Construction of the Egyptian pyramids

There have been many hypotheses about the Egyptian pyramid construction techniques. The construction techniques seem to have developed over time; the earliest pyramids were built in different ways than later ones. Most of the construction hypotheses are based on the idea that their huge stones were moved from a quarry and dragged and lifted into place. Disagreements center on the method by which the stones were conveyed and placed, after being carved using copper chisels to carve them out of the quarry stone. But a recent hypothesis claims that the building blocks were manufactured in-place from a kind of "limestone concrete".

In addition to the many hypotheses about the techniques involved, there are also disagreements as to the kind of workforce used. One hypothesis, suggested by the Greeks, suggests that the workforce was slaves who were forced to work until the pyramid was done. This hypothesis is no longer widely accepted in the modern era. Archaeologists now believe the Great Pyramid of Giza at least was built by tens of thousands of skilled workers who camped near the pyramids and worked for a salary or as a form of tax payment (levee) until the construction was completed. Worker's cemeteries were discovered in 1990 by archaeologists Zahi Hawass and Mark Lehner.

Historical considerations

Third and Fourth Dynasties

During the earliest period, pyramids were constructed wholly of stone. Locally quarried limestone was the material of choice for the main body of these pyramids, while a higher quality of limestone quarried at Tura (near modern Cairo) was used as the outer casing. Granite, quarried near Aswan, was used to construct some architectural elements, including the porticullis (a type of gate) and the roofs and walls of the burial chamber. Occasionally, granite was used in the outer casing as well, such as in the pyramid of Menkaure. In the early pyramids, the layers of stone (called courses) forming the pyramid body were laid sloping inwards; however, this configuration was found to be less stable than simply stacking the stones horizontally on top of each other. The Bent Pyramid at Dahshur seems to indicate acceptance of a newer technique at a transition between these two building techniques. Its lower section is built of sloping courses, while in its upper section the stones are laid horizontally.

Middle Kingdom and onward

During the Middle Kingdom, pyramid construction techniques changed again. Most pyramids built then were little more than mountains of mud brick encased in a veneer of polished limestone. In several cases, later pyramids were built on top of natural hills to further reduce the volume of material needed in their construction. The materials and methods of construction used in the earliest pyramids have ensured their survival in a generally much better state of preservation than for the pyramid monuments of later pharaohs.

Construction method hypotheses

Building the pyramids from quarried stones

One of the major problems faced by the early pyramid builders was the need to move huge quantities of rock. Carvings in some later Egyptian tombs show that 80 men can drag a 2.5-ton block of stone on a sled.[citation needed] Dr R H G Parry[1] has suggested a method for rolling the stones, using a cradle-like machine that had been excavated in various new kingdom temples. Four of those objects could be fitted around a block so it could be rolled easily. Experiments done by the Obayashi Corporation, with concrete blocks 0.8 m square by 1.6 m long and weighing 2.5 tons, showed how 18 men could drag the block over a 1-in-4 incline ramp, at a rate of 18 meters per minute. Vitruvius in De architectura[2] described a similar method for moving irregular weights. While it is unknown if the Egyptians used this method, the experiments show it could have worked using stones of this size. While Egyptologists maintain this, and indeed the pyramids were mostly made of 2.5 ton blocks, there were the 15+ ton and several 70-ton blocks that they do not mention.

As the stones forming the core of the pyramids were roughly cut, especially in the Great Pyramid, the material used to fill the gaps was another problem. Huge quantities of gypsum and rubble were needed. The filling has almost no binding properties, but it was necessary to stabilize the construction. To make the gypsum mortar, it had to be dehydrated by heating, and this required a lot of wood. The findings of the David H. Koch Pyramids Radiocarbon Project[3] suggest that Egypt had to strip its forest and scrap every bit of wood it had to build the pyramids of Giza. When the project tried to date several pyramids using the carbon extracted from the filling in the pyramids' core, they found the dates spanned almost 3000 years, implying that old wood was used for some parts of the pyramids. This was seen only in the Old Kingdom pyramids, especially from Djoser to Menkaure. This could mean that later pyramids were built smaller out of necessity, due to the severely depleted state of Egypt's forest resources.

