Flywheel energy storage: Difference between revisions

m Bot: Migrating 1 interwiki links, now provided by Wikidata on d:q1538992 |

Quinacrine (talk | contribs) |

||

| Line 276: | Line 276: | ||

==External links== |

==External links== |

||

*Boeing Flywheel Energy Storage Technology https://www.uaf.edu/files/acep/BoeingFlywheelOverview_06_20_2012.pdf |

|||

*Federal Technology Alert, Flywheel Energy Storage http://www.edsenerji.com.tr/userfiles/files/Federal%20Alert.pdf |

|||

*Ricardo Kinergy project http://www.greencarcongress.com/2009/11/kinergy-20091124.html |

*Ricardo Kinergy project http://www.greencarcongress.com/2009/11/kinergy-20091124.html |

||

*Magnetal Whitepaper for its Green Energy Storage System - GESS http://www.magnetal.se/GESS.pdf |

*Magnetal Whitepaper for its Green Energy Storage System - GESS http://www.magnetal.se/GESS.pdf |

||

Revision as of 18:06, 17 April 2013

Flywheel energy storage (FES) works by accelerating a rotor (flywheel) to a very high speed and maintaining the energy in the system as rotational energy. When energy is extracted from the system, the flywheel's rotational speed is reduced as a consequence of the principle of conservation of energy; adding energy to the system correspondingly results in an increase in the speed of the flywheel.

Most FES systems use electricity to accelerate and decelerate the flywheel, but devices that directly use mechanical energy are being developed.[1]

Advanced FES systems have rotors made of high strength carbon filaments, suspended by magnetic bearings, and spinning at speeds from 20,000 to over 50,000 rpm in a vacuum enclosure.[2] Such flywheels can come up to speed in a matter of minutes — much quicker than some other forms of energy storage.[2]

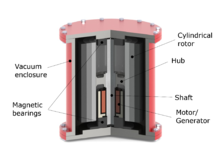

Main components

A typical system consists of a rotor suspended by bearings inside a vacuum chamber to reduce friction, connected to a combination electric motor and electric generator.

First generation flywheel energy storage systems use a large steel flywheel rotating on mechanical bearings. Newer systems use carbon-fiber composite rotors that have a higher tensile strength than steel but are an order of magnitude less heavy.[3]

Magnetic bearings are sometimes used instead of mechanical bearings, to reduce friction.

The expense of refrigeration led to the early dismissal of low temperature superconductors for use in magnetic bearings. However, high-temperature superconductor (HTSC) bearings may be economical and could possibly extend the time energy could be stored economically. Hybrid bearing systems are most likely to see use first. High-temperature superconductor bearings have historically had problems providing the lifting forces necessary for the larger designs, but can easily provide a stabilizing force. Therefore, in hybrid bearings, permanent magnets support the load and high-temperature superconductors are used to stabilize it. The reason superconductors can work well stabilizing the load is because they are perfect diamagnets. If the rotor tries to drift off center, a restoring force due to flux pinning restores it. This is known as the magnetic stiffness of the bearing. Rotational axis vibration can occur due to low stiffness and damping, which are inherent problems of superconducting magnets, preventing the use of completely superconducting magnetic bearings for flywheel applications.

Since flux pinning is the important factor for providing the stabilizing and lifting force, the HTSC can be made much more easily for FES than for other uses. HTSC powders can be formed into arbitrary shapes so long as flux pinning is strong. An ongoing challenge that has to be overcome before superconductors can provide the full lifting force for an FES system is finding a way to suppress the decrease of levitation force and the gradual fall of rotor during operation caused by the flux creep of SC material.

Physical characteristics

General

Compared with other ways to store electricity, FES systems have long lifetimes (lasting decades with little or no maintenance;[2] full-cycle lifetimes quoted for flywheels range from in excess of 105, up to 107, cycles of use),[4] high energy density (100-130 W·h/kg, or 360-500 kJ/kg),[4][5] and large maximum power output. The energy efficiency (ratio of energy out per energy in) of flywheels can be as high as 90%. Typical capacities range from 3 kWh to 133 kWh.[2] Rapid charging of a system occurs in less than 15 minutes.[6] The high energy densities often cited with flywheels can be a little misleading as commercial systems built have much lower energy density, for example 11 W·h/kg, or 40 kJ/kg.[7]

