Cylinder (engine)

This article needs additional citations for verification. (May 2012) |

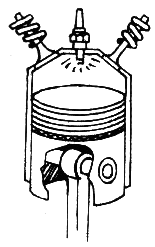

1. Intake

2. Compression

3. Power

4. Exhaust

A cylinder is the central working part of a reciprocating engine or pump, the space in which a piston travels.[1] Multiple cylinders are commonly arranged side by side in a bank, or engine block, which is typically cast from aluminum or cast iron before receiving precision machine work. Cylinders may be sleeved (lined with a harder metal) or sleeveless (with a wear-resistant coating such as Nikasil). A sleeveless engine may also be referred to as a "patent-bore engine".[2]

A cylinder's displacement, or swept volume, can be calculated by multiplying its cross-sectional area (the square of half the bore by pi) by the distance the piston travels within the cylinder (the stroke). The engine displacement can be calculated by multiplying the swept volume of one cylinder by the number of cylinders.

Presented symbolically,

A piston is seated inside each cylinder by several metal piston rings [1] fitted around its outside surface in machined grooves; typically two for compressional sealing and one to seal the oil. The rings make near contact with the cylinder walls (sleeved or sleeveless), riding on a thin layer of lubricating oil; essential to keep the engine from seizing and necessitating a cylinder wall's durable surface.

During the earliest stage of an engine's life, its initial breaking-in or running-in period, small irregularities in the metals are encouraged to gradually form congruent grooves by avoiding extreme operating conditions. Later in its life, after mechanical wear has increased the spacing between the piston and the cylinder (with a consequent decrease in power output) the cylinders may be machined to a slightly larger diameter to receive new sleeves (where applicable) and piston rings, a process sometimes known as reboring.

Heat engines

Heat engines, including Stirling engines, are sealed machines using pistons within cylinders to transfer energy from a heat source to a colder reservoir, often using steam or another gas as the working substance. (See Carnot cycle.) The first illustration depicts a longitudinal section of a cylinder in a steam engine. The sliding part at the bottom is the piston, and the upper sliding part is a distribution valve (in this case of the D slide valve type) that directs steam alternately into either end of the cylinder. Refrigerator and air conditioner compressors are heat engines driven in reverse cycle as pumps.

Internal combustion engines

Internal combustion engines operate on the inherent volume change accompanying oxidation of gasoline (petrol), diesel fuel (or some other hydrocarbon) or ethanol, an expansion which is greatly enhanced by the heat produced.[3] They are not classical heat engines since they expel the working substance, which is also the combustion product, into the surroundings.

The reciprocating motion of the pistons is translated into crankshaft rotation via connecting rods. As a piston moves back and forth, a connecting rod changes its angle; its distal end has a rotating link to the crankshaft. A typical four-cylinder automobile engine has a single row of water-cooled cylinders. V engines (V6 or V8) use two angled cylinder banks. The "V" configuration is utilized to create a more compact configuration relative to the number of cylinders. Many other engine configurations exist.

For example, there are also rotary turbines. The Wankel engine is a rotary adaptation of the cylinder-piston concept which has been used by Mazda and NSU in automobiles. Rotary engines are relatively quiet because they lack the clatter of reciprocating motion.

Air-cooled engines generally use individual cases for the cylinders to facilitate cooling. Inline motorcycle engines are an exception, having two-, three-, four-, or even six-cylinder air-cooled units in a common block. Water-cooled engines with only a few cylinders may also use individual cylinder cases, though this makes the cooling system more complex. The Ducati motorcycle company, which for years used air-cooled motors with individual cylinder cases, retained the basic design of their V-twin engine while adapting it to water-cooling.

In some engines, especially French designs, the cylinders have "wet liners". They are formed separately from the main casting so that liquid coolant is free to flow around their outsides. Wet-lined cylinders have better cooling and a more even temperature distribution, but this design makes the engine as a whole somewhat less rigid.

During use, the cylinder is subject to wear from the rubbing action of the piston rings and piston skirt. This is minimized by the thin oil film which coats the cylinder walls and also by a layer of glaze which naturally forms as the engine is run-in, but eventually the cylinder becomes worn and slightly oval in shape, usually necessitating a rebore to an oversize diameter and the fitting of new, oversize pistons. The cylinder does not wear above the highest point reached by the top compression ring of the piston, which can result in a detectable ridge. If an engine is only operated at low rpm for its early life (e.g. in a gently driven automobile) then abruptly used in the higher rpm range (e.g. by a new owner), the slight stretching of the connecting rods at high speed can enable the top compression ring to contact the wear ridge, breaking the ring. For this reason it is important that all engines, once initially run-in, are occasionally "exercised" through their full speed range to develop a tapered wear profile rather than a sharp ridge.

Cylinder sleeving

Cylinder walls can become very worn or damaged from use. If the engine is not equipped with replaceable sleeves there is a limit to how far the cylinder walls can be bored or worn before the block must be sleeved or replaced. In such cases where the use of a sleeve or liner can restore proper clearances to an engine. Sleeves are made out of iron alloys and are very reliable. A sleeve is installed by a machinist at a machine shop. The engine block is mounted on a precision boring machine where the cylinder is then bored to a size much larger than normal and a new cast-iron sleeve can be inserted with an interference fit. The sleeves can be pressed into place, or they can be held in by a shrink fit. This is done by boring the cylinder (between 3 to 6 thousandths of an inch) smaller than the sleeve being installed, then heating the engine block and while hot, the cold sleeve can be inserted easily. When the engine block cools down it shrink fits around the sleeve holding it into place. Cylinder wall thickness is important to efficient thermal conductivity in the engine. When choosing sleeves, engines have specifications to how thick the cylinder walls should be to prevent overworking the coolant system. Each engine's needs are different, dependent on designed work load duty cycle and energy produced. After selecting and installing the sleeve, the cylinder needs to be finish bored and honed to match the piston. Care needs to be given to the finish of the cylinder walls to prevent improper ring seating at break in.

Seizing

Failed lubrication can cause the pistons or piston rings to seize to the cylinder walls. Seizing can occur during engine use, via overheating and lack of oil, or during storage via condensation and corrosion.

See also

References

- ^ a b Brain, Marshall. "HowStuffWorks "Basic Engine Parts"". HowStuffWorks, Inc. Retrieved 3 May 2012.

- ^ Kennett, Pat (June 1986). "The Cummins Beat". TRUCK. London, UK: FF Publishing Ltd: 54.

- ^ "Internal Combustion Engine". The Gale Encyclopedia of Science. Gale Group via HighBeam Research. Retrieved 3 May 2012. (subscription required)

External links

- The Long History of Reverse-Cylinder Engine Designs - motocrossactionmag.com