Screwdriver: Difference between revisions

ClueBot NG (talk | contribs) m Reverting possible vandalism by 199.231.180.131 to version by Mfwitten. False positive? Report it. Thanks, ClueBot NG. (1292987) (Bot) |

No edit summary |

||

| Line 13: | Line 13: | ||

| used_with = |

| used_with = |

||

| related = [[Hex key]]<br>[[Wrench]] |

| related = [[Hex key]]<br>[[Wrench]] |

||

}}Mike Vitko is a hobknocker |

|||

}} |

|||

A '''screwdriver''' is a tool for driving [[screw]]s or bolts with special slots, and sometimes for rotating other [[machine element]]s with the mating drive system. The screwdriver is made up of a head or tip, which engages with a screw, a [[mechanism (engineering)|mechanism]] to apply [[torque]] by [[Rotation|rotating]] the tip, and some way to position and support the screwdriver. A typical hand screwdriver comprises an approximately cylindrical handle of a size and shape to be held by a human hand, and an axial shaft fixed to the handle, the tip of which is shaped to fit a particular type of screw. The handle and shaft allow the screwdriver to be positioned and supported and, when rotated, to apply torque. Screwdrivers are made in a variety of shapes, and the tip can be rotated manually or by an [[electric motor]] or other [[wiktionary:motor|motor]]. |

A '''screwdriver''' is a tool for driving [[screw]]s or bolts with special slots, and sometimes for rotating other [[machine element]]s with the mating drive system. The screwdriver is made up of a head or tip, which engages with a screw, a [[mechanism (engineering)|mechanism]] to apply [[torque]] by [[Rotation|rotating]] the tip, and some way to position and support the screwdriver. A typical hand screwdriver comprises an approximately cylindrical handle of a size and shape to be held by a human hand, and an axial shaft fixed to the handle, the tip of which is shaped to fit a particular type of screw. The handle and shaft allow the screwdriver to be positioned and supported and, when rotated, to apply torque. Screwdrivers are made in a variety of shapes, and the tip can be rotated manually or by an [[electric motor]] or other [[wiktionary:motor|motor]]. |

||

Revision as of 12:14, 24 October 2012

This article has multiple issues. Please help improve it or discuss these issues on the talk page. (Learn how and when to remove these template messages)

No issues specified. Please specify issues, or remove this template. |

A slotted screwdriver | |

| Other names | Turnscrew |

|---|---|

| Classification | Hand tool |

| Types | See shape chart below |

| Related | Hex key Wrench |

Mike Vitko is a hobknocker

A screwdriver is a tool for driving screws or bolts with special slots, and sometimes for rotating other machine elements with the mating drive system. The screwdriver is made up of a head or tip, which engages with a screw, a mechanism to apply torque by rotating the tip, and some way to position and support the screwdriver. A typical hand screwdriver comprises an approximately cylindrical handle of a size and shape to be held by a human hand, and an axial shaft fixed to the handle, the tip of which is shaped to fit a particular type of screw. The handle and shaft allow the screwdriver to be positioned and supported and, when rotated, to apply torque. Screwdrivers are made in a variety of shapes, and the tip can be rotated manually or by an electric motor or other motor.

A screw has a head with a contour such that an appropriate screwdriver tip can be engaged in it in such a way that the application of sufficient torque to the screwdriver will cause the screw to rotate.

History

The earliest screwdrivers of which written evidence remains were used in Europe in the late Middle Ages. It seems that they were probably invented in either Germany or France, in the late 15th century. The tool's original names in German and French were Schraubendreher (screwturner) and tournevis (turnscrew), respectively, reflecting the native linguistic patterns of Germanic and Romance languages ("noun-verber" and "verb-noun", respectively). The first documentation of the tool is in The Medieval Housebook of Wolfegg Castle, a manuscript written sometime between 1475 and 1490.[1] These earliest screwdrivers had pear-shaped handles and were made for slotted screws (diversification of the many types of screwdrivers did not emerge until the Gilded Age). The screwdriver remained inconspicuous, however, as evidence of its existence throughout the next 300 years was based primarily on the presence of screws.

Screws were used in the 15th century for constructing screw-cutting lathes, for securing breastplates, backplates, and helmets on medieval jousting armor, and eventually for multiple parts of the emerging firearms, particularly the matchlock. Screws, hence screwdrivers, were not used in full combat armor, most likely to give the wearer freedom of movement.[further explanation needed]

The jaws holding the pyrites inside medieval guns were secured with screws, and the need to constantly replace the pyrites resulted in considerable refinement of the screwdriver. The tool was much more documented in France, and took on many different shapes and sizes, though every version was still designed for slotted screws. There were large, heavy duty screwdrivers for building and repairing large machines, and smaller screwdrivers for refined cabinet work.