There is good information concerning the location of the quarries, some of the tools used to cut stone in the quarries (save that no copper chisels have yet been found there), transportation of the stone to the monument, leveling the foundation, and leveling the subsequent tiers of the developing superstructure. Workmen probably used copper chisels, drills, and saws to cut softer stone, such as most of the limestone. The harder stones, such as granite, granodiorite, syenite, and basalt, can not be cut with copper tools alone; instead they were worked with time consuming methods like pounding with dolerite, drilling, and sawing with the aid of an abrasive, like quartzite sand. Blocks were transported by sledge likely lubricated by water. Leveling the foundation was accomplished by use of water filled trenches.

The writings of Herodotus and Diodorus Siculus

The unknowns of pyramid construction chiefly center on the question of how the blocks were moved up the superstructure. There is no known accurate historical or archaeological evidence that definitively resolves the question. Therefore, most discussion on construction methods involves functional possibilities that are supported by limited historical and archaeological evidence.

Historical accounts for the construction of the Egyptian pyramids do little to point definitively to methods to lift the blocks; yet most Egyptologists refer to these accounts when discussing this portion of pyramid construction. The first historical accounts of the construction of these monuments came centuries after the era of pyramid construction, by Herodotus in the 5th century BC and Diodorus Siculus in the 1st century BC. Herodotus' account states:[4]

This pyramid was made like stairs, which some call steps and others, tiers. When this, its first form, was completed, the workmen used short wooden logs as levers to raise the rest of the stones; they heaved up the blocks from the ground onto the first tier of steps; when the stone had been raised, it was set on another lever that stood on the first tier, and the lever again used to lift it from this tier to the next. It may be that there was a new lever on each tier of steps, or perhaps there was only one lever, quite portable, which they carried up to each tier in turn; I leave this uncertain, as both possibilities were mentioned. But this is certain, that the upper part of the pyramid was finished off first, then the next below it, and last of all the base and the lowest part.

Diodorus Siculus' account states:[5]

And 'tis said the stone was transported a great distance from Arabia, and that the edifices were raised by means of earthen ramps, since machines for lifting had not yet been invented in those days; and most surprising it is, that although such large structures were raised in an area surrounded by sand, no trace remains of either ramps or the dressing of the stones, so that it seems not the result of the patient labor of men, but rather as if the whole complex were set down entire upon the surrounding sand by some god. Now Egyptians try to make a marvel of these things, alleging that the ramps were made of salt and natron and that, when the river was turned against them, it melted them clean away and obliterated their every trace without the use of human labor. But in truth, it most certainly was not done this way! Rather, the same multitude of workmen who raised the mounds returned the entire mass again to its original place; for they say that three hundred and sixty thousand men were constantly employed in the prosecution of their work, yet the entire edifice was hardly finished at the end of twenty years.

Both Herodotus' and Diodorus Siculus' writings are known to contain gross errors of fact, and Siculus is routinely accused of borrowing from Herodotus. Herodotus' description of slave labor is one of the most persistent myths of the construction process, and Diodorus Siculus' description of the shipment of the stone from Arabia is incorrect. Since both accounts are known to be unreliable, it is impossible to select either technique from historical documents as correct. However, these documents do give credit to both the levering and ramp methods.

Various kinds of ramps - hypotheses of Mark Lehner and others

Most Egyptologists acknowledge that ramps are the most tenable of the methods to raise the blocks, yet they acknowledge that it is an incomplete method which needs to be supplemented by another device. The method most accepted for assisting ramps is levering [6] (Lehner 1997: 222). The archaeological record gives evidence of only small ramps and inclined causeways, not something that could have been used to construct even a majority of the monument. To add to the uncertainty, there is considerable evidence demonstrating that non-standardized or ad hoc construction methods were used in pyramid construction (Arnold 1991: 98 [7], Lehner 1997: 223).

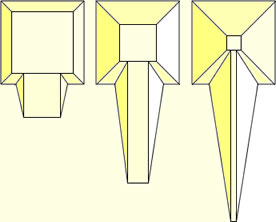

Therefore, there are many proposed ramps and there is a considerable amount of discrepancy regarding what type of ramp was used to build the pyramids.[8] One of the widely discredited ramping methods is the large straight ramp, and it is routinely discredited on functional grounds for its massive size, lack of archaeological evidence, huge labor cost, and other problems (Arnold 1991: 99, Lehner 1997: 215, Isler 2001: 213[9] However, the large straight ramp, seen in the picture above, is the only ramp design that can effectively build the entire monument.

