Transmission electron microscopy: Difference between revisions

m Date maintenance tags and general fixes |

→Improving Resolution: + links |

||

| Line 28: | Line 28: | ||

| journal=Électrons et Photons: Rapports et Discussions du Cinquième Conseil de Physique. Solvay |

| journal=Électrons et Photons: Rapports et Discussions du Cinquième Conseil de Physique. Solvay |

||

| year=1928 |

| year=1928 |

||

}}</ref>. The group was unaware of this publication until 1932, where it was quickly realized that the De Broglie wavelength of electrons was many orders of magnitude smaller than that for light, theoretically allowing for imaging at atomic scales. In April 1932, Ruska suggested the construction of a new electron microscope for direct imaging of specimens inserted into the microscope, rather than simple mesh grids or images of apertures. With this device successful [[diffraction]] and normal imaging of aluminium sheet was achieved, however exceeding the magnification achievable with light microscopy had still not been successfully demonstrated. This goal was achieved in September 1933, using images of cotton |

}}</ref>. The group was unaware of this publication until 1932, where it was quickly realized that the De Broglie wavelength of electrons was many orders of magnitude smaller than that for light, theoretically allowing for imaging at atomic scales. In April 1932, Ruska suggested the construction of a new electron microscope for direct imaging of specimens inserted into the microscope, rather than simple mesh grids or images of apertures. With this device successful [[diffraction]] and normal imaging of aluminium sheet was achieved, however exceeding the magnification achievable with light microscopy had still not been successfully demonstrated. This goal was achieved in September 1933, using images of [[cotton fiber]]s, which were quickly acquired before being damaged by the electron beam. |

||

<!-- Albert Prebus' work is not mentioned by Ruska? --> |

<!-- Albert Prebus' work is not mentioned by Ruska? --> |

||

At this time, interest in the electron microscope had increased, with other groups, such as [[Albert Prebus]] and [[James Hillier]] at the [[University of Toronto]] who constructed the first TEM in north America in 1938 <ref> http://comdir.bfree.on.ca/hillier/hilbio.htm</ref>, continually advancing TEM design. |

At this time, interest in the electron microscope had increased, with other groups, such as [[Albert Prebus]] and [[James Hillier]] at the [[University of Toronto]] who constructed the first TEM in north America in 1938 <ref> http://comdir.bfree.on.ca/hillier/hilbio.htm</ref>, continually advancing TEM design. |

||

Research continued on the electron microscope at [[Siemens]] in 1936, the aim of the research was the development improvement of TEM imaging properties, particularly with regard to biological specimens. In 1939 the first commercial electron microscope, pictured, was installed in the Physics department of I. G Farben-Werke. Further work on the electron microscope was hampered by the destruction of a new laboratory constructed at Siemens by an air-raid, as well as the death of two of the researchers, Heinz Müller and [[Friedrick Krause]] during |

Research continued on the electron microscope at [[Siemens]] in 1936, the aim of the research was the development improvement of TEM imaging properties, particularly with regard to biological specimens. In 1939 the first commercial electron microscope, pictured, was installed in the Physics department of I. G Farben-Werke. Further work on the electron microscope was hampered by the destruction of a new laboratory constructed at Siemens by an [[air-raid]], as well as the death of two of the researchers, Heinz Müller and [[Friedrick Krause]] during [[World War II]]<ref name="ruskaNobelLect"> http://nobelprize.org/nobel_prizes/physics/laureates/1986/ruska-lecture.html</ref>. |

||

=== Further research === |

=== Further research === |

||

Revision as of 22:11, 1 December 2008

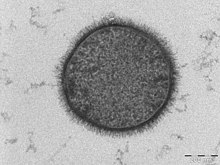

Transmission electron microscopy (TEM) is a microscopy technique whereby a beam of electrons is transmitted through an ultra thin specimen, interacting with the specimen as they pass through. An image is formed from the interaction of the electrons transmitted through the specimen, which is magnified and focused by an objective lens and onto an imaging device, such as a fluorescent screen, as is common in most TEMs, on a layer of photographic film, or to be detected by a sensor such as a CCD camera. The first TEM was built by Max Knoll and Ernst Ruska in 1931, with this group developing the first TEM with resolving power greater than that of light in 1933 and the first commercial TEM in 1939.

