Spider silk: Difference between revisions

Chris G Bot (talk | contribs) File:Wikipedia_Kevlar_Silk_Comparison.jpg may be deleted |

m Journal cites:, added 1 PMID,added 2 Bibcodes, templated 2 journal cites (Diberri fmt authors), added 1 issue number, using AWB (7751) |

||

| Line 11: | Line 11: | ||

==Biodiversity== |

==Biodiversity== |

||

===Uses=== |

===Uses=== |

||

All spiders produce silks and a single spider can produce up to seven different types of silk for different uses<ref name="Foelix 96">{{cite book|last=Foelix, R. F. |title= Biology of spiders |year= 1996 |publisher= Oxford University Press |location= Oxford, N.Y |isbn= |pages= 330 |url= |editor= Series Editor |volume= }}</ref> |

All spiders produce silks and a single spider can produce up to seven different types of silk for different uses.<ref name="Foelix 96">{{cite book|last=Foelix, R. F. |title= Biology of spiders |year= 1996 |publisher= Oxford University Press |location= Oxford, N.Y |isbn= |pages= 330 |url= |editor= Series Editor |volume= }}</ref> This is in contrast to insect silks, where most often only one type of silk is produced by an individual.<ref>{{cite journal |author= Sutherland, T., Young, J. & Weisman, S. |year= 2009 |title= Insect Silk: One Name, Many Materials |journal= Ann. Rev. Entomol. |volume= 55 |pages= 171–188 |doi= 10.1146/annurev-ento-112408-085401}}</ref> Over the 400 million years of evolution, spider silks may be used for a number of different ecological uses, each with properties to match the function of the silk (see [[Spider silk#Properties|Properties]] section). The evolution of spiders has led to more complex and diverse uses of silk throughout its evolution, for example from primitive tube webs 300-400mya to complex orb webs 110mya.<ref name="Hillyard 07">{{cite book|last= Hillyard, P. |title= The Private Life of Spiders |year= 2007 |publisher= New Holland |location= London |isbn= 9781845376901 |pages= 160 |url= |editor= Series Editor |volume= }}</ref> |

||

{| class="wikitable" |

{| class="wikitable" |

||

| Line 21: | Line 21: | ||

| Prey capture |

| Prey capture |

||

| The orb webs produced by the Araneidae (typical orb-weavers); tube webs; tangle webs; sheet webs; lace webs, dome webs; single thread used by the Bolas spiders for ‘fishing’ |

| The orb webs produced by the Araneidae (typical orb-weavers); tube webs; tangle webs; sheet webs; lace webs, dome webs; single thread used by the Bolas spiders for ‘fishing’ |

||

| <ref name=" |

| <ref name="Foelix 96"/><ref name="Hillyard 07"/> |

||

|- |

|- |

||

| Prey immobilization |

| Prey immobilization |

||

| Line 29: | Line 29: | ||

| Reproduction |

| Reproduction |

||

| Male spiders may produce sperm webs; spider eggs are covered in silk cocoons |

| Male spiders may produce sperm webs; spider eggs are covered in silk cocoons |

||

| ⚫ | |||

| ⚫ | |||

|- |

|- |

||

| Dispersal |

| Dispersal |

||

| Line 74: | Line 73: | ||

| Used to form bonds between separate threads for attachment points |

| Used to form bonds between separate threads for attachment points |

||

|} |

|} |

||

| ⚫ | |||

| ⚫ | |||

===Mechanical Properties=== |

===Mechanical Properties=== |

||

Each spider and each type of silk has a set of mechanical properties optimised for their biological function. |

Each spider and each type of silk has a set of mechanical properties optimised for their biological function. |

||

| Line 83: | Line 82: | ||

A frequent mistake made in the mainstream media is to confuse strength and toughness when comparing silk to other materials. As you will see below in detail, weight for weight, silk is stronger than steel, but not as strong as Kevlar. Silk is however tougher than both. |

A frequent mistake made in the mainstream media is to confuse strength and toughness when comparing silk to other materials. As you will see below in detail, weight for weight, silk is stronger than steel, but not as strong as Kevlar. Silk is however tougher than both. |

||

[[File:Wikipedia Kevlar Silk Comparison.jpg|right|thumb|280px| An illustration of the differences between toughness stiffness and strength {{deletable image-caption}}]] |

[[File:Wikipedia Kevlar Silk Comparison.jpg|right|thumb|280px| An illustration of the differences between toughness stiffness and strength {{deletable image-caption}}]] |

||

====Strength==== |

====Strength==== |

||

In detail a dragline silks’ [[tensile strength]] is comparable to that of high-grade [[steel]] (1500 MPa)<ref>{{cite web |url=http://www.springerlink.com/content/t3rk2161k177866k/ |title=SpringerLink - |publisher=www.springerlink.com |accessdate=2010-08-18 }}</ref><ref>{{cite web |url=http://www.matweb.com/search/DataSheet.aspx?MatGUID=210fcd12132049d0a3e0cabe7d091eef&ckck=1 |title=Overview of materials for AISI 4000 Series Steel |publisher=www.matweb.com |accessdate=2010-08-18 }}</ref> |

In detail a dragline silks’ [[tensile strength]] is comparable to that of high-grade [[steel]] (1500 MPa),<ref>{{cite web |url=http://www.springerlink.com/content/t3rk2161k177866k/ |title=SpringerLink - |publisher=www.springerlink.com |accessdate=2010-08-18 }}</ref><ref>{{cite web |url=http://www.matweb.com/search/DataSheet.aspx?MatGUID=210fcd12132049d0a3e0cabe7d091eef&ckck=1 |title=Overview of materials for AISI 4000 Series Steel |publisher=www.matweb.com |accessdate=2010-08-18 }}</ref> and about half as strong as [[aramid]] filaments, such as [[Twaron]] or [[Kevlar]] (3000 MPa).<ref>{{cite web |url=http://www.matweb.com/search/DataSheet.aspx?MatGUID=77b5205f0dcc43bb8cbe6fee7d36cbb5 |title=DuPont Kevlar 49 Aramid Fiber |publisher=www.matweb.com |accessdate=2010-08-18 }}</ref> |

||

====Density==== |

====Density==== |

||

Consisting of mainly protein silks are about a fifth of the density of steel (1.31 g/cm^3). As a result, a strand long enough to circle the Earth would weigh less than {{convert|500|g}}<ref>Spider dragline silk has a tensile strength of roughly 1.3 [[Pascal (unit)|GPa]]. The tensile strength listed for steel might be slightly higher – e.g. 1.65 GPa. [http://www.webcitation.org/query?url=http://www.geocities.com/pganio/materials.html&date=2009-10-26+00:31:25 ]{{cite journal |author= Shao, Z. Vollrath, F. |date=August 15, 2002 |title=Materials: Surprising strength of silkworm silk |journal=[[Nature (journal)|Nature]] |volume=418|pages=741–741 |doi=10.1038/418741a |pmid= 12181556 |issue= 6899}}, but spider silk is a much less dense material, so that a given weight of spider silk is five times as strong as the same weight of steel</ref> |