Other ramps serve to correct these problems of ramp size, yet either run into critiques of functionality, limited archaeological evidence, or the inability to construct the entire monument, mostly due to the limited space available at the top of the monument. There are zig-zagging ramps, straight ramps utilizing the incomplete part of the superstructure (Arnold 1991), spiraling ramps supported by the superstructure and spiraling ramps leaning on the monument as a large accretion are proprosed. Mark Lehner speculated that a spiraling ramp, beginning in the stone quarry to the southeast and continuing around the exterior of the pyramid, may have been used. The stone blocks may have been drawn on sleds along the ramps lubricated by water or milk.[10] Yet each of these ramps are criticized for their inability to construct the entire monument. In other words, ramping methods work fine for most of the superstructure, but cannot create the top or the entire monument.

Levering methods are considered to be the most tenable solution to complement ramping methods, partially due to Herodotus' description; and partially to the Shadoof; an irrigation device first depicted in Egypt during the New Kingdom, and found concomitantly with the Old Kingdom in Mesopotamia. In Lehner's (1997: 222) point of view, levers should be employed to lift the top 3% of the material of the superstructure. It is important to note that the top 4% of this material comprises 1/3rd of the total height of the monument. In other words, in Lehner's view, levers should be employed to lift a small amount of material and a great deal of vertical height of the monument.

In the milieu of levering methods, there are those which lift the block incrementally, as in repeatedly prying up alternating sides of the block and inserting a wooden or stone shims to gradually move the stone up one course; and there are other methods that use a larger lever to move the block up one course in one lifting procedure. Since the discussion of construction techniques to lift the blocks attempts to resolve a gap in the archaeological and historical record with a plausible functional explanation, the following examples by Isler, Keable, and Hussey-Pailos [11] list experimentally tested methods. Isler's method (1985, 1987) is an incremental method and, in the Nova experiment (1992), used wooden shims or cribbing. Isler [12] was able to lift a block up one tier in approximately one hour and 30 minutes. Peter Hodges’ and Julian Keable’s[13] method is similar to Isler's method and instead small manufactured concrete blocks as shims, wooden pallets, and a pit where their experimental tests were performed. Keable was able to perform his method in approximately 2 minutes. Scott Hussey-Pailos's (2005) method [11] uses a simple levering device to lift a block up course in one movement. This method was tested with materials of less strength than historical analogs (tested with materials weaker than those available in ancient Egypt), a factor of safety of 2, and lifted a 2500 pound block up one course in under a minute. This method is presented as a levering device to work complimentary with Mark Lehner's idea of a combined ramp and levering techniques.

Jean-Pierre Houdin's "internal ramp" hypothesis

A recent (2006) construction hypothesis for the Great Pyramid presented by French architect Jean-Pierre Houdin involves the use of an "internal ramp" for the top 70% of the structure.[14] A simplified way of thinking of this method is that the upper part of the pyramid was built "inside out". Houdin and a team of engineers used computer-aided design technology to test and refine the hypothesis, which according to Houdin makes his hypothesis the only one "proven" to be a viable technique.[15]

Houdin has written a book about his hypothesis: Khufu: The Secrets Behind the Building of the Great Pyramid.[16]

The use of wind power

It has also been suggested that Egyptians might have moved the stones with wind power, relying on kites and pulleys rather than huge numbers of workers. On June 23, 2001, Caltech aeronautics professor Mory Gharib and a small team of undergraduates working in the California desert raised a 6900 lb (3.1 tonne), 3 meter tall obelisk into a vertical position in 22 mph (35 km/h) winds in under 25 seconds. They used only a kite, a pulley system, and a support frame to demonstrate that wind power can be harnessed to create large lifting forces. Maureen Clemmons first thought of this idea after seeing an image in Smithsonian of some men raising an obelisk. Clemmons also found a frieze that showed an unidentifiable wing pattern directly above some men and possible ropes.[17]