History

Initial development

Ernst Abbe originally proposed that the ability to resolve detail in an object was limited by the wavelength of the light used in imaging, thus limiting the useful obtainable magnification from an optical microscope to a few micrometres. Developments into UV microscopes, led by Koehler, allowed for an increase in resolving power of about a factor of two. However this required more expensive quartz optical components, due to the absorption of UV by glass. At this point it was believed that obtaining an image with sub-micrometre information was simply impossible due to this wavelength constraint.

It had earlier been recognized by Plücker in 1858 that the deflection of "cathode rays" (electrons) was possible by the use of magnetic fields[1]. This effect had been utilised to build primitive cathode ray oscilloscopes (CROs) as early as 1897 by Ferdinand Braun, intended as a measurement device [2]. Indeed in 1891 it was recognized by Riecke that the cathode rays could be focussed by these magnetic fields, allowing for simple lens designs. Later this theory was extended by Hans Busch in his work published in 1926, who showed that the lens maker's equation, could under appropriate assumptions, be applicable to electrons[3]

In 1928, at the Technological University of Berlin Adolf Matthias, Professor of High voltage Technology and Electrical Installations, appointed Max Knoll to lead a team of researchers to advance the CRO design. The team consisted of several PhD students including Ernst Ruska and Bodo von Borries. This team of researchers concerned themselves with lens design and CRO column placement, which they attempted to obtain the parameters that could be optimised to allow for construction of better CROs, as well as the development of electron optical components which could be used to generate low magnification (nearly 1:1) images. In 1931 the group successfully generated magnified images of mesh grids placed over the anode aperture. The device used two magnetic lenses to achieve higher magnifications, arguably the first electron microscope.

Improving Resolution

At this time the wave nature of electrons, which were considered charged matter particles, had not been fully realised until the publication of the De Broglie hypothesis in 1927[4]. The group was unaware of this publication until 1932, where it was quickly realized that the De Broglie wavelength of electrons was many orders of magnitude smaller than that for light, theoretically allowing for imaging at atomic scales. In April 1932, Ruska suggested the construction of a new electron microscope for direct imaging of specimens inserted into the microscope, rather than simple mesh grids or images of apertures. With this device successful diffraction and normal imaging of aluminium sheet was achieved, however exceeding the magnification achievable with light microscopy had still not been successfully demonstrated. This goal was achieved in September 1933, using images of cotton fibers, which were quickly acquired before being damaged by the electron beam.

At this time, interest in the electron microscope had increased, with other groups, such as Albert Prebus and James Hillier at the University of Toronto who constructed the first TEM in north America in 1938 [5], continually advancing TEM design.

Research continued on the electron microscope at Siemens in 1936, the aim of the research was the development improvement of TEM imaging properties, particularly with regard to biological specimens. In 1939 the first commercial electron microscope, pictured, was installed in the Physics department of I. G Farben-Werke. Further work on the electron microscope was hampered by the destruction of a new laboratory constructed at Siemens by an air-raid, as well as the death of two of the researchers, Heinz Müller and Friedrick Krause during World War II[6].

Further research

After world war II, Ruska resumed work at Siemens, where he continued to develop the electron microscope, producing the first 100kx microscope[6]. The fundamental structure of this microscope design, with multi-stage beam preparation optics, is still used in modern microscopes.

With the development of TEM, the associated technique of STEM was re-investigated and did not become developed until the 1970 s, with Albert Crewe at the University of Chicago developing the field emission gun[7] and adding a high quality objective lens to create the modern STEM. Using this design, Crewe demonstrated the ability to image atoms using annular dark-field imaging. Crewe and coworkers at the University of Chicago developed the cold field emission electron source and built a STEM able to visualize single heavy atoms on thin carbon substrates [8].

Background

Theoretically, the maximum resolution, d, that one can obtain with a light microscope has been limited by the wavelength of the photons that are being used to probe the sample, and the numerical aperture of the system, .