Consisting of mainly protein silks are about a fifth of the density of steel (1.31 g/cm^3). As a result, a strand long enough to circle the Earth would weigh less than {{convert|500|g}}.<ref>Spider dragline silk has a tensile strength of roughly 1.3 [[Pascal (unit)|GPa]]. The tensile strength listed for steel might be slightly higher – e.g. 1.65 GPa. [http://www.webcitation.org/query?url=http://www.geocities.com/pganio/materials.html&date=2009-10-26+00:31:25 ]{{cite journal |author= Shao, Z. Vollrath, F. |date=August 15, 2002 |title=Materials: Surprising strength of silkworm silk |journal=[[Nature (journal)|Nature]] |volume=418|pages=741–741 |doi=10.1038/418741a |pmid= 12181556 |issue= 6899}}, but spider silk is a much less dense material, so that a given weight of spider silk is five times as strong as the same weight of steel</ref> |

||

====Extensibility==== |

====Extensibility==== |

||

Silks are also especially [[ductile]], with some able to stretch up to four times their relaxed length without breaking. |

Silks are also especially [[ductile]], with some able to stretch up to four times their relaxed length without breaking. |

||

====Toughness==== |

====Toughness==== |

||

The combination of strength and ductility gives dragline silks a very high [[toughness]] (or work to fracture), which "equals that of commercial [[polyaramid]] ([[aromatic nylon]]) filaments, which themselves are benchmarks of modern polymer fibre technology"<ref name="Vollrath 01">{{cite journal |author= Vollrath, F. Knight, D.P. |year= 2001 |title=Liquid crystalline spinning of spider silk |journal=[[Nature (journal)|Nature]] |volume=410|pages=541–548 |doi=10.1038/35069000 |pmid= 11279484 |issue= 6828}}</ref><ref>{{cite web |url=http://www.chm.bris.ac.uk/motm/spider/page2.htm |title=Spider Silk |publisher=www.chm.bris.ac.uk |accessdate=2010-08-18 }}</ref> |

The combination of strength and ductility gives dragline silks a very high [[toughness]] (or work to fracture), which "equals that of commercial [[polyaramid]] ([[aromatic nylon]]) filaments, which themselves are benchmarks of modern polymer fibre technology".<ref name="Vollrath 01">{{cite journal |author= Vollrath, F. Knight, D.P. |year= 2001 |title=Liquid crystalline spinning of spider silk |journal=[[Nature (journal)|Nature]] |volume=410|pages=541–548 |doi=10.1038/35069000 |pmid= 11279484 |issue= 6828 |bibcode=2001Natur.410..541V}}</ref><ref>{{cite web |url=http://www.chm.bris.ac.uk/motm/spider/page2.htm |title=Spider Silk |publisher=www.chm.bris.ac.uk |accessdate=2010-08-18 }}</ref> |

||

====Temperature==== |

====Temperature==== |

||

Whilst unlikely to be relevant in nature, dragline silks can hold their strength below −40 °C and up to 220 °C<ref>{{cite journal |author= Yang, Y. |year= 2005 |title= Toughness of spider silk at high and low temperatures |journal= Advanced Materials |volume= 17 |pages= 84–+ |doi= 10.1002/adma.200400344 |display-authors= 1 |last2= Chen |first2= X. |last3= Shao |first3= Z. |last4= Zhou |first4= P. |last5= Porter |first5= D. |last6= Knight |first6= D. P. |last7= Vollrath |first7= F.}}</ref> |

Whilst unlikely to be relevant in nature, dragline silks can hold their strength below −40 °C and up to 220 °C.<ref>{{cite journal |author= Yang, Y. |year= 2005 |title= Toughness of spider silk at high and low temperatures |journal= Advanced Materials |volume= 17 |pages= 84–+ |doi= 10.1002/adma.200400344 |display-authors= 1 |last2= Chen |first2= X. |last3= Shao |first3= Z. |last4= Zhou |first4= P. |last5= Porter |first5= D. |last6= Knight |first6= D. P. |last7= Vollrath |first7= F.}}</ref> |

||

====Supercontraction==== |

====Supercontraction==== |

||

When exposed to water, dragline silks undergo supercontraction, shrinking up to 50% in length and behaving like a weak rubber under tension. Many hypothesis have been suggested as to its use in nature, with the most popular being to automatically tension webs built in the night using the morning dew. |

When exposed to water, dragline silks undergo supercontraction, shrinking up to 50% in length and behaving like a weak rubber under tension. Many hypothesis have been suggested as to its use in nature, with the most popular being to automatically tension webs built in the night using the morning dew. |

||

====Highest Performance==== |

====Highest Performance==== |

||

The strongest known spider silk is produced by the species [[Darwin's bark spider]] (''Caerostris darwini''): "The toughness of forcibly silked fibers averages 350 [[MJ/m3]], with some samples reaching 520 MJ/m3. Thus, ''C. darwini'' silk is more than twice as tough as any previously described silk, and over 10 times tougher than Kevlar"<ref name="Agnarsson 10">Agnarsson I, Kuntner M, Blackledge TA |

The strongest known spider silk is produced by the species [[Darwin's bark spider]] (''Caerostris darwini''): "The toughness of forcibly silked fibers averages 350 [[MJ/m3]], with some samples reaching 520 MJ/m3. Thus, ''C. darwini'' silk is more than twice as tough as any previously described silk, and over 10 times tougher than Kevlar".<ref name="Agnarsson 10">{{cite journal | author = Agnarsson I, Kuntner M, Blackledge TA | year = 2010 | title = Bioprospecting Finds the Toughest Biological Material: Extraordinary Silk from a Giant Riverine Orb Spider | url = | journal = PLoS ONE | volume = 5 | issue = 9| page = e11234 | doi = 10.1371/journal.pone.0011234 }}</ref> |

||

===Types of silk=== |

===Types of silk=== |

||

Many species of spider have different [[spinneret (spider)|glands]] to produce silk with different properties for different purposes, including housing, [[spider web|web]] construction, defense, capturing and detaining [[prey]], egg protection, and mobility (gossamer for ballooning, strands to let the spider drop down on as they are extruded). Different specialized silks have evolved with properties suitable for different uses. For example, ''[[Argiope argentata]]'' has five different types of silk, each used for a different purpose:<ref>Cunningham |