Limestone concrete hypothesis

Materials scientist Joseph Davidovits has claimed that the blocks of the pyramid are not carved stone, but mostly a form of limestone concrete and that they were "cast" as with modern concrete.[18] According to this hypothesis, soft limestone with a high kaolinite content was quarried in the wadi on the south of the Giza Plateau. The limestone was then dissolved in large, Nile-fed pools until it became a watery slurry. Lime (found in the ash of cooking fires) and natron (also used by the Egyptians in mummification) was mixed in. The pools were then left to evaporate, leaving behind a moist, clay-like mixture. This wet "concrete" would be carried to the construction site where it would be packed into reusable wooden moulds and in a few days would undergo a chemical reaction similar to the "setting" of concrete. New blocks, he suggests, could be cast in place, on top of and pressed against the old blocks. Proof-of-concept tests using similar compounds were carried out at a geopolymer institute in northern France and it was found that a crew of ten, working with simple hand tools, could build a structure of fourteen, 1.3- to 4.5-ton blocks in a couple of days.[19] He also claims he found hieroglyphic texts stating they used this technology.

Davidovits' method is not accepted by the academic mainstream. His method deals only with limestone, and not with granite stones weighing well over 10 tons, which he says were carved. Geologists have carefully scrutinized Davidovits suggested technique and concluded his came from natural limestone quarried in the Mokattam Formation.[20] However, Davidovits alleges that the bulk of soft limestone came from the same natural Mokkatam Formation quarries found by geologists, and insists that ancient Egyptians used the soft marly layer instead of the hard one to re-agglomerate stones.

Davidovits' hypothesis recently gained support from Michel Barsoum, a materials science researcher.[21] Michel Barsoum and his colleagues at Drexel University published their findings supporting Davidovit's hypothesis in the Journal of the American Ceramic Society in 2006.[22] they have found particles in pyramid limestone that do not occur in natural limestone.

Dipayan Jana, a petrographer, made a presentation to the ICMA (International Cement Microscopy Association) in 2007[23] and gave a paper[24] in which he concludes "we are far from accepting even as a remote possibility of a “manmade” origin of pyramid stones."

Great Pyramid

Mainstream hypotheses

Some research suggests alternate estimates to the accepted workforce size. For instance, mathematician Kurt Mendelssohn calculated that the workforce may have been 50,000 men at most, while Ludwig Borchardt and Louis Croon placed the number at 36,000. According to Verner, a workforce of no more than 30,000 was needed in the Great Pyramid's construction. Regardless, as Egyptologist Dr. I.E.S. Edwards former Keeper of Antiquities in the British Museum suggests, "Cheops, who may have been a megalomaniac, could never, during a reign of about twenty-three years, have erected a building of the size and durability of the Great Pyramid, if technical advances had not enabled his masons to handle stones of very considerable weight and dimensions" [25]

A construction management study (testing) carried out by the firm Daniel, Mann, Johnson, & Mendenhall in association with Mark Lehner and other Egyptologists, estimates that the total project required an average workforce of 14,567 people and a peak workforce of 40,000. Without the use of pulleys, wheels, or iron tools, they used critical path analysis to suggest the Great Pyramid was completed from start to finish in approximately 10 years.[26] Their study estimates that the number of blocks used in construction was between 2-2.8 million (an average of 2.4 million), but settles on a reduced finished total of 2 million after subtracting the estimated area of the hollow spaces of the chambers and galleries.[26] Most sources agree on this number of blocks somewhere above 2.3 million.[27] Their calculations suggest the workforce could have sustained a rate of 180 blocks per hour (3 blocks/minute) with ten hour work days for putting each individual block in place. They derived these estimates from modern third-world construction projects that did not use modern machinery, but conclude it is still unknown exactly how the Great Pyramid was built.[26] As Dr. Craig Smith of the team points out:

- "The logistics of construction at the Giza site are staggering when you think that the ancient Egyptians had no pulleys, no wheels, and no iron tools. Yet, the dimensions of the pyramid are extremely accurate and the site was leveled within a fraction of an inch over the entire 13.1-acre base. This is comparable to the accuracy possible with modern construction methods and laser leveling. That's astounding. With their `rudimentary tools,' the pyramid builders of ancient Egypt were about as accurate as we are today with 20th century technology."[28]