Early twentieth century scientists theorised ways of getting around the limitations of the relatively large wavelength of visible light (wavelengths of 400–700 nanometers) by using electrons. Like all matter, electrons have both wave and particle properties (as theorized by Louis-Victor de Broglie), and their wave-like properties mean that a beam of electrons can be made to behave like a beam of electromagnetic radiation. The wavelength of electrons is found to be given by equating the de Broglie equation to the kinetic energy of an electron. An additional correction must be made to account for relativistic effects, as in a TEM an electron's velocity approaches the speed of light, c.

Electrons are usually generated in an electron microscope by a process known as thermionic emission from a filament, usually tungsten, in the same manner as a light bulb, or alternatively by field emission. The electrons are then accelerated by an electric potential (measured in volts) and focused by electrostatic and electromagnetic lenses onto the sample. The transmitted beam contains information about electron density, phase and periodicity; this beam is used to form an image.

Components

A TEM is composed of several components, which include a vacuum system in which the electrons travel, an electron emission source for generation of the electron stream, a series of electromagnetic lenses, as well as electrostatic plates. The latter two allow the operator to guide and manipulate the beam as required.

Vacuum system

In order to allow for uninterrupted passage of electrons, the TEM must be evacuated to low pressures, typically on the order of 10-4 to 10-8 kPa[9]. The need for this is two fold, firstly the allowance for the voltage difference between the cathode and the ground without generating an arc, and secondly to reduce the collision frequency of electrons with gas atoms to negligible levels. As the TEM, unlike a CRT, is a system where components must be replaced, specimens inserted and – particularly on older TEMs – film cartridges must be replenished, the ability to re-evacuate a TEM on a regular basis is required. As such, TEMs are equipped with extensive pumping systems and are not permanently vacuum sealed.

To evacuate a TEM, the vacuum system consists of several stages. High pressure "low vacuum" pumps such as Diaphragm pumps are utilized to perform evacuation of the TEM to a sufficiently low pressure to allow the operation of turbomolecular or diffusion pumps which can reduce the TEM's in column pressure even further. To allow for the low vacuum pump to not require continuous operation, whilst accommodating continuous operation of the turbomolecular pumps, the vacuum side of a low pressure pump may be connected to evacuated chambers which serves no other purpose but the accommodation of the turbomolecular exhaust gases.

For high voltage TEMs, even very high vacuum conditions (low pressure) are sufficient to allow for the generation of an electrical arc, particularly at the TEM cathode [citation needed]. As such for higher voltage TEMs a third vacuum system may operate, with the gun isolated from the main chamber either by use of gate valves or by the use of a differential pumping aperture, which is essentially a small hole that prevents gas molecules from entering a high quality vacuum system faster than they can be pumped out. For these very low pressures either an ion pump or a getter material is used.

Poor vacuum in a TEM can cause several problems, from deposition of gas inside the TEM onto the specimen as it is being viewed through a process known as electron beam induced deposition, or in more severe cases damage to the cathode from a electrical discharge. Vacuum problems owing to specimen sublimation are limited by the use of a cold trap to adsorb sublimated gases in the vicinity of the specimen.

Beam formation

From the top down, the TEM consists of an emission source, which may be a tungsten filament, or a lanthanum hexaboride (LaB6) source. For tungsten, this will be of the form of either a hairpin-style filament, or a small spike-shaped filament. LaB6 sources utilize small single crystals. By connecting this gun to an HV source (Typically ~120 kV for many applications) the gun will, given sufficient current, begin to emit electrons into the vacuum. This extraction is usually aided by the use of a Wehnelt cylinder. Once extracted, the upper lenses of the TEM allow for the formation of the electron probe to the desired size and location for later interaction with the sample[10].