Energy density

The maximum energy density of a flywheel rotor is mainly dependent on two factors, the first being the rotor's geometry, and the second being the properties of the material being used. For single-material, isotropic rotors this relationship can be expressed as[8]

- ,

where the variables are defined as follows:

- - kinetic energy of the rotor [J]

- - the rotor's mass [kg]

- - the rotor's geometric shape factor [dimensionless]

- - the tensile strength of the material [Pa]

- - the material's density [kg/m^3]

Geometry (shape factor)

The highest possible value for the shape factor of a flywheel rotor, is , which can only be achieved by the theoretical constant-stress disc geometry.[9] A constant-thickness disc geometry has a shape factor of , while for a rod of constant thickness the value is . A thin cylinder has a shape factor of .

Material properties

For energy storage purposes, materials with high strength, and low density are desirable. For this reason, composite materials are frequently being used in advanced flywheels. The strength-to-density ratio of a material can be expressed in the units [Wh/kg], and values greater than 400 Wh/kg can be achieved by certain composite materials.

Composite rotors

Several modern flywheel rotors are made from composite materials. Examples include the Smart Energy 25 flywheel from Beacon Power Corporation,[10] and the PowerThru flywheel from Phillips Service Industries.[11]

For these rotors, the relationship between material properties, geometry and energy density can be expressed by using a weighed-average approach.[12]

Tensile strength and failure modes

One of the primary limits to flywheel design is the tensile strength of the material used for the rotor. Generally speaking, the stronger the disc, the faster it may be spun, and the more energy the system can store.

When the tensile strength of a composite flywheel's outer binding cover is exceeded the binding cover will fracture, followed by the wheel shattering as the outer wheel compression is lost around the entire circumference, releasing all of its stored energy at once; this is commonly referred to as "flywheel explosion" since wheel fragments can reach kinetic energy comparable to that of a bullet. Composite materials that are wound and glued in layers tend to disintegrate quickly, first into small-diameter filaments that entangle and slow each other, and then into red-hot powder, instead of large chunks of high-velocity shrapnel as can occur with a cast metal flywheel.

For a cast metal flywheel, the failure limit is the binding strength of the grain boundaries of the polycrystalline molded metal. Aluminum in particular suffers from fatigue and can develop microfractures due to repeated low-energy stretching. Angular forces may cause portions of a metal flywheel to bend outward and begin dragging on the outer containment vessel, or to separate completely and bounce randomly around the interior. The rest of the flywheel is now severely unbalanced, which may lead to rapid bearing failure from vibration, and sudden shock fracturing of large segments of the flywheel.

Traditional flywheel systems require strong containment vessels as a safety precaution, which increases the total mass of the device. The energy release from failure can be dampened with a gelatinous or encapsulated liquid inner housing lining, which will boil and absorb the energy of destruction. Still, many customers of large-scale flywheel energy-storage systems prefer to have them embedded in the ground to halt any material that might escape the containment vessel.

Energy storage efficiency

An additional limitation for some flywheel types is energy storage time. Flywheel energy storage systems using mechanical bearings can lose 20% to 50% of their energy in 2 hours.[13] Much of the friction responsible for this energy loss results from the flywheel changing orientation due to the rotation of the earth (a concept similar to a Foucault pendulum). This change in orientation is resisted by the gyroscopic forces exerted by the flywheel's angular momentum, thus exerting a force against the mechanical bearings. This force increases friction. This can be avoided by aligning the flywheel's axis of rotation parallel to that of the earth's axis of rotation.

Conversely, flywheels with Magnetic bearings and high vacuum can maintain 97% mechanical efficiency, and 85% round trip efficiency.[14]

Effects of angular momentum in vehicles

When used in vehicles, flywheels also act as gyroscopes, since their angular momentum is typically of a similar order of magnitude as the forces acting on the moving vehicle. This property may be detrimental to the vehicle's handling characteristics while turning or driving on rough ground; driving onto the side of a sloped embankment may cause wheels to partially lift off the ground as the flywheel opposes sideways tilting forces. On the other hand, this property could be utilized to keep the car balanced so as to keep it from rolling over during sharp turns.[15]

The resistance of angular tilting can be almost completely removed by mounting the flywheel within an appropriately applied set of gimbals, allowing the flywheel to retain its original orientation without affecting the vehicle (see Properties of a gyroscope). This doesn't avoid the complication of gimbal lock, and so a compromise between the number of gimbals and the angular freedom is needed.