Many species of spider have different [[spinneret (spider)|glands]] to produce silk with different properties for different purposes, including housing, [[spider web|web]] construction, defense, capturing and detaining [[prey]], egg protection, and mobility (gossamer for ballooning, strands to let the spider drop down on as they are extruded). Different specialized silks have evolved with properties suitable for different uses. For example, ''[[Argiope argentata]]'' has five different types of silk, each used for a different purpose:<ref>{{cite journal | author = Cunningham A | year = 2007 | title = Taken for a Spin | url = | journal = Science News | volume = 171 | issue = | pages = 231–33 }}</ref><ref>Blackledge, T.A., and Hayashi, C.Y. (2006). Silken toolkits: Biomechanics of silk fibers spun by the orb web spider Argiope argentata. ''Journal of Experimental Biology'' 2009(July 1), pp. 2452–61 ([http://www.sciencenews.org/articles/20070414/bob8.asp references])</ref> |

||

{| class="wikitable" |

{| class="wikitable" |

||

| Line 135: | Line 140: | ||

==Structural== |

==Structural== |

||

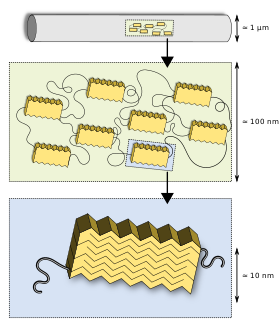

====Macroscopic structure down to protein hierarchy==== |

====Macroscopic structure down to protein hierarchy==== |

||

Silks, as well as many other biomaterials, have a hierarchical structure [e.g. [[cellulose]], [[hair]]]. The [[primary structure]] is its [[amino acid]] sequence, mainly consisting of highly repetitive glycine and alanine blocks<ref name="Hinman 92">{{cite journal |author= Hinman, M. B. & Lewis, R. V. |year= 1992 |title= Isolation of a clone encoding a second dragline silk fibroin. Nephila clavipes dragline silk is a two-protein fiber |journal= J. Biol. Chem. |volume= 267 |pages= |

Silks, as well as many other biomaterials, have a hierarchical structure [e.g. [[cellulose]], [[hair]]]. The [[primary structure]] is its [[amino acid]] sequence, mainly consisting of highly repetitive glycine and alanine blocks,<ref name="Hinman 92">{{cite journal |author= Hinman, M. B. & Lewis, R. V. |year= 1992 |title= Isolation of a clone encoding a second dragline silk fibroin. Nephila clavipes dragline silk is a two-protein fiber |journal= J. Biol. Chem. |volume= 267 |pages= 19320–19324 |doi= }}</ref><ref name="Simmons 96">{{cite journal |author= Simmons, A. H., Michal, C. A. & Jelinski, L. W. |year= 1996 |title= Molecular orientation and two-component nature of the crystalline fraction of spider dragline silk |journal= Science |volume= 271 |pages= 84–87 |doi= }}</ref> why silks are often referred to as a block co-polymer. On a secondary structure level, the short side chained alanine is mainly found in the crystalline domains (beta sheets) of the nano fibril, glycine, having larger side groups, is mostly found in the so called amorphous matrix consisting of helical and beta turn structures.<ref name="Simmons 96"/><ref name="van Beek 02">{{cite journal |author= van Beek, J. D., Hess, S., Vollrath, F. & Meier, B. H. |year= 2002 |title= The molecular structure of spider dragline silk: Folding and orientation of the protein backbone |journal= Proc. Natl. Acad. Sci. U. S. A. |volume= 99 |pages= 10266–10271 |doi= 10.1073/pnas.152162299}}</ref> |

||

This first very basic model of silk was introduced by Termonia in 1994<ref name="Termonia 94">{{cite journal |author= Termonia, Y. |year= 1994 |title= Molecular Modeling of Spider Silk Elasticity |journal= Macromolecules |volume= 27 |pages= |

This first very basic model of silk was introduced by Termonia in 1994<ref name="Termonia 94">{{cite journal |author= Termonia, Y. |year= 1994 |title= Molecular Modeling of Spider Silk Elasticity |journal= Macromolecules |volume= 27 |pages= 7378–7381 |doi= }}</ref> suggested crystallites embedded in an amorphous matrix interlinked with hydrogen bonds. This model has refined over the years: Semi crystalline regions were found<ref name="Simmons 96"/> as well as a fibrillar skin core model suggested for spider silk,<ref>{{cite journal |author= Vollrath, F., Holtet, T., Thogersen, H. C. & Frische, S. |year= 1996 |title= Structural organization of spider silk |journal= Proc. R. Soc. Lond. Ser. B-Biol. Sci. |volume= 263 |pages= 147–151 |doi= }}</ref> later visualized by [[Atomic Force Microscopy|AFM]] and [[Transmission Electron Microscopy|TEM]].<ref>{{cite journal |author= Sponner, A. et al. |year= 2007 |title= Composition and hierarchical organization of a spider silk |journal= Plos One |volume= |pages= e998 |doi= }}</ref> Sizes of the nano fibrillar structure and the crystalline and semi-crystalline regions were revealed by [[Neutron Scattering]].<ref>{{cite journal |author= Sapede, D. et al. |year= 2005 |title= Nanofibrillar structure and molecular mobility in spider dragline silk |journal= European Biophysics Journal |volume= 34 |pages= 623 |doi= }}</ref> |

||

====Non-protein composition==== |

====Non-protein composition==== |

||

Various compounds other then protein are found in spider silks, such as sugars, lipids, ions and pigments which might affect the aggregation behaviour and act as a protection layer in the final fibre<ref name="Vollrath 01"/> |

Various compounds other then protein are found in spider silks, such as sugars, lipids, ions and pigments which might affect the aggregation behaviour and act as a protection layer in the final fibre.<ref name="Vollrath 01"/> |

||

==Biosynthesis== |

==Biosynthesis== |

||

| Line 147: | Line 153: | ||

The unspun silk dope is pulled through silk [[glands]], of which there may be both numerous duplicates and also different types on any one spider species. |

The unspun silk dope is pulled through silk [[glands]], of which there may be both numerous duplicates and also different types on any one spider species. |

||

===Silk gland=== |

===Silk gland=== |

||

The gland's visible, or external, part is termed the [[spinneret]]. Depending on the complexity of the species, spiders will have two to eight sets of spinnerets, usually in pairs. There exist highly different specialised glands in different spiders, ranging from simply a sac with an opening at one end, to the complex, multiple-section Major Ampullate glands of the Nephila golden orb weaving spiders<ref>{{cite journal |author= Dicko, C., Porter, D., Bond, J., Kenney, J. M. & Vollratht, F. |year= 2008 |title= Structural disorder in silk proteins reveals the emergence of elastomericity |journal= Biomacromolecules |volume= 9 |pages= |

The gland's visible, or external, part is termed the [[spinneret]]. Depending on the complexity of the species, spiders will have two to eight sets of spinnerets, usually in pairs. There exist highly different specialised glands in different spiders, ranging from simply a sac with an opening at one end, to the complex, multiple-section Major Ampullate glands of the Nephila golden orb weaving spiders.<ref>{{cite journal |author= Dicko, C., Porter, D., Bond, J., Kenney, J. M. & Vollratht, F. |year= 2008 |title= Structural disorder in silk proteins reveals the emergence of elastomericity |journal= Biomacromolecules |volume= 9 |pages= 216–221 |doi= 10.1021/bm701069y}}</ref> |

||

Behind each spinneret visible on the surface of the spider lies a gland, a generalised form of which is shown in the figure to the right, "Schematic of a generalised gland". |

Behind each spinneret visible on the surface of the spider lies a gland, a generalised form of which is shown in the figure to the right, "Schematic of a generalised gland". |

||

[[File:Spider silk duct.svg|right|thumb|280px| Schematic of a generalised gland of a [[golden-orb web weaving spider]]. Each differently coloured section highlights a discrete section of the gland<ref>{{cite journal |author= Lefèvre, T., Boudreault, S., Cloutier, C. & Pézolet, M. |year= 2008 |title= Conformational and orientational transformation of silk proteins in the major ampullate gland of Nephila clavipes spiders |journal= Biomacromolecules |volume= 9 |pages= |