Manipulation of the electron beam is performed using two physical effects. The interaction of electrons with a magnetic field will cause electrons to move according to the right hand rule, thus allowing for electromagnets to manipulate the electron beam. The use of magnetic fields allows for the formation of a magnetic lens of variable focusing power, the lens shape originating due to the distribution of magnetic flux. Additionally, electrostatic fields can cause the electrons to be deflected through a constant angle. Coupling of two deflections in opposing directions with a small intermediate gap allows for the formation of a shift in the beam path, this being used in TEM for beam shifting, subsequently this is extremely important to STEM. From these two effects, as well as the use of an imaging system (such as a phosphor screen), sufficient control over the beam path is possible for TEM operation.

The lenses of a TEM allow for beam convergence, with the angle of convergence as a variable parameter, giving the TEM the ability to change magnification simply by modifying the amount of current that flows through the quadrupole or hexapole lenses. The quadrupole lens is an arrangement of electromagnetic coils at the vertices of the square, enabling the generation of a lensing magnetic fields, the hexapole configuration simply enhances the lens symmetry by using six, rather than four coils.

Typically a TEM consists of three stages of lensing. The stages are the condensor lenses, the objective lenses, and the projector lenses. The condensor lenses are responsible for primary beam formation, whilst the objective lenses focus the beam down onto the sample itself. The projector lenses are used to expand the beam onto the phosphor screen or other imaging device, such as film. The magnification of the TEM is due to the ratio of the distances between the specimen and the objective lens' image plane[11].

It is noted that TEM configurations differ significantly with implementation, with manufacturers using custom lens configurations, such as in spherical aberration corrected instruments[10], or TEMs utilising energy filtering.

Imaging systems in a TEM consist of a phosphor screen for direct observation by the operator and, optionally, an image recording system such as film based or phosphor screen coupled CCDs. Typically these devices can be removed or inserted into the beam path by the operator as required.

Imaging methods

Imaging methods in TEM utilize the information contained in the electron waves exiting from the sample to form an image. The projector lenses allow for the correct positioning of this electron wave distribution onto the viewing system. The observed intensity of the image, I, assuming sufficiently high quality of imaging device, can be approximated as proportional to the time-average amplitude of the electron wavefunctions, where the wave which form the exit beam is denoted by .

Different imaging methods therefore attempt to modify the electron waves exiting the sample in a form that is useful to obtain information with regards to the sample, or beam itself. From the previous equation, it can be deduced that the observed image depends not only on the amplitude of beam, but also the phase of the electrons, although phase effects may often be ignored at lower magnifications.

Contrast Formation

Contrast formation in the TEM depends greatly on the mode of operation. Complex imaging techniques which utilize the unique ability to change lens strength or to deactivate a lens allows for many operating modes. These modes may be used to discern information that is of particular interest to the investigator.

Bright field The most common mode of operation for a TEM is the bright field imaging mode. In this mode the contrast formation, when considered classically, is formed directly by occlusion and absorption of electrons in the sample. Thicker regions of the sample, or regions with a higher atomic number will appear dark, whilst regions with no sample in the beam path will appear bright – hence the term "bright field".

Diffraction contrast

Samples can exhibit diffraction contrast, whereby the electron beam undergoes Bragg scattering, which in the case of a crystalline sample, disperses electrons into discrete locations in the back focal plane. By the placement of apertures in the back focal plane, i. e. the objective aperture, the desired Bragg reflections can be selected (or excluded), thus only parts of the sample that are causing the electrons to scatter to the selected reflections will end up projected onto the imaging apparatus.

If the reflections that are selected do not include the unscattered beam (which will appear up at the focal point of the lens), then the image will appear dark wherever no sample scattering to the selected peak is present, as such a region without a specimen will appear dark. This is known as a dark-field image.

Modern TEMs are often equipped with specimen holders that allow the user to tilt the specimen to a range of angles in order to obtain specific diffraction conditions, and apertures placed above the specimen allow the user to select electrons that would otherwise be diffracted in a particular direction from entering the specimen.

Applications for this method include the identification of lattice defects in crystals. By carefully selecting the orientation of the sample, it is possible not just to determine the position of defects but also to determine the type of defect present. If the sample is orientated so that one particular plane is only slightly tilted away from the strongest diffracting angle (known as the Bragg Angle), any distortion of the crystal plane that locally tilts the plane to the Bragg angle will produce particularly strong contrast variations. However, defects that produce only displacement of atoms that do not tilt the crystal to the Bragg angle (i. e. displacements parallel to the crystal plane) will not produce strong contrast.

