Fuel cell

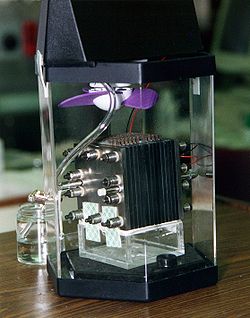

A fuel cell is an electrochemical energy conversion device similar to a battery, but differing from the latter in that it is designed for continuous replenishment of the reactants consumed; i.e. it produces electricity from an external supply of fuel and oxygen as opposed to the limited internal energy storage capacity of a battery. Additionally, the electrodes within a battery react and change as a battery is charged or discharged, whereas a fuel cell's electrodes are catalytic and relatively stable.

Typical reactants used in a fuel cell are hydrogen on the anode side and oxygen on the cathode side (a hydrogen cell). Usually, reactants flow in and reaction products flow out. Virtually continuous long-term operation is feasible as long as these flows are maintained.

Fuel cells are often considered to be very attractive in modern applications for their high efficiency and ideally emission-free use, in contrast to currently more common fuels such as methane or natural gas that generate carbon dioxide. The only by-product of a fuel cell operating on pure hydrogen is water vapor. There is concern, however, about the energy-consuming process of manufacturing the hydrogen. Manufacturing hydrogen requires a hydrogen carrier such as a fossil fuel or water. The former consumes the fossil resource and produces carbon dioxide, while electrolyzing water requires electricity, which is mostly generated at present using conventional fuels (fossil fuel or nuclear power). While alternative energy sources like wind and solar power could also be used, they are more expensive given current prices of fossil fuels and nuclear energy. In this regard, hydrogen fuel technology itself cannot be called truly independent of fossil fuel dependence, unless a totally nuclear option were considered.

Technology

Fuel cells are not constrained by the maximum Carnot cycle efficiency as combustion engines are because they do not operate with a thermal cycle. Consequently, they can have very high efficiencies in converting chemical energy to electrical energy.

In the archetypal example of a hydrogen/oxygen proton-exchange membrane (or "polymer electrolyte") fuel cell (PEMFC), a proton-conducting polymer membrane separates the anode and cathode sides. Each side has an electrode, typically carbon paper coated with platinum catalyst.

On the anode side, hydrogen diffuses to the anode catalyst where it dissociates into protons and electrons. The protons are conducted through the membrane to the cathode, but the electrons are forced to travel in an external circuit (supplying power) because the membrane is electrically insulating.

On the cathode catalyst, oxygen molecules react with the electrons (which have travelled through the external circuit) and protons to form water.

In this example, the only waste product is water vapor and/or liquid water.

Another issue is the CO tolerance of the anode which is limited.

Fuel cells cannot store energy like a battery, but in some applications, such as stand-alone power plants based on discontinuous sources (solar, wind power), they are combined with electrolyzers and storage systems to form an energy storage system. The round-trip efficiency (electricity to hydrogen and back to electricity) of such plants is between 30 and 40%.

In addition to pure hydrogen, researchers have used other, hydrogen-carrying fuels for fuel cells, including diesel, methanol and chemical hydrides.

Efficiency

A fuel cell typically converts the chemical energy of its fuel into electricity with an efficiency of about 50%. The efficiency is however very dependent on the current through the fuel cell: the more current drawn, the lower the efficiency. For a hydrogen cell the efficiency (actual power / theoretical power) is equal to cell voltage divided by 1.23 volts. A cell running at 0.6V has an efficiency of about 50%, meaning that 50% of the energy content of the hydrogen is converted into electrical energy.

It is also important to take losses due to production, transportation and storage into account. Fuel cell vehicles running on compressed hydrogen may have a power plant to wheel efficiency of 22% if the hydrogen is stored as high-pressure gas, and 17% if it is stored as liquid hydrogen (efficiency of Hydrogen Fuel Cell, Diesel-SOFC-Hybrid and Battery Electric Vehicles, Ulf Bossel, European Fuel Cell Forum).

In "combined heat and power" applications, a fuel cell is placed in a location where heat is also needed. A lower fuel-to-electricity conversion efficiency is tolerated (typically 15-20%), because most of the energy not converted into electricity is utilized as heat. Some heat is lost with the exhaust gas just as in a normal furnace, so the combined heat and power efficiency is still lower than 100%, typically around 80%. In terms of exergy however, the process is inefficient, and one could do better by maximizing the electricity generated and then using the electricity to drive a heat pump.

