a gravity arm and then later on part company from it at a lower point. They part company because the gravity arm comes into contact with, and unlocks, the mechanism which re-sets the gravity arm in its raised position.

Electromechanical escapements

In the late 19th century, electromechanical escapements were developed. In these, a switch or phototube turned an electromagnet on for a brief section of the pendulum's swing. These are amongst some of the best escapements known. On some clocks the pulse of electricity that drove the pendulum would also drive a plunger to move the gear train.

Hipp clock

In the middle of the 19th century Matthias Hipp invented a switch for a clock which was impulsed electro-magnetically.[citation needed] The pendulum drove a ratchet wheel via a pawl on the pendulum rod and the ratchet wheel drove the rest of the clock train to indicate the time. The pendulum was not impulsed on every swing or even at a set interval of time. It was only impulsed when its arc of swing had decayed below a certain level. As well as the counting pawl, the pendulum also carried a small vane, pivoted at the top, which was completely free to swing. It was placed so that it dragged across a triangular polished block with a vee-groove in the top of it. When the arc of swing of the pendulum was large enough, the vane crossed the groove and swung free on the other side. If the arc was too small then the vane never left the far side of the groove and, when the pendulum swung back it pushed the block strongly downwards. The block carried a contact which completed the circuit to the electromagnet which impulsed the pendulum. The pendulum was only impulsed as it required it.

Free pendulum clock

In the 20th century William Harrison Shortt invented a free pendulum clock, patented in September of 1921 and manufactured by the Synchronome Company, with an accuracy of one hundredth of a second per day. In this system the time keeping "master" pendulum, whose rod is made from a special steel alloy with 36% nickel called Invar whose length does not change very much with temperature, swings as free of external influence as possible sealed in a vacuum chamber and does no work. It is in mechanical contact with its escapement for only a fraction of a second every 30 seconds. A secondary "slave" pendulum turns a ratchet, which triggers an electromagnet every thirty seconds. This electromagnet releases a gravity lever onto the escapement above the master pendulum. A fraction of a second later, the motion of the master pendulum releases the gravity lever to fall farther. In the process, the gravity lever gives a tiny impulse to the master pendulum, which keeps that pendulum swinging. The gravity lever falls onto a pair of contacts, completing a circuit that does several things:

- energizes a second electromagnet to raise the gravity lever above the master pendulum to its top position,

- sends a pulse to activate one or more clock dials, and

- sends a pulse to a synchronizing mechanism that keeps the slave pendulum in step with the master pendulum.

Since it is the slave pendulum that releases the gravity lever, this synchronization is vital to the functioning of the clock. The slave clock is set to run slightly slow and the re-set circuit for the gravity arm activates a pivoted arm which just engages with the tip of a blade spring on the pendulum of the slave clock. If the slave clock has lost too much time its blade spring pushes against the arm and this accelerates the clock. The amount of this gain is such that the blade spring doesn't engage on the next cycle but does on the next again. This form of clock became a standard for use in observatories, and was the first clock capable of detecting small variations in the speed of Earth's rotation.

References

- Rawlings, Arthur Lionel (1993). The Science of Clocks and Watches, 3rd Ed. Upton, UK: The British Horological Institute. ISBN 0-9509621-3-9.

- Britten, Frederick J. (1881). The Watch and Clockmaker's Handbook, 4th Ed. London: W. Kent & Co., p.56-58

- Glasgow, David (1885). Watch and Clock Making. London: Cassel & Co. pp. 137–154.

{{cite book}}: Cite has empty unknown parameter:|coauthors=(help) - Grimsthorpe, Edmund Beckett (1911). "Watch". Encyclopaedia Britannica, 11th Ed. Vol. 28. The Encyclopaedia Britannica Co. pp. 362–366. Retrieved 2007-10-18.

- Milham, Willis I. (1945). Time and Timekeepers. New York: MacMillan. ISBN 0780800087.

Notes

- ^ White, Lynn Jr. (1966). Medieval Technology and Social Change. Oxford Press. pp. p.187.

{{cite book}}:|pages=has extra text (help) - ^ a b Cipolla, Carlo M. (2004). Clocks and Culture, 1300 to 1700. W.W. Norton & Co. pp. p.31. ISBN 0393324435.

{{cite book}}:|pages=has extra text (help) - ^ Needham, Joseph (1986). Science and Civilization in China: Volume 4, Physics and Physical Technology, Part 2, Mechanical Engineering. Taipei: Caves Books Ltd. Page 165.