[[File:Spider silk duct.svg|right|thumb|280px| Schematic of a generalised gland of a [[golden-orb web weaving spider]]. Each differently coloured section highlights a discrete section of the gland<ref>{{cite journal |author= Lefèvre, T., Boudreault, S., Cloutier, C. & Pézolet, M. |year= 2008 |title= Conformational and orientational transformation of silk proteins in the major ampullate gland of Nephila clavipes spiders |journal= Biomacromolecules |volume= 9 |pages= 2399–2407 |doi= 10.1021/bm800390j}}</ref><ref>{{cite journal |author= Heim, M., Keerl, D. & Scheibel, T. |year= 2009 |title= Spider Silk: From Soluble Protein to Extraordinary Fiber |journal= Angewandte Chemie-International Edition |volume= 48 |pages= 3584–3596 |doi= 10.1002/anie.200803341}}</ref><ref>{{cite journal |author= Knight, D. P. & Vollrath, F. |year= 2001 |title= Comparison of the spinning of Selachian egg case ply sheets and orb web spider dragline filaments |journal= Biomacromolecules |volume= 2 |pages= 323–334 |doi= 10.1021/bm0001446}}</ref>]] |

||

The gland described here will be based upon the major apullate gland from a golden orb weaving spiders as they are the most studied and probably the most complex. |

The gland described here will be based upon the major apullate gland from a golden orb weaving spiders as they are the most studied and probably the most complex. |

||

1. The first section of the gland labelled 1 on Figure 1 is the secretory or tail section of the gland. The walls of this section are lined with cells which secrete proteins Spidroin I and Spidroin II, the main components of this spider’s dragline. These proteins are found in the form of droplets which gradually elongate to form long channels along the length of the final fibre, hypothesized to assist in preventing crack formation or even self-healing of the fibre<ref>{{cite journal |author= Heinhorst, S., Cannon, G. |year= 2002 |title= Nature: Self-Healing Polymers and Other Improved |journal=J. Chem. Educ . |volume= 79 |pages= 10 |doi=10.1021/ed079p10}}</ref> |

1. The first section of the gland labelled 1 on Figure 1 is the secretory or tail section of the gland. The walls of this section are lined with cells which secrete proteins Spidroin I and Spidroin II, the main components of this spider’s dragline. These proteins are found in the form of droplets which gradually elongate to form long channels along the length of the final fibre, hypothesized to assist in preventing crack formation or even self-healing of the fibre.<ref>{{cite journal |author= Heinhorst, S., Cannon, G. |year= 2002 |title= Nature: Self-Healing Polymers and Other Improved |journal=J. Chem. Educ . |volume= 79 |pages= 10 |doi=10.1021/ed079p10}}</ref> |

||

2. The second section is the storage sac. This stores and maintains the gel-like unspun silk dope until it is required by the spider. In addition to storing the unspun silk gel, it secretes proteins that coat the surface of the final fibre<ref>{{cite journal |author=Vollrath, F. & Knight, D. P. |year=2001 |title=Liquid crystalline spinning of spider silk |journal= Nature |volume= 410 |pages= |

2. The second section is the storage sac. This stores and maintains the gel-like unspun silk dope until it is required by the spider. In addition to storing the unspun silk gel, it secretes proteins that coat the surface of the final fibre.<ref>{{cite journal |author=Vollrath, F. & Knight, D. P. |year=2001 |title=Liquid crystalline spinning of spider silk |journal= Nature |volume= 410 |pages= 541–548 |doi=10.1038/35069000 |issue=6828 |pmid=11279484}}</ref> |

||

3. The funnel rapidly reduces the large diameter of the storage sac to the small diameter of the tapering duct. |

3. The funnel rapidly reduces the large diameter of the storage sac to the small diameter of the tapering duct. |

||

| Line 164: | Line 171: | ||

4. The final length is the tapering duct, the site of most of the fibre formation. This consists of a tapering tube with several tight about turns, a valve almost at the end (mentioned in detail at point No. 5 below) ending in a spigot from which the silk fibre emerges. The tube here tapers hyperbolically, therefore the unspun silk is under constant shear stress which is an important factor in fibre formation. This section of the duct is lined with cells that exchange ions and remove water from the fibre. The spigot at the end has lips which clamp around the fibre, controlling fibre diameter and further retaining water. |

4. The final length is the tapering duct, the site of most of the fibre formation. This consists of a tapering tube with several tight about turns, a valve almost at the end (mentioned in detail at point No. 5 below) ending in a spigot from which the silk fibre emerges. The tube here tapers hyperbolically, therefore the unspun silk is under constant shear stress which is an important factor in fibre formation. This section of the duct is lined with cells that exchange ions and remove water from the fibre. The spigot at the end has lips which clamp around the fibre, controlling fibre diameter and further retaining water. |

||

5. Almost at the end of the tapering duct is a valve, approximate position marked ‘5’ on figure 1. Though discovered some time ago, the precise purpose of this valve is still under discussion. It is believed to assist in restarting and rejoining broken fibres<ref name="Vollrath 98">{{cite journal |author= Vollrath, F. & Knight, D. P. |year= 1998 |title= Structure and function of the silk production pathway in spider Nephila edulis |journal= Int J Biol Macromol |volume= 24 |pages= |

5. Almost at the end of the tapering duct is a valve, approximate position marked ‘5’ on figure 1. Though discovered some time ago, the precise purpose of this valve is still under discussion. It is believed to assist in restarting and rejoining broken fibres<ref name="Vollrath 98">{{cite journal |author= Vollrath, F. & Knight, D. P. |year= 1998 |title= Structure and function of the silk production pathway in spider Nephila edulis |journal= Int J Biol Macromol |volume= 24 |pages= 243–249 |doi=10.1016/S0141-8130(98)00095-6}}</ref> acting much in the way of a [[helical pump]], regulating the thickness of the fibre,<ref name="Wilson69"/> and/ or clamping the fibre as a spider falls upon it.<ref name="Vollrath 98"/><ref>{{cite journal |author= Wilson, R. S. |year= 1962 |title= The Control of Dragline Spinning in the Garden Spider |journal= Quarterly Journal of Microscopical Science |volume= 103 |pages= 557–571 |doi= }}</ref> There is some discussion on the similarity of the silk worm’s silk press and the roles each of these valves play in the production of silk in these two organisms. |

||

| ⚫ | Throughout the process the unspun silk appears to have a nematic texture<ref>{{cite journal |author= Magoshi, J., Magoshi, Y. & Nakamura, S. |year= 1985 |title= Physical properties and structure of silk: 9. Liquid crystal formation of silk fibroin |journal= Polym. Commun. |volume= 26 |pages= |

||

| ⚫ | Throughout the process the unspun silk appears to have a nematic texture,<ref>{{cite journal |author= Magoshi, J., Magoshi, Y. & Nakamura, S. |year= 1985 |title= Physical properties and structure of silk: 9. Liquid crystal formation of silk fibroin |journal= Polym. Commun. |volume= 26 |pages= 60–61 |doi= }}</ref>in a similar manner to a [[liquid crystal]]. This allows the unspun silk to flow through the duct as a liquid but maintain a molecular order. |

||

As an example of a complex spinning field, the spinneret apparatus of an adult [[Araneus diadematus]] (garden cross spider) consists of the following glands<ref name="Heimer" |

As an example of a complex spinning field, the spinneret apparatus of an adult [[Araneus diadematus]] (garden cross spider) consists of the following glands<ref name="Heimer"/>: |

||

*500 [[Glandulae piriformes]] for attachment points |

*500 [[Glandulae piriformes]] for attachment points |

||

Revision as of 08:28, 25 June 2011

Spider silk is a protein fibre spun by spiders. Spiders use their silk to make webs or other structures, which function as nets to catch other animals, or as nests or cocoons for protection for their offspring. They can also suspend themselves using their silk.