Economy

Currently, fuel cells are a very expensive alternative to internal combustion engines. It is common to hear that the main cost is the platinum catalyst, but currently the bipolar plates connecting one cell to the next are much more important in determining the cost. These need thorough machining and tedious labor to assemble, especially since most work is done by hand or with limited automation because of the small quantities sold. Optimists expect that demand will rise and mass production will become sustainable, causing prices to sink rapidly.

In 2002, typical cells had a catalyst content of USD 1000 per kW of electric power output, which is expected, by 2007, to be reduced to USD 30 per kW [1]. It is important to note, however, that the world reserves of platinum are insufficient (in fact, only one fourth) to support a mass conversion of all vehicles to fuel cells: a significant introduction of vehicles with present technology would therefore make the market value of platinum soar.

General Motors believes that fuel cell vehicles will be available at market prices around the end of this decade. Other companies are also working hard to make fuel cells a reality. Ballard Power Systems of Vancouver, a pioneer of the technology, have agreed to be a fuel cell supplier to many automobile companies, including Ford, Volvo, Mazda, General Motors, and Honda. Ballard's success right now has been at being able to lower the cost: they have developed a catalyst with 1/10 the amount of platinum than before.

History

The principle of the fuel cell was discovered by Swiss scientist Christian Friedrich Schönbein in 1838 and published in the January 1839 edition of the "Philosophical Magazine" [2]. Based on this work, the first fuel cell was developed by Welsh scientist Sir William Grove. A sketch was published in 1843,and he created the first fuel cell. The fuel cell he made used similar materials to today's Phosphoric-acid fuel cell. It wasn't until 1959 that British engineer Francis Thomas Bacon successfully developed a 5 kW stationary fuel cell. In 1959, a team led by Harry Ihrig built a 15 kW fuel cell tractor for Allis-Chalmers that was demonstrated across the US at state fairs. This system used potassium hydroxide as the electrolyte and compressed hydrogen and oxygen as the reactants. Later, in 1959, Bacon and his colleagues demonstrated a practical five-kilowatt unit capable of powering a welding machine, which led, in the 1960s to Bacon's patents being licensed by Pratt and Whitney from the U.S. where the concepts were used in the U.S. space program to supply electricity and drinking water (hydrogen and oxygen being readily available from the spacecraft tanks).

Parallel with Pratt & Whitney Aircraft, General Electric developed the first proton exchange membrane fuel cells (PEMFCs) for the Gemini space missions in the early 1960s. The first mission to utilize PEFCs was Gemini V. However, the Apollo space missions and subsequent Apollo-Soyuz, Skylab and Space Shuttle missions utilized fuel cells based on Bacon's design, developed by Pratt & Whitney Aircraft.

Extremely expensive materials were used and the fuel cells required very pure hydrogen and oxygen. Early fuel cells tended to require inconveniently high operating temperatures that were a problem in many applications. However, fuel cells were seen to be desirable due to the large amounts of fuel available (hydrogen & oxygen).

Despite their success in space programs, fuel cell systems were limited to space missions and other special applications, where high cost could be tolerated. It was not until the late 1980s and early 1990s that fuel cells became a real option for wider application base. Several pivotal innovations, e.g. low platinum catalyst loading and thin film electrodes drove the cost of fuel cells down, making development of PEMFC systems such as automobiles more or less realistic. (See Hydrogen car)

The fuel cell industry

United Technologies (UTX) was the first company to manufacture fuel cells. In the 1960s the company provided NASA with fuel cells to generate electricity for the Apollo missions. UTX's UTC Power subsidiary [3] was the first company to manufacture and commercialize a large, stationary fuel cell system for use as a co-generation power plant in hospitals, universities, and large office buildings. UTC Power continues to market this fuel cell as the PureCell 200 [4], a 200 kW system. UTC Power continues to be the sole supplier of fuel cells to NASA for use in space vehicles, having supplied the Apollo missions and currently the space shuttle, and is developing fuel cells for automobiles, buses, and cell phone towers. UTC Power claims to be "the global leader in the development and production of fuel cell technology" for both transportation and on-site power markets. In the automotive fuel cell market, UTC Power demonstrated the first fuel cell capable of starting under freezing conditions with its proton exchange membrane (PEM) automotive fuel cell. Note: UTC Power also uses the UTC Fuel Cells [5] name when referring to fuel cell products.

Ballard Power Systems is a major developer and manufacturer of the PEM fuel cells and claims to lead the world in automotive fuel cell technology. Ford Motor Company and DaimlerChrysler are major investors in Ballard. In 2003, most automobile companies were customers of Ballard, with only General Motors and Toyota pursuing internal development of fuel cells for automotive use which broke up in 2005; in 2004 Nissan and Honda started similar research programs. GM apparently now teams with DaimlerChrysler and BMW [6].