The entire Giza Plateau is believed to have been constructed over the reign of five pharaohs in less than a hundred years. In the hundred years prior to Giza, beginning with Djoser who ruled from 2687-2667 BC, three other massive pyramids were built - the Step pyramid of Saqqara (believed to be the first Egyptian pyramid), the Bent Pyramid, and the Red Pyramid. Also during this period (between 2686 and 2498 BC) the Wadi Al-Garawi dam which used an estimated 100,000 cubic meters of rock and rubble was built.[29]

Traditionally, the evidence for dating the Great Pyramid by Egyptologists has been based primarily on fragmented summaries of early Christian writings gleaned from the work of the Hellenistic Period Egyptian priest Manethô who compiled the now lost Egyptian history Aegyptika. These Christian works, and to a lesser degree earlier Egyptian sources, mainly the Turin Canon and Table of Abydos among others, combine to form the main body of historical reference for Egyptologists giving a timeline by popular consensus of rulers known as the "King's List", found in the reference archive; the Cambridge Ancient History.[30][31][32] As a result, given Egyptologists have ascribed the pyramid to Khufu, establishing the time he reigned by default subsequently dates the monument as well as the confines for its completion of construction.

The Edgar Cayce Foundation, researching claims that the pyramids were at least 10,000 years old, funded the "David H. Koch Pyramids Radiocarbon Project" in 1984. The project took samples of organic material (such as ash and charcoal deposits) from several locations within the Great Pyramid, and other pyramids and monuments from the Old Kingdom period (ca. 3rd millennium BC). These samples were subjected to radiocarbon dating to produce calibrated date-equivalent estimates of their age. This yielded results averaging 374 years earlier than the estimated historical date accepted by Egyptologists (2589 – 2504 BC) but still more recent than 10,000 years ago.[33] Samples taken from the upper courses of the Great Pyramid gave upper dates of 3809 BC (± 160yrs), nearly 1400yrs before the time of Khufu, while the lower courses provided dates ranging from 3090-2723 B.C (± 100-400yrs) which correspond much more closely to the time Khufu is believed to have reigned [34]. In the absence of the "old wood" hypothesis, the study admits "The 1984 results left us with too little data to conclude that the historical chronology of the Old Kingdom was in error by nearly 400 years, but we considered this at least a possibility."[33]

A second dating in 1995 with new but similar material obtained dates ranging between 100-400 years, again earlier than those indicated by the historic record. This raised questions concerning the origin and date of the wood. Massive quantities of wood were used and burned, so to reconcile the earlier dates the authors of the study hypothesized that possibly "old wood" was used, assuming that wood was harvested from any source available, including old construction material from all over Egypt. It is also known, given the poor quality and relative scarcity of native Egyptian woods, that King Sneferu (and later Egyptian pharohs) imported fine woods from Lebanon and other countries such as Nubia for the creation of decorative furniture, royal boats (as found buried around the Giza Plateau), or other luxuries generally reserved for royalty. But as Mark Lehner points out such efforts were not without "great cost".[35] It is unknown, given the expense, effort, and value of such woods, if they were ever imported as an expendable source of industrial fuel, especially on such a large scale.

Project scientists based their conclusions on the evidence that some of the material in the 3rd Dynasty pyramid of Pharaoh Djoser and other monuments had been recycled, concluding that the construction of the pyramids marked a major depletion of Egypt's exploitable wood. Dating of more short-lived material around the pyramid (cloth, small fires, etc) yielded dates nearer to those indicated by historical records. [36]

A study by egyptologist Kate Spence shows how the changes in orientation of 8 pyramids corresponds with changes of position of those stars through time. This would date the start of the construction of the pyramid at 2467 BC.[37]

Alternative History Hypotheses

In common with many other monumental structures from antiquity, the Great Pyramid has over time been the subject of a great number of speculative or alternative hypotheses, which put forward a variety of explanations about its origins, dating, construction and purpose. A theme found in some of the alternative hypotheses put forward concerning the Giza pyramids and many other megalithic sites around the world, is the suggestion that these are not the products of the civilizations and cultures known to conventional history, but are instead the much older remnants of some hitherto unknown advanced ancient culture. This progenitor civilization is supposed to have been destroyed in antiquity by some devastating catastrophe brought about by the end of the last ice age, according to most of these accounts sometime around 10,000 BC. For the Great Pyramid of Giza in particular, it is maintained (depending on the author) that either it was ordained and built by this now-vanished civilization, or else that its construction was somehow influenced by knowledge (now lost) acquired from this civilization. The latter point of view is more common among recent authors such as Hancock and Bauval, who believe that the Great Pyramid incorporates star shafts 'locked in' to Orion's Belt and Sirius at around 2450 BC, though they argue the Giza ground-plan was laid out in 10,450 BC.[38]