Electron Energy Loss

Utilizing the advanced technique of EELS, for TEMs appropriately equipped electrons can be rejected based upon their voltage (which, due to constant charge is their energy), using magnetic sector based devices known as EELS spectrometers. These devices allow for the selection of particular energy values, which can be associated with the way the electron has interacted with the sample. For example different elements in a sample result in different electron energies in the beam after the sample. This normally results in chromatic aberration – however this effect can, for example, be used to generate an image which provides information on elemental composition, based upon the atomic absorption of electrons during electron-electron interaction.

EELS spectrometers can often be operated in both a spectroscopic and imaging modes, allowing for isolation or rejection of elastically scattered beams. As for many images inelastic scattering will include information that may not be of interest to the investigator thus reducing observable signals of interest, EELS imaging can be used to enhance contrast in observed images, including both bright field and diffraction, by rejecting unwanted components.

Phase Contrast

Crystal structure can also be investigated by High Resolution Transmission Electron Microscopy (HRTEM), also known as phase contrast. When utilizing a Field emission source, the images are formed due to differences in phase of electron waves, which is caused by specimen interaction. Image formation is given by the complex modulus of the incoming electron beams. As such, the image is not only dependent on the number of electrons hitting the screen, making direct interpretation of phase contrast images more complex. However this effect can be used to advantage, as it can be manipulated provide more information about the sample, such as in complex phase retrieval techniques.

Diffraction

As previously stated, by adjusting the magnetic lenses such that the back focal plane of the lens is placed on the imaging apparatus a diffraction pattern can be generated. .

For thin crystalline samples, this produces an image that consists of a series of dots in the case of a single crystal, or a series of rings in the case of a polycrystalline material. For the single crystal case the diffraction pattern is dependent upon the orientation of the specimen. This image provides the investigator with information about the space group symmetries in the crystal and the crystal's orientation to the beam path. This is typically done without utilizing any information but the position at which the diffraction spots appear and the observed image symmetries.

Diffraction patterns can have a large dynamic range, and for crystalline samples, may have intensities greater than that which can be recorded by CCD. As such, TEMs may still be equipped with film cartridges for the purpose of obtaining these images

Analysis of diffraction patterns beyond point-position can be complex, as the image is sensitive to a number of factors such as specimen thickness and orientation, objective lens defocus, spherical and chromatic aberration. Although quantitative interpretation of the contrast shown in lattice images is possible, it is inherently complicated and can require extensive computer simulation and analysis, such as multislice analysis[12].

More complex diffraction behavior is also possible, with phenomena such as Kikuchi lines or convergent beam electron diffraction (CBED) providing additional information, beyond structural data, such as sample thickness.

Sample preparation

The TEM is used heavily in material science, metallurgy and the biological sciences. In each case the specimens must be very thin and able to withstand the high vacuum present inside the instrument.

Sample preparation in TEM can be a complex procedure. TEM specimens are typically hundreds of nanometres thick, as the electron beam interacts readily with the sample, an effect that increases roughly with atomic number. High quality samples will have a thickness that is comparable to the mean free path of the electrons that travel through the samples, which may be only a few tens of nanmetres. Preparation of TEM specimens is specific to the material under analysis and the desired information to obtain from the specimen. As such, many generic techniques have been used for the preparation of the required thin sections.

To withstand the instrument vacuum, biological specimens are typically held at liquid nitrogen temperatures after embedding in vitreous ice, or fixated using either a negative staining material such as uranyl acetate or by plastic embedding.

In material science and metallurgy the specimens tend to be naturally resistant to vacuum, but still must be prepared as a thin foil, or etched so some portion of the specimen is thin enough for the beam to penetrate. Constraints on the thickness of the material may be limited by the scattering cross-section of the atoms from which the material is comprised. Materials that have dimensions small enough to be electron transparent, such as powders or nanotubes, can be quickly produced by the deposition of a dilute sample containing the specimen onto support grids or films.

