Oxyhydrogen: Difference between revisions

m →As a fuel supplement: burn |

minor change - added links to refractory materials and oil bubbler |

||

| Line 1: | Line 1: | ||

{{Redirect|Knallgas|bacteria which oxidize hydrogen|Knallgas-bacteria}} |

{{Redirect|Knallgas|bacteria which oxidize hydrogen|Knallgas-bacteria}} |

||

{{TOCright}} |

{{TOCright}} |

||

'''Oxyhydrogen''' is a mixture of [[hydrogen]] and [[oxygen]] gases, typically in a 2:1 atomic ratio, the same proportion as water.<ref name="encyclopedia"/> This gaseous mixture is widely used for torches for the processing of refractory materials. |

'''Oxyhydrogen''' is a mixture of [[hydrogen]] and [[oxygen]] gases, typically in a 2:1 atomic ratio, the same proportion as water.<ref name="encyclopedia"/> This gaseous mixture is widely used for torches for the processing of [[refractory]] materials. |

||

== Properties == |

== Properties == |

||

| Line 63: | Line 63: | ||

}}</ref>]] |

}}</ref>]] |

||

A '''water torch''' is a kind of oxyhydrogen torch that is fed by oxygen and hydrogen generated on demand by [[water electrolysis]]. The device avoids the need for bottled oxygen and hydrogen, and requires electricity. Water torches must be designed to mitigate [[Flashback (welding)|flashback]] by strengthening the electrolytic chamber. Use of an intermediary water bubbler eliminates potential electrolyzer damage from flashback, with a dry [[flashback arrestor]] being ineffective due to flame velocity. The bubbler is connected directly in series with the output gas. A water bubbler is sometimes referred to as a wet flashback arrestor, and effectively captures any remaining [[electrolyte]] in the output gas. Suitable electrolytes include [[Sodium hydroxide|sodium]] or [[potassium hydroxide]], and other salts that ionize well.<ref name="GW"/> Also "the electrolyzer system must be of high enough pressure to keep the gas velocity at the nozzle above the combustion velocity of the flame, or the system will backfire".<ref name="GW"/> For images of water torch equipment see these links: [http://www.jewelerssupplies.com/media/140795.jpg] [http://www.ottofrei.com/store/images_detailed/d_5120.jpg] [http://watertorch.com/images/pictures/bgmach/bgmachport/1200depth.jpg][http://www.sra-solder.com/images/wwpic1.jpg][http://www.brownsgas.com/i//oxyhydrogengeneratorhd350.jpg][http://www.brownsgas.com/i//bb600_1.jpg][http://www.brownsgas.com/i//model_1500.jpg][http://www.brownsgas.com/i//rai1500.jpg]. |

A '''water torch''' is a kind of oxyhydrogen torch that is fed by oxygen and hydrogen generated on demand by [[water electrolysis]]. The device avoids the need for bottled oxygen and hydrogen, and requires electricity. Water torches must be designed to mitigate [[Flashback (welding)|flashback]] by strengthening the electrolytic chamber. Use of an intermediary water [[Oil bubbler|bubbler]] eliminates potential electrolyzer damage from flashback, with a dry [[flashback arrestor]] being ineffective due to flame velocity. The bubbler is connected directly in series with the output gas. A water bubbler is sometimes referred to as a wet flashback arrestor, and effectively captures any remaining [[electrolyte]] in the output gas. Suitable electrolytes include [[Sodium hydroxide|sodium]] or [[potassium hydroxide]], and other salts that ionize well.<ref name="GW"/> Also "the electrolyzer system must be of high enough pressure to keep the gas velocity at the nozzle above the combustion velocity of the flame, or the system will backfire".<ref name="GW"/> For images of water torch equipment see these links: [http://www.jewelerssupplies.com/media/140795.jpg] [http://www.ottofrei.com/store/images_detailed/d_5120.jpg] [http://watertorch.com/images/pictures/bgmach/bgmachport/1200depth.jpg][http://www.sra-solder.com/images/wwpic1.jpg][http://www.brownsgas.com/i//oxyhydrogengeneratorhd350.jpg][http://www.brownsgas.com/i//bb600_1.jpg][http://www.brownsgas.com/i//model_1500.jpg][http://www.brownsgas.com/i//rai1500.jpg]. |

||

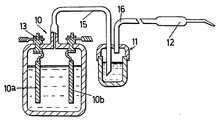

[[Image:Seriescellelectrolyzerdesign.png|thumb|left|The series cell design by Yull Brown.<ref name="US patent 4014777"/> ]] |

[[Image:Seriescellelectrolyzerdesign.png|thumb|left|The series cell design by Yull Brown.<ref name="US patent 4014777"/> ]] |

||

Revision as of 23:53, 28 April 2008

Oxyhydrogen is a mixture of hydrogen and oxygen gases, typically in a 2:1 atomic ratio, the same proportion as water.[1] This gaseous mixture is widely used for torches for the processing of refractory materials.