Many small spiders use silk threads for ballooning, the popular, though technically inaccurate, scientific term for the dynamic kiting[1][2] spiderlings (mostly) use for dispersal. They extrude several threads into the air and let themselves be carried away by upward winds. Although most rides will end a few yards later, it seems to be a common way for spiders to invade islands. Many sailors have reported that spiders have been caught in their ship's sails, even when far from land. The extremely fine silk used by spiders for ballooning is known as gossamer.[3]

In some cases, spiders may even use silk as a source of food.[4][5]

Methods have been developed to silk a spider forcibly.[6]

Biodiversity

Uses

All spiders produce silks and a single spider can produce up to seven different types of silk for different uses.[7] This is in contrast to insect silks, where most often only one type of silk is produced by an individual.[8] Over the 400 million years of evolution, spider silks may be used for a number of different ecological uses, each with properties to match the function of the silk (see Properties section). The evolution of spiders has led to more complex and diverse uses of silk throughout its evolution, for example from primitive tube webs 300-400mya to complex orb webs 110mya.[9]

| Ecological use | Example | Reference |

|---|---|---|

| Prey capture | The orb webs produced by the Araneidae (typical orb-weavers); tube webs; tangle webs; sheet webs; lace webs, dome webs; single thread used by the Bolas spiders for ‘fishing’ | [7][9] |

| Prey immobilization | Silk used a ‘swathing bands’ to wrap up prey. Often combined with immobilising prey using a venom. | [7] |

| Reproduction | Male spiders may produce sperm webs; spider eggs are covered in silk cocoons | [7][10] |

| Dispersal | ‘Ballooning’ used by many small spiders | [2] |

| Source of food | The kleptoparasitic Argyrodes eating the silk of host spider webs | [11] |

| Nest lining | Tube webs used by ‘primitive’ spider such as the European Tube Web Spider (Segestria florentina). Threads radiate out of nest to provide a sensory link to the outside. | [9] |

Types

Meeting the specification for all these ecological uses requires different types of silk suited to different broad properties, either as a fibre, a structure of fibres or a silk-globule. These include glues, fibres for structural support, structures for protection, as well as structures that can cope with energy absorption and vibration transmission. In a spider, these silk types are produced in different glands; so the silk from a particular gland can be linked to its use by the spider. See the later section for details on the mechanical properties of silk and how the structure of silk can achieve these different properties.

| Gland | Silk Use |

|---|---|

| Ampullate (Major) | Dragline silk - used for the web’s outer rim and spokes and the lifeline. |

| Ampullate (Minor) | Used for temporary scaffolding during web construction. |

| Flagelliform | Capture-spiral silk - used for the capturing lines of the web. |

| Tubuliform | Egg cocoon silk - used for protective egg sacs. |

| Aciniform | Used to wrap and secure freshly captured prey; used in the male sperm webs; used in stabilimenta |

| Aggregate | A silk glue of sticky globules |

| Piriform | Used to form bonds between separate threads for attachment points |

Properties

Mechanical Properties

Each spider and each type of silk has a set of mechanical properties optimised for their biological function.

Most silks, in particular dragline silk, have evolved exceptional mechanical properties. They exhibit a unique combination of high tensile strength and extensibility (ductility). This enables a silk fibre to absorb a lot of energy before breaking (toughness, the area under a stress-strain curve).

A frequent mistake made in the mainstream media is to confuse strength and toughness when comparing silk to other materials. As you will see below in detail, weight for weight, silk is stronger than steel, but not as strong as Kevlar. Silk is however tougher than both.

This file may be deleted at any time.

Strength

In detail a dragline silks’ tensile strength is comparable to that of high-grade steel (1500 MPa),[12][13] and about half as strong as aramid filaments, such as Twaron or Kevlar (3000 MPa).[14]

Density

Consisting of mainly protein silks are about a fifth of the density of steel (1.31 g/cm^3). As a result, a strand long enough to circle the Earth would weigh less than 500 grams (18 oz).[15]

Extensibility

Silks are also especially ductile, with some able to stretch up to four times their relaxed length without breaking.

Toughness

The combination of strength and ductility gives dragline silks a very high toughness (or work to fracture), which "equals that of commercial polyaramid (aromatic nylon) filaments, which themselves are benchmarks of modern polymer fibre technology".[16][17]

Temperature

Whilst unlikely to be relevant in nature, dragline silks can hold their strength below −40 °C and up to 220 °C.[18]

Supercontraction

When exposed to water, dragline silks undergo supercontraction, shrinking up to 50% in length and behaving like a weak rubber under tension. Many hypothesis have been suggested as to its use in nature, with the most popular being to automatically tension webs built in the night using the morning dew.

Highest Performance

The strongest known spider silk is produced by the species Darwin's bark spider (Caerostris darwini): "The toughness of forcibly silked fibers averages 350 MJ/m3, with some samples reaching 520 MJ/m3. Thus, C. darwini silk is more than twice as tough as any previously described silk, and over 10 times tougher than Kevlar".[19]

Types of silk

Many species of spider have different glands to produce silk with different properties for different purposes, including housing, web construction, defense, capturing and detaining prey, egg protection, and mobility (gossamer for ballooning, strands to let the spider drop down on as they are extruded). Different specialized silks have evolved with properties suitable for different uses. For example, Argiope argentata has five different types of silk, each used for a different purpose:[20][21]

| Silk | Use |

|---|---|

| major-ampullate (dragline) silk | Used for the web's outer rim and spokes and the lifeline. Can be as strong per unit weight as steel, but much tougher. |

| capture-spiral silk | Used for the capturing lines of the web. Sticky, extremely stretchy and tough. |

| tubiliform (aka cylindriform) silk | Used for protective egg sacs. Stiffest silk. |

| aciniform silk | Used to wrap and secure freshly captured prey. Two to three times as tough as the other silks, including dragline. |

| minor-ampullate silk | Used for temporary scaffolding during web construction |

Composition

Spider silk is composed of complex protein molecules. This, coupled with the isolation stemming from the spider's predatory nature, has made the study and replication of the substance quite challenging. Because of the repetitive nature of the DNA encoding the silk protein, it is difficult to determine its sequence and to date, silk-producing sequences have only been decoded for fourteen species of spider. In 2005, independent researchers at the University of Wyoming (Tian and Lewis), University of the Pacific (Hu and Vierra), the University of California at Riverside (Garb and Hayashi) and Shinshu University (Zhao and Nakagaki) have uncovered the molecular structure of the gene for the protein that various female spider species use to make their silken egg cases.