The center axle of the flywheel acts as a single gimbal, and if aligned vertically, allows for the 360 degrees of yaw in a horizontal plane. However, for instance driving up-hill requires a second pitch gimbal, and driving on the side of a sloped embankment requires a third roll gimbal.

Full-motion gimbals

Although the flywheel itself may be of a flat ring shape, a free-movement gimbal mounting inside a vehicle requires a spherical volume for the flywheel to freely rotate within. Left to its own, a spinning flywheel in a vehicle would slowly precess following the Earth's rotation, and precess further yet in vehicles that travel long distances over the Earth's curved spherical surface.

A full-motion gimbal has additional problems of how to communicate power into and out of the flywheel, since the flywheel could potentially flip completely over once a day, precessing as the Earth rotates. Full free rotation would require slip rings around each gimbal axis for power conductors, further adding to the design complexity.

Limited-motion gimballs

To reduce space usage, the gimbal system may be of a limited-movement design, using shock absorbers to cushion sudden rapid motions within a certain number of degrees of out-of-plane angular rotation, and then gradually forcing the flywheel to adopt the vehicle's current orientation. This reduces the gimbal movement space around a ring-shaped flywheel from a full sphere, to a short thickened cylinder, encompassing for example +/- 30 degrees of pitch and +/- 30 degrees of roll in all directions around the flywheel.

Counterbalancing of angular momentum

An alternative solution to the problem is to have two joined flywheels spinning synchronously in opposite directions. They would have a total angular momentum of zero and no gyroscopic effect. A problem with this solution is that when the difference between the momentum of each flywheel is anything other than zero the housing of the two flywheels would exhibit torque. Both wheels must be maintained at the same speed to keep the angular velocity at zero. Strictly speaking, the two flywheels would exert a huge torqueing moment at the central point, trying to bend the axle. However, if the axle were sufficiently strong, no gyroscopic forces would have a net effect on the sealed container, so no torque would be noticed.

To further balance the forces and spread out strain, a single large flywheel can be balanced by two half-size flywheels on each side, or the flywheels can be reduced in size to be a series of alternating layers spinning in opposite directions. However this increases housing and bearing complexity.

Applications

Transportation

Road

In the 1950s, flywheel-powered buses, known as gyrobuses, were used in Yverdon, Switzerland and there is ongoing research to make flywheel systems that are smaller, lighter, cheaper and have a greater capacity. It is hoped that flywheel systems can replace conventional chemical batteries for mobile applications, such as for electric vehicles. Proposed flywheel systems would eliminate many of the disadvantages of existing battery power systems, such as low capacity, long charge times, heavy weight and short usable lifetimes. Flywheels may have been used in the experimental Chrysler Patriot, though that has been disputed.[16]

Flywheels have also been proposed for use in continuously variable transmissions. Punch Powertrain is currently working on such a device.[17]

During the 1990s, Rosen Motors developed a gas turbine powered series hybrid automotive powertrain using a 55,000 rpm flywheel to provide bursts of acceleration which the small gas turbine engine could not provide. The flywheel also stored energy through regenerative braking. The flywheel was composed of a titanium hub with a carbon fiber cylinder and was gimbal-mounted to minimize adverse gyroscopic effects on vehicle handling. The prototype vehicle was successfully road tested in 1997 but was never mass-produced.[18]

Rail vehicles

Flywheel systems have also been used experimentally in small electric locomotives for shunting or switching, e.g. the Sentinel-Oerlikon Gyro Locomotive. Larger electric locomotives, e.g. British Rail Class 70, have sometimes been fitted with flywheel boosters to carry them over gaps in the third rail. Advanced flywheels, such as the 133 kW·h pack of the University of Texas at Austin, can take a train from a standing start up to cruising speed.[2]

The Parry People Mover is a railcar which is powered by a flywheel. It was trialled on Sundays for 12 months on the Stourbridge Town Branch Line in the West Midlands, England during 2006 and 2007 and was intended to be introduced as a full service by the train operator London Midland in December 2008 once two units had been ordered. In January 2010, both units are in operation.[19]

Rail electrification

FES can be used at the lineside of electrified railways to help regulate the line voltage thus improving the acceleration of unmodified electric trains and the amount of energy recovered back to the line during regenerative braking, thus lowering energy bills.[20] Trials have taken place in London, New York, Lyon and Tokyo,[21] and New York MTA's Long Island Rail Road is now investing $5.2m in a pilot project on LIRR's West Hempstead Branch line.[22]