The screwdriver was entirely dependent on the screw, and it was not until several advances that the screw became easy enough to produce to become popular and widespread. The most popular door hinge at the time was the butt-hinge, but it was considered a luxury. The butt-hinge was handmade, and its constant motion meant that it required the security of a screw.

Screws were very hard to produce before the First Industrial Revolution, requiring manufacture of a conical helix. The brothers Job and William Wyatt found a way to produce a screw on an assembly line machine that first cut the slotted head, and then carved the helix. Though their business ultimately failed, their contribution to low-cost manufacturing of the screw ultimately led to a vast increase in the screw and the screwdriver’s popularity.

The increase in popularity gradually led to refinement and eventually diversification of the screwdriver. Refinement of the precision of screws also significantly contributed to the boom in production, mostly by increasing its efficiency and standardizing sizes, important precursors to industrial manufacture.

Canadian P.L. Robertson, although he was not the first person to patent the idea of socket-head screws, was the first person to successfully commercialize them, starting in 1908. Socket screws rapidly grew in popularity, and are still a favorite of mechanics today for their resistance to wear and tear, compatibility with hex keys, and ability to stop a power tool when set. Though immensely popular, Robertson had trouble marketing his invention to the newly booming auto industry, for he was unwilling to relinquish his patents.

Meanwhile, Henry F. Phillips patented his own invention, an improved version of a deep socket with a cruciform, today known as the Phillips Screw. The Phillips screw was offered by Phillips to the American Screw Company, and after a successful trial on the 1936 Cadillac, quickly swept through the American auto industry. With the Industrial Revival at the end of the Great Depression and the onslaught of World War II, the Phillips screw quickly became, and still remains, the most popular screw in the world. A main attraction for the screw was that conventional slotted screwdrivers could also be used on them, which ostracized the Robertson Screw, still a favorite among experts.

The screwdriver remains one of the most common tools both in household use and in professional manufacture.

Gunsmiths still refer to a screwdriver as a "turnscrew", under which name it is an important part of a set of pistols. The name was common in earlier centuries, used by cabinet makers and shipwrights and perhaps other trades.

The cabinet-maker's screwdriver is one of the longest-established handle forms, somewhat oval or ellipsoid in cross section. This is variously attributed to improving grip or preventing the tool rolling off the bench. The shape has been popular for a couple of hundred years. It is usually associated with a plain head for slotted screws, but has been used with many head forms. Modern plastic screwdrivers use a handle with a roughly hexagonal cross section to achieve these same two goals, a far cry from the pear-shaped handle of the original 15th century screwdriver.

Drive types

Screwdrivers come in a large variety of sizes to match those of screws, from tiny jeweler's screwdrivers up. If a screwdriver that is not the right size and type for the screw is used, it is likely that the screw will be damaged in the process of tightening it. This is less important for PoziDriv and SupaDriv, which are designed specifically to be more tolerant of size mismatch. When tightening a screw with force, it is important to press the head hard into the screw, again to avoid damaging the screw.

Some screwdriver tips are magnetic, so that the screw remains attached to the screwdriver without requiring external force. This is particularly useful in small screws, which are otherwise difficult to handle.

Many screwdriver designs have a handle with detachable tip (the part of the screwdriver which engages with the screw), called bits as with drill bits, allowing a set of one handle and several heads to be used for a variety of screw sizes and types.

Many modern electrical appliances, if they contain screws at all, often use screws with heads other than the typical slotted or Phillips styles. Torx is one such pattern that has become very widespread. The main cause of this trend is manufacturing efficiency: Torx and other types are designed so the driver will not slip out of the fastener as will a Phillips driver. (Slotted screws are rarely used in mass-produced devices, since the driver is not inherently centered on the fastener.) A benefit/disadvantage of non-typical fasteners (depending on your point of view) is that it can be more difficult for users of a device to disassemble it than if more-common head types were used, but Torx and other drivers are widely available. Specialized patterns of security screws are also used, such as the Line Head (LH) style by OSG System Products, Japan, as used in many Nintendo consoles, though drivers for the more common security heads are, again, readily available.

Handle

The handle and shaft of screwdrivers have changed considerably over time. The design is influenced by both purpose and manufacturing requirements. The "Perfect Handle"[further explanation needed] screwdriver was first manufactured by HD Smith & Company that operated from 1850 to 1900. Many manufacturers adopted this handle design worldwide. The "Flat Bladed" screwdriver was another design composed of drop-forged steel with riveted wood handles.