Although different species of spider, and different types of silk, have different protein sequences, a general trend in spider silk structure is a sequence of amino acids (usually alternating glycine and alanine, or alanine alone) that self-assemble into a beta sheet conformation. These "Ala rich" blocks are separated by segments of amino acids with bulky side-groups. The beta sheets stack to form crystals, whereas the other segments form amorphous domains. It is the interplay between the hard crystalline segments, and the strained elastic semi amorphous regions, that gives spider silk its extraordinary properties.[22] [23] The high toughness is due to the breaking of hydrogen bonds in these regions.

Various compounds other than protein are used to enhance the fiber's properties. Pyrrolidine has hygroscopic properties and helps to keep the thread moist. It occurs in especially high concentration in glue threads. Potassium hydrogen phosphate releases protons in aqueous solution, resulting in a pH of about 4, making the silk acidic and thus protecting it from fungi and bacteria that would otherwise digest the protein. Potassium nitrate is believed to prevent the protein from denaturing in the acidic milieu.[24]

Structural

Macroscopic structure down to protein hierarchy

Silks, as well as many other biomaterials, have a hierarchical structure [e.g. cellulose, hair]. The primary structure is its amino acid sequence, mainly consisting of highly repetitive glycine and alanine blocks,[25][26] why silks are often referred to as a block co-polymer. On a secondary structure level, the short side chained alanine is mainly found in the crystalline domains (beta sheets) of the nano fibril, glycine, having larger side groups, is mostly found in the so called amorphous matrix consisting of helical and beta turn structures.[26][27] This first very basic model of silk was introduced by Termonia in 1994[28] suggested crystallites embedded in an amorphous matrix interlinked with hydrogen bonds. This model has refined over the years: Semi crystalline regions were found[26] as well as a fibrillar skin core model suggested for spider silk,[29] later visualized by AFM and TEM.[30] Sizes of the nano fibrillar structure and the crystalline and semi-crystalline regions were revealed by Neutron Scattering.[31]

Non-protein composition

Various compounds other then protein are found in spider silks, such as sugars, lipids, ions and pigments which might affect the aggregation behaviour and act as a protection layer in the final fibre.[16]

Biosynthesis

Silk including spider silk is definitively unlike any other fibre or biological material- rather than being continuously grown such as hair of keratin and cellulose of plants, or even compacted matter such as beetle flax, it is ‘spun’ on demand from a liquid silk precursor, named unspun silk dope.

The spinning process occurs when a fibre is pulled away from the body of a spider, be that by the spider’s legs, by the spider falling and using its own weight, or by any other method including being pulled by humans. The name ‘spinning’ is misleading as no rotation of any component occurs, but the name comes from when it was thought that spiders produced their thread in a similar manner to the spinning wheels of old. In fact the process is a pulltrusion[32] - similar to extrusion, with the subtlety that the force is induced by pulling at the finished fibre rather than being squeezed out of a reservoir of some kind.

The unspun silk dope is pulled through silk glands, of which there may be both numerous duplicates and also different types on any one spider species.

Silk gland

The gland's visible, or external, part is termed the spinneret. Depending on the complexity of the species, spiders will have two to eight sets of spinnerets, usually in pairs. There exist highly different specialised glands in different spiders, ranging from simply a sac with an opening at one end, to the complex, multiple-section Major Ampullate glands of the Nephila golden orb weaving spiders.[33]

Behind each spinneret visible on the surface of the spider lies a gland, a generalised form of which is shown in the figure to the right, "Schematic of a generalised gland".

The gland described here will be based upon the major apullate gland from a golden orb weaving spiders as they are the most studied and probably the most complex.

1. The first section of the gland labelled 1 on Figure 1 is the secretory or tail section of the gland. The walls of this section are lined with cells which secrete proteins Spidroin I and Spidroin II, the main components of this spider’s dragline. These proteins are found in the form of droplets which gradually elongate to form long channels along the length of the final fibre, hypothesized to assist in preventing crack formation or even self-healing of the fibre.[37]

2. The second section is the storage sac. This stores and maintains the gel-like unspun silk dope until it is required by the spider. In addition to storing the unspun silk gel, it secretes proteins that coat the surface of the final fibre.[38]

3. The funnel rapidly reduces the large diameter of the storage sac to the small diameter of the tapering duct.

4. The final length is the tapering duct, the site of most of the fibre formation. This consists of a tapering tube with several tight about turns, a valve almost at the end (mentioned in detail at point No. 5 below) ending in a spigot from which the silk fibre emerges. The tube here tapers hyperbolically, therefore the unspun silk is under constant shear stress which is an important factor in fibre formation. This section of the duct is lined with cells that exchange ions and remove water from the fibre. The spigot at the end has lips which clamp around the fibre, controlling fibre diameter and further retaining water.

5. Almost at the end of the tapering duct is a valve, approximate position marked ‘5’ on figure 1. Though discovered some time ago, the precise purpose of this valve is still under discussion. It is believed to assist in restarting and rejoining broken fibres[39] acting much in the way of a helical pump, regulating the thickness of the fibre,[32] and/ or clamping the fibre as a spider falls upon it.[39][40] There is some discussion on the similarity of the silk worm’s silk press and the roles each of these valves play in the production of silk in these two organisms.

Throughout the process the unspun silk appears to have a nematic texture,[41]in a similar manner to a liquid crystal. This allows the unspun silk to flow through the duct as a liquid but maintain a molecular order.

As an example of a complex spinning field, the spinneret apparatus of an adult Araneus diadematus (garden cross spider) consists of the following glands[24]:

- 500 Glandulae piriformes for attachment points

- 4 Glandulae ampullaceae for the web frame

- about 300 Glandulae aciniformes for the outer lining of egg sacs, and for ensnaring prey

- 4 Glandulae tubuliformes for egg sac silk

- 4 Glandulae aggregatae for glue

- 2 Glandulae coronatae for the thread of glue lines.

Human uses

Peasants in the southern Carpathian Mountains used to cut up tubes built by Atypus and cover wounds with the inner lining. It reportedly facilitated healing, and even connected with the skin. This is believed to be due to antiseptic properties of spider silk[24] and because the silk is rich in vitamin K, which can be effective in clotting blood.[42]

Some fishermen in the Indo-Pacific ocean use the web of Nephila to catch small fish.[24]

The silk of Nephila clavipes has recently been used to help in mammalian neuronal regeneration.[43]

At one time, it was common to use spider silk as a thread for crosshairs in optical instruments such as telescopes, microscopes,[44] and telescopic rifle sights.[45]

Due to the difficulties in extracting and processing substantial amounts of spider silk, there is currently only one known piece of cloth made of spider silk, an 11-by-4-foot (3.4 by 1.2 m) textile with a golden tint made in Madagascar in 2009. 82 people worked for four years to collect over one million golden orb spiders and extract silk from them.[46]

Artificially produced spider silk

Spider silk is as strong as many industrial fibers (see tensile strength for common comparisons). There is commercial interest in duplicating spider silk artificially, since spiders use renewable materials as input and operate at room temperature, low pressures and using water as a solvent. However, it has been difficult to find a commercially viable process to mass-produce spider silk.