Uninterruptible power supplies

Flywheel power storage systems in production as of 2001 have storage capacities comparable to batteries and faster discharge rates. They are mainly used to provide load leveling for large battery systems, such as an uninterruptible power supply for data centers as they save a considerable amount of space compared to battery systems.[23]

Flywheel maintenance in general runs about one-half the cost of traditional battery UPS systems. The only maintenance is a basic annual preventive maintenance routine and replacing the bearings every five to ten years, which takes about four hours.[6] Newer flywheel systems completely levitate the spinning mass using maintenance-free magnetic bearings, thus eliminating mechanical bearing maintenance and failures.[6]

Costs of a fully installed flywheel UPS are about $330 per kilowatt.[24] In combination with a diesel generator set or integrated design, it supplies continuous power as long as there is fuel.

Laboratories

A long-standing niche market for flywheel power systems are facilities where circuit-breakers and similar devices are tested: even a small household circuit-breaker may be rated to interrupt a current of 10,000 or more amperes, and larger units may have interrupting ratings of 100,000 or 1,000,000 amperes. The enormous transient loads produced by deliberately forcing such devices to demonstrate their ability to interrupt simulated short circuits would have unacceptable effects on the local grid if these tests were done directly from building power. Typically such a laboratory will have several large motor-generator sets, which can be spun up to speed over some minutes; then the motor is disconnected before a circuit breaker is tested.

Other similar high power applications are in tokamak fusion (like the Joint European Torus) and laser experiments, where very high currents are also used for very brief intervals. JET has two 775 ton flywheels that can spin up to 225 rpm.[25]

Amusement rides

The Incredible Hulk roller coaster at Universal's Islands of Adventure features a rapidly accelerating uphill launch as opposed to the typical gravity drop. This is achieved through powerful traction motors that throw the car up the track. To achieve the brief very high current required to accelerate a full coaster train to full speed uphill, the park utilizes several motor generator sets with large flywheels. Without these stored energy units, the park would have to invest in a new substation or risk browning-out the local energy grid every time the ride launches.

Pulse power

Since FES can store and release energy quickly, they have found a niche providing pulsed power (see compulsator).

Motor sports

The FIA has re-allowed the use of KERS (see kinetic energy recovery system) as part of its Formula One 2009 Sporting Regulations.[26] which is now back in for the 2011 Formula 1 season. Using a continuously variable transmission (CVT), energy is recovered from the drive train during braking and stored in a flywheel. This stored energy is then used during acceleration by altering the ratio of the CVT.[27] In motor sports applications this energy is used to improve acceleration rather than reduce carbon dioxide emissions—although the same technology can be applied to road cars to improve fuel efficiency.[28]

Automobile Club de l'Ouest, the organizer behind the annual 24 Hours of Le Mans event and the Le Mans Series, is currently "studying specific rules for LMP1 which will be equipped with a kinetic energy recovery system."[29]

Grid energy storage

Beacon Power opened a 20 MW, (5 MWh over 15 mins)[14] flywheel energy storage plant in Stephentown, New York in 2011.[30] Lower carbon emissions, faster response times and ability to buy power at off-peak hours are among some advantages of using flywheels instead of traditional sources of energy for peaking power plants.[31]

Wind turbines

Flywheels may be used to store energy generated by wind turbines during off-peak periods or during high wind speeds.

Beacon Power began testing of their Smart Energy 25 (Gen 4) flywheel energy storage system at a wind farm in Tehachapi, California. The system is part of a wind power/flywheel demonstration project being carried out for the California Energy Commission (Beacon Power Press Release March 2010).

Toys

Friction motors used to power many toy cars, trucks, trains, action toys and such, are simple flywheel motors.

Toggle action presses

In industry, toggle action presses are still popular. The usual arrangement involves a very strong crankshaft and a heavy duty connecting rod which drives the tup. Large and heavy flywheels are driven by electric motors but the flywheels only turn the crankshaft when clutches are activated.

Comparison to batteries

This article contains a pro and con list. (November 2012) |

Flywheels are not as adversely affected by temperature changes, can operate at a much wider temperature range, and are not subject to many of the common failures of chemical rechargeable batteries.[32] They are also less potentially damaging to the environment, being largely made of inert or benign materials.