- ^ Needham, Joseph (1986). Science and Civilization in China: Volume 4, Physics and Physical Technology, Part 2, Mechanical Engineering. Taipei: Caves Books Ltd. Pages 445 & 448, 469–471.

- ^ Needham, Joseph (1986). Science and Civilization in China: Volume 4, Physics and Physical Technology, Part 2, Mechanical Engineering. Taipei: Caves Books Ltd. Page 443.

- ^ Needham, Joseph (1986). Science and Civilization in China: Volume 4, Physics and Physical Technology, Part 2, Mechanical Engineering. Taipei: Caves Books Ltd. Page 445.

- ^ a b Rawlings, Arthur Lionel (1993). The Science of Clocks and Watches, 3rd Ed. Upton, UK: The British Horological Institute. ISBN 0-9509621-3-9.

- ^ Hall, E. T. (1996). "The Littlemore Clock". NAWCC Chapter 161 - Horological Science. National Association of Watch and Clock Collectors.

{{cite web}}: External link in|work= - ^ Milham, Willis I. (1945). Time and Timekeepers. New York: MacMillan. pp. p.180. ISBN 0780800087.

{{cite book}}:|pages=has extra text (help) - ^ Britten, Frederick J. (1896). Watch and Clockmaker's Handbook, 9th Edition. E.F.& N. Spon. p. 108.

- ^ Smith, Alan (2000) The Towneley Clocks at Greenwich Observatory Retrieved 2007-11-16

- ^ Milham 1945, p.185

- ^ Milham 1945, p.235

- ^ Milham 1945, p.265-268

- ^ Milham 1945, p.272

- ^ Nelthropp, Harry Leonard (1873). A Treatise on Watchwork, Past and Present. E. & F.N. Spon., p.159-164. British patent no. 1811

- ^ a b c Glasgow, David (1885). Watch and Clock Making. London: Cassel & Co.

{{cite book}}: Cite has empty unknown parameter:|coauthors=(help), p137-154 - ^ Mundy, Oliver (June, 2007). "Watch Escapements". The Watch Cabinet. Retrieved 2007-10-18.

{{cite web}}: Check date values in:|date=(help) - ^ Buser, Roland (June, 2007). "Duplex Escapement". Glossary, Watch Collector's Paradise. Retrieved 2007-10-18.

{{cite web}}: Check date values in:|date=(help) - ^ Milham 1945, p.407

- ^ Stephenson, C. L. (2003). "A History of the Waterbury Watch Co". The Waterbury Watch Museum. Retrieved 2007-10-18.

- ^ Milham 1945, p.238

- ^ Grimsthorpe, Edmund Beckett (1911). "Watch". Encyclopaedia Britannica, 11th Ed. Vol. 28. The Encyclopaedia Britannica Co. pp. 362–366. Retrieved 2007-10-18.

- ^ Daniels, George. "About George Daniels". Daniels London. Retrieved 2008-06-12.

{{cite web}}: Cite has empty unknown parameter:|coauthors=(help) - ^ Thompson, Curtis (2001). "Where George Daniels shopped the Co-Axial..." Chuck Maddox home page. Retrieved 2008-06-12.

{{cite web}}: Cite has empty unknown parameter:|coauthors=(help); External link in|publisher= - ^ Nicolet, J.C. (1999). "Could you explain the mechanism of the coaxial watch?". Questions in Time. Europa star online. Retrieved 2008-06-12.

{{cite web}}: Cite has empty unknown parameter:|coauthors=(help) - ^ a b Odets, Walt (1999). "The Omega Coaxial: An impressive achievement". The Horologium. TimeZone.com. Retrieved 2008-06-12.

{{cite web}}: Cite has empty unknown parameter:|coauthors=(help)

See also

- Lever escapement

- Co-axial escapement

- Horology

- Su Song

- Galileo's escapement

- Riefler escapement

- Tourbillon

External links

- Mark Headrick's horology page, with animated pictures of many escapements

- Performance Of The Daniels Coaxial Escapement, Horological Journal, August 2004

- Watch and Clock Escapements, The Keystone (magazine), 1904, via Project Gutenberg: "A Complete Study in Theory and Practice of the Lever, Cylinder and Chronometer Escapements, Together with a Brief Account of the Origin and Evolution of the Escapement in Horology."

- US Patent number 5140565, issued 23 March 1992, for a cycloidal pendulum similar to that of Huygens

- findarticles.com: Obituary of Professor Edward Hall, The Independent (London), 16 August 2001

- American Watchmakers-Clockmakers Institute, non-profit trade association

- Federation of the Swiss Watch Industry FH, watch industry trade association