Perth in Western Australia is also participating in the trial with three fuel cell powered buses now operating between Perth and the port city of Fremantle. The trial is to be extended to other Australian cities over the next three years.

Plug Power Inc. is a major player in the design, development and manufacture of PEM fuel cells for stationary applications, including products aimed at telecommunication, prime power, and combined heat and power (CHP) applications.

In late 2004, Mechanical Technology Inc.'s subsidiary, MTI MicroFuel Cells debuted its first Direct Methanol Fuel Cell (DMFC)[7] for commercial use. MTI's Mobion™ cord-free rechargeable power pack technology consists of a fuel cell which runs on 100% (neat) Methanol. MTI's Mobion line is being released in industrial, consumer, and military markets as a low-cost replacement for lithium-ion batteries.

In 2006 Staxon [8]introduced an inexpensive OEM fuelcell module for system integration.

Advantages and disadvantages

Environmental effects

A common misconception among the public is that elemental hydrogen is a source of energy. This is not the case—hydrogen is not a primary source of energy: it is only an energy storage medium, and must be manufactured using energy from other sources.

The physical laws relating to the conservation of energy unfortunately create a situation where the energy needed to create the fuel in the first place may reduce the ultimate energy efficiency of the system to below that of the most efficient gasoline internal-combustion engines; this is especially true if the hydrogen has to be compressed to high pressures or liquified, as it does in automobile applications (the electrolysis of water is itself a rather inefficient process, usually requiring at least 50 % more electricity than the energy stored in the produced hydrogen). However, even the most efficient internal-combustion engines are not very efficient in absolute terms; furthermore, gasoline is not a primary energy source, because crude oil has to be treated in a refinery to obtain gasoline.

As an alternative to electrolysis, hydrogen can be generated from methane (the primary component of natural gas) with approximately 80% efficiency, or with other hydrocarbons to a varying degree of efficiency. The hydrocarbon-conversion method releases greenhouse gases, but, since the production is concentrated in one facility, and not distributed on every single vehicle or utility, it is possible to separate the gases and dispose of them properly, for example by injecting them in an oil or gas reservoir. A CO2 injection project has been started by Norwegian company Statoil in the North Sea, at the Sleipner field. [9]

Other types of fuel cells do not face these problems, however. For example, biological fuel cells take glucose and methanol from food scraps and convert it into hydrogen and food for the bacteria.

However, another environmental problem faced by all types of hydrogen fuel cells has been pointed out in a paper published in Science magazine by a group of Caltech scientists. They note that if hydrogen fuel cell usage becomes widespread enough to replace gasoline internal-combustion engines, small amounts of hydrogen leaking from storage containers and pipelines will have a detrimental impact on the Earth's ozone layer. However, their findings remain controversial, and their assumptions regarding the amount of hydrogen leaked have been disputed by industry officials.

Finally, roughly 50% of all electricity produced in the United States comes from coal. The problem is that coal is a relatively dirty energy source. If electrolysis (a process that uses electricity) is used to create hydrogen using energy from power plants, it is essentially creating hydrogen fuel from coal. Though the fuel cell itself will only emit heat and water as waste, the problem of pollution is still present at power plants.

Fuel cell design issues

To make fuel cells economically competitive, there are many practical problems to be overcome as well. Water management remains a key problem in Proton Exchange Membrane Fuel Cells or (PEMFCs) where the membrane must be hydrated, requiring water to be evaporated at precisely the same rate that it is produced. If water is evaporated too quickly, the membrane dries, resistance across it increases, and eventually it will crack, creating a gas "short circuit" where hydrogen and oxygen combine directly, generating heat that will damage the fuel cell. If the water is evaporated too slowly, the electrodes will flood, preventing the reactants from reaching the catalyst and stopping the reaction. Methods to dispose of the excess water are being developed by fuel cell companies.

At the same time many other variables must be juggled, including temperature throughout the cell (which changes and can sometimes destroy a cell through thermal loading), reactant and product levels at various cells. Materials must be chosen to do various tasks which none fill completely. Durability and lifetime of the cells can be serious issues for some cells, low power densities for others. Putting all of these factors together hasn't been accomplished decisively yet, and remains the challenge.