Tissue sectioning

By passing samples over a glass or diamond edge, small, thin sections can be readily obtained using a semi-automated method [13]. This method is used to obtain thin, minimally deformed samples that allow for the observation of tissue samples. Additionally inorganic samples have been studied, such as aluminium, although this usage is limited owing to the heavy damage induced in the less soft samples [14].

Sample Staining

Details in light microscope samples can be enhanced by stains that absorb light. Similarly TEM samples, usually of biological tissues, can utilize stains to enhance contrast. The stain absorbs electrons or scatter out of the part of the electron beam that is projected onto the imaging system. Compounds of heavy metals such as osmium, lead, or uranium may be used prior to TEM observation to selectively deposit electron dense atoms in or on the sample in desired cellular or protein regions.

Mechanical milling Mechanical polishing may be used to prepare samples. Polishing needs to be done to a high quality, to ensure constant sample thickness across the region of interest. A diamond, or cubic boro-nitride polishing compound may be used in the final stages of polishing to remove any scratches that may cause contrast fluctuations due to varying sample thickness. Even after careful mechanical milling, additional fine methods such as ion etching may be required to perform final stage thinning.

Chemical etching Certain samples may be prepared by chemical etching, particularly metallic specimens. These samples are thinned using a chemical etchant, such as an acid, to prepare the sample for TEM observation. Devices to control the thinning process may allow the operator to control either the voltage or current passing through the specimen, and may include systems to detect when the sample has been thinned to a sufficient level of optical transparancy.

Ion etching

Ion etching is a sputtering process that can remove very fine quantities of material. This is used to perform a finishing polish of specimens polished by other means. Ion etching uses an inert gas passed through an electric field to generate a plasma stream that is directed to the sample surface. Accelleration energies for gases such as argon are typically a few kilovolts. The sample may be rotated to promote even polishing of the sample surface. The sputtering rate of such methods are on the order of tens of microns per hour, limiting the method to only extremely fine polishing.

More recently Focussed ion beam methods have been used to prepare samples. FIB is a relatively new technique to prepare thin samples for TEM examination from larger specimens. Because FIB can be used to micro-machine samples very precisely, it is possible to mill very thin membranes from a specific area of interest in a sample, such as a semiconductor or metal. Unlike intert gas ion sputtering, FIB makes use of significantly more energetic gallium ions and may alter the composition or structure of the material through gallium implantation [citation needed].

Modifications

The capabilities of the TEM can be further extended by additional stages and detectors, sometimes incorporated on the same microscope. An electron cryomicroscope is a TEM with a specimen holder capable of maintaining the specimen at liquid nitrogen or liquid helium temperatures. This allows imaging specimens prepared in vitreous ice, the preferred preparation technique for imaging individual molecules or macromolecular assemblies.

A TEM can be modified into a scanning transmission electron microscope (STEM) by the addition of a system that rasters the beam across the sample to form the image, combined with suitable detectors.

An analytical TEM is one equipped with detectors that can determine the elemental composition of the specimen by analyzing its X-ray spectrum or the energy-loss spectrum of the transmitted electrons.

Modern research TEMs may include aberration correctors,[10] to reduce the amount of distortion in the image, allowing information on features on the scale of 0.1& nbsp; nm to be obtained (resolutions down to 0.05& nbsp; nm have been achieved [15]) at magnifications of 50 million times [16]. Incident beam Monochromators may also be used which reduce the energy spread of the incident electron beam to less than 0.15& nbsp; eV. Major TEM makers include JEOL, Hitachi High-technologies, FEI Company (from merging with Philips Electron Optics) and Carl Zeiss.

Limitations

There are a number of drawbacks to the TEM technique. Many materials require extensive sample preparation to produce a sample thin enough to be electron transparent, which makes TEM analysis a relatively time consuming process with a low throughput of samples. Graphene, a carbon nanomaterial, relatively transparent, very hard and just one atom thick, is currently being used as a platform on which the materials to be examined are placed. Being almost transparent to electrons, a graphene substrate has been able to show single hydrogen atom and hydrocarbons. The structure of the sample may also be changed during the preparation process. Also the field of view is relatively small, raising the possibility that the region analyzed may not be characteristic of the whole sample. There is potential that the sample may be damaged by the electron beam, particularly in the case of biological materials.

