Haber process

The Haber process, also called the Haber–Bosch process, is the industrial implementation of the reaction of nitrogen gas and hydrogen gas. It is the main industrial procedure to produce ammonia:[1]

- N2 + 3 H2 → 2 NH3 (ΔH = −92.4 kJ·mol−1)

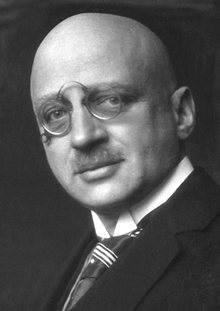

Nitrogen is a strong limiting nutrient in plant growth. Carbon and oxygen are also critical, but are easily obtained by plants from soil and air. Even though air is 78% nitrogen, atmospheric nitrogen is nutritionally unavailable because nitrogen molecules are held together by strong triple bonds. Nitrogen must be 'fixed', i.e. converted into some bioavailable form, through natural or man-made processes. It was not until the early 20th century that Fritz Haber developed the first practical process to convert atmospheric nitrogen to ammonia, which is nutritionally available. Prior to the discovery of the Haber process, ammonia had been difficult to produce on an industrial scale.[2][3][4][5] Nitrogen fixation was already being done on an industrial scale using the Birkeland–Eyde process, but this is very energy-inefficient.

Fertilizer generated from ammonia produced by the Haber process is estimated to be responsible for sustaining one-third of the Earth's population.[6] It is estimated that half of the protein within human beings is made of nitrogen that was originally fixed by this process; the remainder was produced by nitrogen fixing bacteria and archaea.[7]

History

Early in the twentieth century, several chemists tried to make ammonia from atmospheric nitrogen. German chemist Fritz Haber discovered a process that is still used today.[8]

Robert Le Rossignol was instrumental in the development of the high-pressure devices used in the Haber process.[9] They demonstrated their process in the summer of 1909 by producing ammonia from air drop by drop, at the rate of about 125 ml (4 US fl oz) per hour. The process was purchased by the German chemical company BASF, which assigned Carl Bosch the task of scaling up Haber's tabletop machine to industrial-level production.[3][10] He succeeded in this process in 1910. Haber and Bosch were later awarded Nobel prizes, in 1918 and 1931 respectively, for their work in overcoming the chemical and engineering problems posed by the use of large-scale, continuous-flow, high-pressure technology.

Ammonia was first manufactured using the Haber process on an industrial scale in 1913 in BASF's Oppau plant in Germany, production reaching 20 tonnes/day the following year.[11] During World War I, the synthetic ammonia was used for the production of nitric acid, a precursor to munitions. The Allies had access to large amounts of sodium nitrate deposits in Chile (so called "Chile saltpetre") that belonged almost totally to British industries. As Germany lacked access to such readily available natural resources, the Haber process proved important to the German war effort.[12]

The process

This conversion is typically conducted at 15–25 MPa (2,200–3,600 psi) or 150–250 bar and between 300–550 °C (572–1,022 °F), as the gases are passed over four beds of catalyst, with cooling between each pass so as to maintain a reasonable equilibrium constant. On each pass only about 15% conversion occurs, but any unreacted gases are recycled, and eventually an overall conversion of 97% is achieved.[1]

The steam reforming, shift conversion, carbon dioxide removal, and methanation steps each operate at absolute pressures of about 2.5–3.5 MPa (360–510 psi) or 25–35 bar, and the ammonia synthesis loop operates at absolute pressures ranging from[clarification needed] 6–18 MPa (870–2,610 psi) or 60–180 bar, depending upon which proprietary process design is used.[1]

Sources of hydrogen

The major source is methane from natural gas. The conversion, steam reforming, is conducted with air, which is deoxygenated by the combustion of natural gas. Originally Bosch obtained hydrogen by the electrolysis of water.

Reaction rate and equilibrium

Nitrogen (N2) is very unreactive because the molecules are held together by strong triple bonds. The Haber process relies on catalysts that accelerate the scission of this triple bond.

Two opposing considerations are relevant to this synthesis: the position of the equilibrium and the rate of reaction. At room temperature, the equilibrium is strongly in favor of ammonia, but the reaction doesn't proceed at a detectable rate. The obvious solution is to raise the temperature, but because the reaction is exothermic, the equilibrium constant (using atm units) becomes 1 around 150° or 200 °C. (See Le Chatelier's principle.)

| Temperature (°C) | Kp |

|---|---|

| 300 | 4.34 x 10−3 |

| 400 | 1.64 x 10−4 |

| 450 | 4.51 x 10−5 |

| 500 | 1.45 x 10−5 |

| 550 | 5.38 x 10−6 |

| 600 | 2.25 x 10−6 |

Above this temperature, the equilibrium quickly becomes quite unfavourable at atmospheric pressure, according to the Van 't Hoff equation. Thus one might suppose that a low temperature is to be used and some other means to increase rate. However, the catalyst itself requires a temperature of at least 400 °C to be efficient.