It is not possible to use spiders themselves to produce industrially useful quantities of spider silk, due to the difficulties of managing large quantities of spiders (although this was tried with Nephila silk[24]). Unlike silkworms, spiders eat one another, so spiders cannot be kept together.

The properties of silk are determined both by its chemical composition and the mechanical process by which it is produced.

The spider's highly sophisticated spinneret is instrumental in organizing the silk proteins into strong domains. The spinneret creates a gradient of protein concentration, pH, and pressure, which drive the protein solution through liquid crystalline phase transitions, ultimately generating the required silk structure, a mixture of crystalline and amorphous biopolymer regions. Replicating these complex conditions in a laboratory environment has proved difficult. Nexia used wet spinning and squeezed the silk protein solution through small extrusion holes in order to simulate the behavior of the spinneret, but this has so far not been sufficient to replicate the properties of native spider silk.[47]

One approach which does not involve farming spiders is to extract the spider silk gene and use other organisms to produce the spider silk. In 2000 Canadian biotechnology company Nexia successfully produced spider silk protein in transgenic goats which carried the gene for it; the milk produced by the goats contained significant quantities of the protein, 1–2 grams of silk proteins per liter of milk. Attempts to spin the protein into a fiber similar to natural spider silk resulted in fibers with tenacities of 2–3 grams per denier (see BioSteel).[48][49]

Extrusion of protein fibers in an aqueous environment is known as "wet-spinning". This process has so far produced silk fibers of diameters ranging from 10 to 60 μm, compared to diameters of 2.5–4 μm for natural spider silk.

In March 2010, researchers from the Korea Advanced Institute of Science & Technology (KAIST) have succeeded in making spider silk directly with the bacteria E.coli, modified with certain genes of the spider Nephila clavipes. This thus eliminates dependency on the spider for milking and allows to manufacture the spider silk at a more cost-effective manner.[50]

The company Kraig Biocraft Laboratories[51] has used research from the Universities of Wyoming and Notre Dame in a collaborative effort to create a silkworm that is genetically altered to produce spider silk. In September 2010 it was announced at a press conference at the University of Notre Dame that the effort had been successful.[52]

See also

- Hagfish – produces similar fiber.

- Silk – natural fiber produced by silkworms, the larvae of the moth Bombyx mori.

- "The Silk Spinners", a BBC program about silk-producing animals.

References

- ^ Spiders By Ann R. Heinrichs. Google Books. She observes that the so-called ballooning is like a kite or balloon; she is mechanically correct about the kite part, as no true balloon is ever formed by the spider as told in the other references.

- ^ a b Flying Spiders over Texas! Coast to Coast. Chad B., Texas State University Undergrad Describes the mechanical kiting of spider "ballooning".

- ^ Oxford English Dictionary.

- ^ "Spider Silk". School of Chemistry – Bristol University – UK. Retrieved 2007-05-22.

- ^ Miyashita, Tadashi (2004). "Silk feeding as an alternative foraging tactic in a kleptoparasitic spider under seasonally changing environments". Journal of Zoology. 262 (03): 225–229. doi:10.1017/S0952836903004540. Retrieved 2007-05-22.

{{cite journal}}: Unknown parameter|coauthors=ignored (|author=suggested) (help); Unknown parameter|month=ignored (help) - ^ An Apparatus and Technique for the Forcible Silking of Spiders

- ^ a b c d Foelix, R. F. (1996). Series Editor (ed.). Biology of spiders. Oxford, N.Y: Oxford University Press. p. 330.

{{cite book}}:|editor=has generic name (help) - ^ Sutherland, T., Young, J. & Weisman, S. (2009). "Insect Silk: One Name, Many Materials". Ann. Rev. Entomol. 55: 171–188. doi:10.1146/annurev-ento-112408-085401.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ a b c Hillyard, P. (2007). Series Editor (ed.). The Private Life of Spiders. London: New Holland. p. 160. ISBN 9781845376901.

{{cite book}}:|editor=has generic name (help) - ^ Nentwig, W. & Heimer, S. (1987). Wolfgang Nentwig (ed.). Ecological aspects of spider webs. Springer-Verlag. p. 211.

{{cite book}}: CS1 maint: multiple names: authors list (link) - ^ Miyashita, Tadashi (2004). "Silk feeding as an alternative foraging tactic in a kleptoparasitic spider under seasonally changing environments". Journal of Zoology. 262 (03): 225–229. doi:10.1017/S0952836903004540. Retrieved 2007-05-22.

{{cite journal}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ "SpringerLink -". www.springerlink.com. Retrieved 2010-08-18.

- ^ "Overview of materials for AISI 4000 Series Steel". www.matweb.com. Retrieved 2010-08-18.

- ^ "DuPont Kevlar 49 Aramid Fiber". www.matweb.com. Retrieved 2010-08-18.

- ^ Spider dragline silk has a tensile strength of roughly 1.3 GPa. The tensile strength listed for steel might be slightly higher – e.g. 1.65 GPa. [1]Shao, Z. Vollrath, F. (August 15, 2002). "Materials: Surprising strength of silkworm silk". Nature. 418 (6899): 741–741. doi:10.1038/418741a. PMID 12181556.

{{cite journal}}: CS1 maint: multiple names: authors list (link), but spider silk is a much less dense material, so that a given weight of spider silk is five times as strong as the same weight of steel - ^ a b Vollrath, F. Knight, D.P. (2001). "Liquid crystalline spinning of spider silk". Nature. 410 (6828): 541–548. Bibcode:2001Natur.410..541V. doi:10.1038/35069000. PMID 11279484.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ "Spider Silk". www.chm.bris.ac.uk. Retrieved 2010-08-18.

- ^ Yang, Y.; et al. (2005). "Toughness of spider silk at high and low temperatures". Advanced Materials. 17: 84–+. doi:10.1002/adma.200400344.

- ^ Agnarsson I, Kuntner M, Blackledge TA (2010). "Bioprospecting Finds the Toughest Biological Material: Extraordinary Silk from a Giant Riverine Orb Spider". PLoS ONE. 5 (9): e11234. doi:10.1371/journal.pone.0011234.

{{cite journal}}: CS1 maint: multiple names: authors list (link) CS1 maint: unflagged free DOI (link) - ^ Cunningham A (2007). "Taken for a Spin". Science News. 171: 231–33.