Unlike lithium ion polymer batteries which operate for a finite period of roughly 36 months, a flywheel can potentially have an indefinite working lifespan. Flywheels built as part of James Watt steam engines have been continuously working for more than two hundred years.[33] Working examples of ancient flywheels used mainly in milling and pottery can be found in many locations in Africa, Asia, and Europe.[34][35]

However, this is a somewhat unfair comparison because batteries are typically a complex sealed device that is minimally maintained throughout its service life. Flywheels in a sealed device would have a similar lifespan because eventually components such as bearings wear out and need replacement. Open flywheels are subject to airborne dust collecting in the bearing grease, which will lead to loss of efficiency and eventually seizure if the grease is not periodically replaced or replenished.

Bearing replacement can be quite difficult due to the high mass of the flywheel, and may require a large crane to lift and support it while the bearings are serviced. Severe injury or death from pinching and crushing can occur during servicing due to the very high mass of the flywheel, which also has the potential to roll away at high speed on gently sloped surfaces, if not properly restrained or supported during servicing.

Another advantage of flywheels is that by a simple measurement of the rotation speed it is possible to know the exact amount of energy stored.

See also

- Energy storage

- List of energy topics

- Compensated pulsed alternator

- Grid energy storage

- Launch loop

- List of energy storage projects

- Plug-in hybrid

- Rechargeable battery

- Regenerative brake

- Electric double-layer capacitor

- Rotational energy

References

- ^ Torotrak Toroidal variable drive CVT, retrieved June 7, 2007.

- ^ a b c d e Castelvecchi, Davide (May 19 2007). "Spinning into control: High-tech reincarnations of an ancient way of storing energy". Science News. 171 (20): 312–313. doi:10.1002/scin.2007.5591712010.

{{cite journal}}: Check date values in:|date=(help) - ^ Flybrid System KERS using carbon fiber flywheel

- ^ a b Storage Technology Report, ST6 Flywheel

- ^ "Next-gen Of Flywheel Energy Storage". Product Design & Development. Retrieved 2009-05-21.

- ^ a b c Vere, Henry. "A Primer of Flywheel Technology". Distributed Energy. Retrieved 2008-10-06.

- ^ rosseta Technik GmbH, Flywheel Energy Storage Model T4, retrieved February 4, 2010.

- ^ Genta, Giancarlo (1985). Kinetic Energy Storage. London: Butterworth & Co. Ltd.

- ^ Genta, Giancarlo (1989). "Some considerations on the constant stress disc profile". Meccanica. 24: 235–248. doi:10.1007/BF01556455.

- ^ "Smart Energy 25 Flywheel". Retrieved 2012-04-29.

- ^ "PowerThru flywheel". Retrieved 2012-04-29.

- ^ Janse van Rensburg, P.J. "Energy storage in composite flywheel rotors". University of Stellenbosch.

- ^ rosseta Technik GmbH, Flywheel Energy Storage, German, retrieved February 4, 2010.

- ^ a b Beacon Power Corp, Frequency Regulation and Flywheels fact sheet, retrieved July 11, 2011.

- ^ Study on Rollover prevention of heavy-duty vehicles by using flywheel energy storage systems, Suda Yoshihiro, Huh Junhoi, Aki Masahiko, Shihpin Lin, Ryoichi Takahata, Naomasa Mukaide, Proceedings of the FISITA 2012 World Automotive Congress, Lecture Notes in Electrical Engineering Volume 197, 2013, pp 693-701, doi:10.1007/978-3-642-33805-2_57

- ^ Allpar - The Chrysler Patriot

- ^ Punch Powertrain working on flywheel-equipped CVT

- ^ Wakefield, Ernest (1998). History of the Electric Automobile: Hybrid Electric Vehicles. SAE. p. 332. ISBN 0-7680-0125-0.

- ^ "Parry People Movers for Stourbridge branch line". London Midland. 2008-01-03. Archived from the original on 2008-05-17. Retrieved 2008-03-19.

- ^ "High-speed flywheels cut energy bill". Railway Gazette International. 2001-04-01. Retrieved 2010-12-02.

- ^ "Kinetic energy storage wins acceptance". Railway Gazette International. 2004-04-01. Retrieved 2010-12-02.

- ^ "New York orders flywheel energy storage". Railway Gazette International. 2009-08-14. Retrieved 2011-02-09.

- ^ "Flywheel gains as alternative to batteries".