Pressure is the obvious choice to favour the forward reaction because there are 4 moles of reactant for every 2 moles of product (see entropy), and the pressure used (around 200 atm) alters the equilibrium concentrations to give a profitable yield.[citation needed]

Economically, though, pressure is an expensive commodity. Pipes and reaction vessels need to be strengthened, valves more rigorous, and there are safety considerations of working at 200 atm. In addition, running pumps and compressors takes considerable energy. Thus the compromise used gives a single pass yield of around 15%.[citation needed]

Another way to increase the yield of the reaction would be to remove the product (i.e. ammonia gas) from the system. In practice, gaseous ammonia is not removed from the reactor itself, since the temperature is too high; but it is removed from the equilibrium mixture of gases leaving the reaction vessel. The hot gases are cooled enough, whilst maintaining a high pressure, for the ammonia to condense and be removed as liquid. Unreacted hydrogen and nitrogen gases are then returned to the reaction vessel to undergo further reaction.[citation needed]

Catalysts

The most popular catalysts are based on iron promoted with K2O, CaO, SiO2, and Al2O3. The original Haber–Bosch reaction chambers used osmium as the catalyst. Haber noted uranium was superior but harder to obtain. Under Bosch's direction in 1909, the BASF researcher Alwin Mittasch discovered a much less expensive iron-based catalyst, which is still used today. Some ammonia production utilizes ruthenium-based catalysts (the KAAP process). Ruthenium forms more active catalysts that allows milder operating pressures. Such catalysts are prepared by decomposition of triruthenium dodecacarbonyl on graphite.[1]

In industrial practice, the iron catalyst is obtained from finely ground iron powder, which in turn is usually obtained by reduction of high purity magnetite (Fe3O4). The pulverized iron metal is burnt (oxidized) to give magnetite of a defined particle size. The magnetite particles are then partially reduced, removing some of the oxygen in the process. The resulting catalyst particles consist of a core of magnetite, encased in a shell of wüstite (FeO), which in turn is surrounded by an outer shell of iron metal. The catalyst maintains most of its bulk volume during the reduction, resulting in a highly porous high surface area material, which enhances its effectiveness as a catalyst. Other minor components of the catalyst include calcium and aluminium oxides, which support the iron catalyst and help it maintain its surface area. These oxides of Ca, Al, K, and Si are immune to reduction by the hydrogen.[1]

The reaction mechanism, involving the heterogeneous catalyst, is believed to involve the following steps:[citation needed]

- N2 (g) → N2 (absorbed)

- N2 (absorbed) → 2 N (absorbed)

- H2(g) → H2 (absorbed)

- H2 (absorbed) → 2 H (absorbed)

- N (absorbed) + 3 H(absorbed)→ NH3 (absorbed)

- NH3 (absorbed) → NH3 (g)

Reaction 5 occurs in three steps, forming NH, NH2, and then NH3. Experimental evidence points to reaction 2 as being the slow, rate-determining step. This is not unexpected since the bond broken, the nitrogen triple bond, is the strongest of the bonds that must be broken.

A major contributor to the elucidation of this mechanism is Gerhard Ertl.[14]

Economic and environmental aspects

The Haber process now produces 500 million short tons (454 million tonnes) of nitrogen fertilizer per year, mostly in the form of anhydrous ammonia, ammonium nitrate, and urea. 3–5% of the world's natural gas production is consumed in the Haber process (~1–2% of the world's annual energy supply).[15][16][17][18] In combination with pesticides, these fertilizers have quadrupled the productivity of agricultural land:

- With average crop yields remaining at the 1900 level the crop harvest in the year 2000 would have required nearly four times more land and the cultivated area would have claimed nearly half of all ice-free continents, rather than under 15% of the total land area that is required today.[19]

Due to its dramatic impact on the human ability to grow food, the Haber process served as the "detonator of the population explosion", enabling the global population to increase from 1.6 billion in 1900 to today's 7 billion.[20] According to Howarth (2008), nearly 80% of the nitrogen found in human tissues originated from the Haber-Bosch process.[21] Since nitrogen use efficiency is typically less than 50%,[22] our heavy use of industrial nitrogen fixation is severely disruptive to our biological habitat.[2][21]

See also

References

- ^ a b c d e Max Appl "Ammonia" in Ullmann's Encyclopedia of Industrial Chemistry 2006 Wiley-VCH, Weinheim. doi:10.1002/14356007.a02_143.pub2

- ^ a b Smil, Vaclav (2004). Enriching the Earth: Fritz Haber, Carl Bosch, and the Transformation of World Food Production. Cambridge, MA: MIT Press. ISBN 9780262693134.