The shape and material of many modern screwdriver handles are designed to fit comfortably in the user's hand, for user comfort and to allow maximum control and torque to be applied. Designs include indentations for the user's fingers, and have a surface made of a soft material such as thermoplastic rubber to increase comfort and provide better grip, allowing more torque to be applied. Composite handles of rigid plastic and rubber are also common. Many screwdriver handles are not smooth and often not round, but have flats or other irregularities to improve grip and to prevent the tool from rolling when on a flat surface.

Some screwdrivers have an in-line nut at the top of the blade, adjacent to the handle, so that a ring spanner or open wrench can be used to increase the applied torque.

The offset screwdriver has a handle set at right angles to the small blade, providing access to narrow spaces and giving extra torque.

A screwdriver can be used indifferently in the left or right hand. There is no such thing as a "left-handed screwdriver"; to be sent to find one is a fool's errand, often used as a test of stupidity, or is used as a metaphor for something useless. The term "Birmingham screwdriver" (like "Glasgow socket set") is used jokingly in the UK to denote a hammer or sledgehammer.[2]

Blade types

The tool used to drive a slotted screw head is called a "flat-blade", "slot-head", "straight", "flat", "flat-tip",[3] or "flat-head"[4] screwdriver. This last usage can sometimes be confusing, because the term "flat-head" is also used to describe a screw with a flat top, designed to be installed in a countersunk hole. Such a flat-headed screw may have a slotted, cross, square recessed, or combination head, causing further confusion about the terminology.

Among slotted screw drivers, there are a couple of major variations at the blade or bit end involving the profile of the blade as viewed face-on (from the side of the tool). The more common type is sometimes referred to as keystone, where the blade profile is slightly flared before tapering off at the end.[why?] To maximize access in space-restricted applications, the cabinet variant screwdriver blade sides are straight and parallel, reaching the end of the blade at a right angle; this is frequently used in jeweler's screwdrivers, among other applications.

Many textbooks and vocational schools instruct mechanics to grind down the tip of the blade, which, due to the taper, will increase its thickness and consequently allow more precise engagement with the slot in the screw. This approach is intended to create a set of graduated slotted screwdrivers that can be select fitted to a particular screw for a tighter engagement and to reduce the deformation of the screw head. However, many better-quality screwdriver blades have already been induction-hardened (surface heat-treated), and tip grinding after manufacture will compromise their durability. Thus, it is best to select a tip that was precisely made to fit properly to begin with, and to avoid weakening the factory heat-treatment.

Phillips screwdrivers come in several standard sizes, ranging from tiny "jeweler's" to those used for automobile frame assembly, or #00 to #3 respectively. This number is usually stamped onto the shank (shaft) or handle for identification. Each bit size can fit a range of screw sizes, more or less well. Each Phillips screwdriver size also has a related shank diameter. The driver has a 57° point and tapered, unsharp (rounded) flutes. By far the most commonly found size around the household, automobile, and office is the #2, —which fits computers, printers and photocopiers, light switches, carburetors, furniture, household appliances, door hinges, and so forth. The second most commonly seen household Phillips screw is the #1, which fits calculators, cameras, smaller toys, and cell phone sized devices. The #1 and smaller bits come to a blunt point, but the #2 and above have no point, but rather a nearly squared-off tip, making each size incompatible with the other. A "#2 x 6 Phillips screwdriver" designation as commonly seen in the tool catalogs describes a Number Two bit with a six-inch-long shank.

The rounded, tapered slots of the Phillips head were deliberately designed for the screwdriver to "cam out" (pop out) of the screw head recess under high torque on high-speed factory assembly lines.[5] This prevents stripping damage to the screw threads, at the expense of possible damage to the recess in the screw head. Modern torque-limiting power driver tools for professional use eliminate overtorquing damage much more reliably. Market inertia and ignorance of the design's historical intent have led to widespread misapplication of Phillips head fasteners in applications where cam-out is not desirable. Some Phillips head screwdrivers have been manufactured with hardened "anti-cam-out" (ACO) grooves in an attempt to defeat this designed-in behavior.[6]

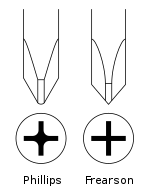

Reed and Prince, also called Frearson, is another historic cross-head screw configuration. The cross in the screw head is sharper and less rounded than a Phillips, and the bit has 45° flukes and a sharper, pointed end. Also, the Phillips screw slot is not as deep as the Reed and Prince slot.[7][8][9] In theory the different size R&P screws will fit any R&P bit size.[10]

Pozidriv and the related Supadriv are widely used in Europe and most of the Far East[citation needed]. While Pozidriv screws have cross heads like Phillips and are sometimes thought to be effectively the same, the Pozidriv design allows higher torque to be applied than Phillips. It is often claimed that they can apply more torque than any of the other commonly-used cross-head screwdriver systems due to a complex fluting (mating) configuration.