The a priori existence of such a civilization is postulated by such authors who believe this is the only reasonable explanation for how advanced ancient cultures, such as Egypt and Sumer, were able to reach high levels of technological advancement with what they claim is little or no local precedent. This precedent they argue exists in the form of megalithic ruins found all over the globe that are claimed to be too complex to have been constructed by the cultures they are typically ascribed to. As one of these authors, John Anthony West writes in reference to Egypt: "How does a complex civilization spring full blown into being? Look at a 1905 automobile and compare it to a modern one. There is no mistaking the process of 'development'. But in Egypt there are no parallels. Everything is right there from the start."[39]

According to author Richard Noone in his book 5/5/2000, a Great Pyramid feasibility study relating to the quarrying of the stone was performed at his request in 1978 by Merle Booker, Technical Director of the Indiana Limestone Institute of America. Using modern equipment, Booker concludes: “Utilizing the entire Indiana Limestone industry’s facilities as they now stand [for 33 quarries], and figuring on tripling present average production, it would take approximately 27 years to quarry, fabricate and ship the total requirements.” Noone says Booker assumes sufficient quantities of railroad cars would be available without delay or downtime during this 27 year period and does not factor in the increasing costs of completing the work. The time of completion does not include preparing the site, actual construction, or any other logistical factor and is solely related to the time required to preform the work required for modern equipment to quarry, fabricate and ship the stone. Booker calculates the stone needed by deriving a total volume from the base and slope of the pyramid and estimates a total of 131,467,940 cubic feet of quarried, finished stone would be required to complete the job. [40]

References

- ^ ATSE - Parry

- ^ "Vitruvius's books of architecture"

- ^ David H. Koch Pyramids Radiocarbon Project

- ^ Godley, A. D. ed. (1920) Herodotus, The Histories. Harvard University Press. Book 2 Chapter 125.

- ^ Murphy, Edwin. (1990) The Antiquities of Egypt: A Translation with Notes of Book I of the Library of History of Diodorus Siculus. Transaction Publishers. ISBN 9780887383038

- ^ Lehner, Mark 1997. The Complete Pyramids. Thames and Hudson. New York.

- ^ Arnold, Dieter. 1991. Building in Egypt: Pharonic Stone Masonry. Oxford University Press. New York, New York.

- ^ Hawass, Zahi (2006). "Building a Pyramid". Retrieved 2007-03-17.

- ^ Isler, Martin “On Pyramid Building II.” in Journal of the American Research Center in Egypt. XXII: 95-112. 2001. Sticks, Stones, and Shadows: Building the Egyptian Pyramids. University of Oklahoma Press, Norman).

- ^ (2006) ThinkQuest. Cheops' Pyramid at Giza

- ^ a b Hussey-Pailos, R. Scott 2005. Construction of the Top of the Egyptian Pyramids [electronic resource] : An Experimental Test of a Levering Device. Gainesville, Fla.] : University of Florida http://uf.aleph.fcla.edu/F/9VEY29LTF5JVSKSVX145H96UC2U63V75K64S84QGRMMG8UMFA9-01302?func=full-set-set&set_number=012575&set_entry=000001&format=999 or http://www.scott.hussey.com/R_Hussey.PDF

- ^ Nova 1997. This Old Pyramid: Transcript. Electronic Document [1]

- ^ Hodges, Peter. (Julian Keable ed.) 1989. How the Pyramids Were Built. Dotesios Printers Ltd. Trowbridge, Wiltshire.

- ^ BBC NEWS | Middle East | Mystery of Great Pyramid 'solved'

- ^ 2600 B.C. Lean Manufacturing (Tech Trends Feature) - Cadalyst AEC

- ^ Farid Atiya Press, 2006. ISBN 9789771730613

- ^ (July 6, 2001)(2006) National Geographic. Researchers Lift Obelisk with kite to test hypothesis on ancient pyramids

- ^ French language wikipedia article describing his hypothesis

- ^ Ari-Kat technology, Science Applied to Archeology.