In vehicle usage, many problems are amplified. For instance, cars must be required to start in any weather conditions a person can reasonably expect to encounter: about 80% of the world's cars are legally subject to the requirement of being able to start from sub-zero temperatures. Fuel cells have no difficulty operating in the hottest locations, but the coldest do present a problem. Honda's FCX was the first fuel cell powered vehicle to do so, but temperatures below -20 degrees Celsius still prohibit the fuel cell stack from starting.

Fuel cell applications

Fuel cells are very useful as power sources in remote locations, such as spacecraft, remote weather stations, large parks, rural locations, and in certain military applications. A fuel cell system running on hydrogen can be compact, lightweight and has no major moving parts.

A near-term application is combined heat and power (CHP) for office buildings and factories. This type of system generates constant electric power (selling excess power back to the grid when it is not consumed), and at the same time produce hot air and water from the waste heat. Phosphoric-acid fuel cells (PAFC) comprise the largest segment of existing CHP products worldwide and can provide combined efficiencies close to 80% (45-50% electric + remainder as thermal). The largest manufacturer of PAFC fuel cells is UTC Power, a division of United Technologies Corporation. Molten-carbonate fuel cells have also been installed in these applications, and Solid-oxide fuel cell prototypes exist.

Because fuel cells have a high cost per kilowatt, and because their efficiency decreases with increasing power density, they are usually not considered for applications with high load variations. In particular, they are not suited for energy storage systems in small and medium scale. An electrolyzer and fuel cell would return less than 50 percent of the input energy (this is known as round-trip efficiency), while a much cheaper lead-acid battery might return about 90 percent.

However, since electrolyzer systems do not store fuel in themselves, but rather rely on external storage units, they can be successfully applied in large-scale energy storage, rural areas being one example. In this application, batteries would have to be largely oversized to meet the storage demand, but fuel cells only need a larger storage unit (typically cheaper than an electrochemical device).

The use of fuel cells for cogeneration of electricity and hot water in households is a potential long-term application, with various pilot programs launched in 2005 across the industry.

One such pilot program exists on Stuart Island off the State of Washington. There the Stuart Island Energy Initiative has built a complete system by which solar panels generate the currrent to run several electrolyzers whose hydrogen is stored in a 500 gallon tank at 150-200 PSI. The hydrogen is then used to run a 48V ReliOn hydrogen fuel cell that provides full electric back-up to the residential site on this off the grid island (see external link to SIEI.ORG).

Hydrogen vehicles and refuelling

The first hydrogen refueling station was opened in Reykjavík, Iceland on April 2003. This station serves three buses built by DaimlerChrysler that are in service in the public transport net of Reykjavík. The station produces the hydrogen it needs by itself, with an electrolyzing unit (produced by Norsk Hydro), and does not need refilling: all that enters is electricity and water. Shell is also a partner in the project. The station has no roof, in order to allow any leaked hydrogen to escape to the atmosphere.

There are numerous prototype or production cars and buses based on fuel cell technology being researched or manufactured. Research is ongoing at companies like BMW, Hyundai, and Nissan, among many others. However, a practical commercial automobile is not expected until at least 2010 according to the industry. There are, however, fuel cell-powered buses currently active or in production, such as a fleet of Thor buses with UTC Power fuel cells in California, operated by SunLine Transit Agency [10].

Currently, a team of college students called Energy-Quest is planning to take a hydrogen fuel cell powered boat around the world (as well as other projects using efficient or renewable fuels). Their venture is called the Triton.

Sodium borohydride (NaBH4) is a chemical compound that may hold future promise due to the ease with which hydrogen can be stored under normal atmospheric pressures in automobiles that have fuel cells.

Suggested applications

- Base load power plants

- Mobile phone power

- Electric vehicles

- Auxiliary power

- Off-grid power supply

- Portable electronics

See also

Types of fuel cells

- Alkaline fuel cell

- Biological fuel cell

- Direct borohydride fuel cell

- Direct-methanol fuel cell

- Formic acid fuel cell

- Molten-carbonate fuel cell

- Phosphoric-acid fuel cell

- Proton-exchange fuel cell

- Protonic Ceramic Fuel Cell

- Reversible fuel cell

- Solid-oxide fuel cell

- Redox fuel cell

- Zinc fuel cell ('Air' fuel cell)

Related technologies

References

External links

- Fuel cell (animation)

- US DOE EERE (Energy Efficiency and Renewable Energy) fuel cells page

- PhysicsWorld: Fuel cells

- How Hydrogen Can Save America (Wired Magazine)

- Fuel cell basics

- How Stuff Works: Fuel Cells

- Fuel-Cells.org, The Online Fuel Cell Information Resource

- Ballard Power Systems

- Plug Power Inc.

- Stuart Island Energy Initiative