Resolution limits

Resolution of the HRTEM is limited by spherical and chromatic aberration, but a new generation of aberration correctors has been able to overcome spherical aberration. [10] Software correction of spherical aberration has allowed the production of images with sufficient resolution to show carbon atoms in diamond separated by only 0.89 Ångströms and atoms in silicon at 0.78 Ångströms (78 pm) at magnifications of 50 million times. Improved resolution has also allowed the imaging of lighter atoms that scatter electrons less efficiently—lithium atoms have been imaged in lithium battery materials[17]. The ability to determine the positions of atoms within materials has made the HRTEM an indispensable tool for nanotechnology research and development in many fields, including heterogeneous catalysis and the development of semiconductor devices for electronics and photonics.

See also

- Electron beam induced deposition

- Electron diffraction

- Electron energy loss spectroscopy (EELS)

- Electron microscope

- Energy filtered transmission electron microscopy (EFTEM)

- High-resolution transmission electron microscopy (HRTEM)

- Scanning confocal electron microscopy

- Scanning electron microscope (SEM)

- Scanning transmission electron microscope (STEM)

- Transmission Electron Aberration-corrected Microscope

References

- ^ Plücker, J. (1858). ""Über die Einwirkung des Magneten auf die elektrischen Entladungen in verdünnten Gasen"". Poggendorffs Annalen der Physik und Chemie. 103: 88--106.

- ^ "Ferdinand Braun, The Nobel Prize in Physics 1909, Biography".

- ^ ""The Nobel Prize in Physics 1986, Perspectives - Life through a Lens"".

- ^ Broglie, L. (1928). "La nouvelle dynamique des quanta". Électrons et Photons: Rapports et Discussions du Cinquième Conseil de Physique. Solvay.

- ^ http://comdir.bfree.on.ca/hillier/hilbio.htm

- ^ a b http://nobelprize.org/nobel_prizes/physics/laureates/1986/ruska-lecture.html

- ^ Crewe, Albert V (1969). "A Simple Scanning Electron Microscope". Rev. Sci. Inst. 40: 241–246. doi:10.1063/1.1683910.

{{cite journal}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ Crewe, Albert V (1970). "Visibility of a single atom". Science. 168: 1338–1340. doi:10.1126/science.168.3937.1338. PMID 17731040.

{{cite journal}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - ^ "The Vacuum System Of a TEM".

- ^ a b c d Topical review "Optics of high-performance electron Microscopes" Sci. Technol. Adv. Mater. 9 (2008) 014107 (30pages) free download Cite error: The named reference "rose" was defined multiple times with different content (see the help page).

- ^ "The objective lens of a TEM, the heart of the electron microscope".

- ^ "The Scattering of Electrons by Atoms and Crystals. I. A New Theoretical Approach". Acta Crystallographica. 199 (3): 609–619. 1957.

- ^ "A study in Microtomy for Electron Microscopy". The anatomical record. 117 (4). 1953.

{{cite journal}}: Unknown parameter|authors=ignored (help) - ^ Phillips (1961). "Diamond knife ultra microtomy of metals and the structure

of microtomed sections". British Journal of Applied Physics. 12.

{{cite journal}}: line feed character in|title=at position 58 (help) - ^ TEAM Project Achieves Microscopy Breakthrough

- ^ The Scale of Things (Office of Basic Energy Sciences)

- ^ "Imaging lithium atoms at sub-Ångström resolution" (PDF).

External links

- The National Center for Electron Microscopy, Berkeley California USA

- The National Center for Macromolecular Imaging, Houston Texas USA

- The National Resource for Automated Molecular Microscopy, La Jolla California USA

- Manufacturer of TEM's (FEI Company)

- Delong Group

- Tutorial courses in Transmission Electron Microscopy

- Cambridge University Teaching and Learning Package on TEM