- ^ Harrell, James A. and Bret E. Penrod. 1993. "The Great Pyramid Debate -- Evidence from the Lauer Sample." Journal of Geological Education, vol. 41:358-363.

- ^ http://news.yahoo.com/s/livescience/20070522/sc_livescience/thesurprisingtruthbehindtheconstructionofthegreatpyramids

- ^ M. W. Barsoum, A. Ganguly, G. Hug (2006). Microstructural Evidence of Reconstituted Limestone Blocks in the Great Pyramids of Egypt. Journal of the American Ceramic Society 89 (12), 3788–3796. Blackwell Synergy - J American Ceramic Society

- ^ http://www.cmc-concrete.com/CMC%20Seminars/2007%20ICMA%20Pyramid.pdf The Egyptian Pyramid Enigma - large pdf file

- ^ http://www.cmc-concrete.com/CMC%20Publications/2007,%20The%20Great%20Pyramid%20Debate,%2029th%20ICMA.pdf The Great Pyramid Debate: Evidence from Detailed Petrographic Examinations of Casing Stones from the Great Pyramid of Khufu, a Natural Limestone from Tura, and a Man-Made (Geopolymeric) Limestone, Proceedings of the 29th Conference on Cement Microscopy, International Cement Microscopy Association, Quebec City, Canada, May 2007 - another large pdf file

- ^ pgs. 167-168, The Great Pyramids of Egypt, Dr. I.E.S. Edwards, 1975 Penguin books, New York ISBN 0-14-022549-8

- ^ a b c Civil Engineering magazine, June 1999 url=http://web.archive.org/web/20070608101037/http://www.pubs.asce.org/ceonline/0699feat.html

- ^ "Khufu's Inside Story". Nova online. PBS.org. 1997. Retrieved 2007-04-13.

{{cite web}}: Cite has empty unknown parameter:|coauthors=(help) - ^ "http://findarticles.com/p/articles/mi_m0EIN/is_1999_Feb_5/ai_53718895"

- ^ (September 16-22, 2004)(2006) Al Ahram. The World's Oldest Dam

- ^ "http://www.phouka.com/pharaoh/egypt/history/00kinglists.html"

- ^ "http://www.friesian.com/notes/oldking.htm"

- ^ "http://www.egyptologyonline.com/manetho.htm"

- ^ a b (September/October 1999) (2006) Archeology Dating the Pyramids Volume 52 Number 5 by members of the David H. Koch Pyramids Radiocarbon Project

- ^ Schoch, Robert M. (2003). Voyages of the Pyramid Builders. Penguin Books. pp. 14–18. ISBN 1585422037.

- ^ NOVA | Transcripts | This Old Pyramid | PBS

- ^ http://www.ipp.phys.ethz.ch/research/experiments/tandem/Annual/2001/06.pdf Bonani, Georges; Haas, Herbert; Hawass, Zahi; Lehner, Mark; Nakhla, Shawki; Nolan, John; Wenke, Robert; Wölfli, Willy, Radiocarbon Dates Of Old And Middle Kingdom Monuments In Egypt, Radiocarbon, Volume 43, Issue 3, Pages 1147-1430 (May 2001) , pp. 1297-1320(24)

- ^ (November 15, 2000) (2006) New Scientist. Pyramid precision

- ^ (2006) Graham Hancock. Like a Thief in the Night

- ^ (1979)(2006). Serpent in the Sky.

- ^ pgs. 104-105, 5/5/2000, Richard Noone, 1982 Three rivers Press, New York ISBN 0-609-80067-1

External links

- Pyramid construction using movable wooden ramps.

- How to Build a Pyramid, Archaeology Magazine, May/June 2007

- Jean-Pierre Houdin's hypothesis in Real-Time 3D

- Engineering the Pyramids - Materials Science and Engineering @ Drexel University

- http://www.cheops-pyramide.ch/pyramid-building.html

- http://www.prevos.net/pyramid/construction.htm

- http://www.haitheory.com

- Great Pyramid of Giza | Google Maps