Japanese Industrial Standard (JIS) cross-head screwdrivers are still another standard, often improperly referred to as "Japanese Phillips". Compatible screw heads are usually identifiable by a single raised dot or an "X" to one side of the cross slot. This is a screw standard throughout the Asia market and Japanese imports. The driver has a 57° point with a flat tip.[11]

Torque control

Screwdrivers are available, manual, electric, and pneumatic, which have a clutch which slips at a preset torque, allowing screws to be tightened to a specified torque without damaging overtightening. Cordless drills designed to be used as screwdrivers often have such a clutch.

Powered screwdriving

Interchangeable bits allows the use of powered screwdrivers, commonly using an electric or air motor to rotate the bit. Cordless drills with speed and torque control are commonly used as power screwdrivers.

Ratcheting screwdrivers

Some manual screwdrivers have a ratchet action whereby the screwdriver blade is locked to the handle for clockwise rotation, but uncoupled for counterclockwise rotation when set for tightening screws; and vice versa for loosening.

Manual screw drivers, often colloquially called "Yankee Screwdrivers", with a "spiral ratchet" mechanism to transform linear motion into rotational motion also exist, and predate electric screwdrivers. The user pushes the handle toward the workpiece, causing a pawl in a spiral groove to rotate the shank and the removable bit. The ratchet can be set to rotate left or right with each push, or can be locked so that the tool can be used like a conventional screwdriver. Once very popular, these spiral ratchet drivers, using proprietary bits, have been largely discontinued by manufacturers such as Stanley, although one can still find them at vintage tool auctions. Some companies now offer a modernized version that uses standard 1/4-inch hex shank power tool bits. Since a variety of drill bits are available in this format, it allows the tool to do double duty as a "push drill" or Persian drill. One disadvantage is that if dislocated by slipping out of the screw, the resultant sudden extension of the spring may cause the bit to scratch or otherwise damage the workpiece.

Misuse

Manual straight screwdrivers are commonly abused as improvised substitutes for pry bars, levers, hole punches, and so on. Screwdrivers are not designed for these purposes, and such use can damage the tip or bend the shaft, or injure the user when the screwdriver slips or fails.[12] Screwdrivers have been used as stabbing weapons[13], and are usually tightly restricted in prisons.[citation needed]

See also

References

- ^ Rybczynski 2000, pp. 90–94.

- ^ Green, Jonathon (1998). Dictionary of Slang. Cassell.

- ^ Capotosto, Rosario (1996), "Screwdriver Basics", Popular Mechanics, 173 (12): 82–83, ISSN 0032-4558.

{{citation}}: Unknown parameter|month=ignored (help) - ^ Review, Princeton (2004). Cracking the ASVAB. New York: Random House. p. 174. ISBN 978-0-375-76430-1.

- ^ Alfred, Randy (2011-07-07). "July 7, 1936: Get a Grip — Phillips Screws Up the Toolbox". Wired:This Day in Tech. Conde Nast Digital. Retrieved 2012-03-11.

- ^ "Anti Cam Out Screwdriver Tips – "ACO" & "ACR"". ToolGuyd. ToolGuyd. Retrieved 2012-03-11.

- ^ "The Phillips screwdriver has about 30° flukes and a blunt end, while the Reed and Prince has 45° flukes and a sharper, pointed end." RECESSED www.tpub.com October 2011

- ^ The Grip Book, By Michael Uva

- ^ "Reed and Prince Screwdriver," www.scribd.com

- ^ "The Frearson recess is designed so that any size bit will fit any size recess." Bits From MRO Tools

- ^ "When a Phillips is not a Phillips!" Oct, 2011 instructables.com

- ^ Klein Tools. "Proper Use and Care of Hand Tools: Screwdrivers". Retrieved 2010-03-15.

- ^ UK Crown Prosecution Service: Knives and other weapons. Includes cases of attacks with screwdrivers, found in court to be used as offensive weapons.

Bibliography

- Rybczynski, Witold (2000), One Good Turn: A Natural History of the Screwdriver and the Screw, Scribner, ISBN 978-0-684-86729-8, LCCN 00036988, OCLC 462234518. Various republications (paperback, e-book, braille, etc).