Properties

Oxyhydrogen will combust when brought to its autoignition temperature. For a stoichiometric mixture at normal atmospheric pressure, autoignition occurs at about 570 °C (1065 °F).[2] The minimum energy required to ignite such a mixture with a spark is about 0.02 millijoules.[2] At normal temperature and pressure, oxyhydrogen can burn when it is between about 4% and 94% hydrogen by volume.[2]

When ignited, the gas mixture converts to water vapor and releases energy, which sustains the reaction: 241.8 kJ of energy (LHV) for every mole of Template:Hydrogen burned. The amount of heat energy released is independent of the mode of combustion, but the temperature of the flame varies.[1] The maximum temperature of about 2800 °C is achieved with a pure stoichiometric mixture, about 700 degrees hotter than a hydrogen flame in air.[3][4][5] When either of the gases is mixed in excess of this ratio, or when mixed with an inert gas like nitrogen, the heat must spread throughout a greater quantity of matter and the temperature will be lower.[1]

Production

A pure stoichiometric mixture is most easily obtained by water electrolysis, which uses an electric current to dissociate the water molecules:

- electrolysis: 2 H2O → 2 H2 + O2

- combustion: 2 H2 + O2 → 2 H2O

The energy required to generate the oxyhydrogen always exceeds the energy released by combusting it. (See Electrolysis of water:Efficiency).

Applications

Historic uses

Many forms of oxyhydrogen lamps have been described, such as the limelight, which used an oxyhydrogen flame to heat a piece of lime to white hot incandescence.[6] Because of the explosiveness of the oxyhydrogen, limelights have been replaced by electric lighting.

It was much used in platinum works, as platinum could be melted (at a temperature of 1768.3 °C) only in an oxyhydrogen flame, or an electric furnace (which is now used instead).

Oxyhydrogen torch

An oxyhydrogen torch is an oxy-gas torch, which burns hydrogen (the fuel) with oxygen (the oxidizer). It is used for cutting and welding metals, glass, and thermoplastics.[6] An oxyhydrogen torch is used in the glass industry for "fire polishing"; slightly melting the surface of glass to remove scratches and dullness.

The oxyhydrogen flame begins a short distance from the torch tip; if the distance is great enough the torch tip can remain relatively cool.[7]

Water torch

A water torch is a kind of oxyhydrogen torch that is fed by oxygen and hydrogen generated on demand by water electrolysis. The device avoids the need for bottled oxygen and hydrogen, and requires electricity. Water torches must be designed to mitigate flashback by strengthening the electrolytic chamber. Use of an intermediary water bubbler eliminates potential electrolyzer damage from flashback, with a dry flashback arrestor being ineffective due to flame velocity. The bubbler is connected directly in series with the output gas. A water bubbler is sometimes referred to as a wet flashback arrestor, and effectively captures any remaining electrolyte in the output gas. Suitable electrolytes include sodium or potassium hydroxide, and other salts that ionize well.[7] Also "the electrolyzer system must be of high enough pressure to keep the gas velocity at the nozzle above the combustion velocity of the flame, or the system will backfire".[7] For images of water torch equipment see these links: [1] [2] [3][4][5][6][7][8].

Brown's design

Some models of water torches mix the two gases immediately after production (vs. the torch tip) making the gas mixture more accurate.[8] This electrolyzer design is referred to as "common-ducted",[7] and the first was invented by William A. Rhodes in 1966.[9] Oxyhydrogen gas produced in a common-ducted electrolyzer is commonly referred to as "Brown's gas", after Yull Brown who received a utility patent for a series cell common-ducted electrolyzer in 1977 and 1978 (the term "Brown's gas" is not used in his patents, but "a mixture of oxygen and hydrogen" is referenced).[8][10] Brown's torches also used an electric arc to increase the temperature of the flame (called atomic welding):[8]

As a fuel supplement

Oxyhydrogen can be used as a fuel supplement with the hydrogen component having an affect on the burn rate and lean burn limit of hydrocarbon fuels.[11][12][13][14] See: hydrogen fuel enhancement.