- ^ Blackledge, T.A., and Hayashi, C.Y. (2006). Silken toolkits: Biomechanics of silk fibers spun by the orb web spider Argiope argentata. Journal of Experimental Biology 2009(July 1), pp. 2452–61 (references)

- ^ Liu, Y., Sponner, A., Porter, D., Vollrath, F. (2008). "Proline and Processing of Spider Silks". Biomacromolecules. 9 (1): 116–121. doi:10.1021/bm700877g. PMID 18052126.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ Papadopoulos, P., Ene, R., Weidner, I., Kremer, F. (2009). "Similarities in the Structural Organization of Major and Minor Ampullate Spider Silk". Macromol. Rapid Commun. 30 (9–10): 851–857. doi:10.1002/marc.200900018.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ a b c d e Heimer, S. (1988). Wunderbare Welt der Spinnen. Urania. p.12 Cite error: The named reference "Heimer" was defined multiple times with different content (see the help page).

- ^ Hinman, M. B. & Lewis, R. V. (1992). "Isolation of a clone encoding a second dragline silk fibroin. Nephila clavipes dragline silk is a two-protein fiber". J. Biol. Chem. 267: 19320–19324.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ a b c Simmons, A. H., Michal, C. A. & Jelinski, L. W. (1996). "Molecular orientation and two-component nature of the crystalline fraction of spider dragline silk". Science. 271: 84–87.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ van Beek, J. D., Hess, S., Vollrath, F. & Meier, B. H. (2002). "The molecular structure of spider dragline silk: Folding and orientation of the protein backbone". Proc. Natl. Acad. Sci. U. S. A. 99: 10266–10271. doi:10.1073/pnas.152162299.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ Termonia, Y. (1994). "Molecular Modeling of Spider Silk Elasticity". Macromolecules. 27: 7378–7381.

- ^ Vollrath, F., Holtet, T., Thogersen, H. C. & Frische, S. (1996). "Structural organization of spider silk". Proc. R. Soc. Lond. Ser. B-Biol. Sci. 263: 147–151.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ Sponner, A.; et al. (2007). "Composition and hierarchical organization of a spider silk". Plos One: e998.

{{cite journal}}: Explicit use of et al. in:|author=(help) - ^ Sapede, D.; et al. (2005). "Nanofibrillar structure and molecular mobility in spider dragline silk". European Biophysics Journal. 34: 623.

{{cite journal}}: Explicit use of et al. in:|author=(help) - ^ a b Wilson, R. S. (1969). "control of drag-line spinning in certain spiders". Am. Zool. 9: 103-&.

- ^ Dicko, C., Porter, D., Bond, J., Kenney, J. M. & Vollratht, F. (2008). "Structural disorder in silk proteins reveals the emergence of elastomericity". Biomacromolecules. 9: 216–221. doi:10.1021/bm701069y.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ Lefèvre, T., Boudreault, S., Cloutier, C. & Pézolet, M. (2008). "Conformational and orientational transformation of silk proteins in the major ampullate gland of Nephila clavipes spiders". Biomacromolecules. 9: 2399–2407. doi:10.1021/bm800390j.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ Heim, M., Keerl, D. & Scheibel, T. (2009). "Spider Silk: From Soluble Protein to Extraordinary Fiber". Angewandte Chemie-International Edition. 48: 3584–3596. doi:10.1002/anie.200803341.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ Knight, D. P. & Vollrath, F. (2001). "Comparison of the spinning of Selachian egg case ply sheets and orb web spider dragline filaments". Biomacromolecules. 2: 323–334. doi:10.1021/bm0001446.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ Heinhorst, S., Cannon, G. (2002). "Nature: Self-Healing Polymers and Other Improved". J. Chem. Educ . 79: 10. doi:10.1021/ed079p10.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ Vollrath, F. & Knight, D. P. (2001). "Liquid crystalline spinning of spider silk". Nature. 410 (6828): 541–548. doi:10.1038/35069000. PMID 11279484.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ a b Vollrath, F. & Knight, D. P. (1998). "Structure and function of the silk production pathway in spider Nephila edulis". Int J Biol Macromol. 24: 243–249. doi:10.1016/S0141-8130(98)00095-6.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ Wilson, R. S. (1962). "The Control of Dragline Spinning in the Garden Spider". Quarterly Journal of Microscopical Science. 103: 557–571.

- ^ Magoshi, J., Magoshi, Y. & Nakamura, S. (1985). "Physical properties and structure of silk: 9. Liquid crystal formation of silk fibroin". Polym. Commun. 26: 60–61.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ Jackson, Robert R (1974). "Effects of D-Amphetamine Sulphate and Diasepam on Thread Connection Fine Structure in a Spider's Web" (PDF). North Carolina Department of Mental Health.

- ^ Allmeling, C., Jokuszies, A., Reimers, K., Kall, S., Vogt, P.M. (2006): Use of spider silk fibers as an innovative material in a biocompatible artificial nerve conduit. J. Cell. Mol. Med. 10(3):770–77 PDF – doi:10.2755/jcmm010.003.18

- ^ Berenbaum, May R., Field Notes – Spin Control, The Sciences, The New York Academy Of Sciences, September/October 1995

- ^ Example of use of spider silk for telescopic rifle sights

- ^ "1 Million Spiders Make Golden Silk for Rare Cloth".

- ^ Scheibel, T. (2004): Spider silks: recombinant synthesis, assembly, spinning, and engineering of synthetic proteins. "Microb Cell Fact" 3:14 [2]

- ^ http://www.nexiabiotech.com/en/00_home/index.php

- ^ http://www.sciencedirect.com.libproxy.lib.unc.edu/science?_ob=ArticleURL&_udi=B6TCW-4S4J6G0-3&_user=130907&_coverDate=05%2F31%2F2008&_rdoc=5&_fmt=high&_orig=browse&_srch=doc-info(%23toc%235181%232008%23999739994%23686677%23FLA%23display%23Volume)&_cdi=5181&_sort=d&_docanchor=&_ct=9&_acct=C000004198&_version=1&_urlVersion=0&_userid=130907&md5=4e943bf9f8b13ee1aca065ebce361f56

- ^ Spider silk made using bacteria

- ^ "Kraig Biocraft Laboratories".

- ^ "University of Notre Dame".

- Forbes, Peter (4th Estate, London 2005). The Gecko's Foot – Bio Inspiration: Engineered from Nature, ISBN 0-00-717990-1 in H/B.

- Graciela C. Candelas, José Cintron. "A spider fibroin and its synthesis", Journal of Experimental Zoology (1981), Department of Biology, University of Puerto Rico, Río Piedras, Puerto Rico 00931.

External links

- The Silk Gland – A very nice breakdown of the silk gland, its parts and uses with images and drawings.

- Spiders in Space – NASA article and database information on the research of spiders in space.

- Israeli and German scientists created artificial silk using genetically engineered spider proteins – Article on IsraCast

- The mechanical design of spider silks: from fibroin sequence to mechanical function – Article on The Journal of Experimental Biology

- The Real Spider-Man – Article on forming Spider Silk Fibers from Caterpillars

- Genetic tweak boosts stiffness of spider silk

- Silk & Webs – The Arachnology Home Page

- Silk Research Group at Oxford University

- Finding Inspiration in Spider Silk Fibers

- Russian Scientists Created Industrial Technology of Spider Silk Fibers production

- TeachersTV programme on Spider Silk