Intelligent Diesel Engine

MAN B&W diesel and New Sulzer diesel are developing “Smart” camshaftless engines utilizing electronically controlled fuel injection and exhaust valve actuation Systems.[1] Research and development has advanced so that smart low-speed diesel engines are being installed in new ships.[2]

Intelligent System

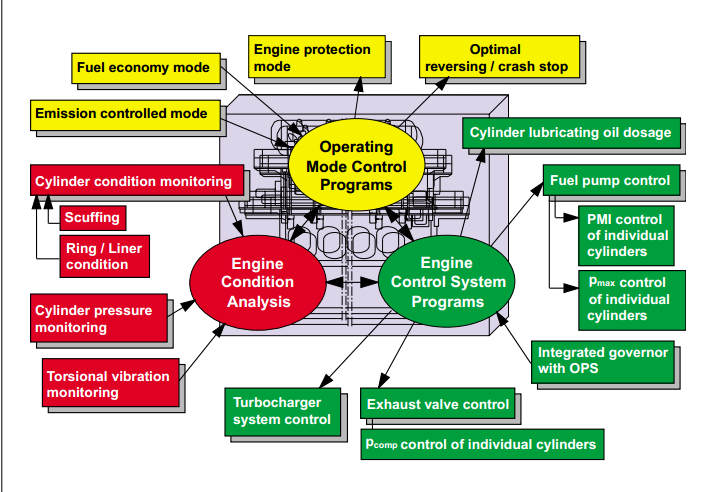

The concept of the intelligent engine revolves around the idea that the engine is thinking for itself. The brain of the system is a electronic control system that analyzes the condition of the engine and the operation of the engine’s system( The fuel injection, exhaust valve, cylinder lube oil and turbo charging system). Along with the control and timing needed to make the diesel run smoothly, the intelligent diesel goes beyond that by monitoring and evaluating the condition of the engine, based on engine conditions the smart system can actively protect the engine from damage due to overload, lack of maintenance and maladjustment. The intelligent engines’ finite control gives the bridge the ability to manually adjust more variables than the current camshaft system. Along with manual controls, operators can specifically design programs that optimize fuel economy, emission, turbo output, allowing for high performance under different loads.[3]

Replacing the Camshaft

The convenience of the camshaft is that not only does it keep the timing of the opening and closing valves and injecting fuel through its cams. It is also responsible for the mechanical force that is required to actually open and close the valves and power the port and helix fuel pump. The camshaftless intelligent system uses the rotation of the engine to power a axial piston pump that pressurizes a hydraulic oil system. The potential energy from the hydraulic pressure is directed by the electronically controlled servo system to drive InFI (Intelligent Fuel Injection), and InVA (Intelligent Valve Actuation) system.

Improving the Marine Diesel Engine

The Intelligent, Camshaftless, diesel engines offer several potential improvements for marine diesel main engines. Variable electronically-controlled timing of fuel injection and exhaust valves for lower specific fuel consumption and better performance parameters.[4] The electronic controls also offer lower RPM for maneuvering, including better astern and crash stop performance. With the smarter InFI system the ship operator can more precisely control fuel consumption and improve emission characteristics. The highly integrated monitoring system allows for the potential of longer time between overhauls by equalizing the thermal load between cylinders.[5]

The Smart Diesel in Service

The Bow Cecil chemical tanker was one of the first ships built with a Intelligent main propulsion engine. The success of the MAN diesel 7S50ME-c engine in Bow Cecil, proved to the industry that intelligent diesel is a viable option.

References

- ^ woodyard, doug (2004). Pounder's marine diesel engines and gas turbines. burlington, MA: elsevier ltd.

- ^ "The Intelligent Engine: Development Status and Prospects" (PDF). Retrieved 18 April 2012.

- ^ Ayub, Akber (2010). Marine Diesel Engines. New Dehli: Ane pvt.

- ^ "Odfjell opts for electronically controlled engine after Bow Cecil success". Retrieved 18 April 2012.

- ^ "Intelligent Engines – The New Generation Machines". Retrieved 18 April 2012.