Heating

- Sang Nam Kim claims "an energy generating apparatus using the cyclic combustion of Brown gas wherein a heat generating unit is heated to a temperature of 1,000°C".[15]

Klein's design

HHO gas or Klein gas is an oxyhydrogen mixture made by water electrolysis, which has been trademarked Aquygen by the firm Hydrogen Technology Applications. Dennis Klein's patent states that his electrolyzer differs from Yull Brown's in that it lacks the electric arc feature.[16] The claimed applications of HHO are practically indistinguishable from the original claims of Yull Brown.

The HHO trademark is associated with an unproven state of matter called magnegases, and a discredited theory about magnecules, [17] which is the basis for a number of fraudulent claims, and third party water-fuelled car scam attempts.

References

- ^ a b c 1911 Encyclopedia. "Oxyhydrogen Flame". (Available here Accessed 2008-01-19.)

- ^ a b c O'Connor, Ken. "Hydrogen". NASA Glenn Research Center Glenn Safety Manual.

{{cite book}}: External link in|chapterurl=|chapterurl=ignored (|chapter-url=suggested) (help) - ^ Calvert, Dr. James B. (2006-09-09). "Hydrogen". University of Denver faculty page. Retrieved 2008-04-05. "An air-hydrogen torch flame reaches 2045 °C, while an oxyhydrogen flame reaches 2660 °C."

- ^ "Adiabatic Flame Temperature". The Engineering Toolbox. Retrieved 2008-04-05. "Oxygen as Oxidizer: 3079 K, Air as Oxidizer: 2384 K"

- ^ "Temperature of a Blue Flame". Retrieved 2008-04-05. "Hydrogen in air: 2,400 K, Hydrogen in Oxygen: 3,080 K"

- ^ a b William Augustus Tilden. Chemical Discovery and Invention in the Twentieth Century. Adamant Media Corporation. p. 80. ISBN 0543916464.

- ^ a b c d George Wiseman. Brown's Gas Book 2. Eagle Research. p. 59. ISBN 1895882192.

- ^ a b c d e US patent 4014777, Yull Brown, "Welding", issued 1977-03-29

- ^ US patent 3262872, William Rhodes, "Generator Patent", issued 1966-7-26

- ^ US patent 4081656, Yull Brown, "Arc-assisted oxy/hydrogen welding", issued 1978-3-28

- ^ Mathur H.B., Das L.M. (1991). "Performance characteristics of a Hydrogen Fueled SI Engine using Timed Manifold Injection". Int. J. Hydrogen Energy (vol 16, pp. 115-117, 1991).

{{cite journal}}:|issue=has extra text (help) - ^ Yougen Kong, Sam Crane, Palak Patel and Bill Taylor (January, 2004). "NOx Trap Regeneration with an On-Board Hydrogen Generation Device". SAE Technical Paper Series (2004-01-0582): p. 6-7.

{{cite journal}}:|pages=has extra text (help); Check date values in:|date=(help)CS1 maint: multiple names: authors list (link) - ^ John Houseman and D.J. Cerini at the Jet Propulsion Lab., California Institute of Technology "On-Board Hydrogen Generator for a Partial Hydrogen Injection Internal Combustion Engine". Abstracts of papers of the American Chemical Society (1974) West Coat Meeting, Anaheim, Calif. August 12-16 (meeting abstract paper# 740600)

- ^ Hoehn FW, Baisley RL, Dowdy MW, "Advances In Ultralean Combustion Technology Using Hydrogren-Enriched Gasoline", IEEE Transactions on Aerospace and Electronic Systems 11 (5): 958-958 1975. (meeting abstract)

- ^ US patent 6443725, Sang Nam Kim, "Apparatus for generating energy using cyclic combustion of brown gas", issued 2002-9-3

- ^ US patent 6,689,259, Dennis Klein, "Mixed gas generator", issued 2004-2-10

- ^ J. M. Calo (November 3, 2006). "Comments on "A new gaseous and combustible form of water," by R.M. Santilli (Int. J. Hydrogen Energy 2006: 31(9), 1113–1128)". International Journal of Hydrogen Energy (32): p. 1309-1312.

{{cite journal}}:|pages=has extra text (help)doi:10.1016/j.ijhydene.2006.11.004

This article incorporates text from a publication now in the public domain: Chisholm, Hugh, ed. (1911). Encyclopædia Britannica (11th ed.). Cambridge University Press. {{cite encyclopedia}}: Missing or empty |title= (help)