- ^ Active Power Article – Flywheel energy storage

- ^ "Week 20: JET Experiments: sensitive to TV schedules".

- ^ F1 technical regulations

- ^ - Flybrid Systems

- ^ - Flybrid Systems, Road Car Application

- ^ "ACO Technical Regulations 2008 for Prototype "LM"P1 and "LM"P2 classes, page 3" (PDF). Automobile Club de l'Ouest (ACO). 2007-12-20. Retrieved 2008-04-10. [dead link]

- ^ Beacon Power Flywheel Plant in Stephentown Reaches Full 20 MW Capacity

- ^ Flywheel-based Solutions for Grid Reliability

- ^ http://www.mpoweruk.com/lithium_failures.htm

- ^ Powerhouse Museum. "Boulton and Watt steam engine". Powerhouse Museum, Australia. Retrieved 2 August 2012.

- ^ Donners, K.; Waelkens, M.; Deckers, J. (2002). "Water Mills in the Area of Sagalassos: A Disappearing Ancient Technology". Anatolian Studies. 52: 1–17. doi:10.2307/3643076.

- ^ Wilson, A. (2002). "Machines, Power and the Ancient Economy". The Journal of Roman Studies. 92: 1–32. doi:10.2307/3184857.

Further reading

- Beacon Power Applies for DOE Grants to Fund up to 50% of Two 20 MW Energy Storage Plants, Sep. 1, 2009 [1]

- Sheahen, T., P. (1994). Introduction to High-Temperature Superconductivity. New York: Plenum Press. pp. 76–78, 425–431. ISBN 0-306-44793-2.

{{cite book}}: CS1 maint: multiple names: authors list (link) - El-Wakil, M., M. (1984). Powerplant Technology. McGraw-Hill. pp. 685–689.

{{cite book}}: CS1 maint: multiple names: authors list (link) - Koshizuka, N. (2003). "Progress of superconducting bearing technologies for flywheel energy storage systems". Physica C (386): 444–450.

{{cite journal}}: Unknown parameter|coauthors=ignored (|author=suggested) (help) - Wolsky, A., M. (2002). "The status and prospects for flywheels and SMES that incorporate HTS". Physica C (372–376): 1495–1499.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - Sung, T., H. (2002). "Designs and analyses of flywheel energy storage systems using high-Tc superconductor bearings". Cryogenics. 42 (6–7): 357–362. doi:10.1016/S0011-2275(02)00057-7.

{{cite journal}}: Unknown parameter|coauthors=ignored (|author=suggested) (help)CS1 maint: multiple names: authors list (link) - Akhil, Abbas (2007). "Cost Analysis of Energy Storage Systems for Electric Utility Applications" (pdf). Sandia National laboratories.

{{cite web}}: Unknown parameter|coauthors=ignored (|author=suggested) (help); Unknown parameter|month=ignored (help) - Larbalestier, David (1997). "Flywheels". Power Applications of Superconductivity in Japan and Germany. World Technology Evaluation Center.

{{cite web}}: Unknown parameter|coauthors=ignored (|author=suggested) (help); Unknown parameter|month=ignored (help)CS1 maint: extra punctuation (link) - "A New Look at an Old Idea: The Electromechanical Battery" (PDF). Science & Technology Review. Lawrence Livermore National Laboratory: 12–19. 1996.

{{cite journal}}: Unknown parameter|month=ignored (help) - Janse van Rensburg, P.J. (2011). "Energy storage in composite flywheel rotors". University of Stellenbosch, South Africa.

{{cite web}}: Unknown parameter|month=ignored (help) - Devitt, Drew (2010). "Making a case for flywheel energy storage". Renewable Energy World Magazine North America.

{{cite web}}: Unknown parameter|month=ignored (help)

External links

- Boeing Flywheel Energy Storage Technology https://www.uaf.edu/files/acep/BoeingFlywheelOverview_06_20_2012.pdf

- Federal Technology Alert, Flywheel Energy Storage http://www.edsenerji.com.tr/userfiles/files/Federal%20Alert.pdf

- Ricardo Kinergy project http://www.greencarcongress.com/2009/11/kinergy-20091124.html

- Magnetal Whitepaper for its Green Energy Storage System - GESS http://www.magnetal.se/GESS.pdf

- Magnetal analysis on gyro forces induced by flywheel energy storage - http://www.magnetal.se/MagnetalGyro.pdf