- ^ a b Hager, Thomas (2008). The Alchemy of Air. Harmony Books, New York. ISBN 978-0-307-35178-4.

- ^ Fertilizer Industry: Processes, Pollution Control and Energy Conservation by Marshall Sittig (1979) Noyes Data Corp., N.J. ISBN 0-8155-0734-8

- ^ "Heterogeneous Catalysts: A study Guide"

- ^ Wolfe, David W. (2001). Tales from the underground a natural history of subterranean life. Cambridge, Mass: Perseus Pub. ISBN 0-7382-0128-6. OCLC 46984480.

- ^ BBC: Discovery - Can Chemistry Save The World? - 2. Fixing the Nitrogen Fix

- ^ "Feed The World" (PDF). http://www.tcetoday.com. March 2010.

{{cite web}}: External link in|publisher= - ^ "Robert Le Rossignol, 1884–1976: Professional Chemist" (PDF), ChemUCL Newsletter, UCL Department of Chemistry: 8, 2009

- ^ US Pat 990191

- ^ Philip & Phyllis Morris, From Fertile Minds (review) American Scientist 2001

- ^ "Nobel Award to Haber". New York Times. 3 February 1920. Retrieved 11 October 2010.

- ^ Brown, Theodore L., LeMay,Jr., H. Eugene, Bursten, Bruce E. "Chemistry: The Central Science". Tenth Ed., Upper Saddle River, NJ: Pearson, 2006. Table 15.2. ISBN 0-13-109686-9

- ^ F. Bozso, G. Ertl, M. Grunze and M. Weiss (1977). "Interaction of nitrogen with iron surfaces: I. Fe(100) and Fe(111)". Journal of Catalysis. 49 (1): 18–41. doi:10.1016/0021-9517(77)90237-8.

{{cite journal}}: CS1 maint: multiple names: authors list (link). R. Imbihl, R. J. Behm, G. Ertl and W. Moritz (1982). "The structure of atomic nitrogen adsorbed on Fe(100)". Surface Science. 123 (1): 129–140. Bibcode:1982SurSc.123..129I. doi:10.1016/0039-6028(82)90135-2.{{cite journal}}: CS1 maint: multiple names: authors list (link). G. Ertl, S. B. Lee and M. Weiss (1982). "Kinetics of nitrogen adsorption on Fe(111)". Surface Science. 114 (2–3): 515–526. Bibcode:1982SurSc.114..515E. doi:10.1016/0039-6028(82)90702-6.. G. Ertl (1983). "Primary steps in catalytic synthesis of ammonia". Journal of Vacuum Science and Technology A. 1 (2): 1247–1253. doi:10.1116/1.572299. - ^ Smil, Vaclav (2004). Enriching the Earth: Fritz Haber, Carl Bosch, and the Transformation of World Food Production. Cambridge, MA: MIT Press. ISBN 9780262693134.

- ^ "International Energy Outlook 2007".

- ^ Fertilizer statistics. "?".

- ^ Smith, Barry E. (September 2002). "Structure. Nitrogenase reveals its inner secrets". Science. 297 (5587): 1654–5. doi:10.1126/science.1076659. PMID 12215632.

- ^ Smil, Vaclav (2011). Nitrogen cycle and world food production. World Agriculture 2:9-1.

- ^ Smil, Vaclav (1999). Detonator of the population explosion. Nature 400:415.

- ^ a b Howarth, R. W. (2008). Coastal nitrogen pollution: a review of sources and trends globally and regionally. Harmful Algae 8, 14–20.

- ^ Oenema, O., Witzke, H.P., Klimont, Z., Lesschen, J.P. and Velthof, G.L. (2009). Integrated assessment of promising measures to decrease nitrogen losses in agriculture in EU-27. Agriculture, Ecosystems and Environment 133, 280-288.

- "The Haber Process". Chemguide.co.uk.

External links

- Haber-Bosch process, most important invention of the 20th century, according to V. Smil, Nature, July 29, 1999, p 415 (by Jürgen Schmidhuber)

- Britannica guide to Nobel Prizes: Fritz Haber

- Nobel e-Museum - Biography of Fritz Haber

- BASF - Fertilizer out of thin air

- Uses and Production of Ammonia

- Haber Process for Ammonia Synthesis