Cathode-ray tube: Difference between revisions

No edit summary |

No edit summary |

||

| Line 12: | Line 12: | ||

</ol>]] |

</ol>]] |

||

The '''cathode ray tube (CRT)''', invented by [[Germany|German]] [[physics|physicist]] [[Karl Ferdinand Braun]] in 1897, is the [[display device]] that was first used for [[computer display]]s, [[video monitor]]s, [[television]]s, [[radar]] displays and [[oscilloscope]]s. The CRT developed from [[Philo Farnsworth]]'s work was used in all television sets until the |

The '''cathode ray tube (CRT)''', invented by [[Germany|German]] [[physics|physicist]] [[Karl Ferdinand Braun]] in 1897, is the [[display device]] that was first used for [[computer display]]s, [[video monitor]]s, [[television]]s, [[radar]] displays and [[oscilloscope]]s. The CRT developed from [[Philo Farnsworth]]'s work was used in all television sets until the 1990s and the development of practical [[plasma screen]]s, [[Liquid crystal display television|LCD TVs]], [[DLP]], [[Organic light-emitting diode|OLED]] displays, and other technologies. As a result of CRT technology, [[television]] has aquired the monniker "the tube" even when referring to non-CRT sets. |

||

A cathode ray tube technically refers to any electronic vacuum tube employing a focused beam of electrons. This article will concentrate on the families of cathode ray tubes used as displays for television, radar, oscilloscopes etc. Another important type of cathode ray tube is the [[video camera tube]]. |

A cathode ray tube technically refers to any electronic vacuum tube employing a focused beam of electrons. This article will concentrate on the families of cathode ray tubes used as displays for television, radar, oscilloscopes etc. Another important type of cathode ray tube is the [[video camera tube]]. |

||

Revision as of 09:50, 29 December 2006

- Electron guns

- Electron beams

- Focusing coils

- Deflection coils

- Anode connection

- Mask for separating beams for red, green, and blue part of displayed image

- Phosphor layer with red, green, and blue zones

- Close-up of the phosphor-coated inner side of the screen

The cathode ray tube (CRT), invented by German physicist Karl Ferdinand Braun in 1897, is the display device that was first used for computer displays, video monitors, televisions, radar displays and oscilloscopes. The CRT developed from Philo Farnsworth's work was used in all television sets until the 1990s and the development of practical plasma screens, LCD TVs, DLP, OLED displays, and other technologies. As a result of CRT technology, television has aquired the monniker "the tube" even when referring to non-CRT sets.

A cathode ray tube technically refers to any electronic vacuum tube employing a focused beam of electrons. This article will concentrate on the families of cathode ray tubes used as displays for television, radar, oscilloscopes etc. Another important type of cathode ray tube is the video camera tube.

General description

The earliest version of the CRT was a cold-cathode diode, a modification of the Crookes tube with a phosphor-coated screen, sometimes called a Braun tube. The first version to use a hot cathode was developed by John B. Johnson (who gave his name to the term Johnson noise) and Harry Weiner Weinhart of Western Electric, and became a commercial product in 1922.

Cathode rays exist in the form of streams of high speed electrons emitted from the heating of a cathode inside a vacuum tube, at its rear end. The emitted electrons form a beam within the tube due to the voltage difference applied across the two electrodes (the CRT screen typically forms the anode). The beam is then perturbed (deflected), either by a magnetic or an electric field, to trace over ('scan') the inside surface of the screen (anode). The screen is covered with a phosphorescent coating (often transition metals or rare earth elements), which emits visible light when excited by the electrons.

In television sets and modern computer monitors, the entire front area of the tube is scanned systematically in a fixed pattern called a raster. An image is produced by modulating the intensity of the electron beam with a received video signal (or another signal derived from it). In all modern TV sets, the beam is deflected with a magnetic field applied to the neck of the tube with a "magnetic yoke", a set of wire coils driven by electronic circuits. This usage of electromagnets to change the electron beam's original direction is known as "magnetic deflection".

The source of the electron beam is the electron gun, which produces a stream of electrons through thermionic emission, and focuses it into a thin beam. The gun is located in the narrow, cylindrical neck at the extreme rear of a CRT and has electrical connecting pins, usually arranged in a circular configuration, extending from its end. These pins provide external connections to the cathode, to various grid elements in the gun used to focus and modulate the beam, and, in electrostatic deflection CRTs, to the deflection plates. Since the CRT is a hot-cathode device, these pins also provide connections to one or more filament heaters within the electron gun. When a CRT is operating, the heaters can often be seen glowing orange through the glass walls of the CRT neck. The need for these heaters to 'warm up' causes a delay between the time that a CRT is first turned on, and the time that a display becomes visible. In older tubes, this could take fifteen seconds or more; modern CRT displays have fast-starting circuits which produce an image within about two seconds, using either briefly increased heater current or elevated cathode voltage. Once the CRT has warmed up, the heaters stay on continuously. The electrodes are often covered with a black layer, a patented process used by all major CRT manufacturers to improve electron density.

The electron gun is often mounted slightly off-axis, as it accelerates not only electrons but also ions present in the imperfect vacuum (some of which result from outgassing of the internal tube components). These ions are heavier than electrons, and therefore are deflected less by the magnetic field from the deflection coils; in older constructions with in-axis guns, the ions bombard the phosphor in the center of the screen and accelerate deterioration. Some very old black and white TV sets show browning of the center of the screen, known as ion burn, from this bombardment. The combination of an off-axis mounting of the electron gun and permanent magnets bending the electron beam back in the desired direction forms an ion trap. The particles are deflected towards the side of the neck of the tube, and only the lighter electrons are deflected sufficiently back towards the screen; the heavier ions hit the side of the tube and dissipate (this system was later replaced by the aluminium coating mentioned below).

The interior side of the phosphor layer is often covered with a layer of aluminium. The phosphors are usually poor electrical conductors, which leads to deposition of residual charge on the screen, effectively decreasing the energy of the impacting electrons due to electrostatic repulsion (an effect known as "sticking"). The aluminium layer is connected to the conductive layer inside the tube, and disposes of this charge. Additionally, it reflects the phosphor light in the desired direction (towards the viewer), and protects the phosphor from ion bombardment.

Oscilloscope tubes

For use in an oscilloscope, the design somewhat different. Rather than tracing out a raster, the electron beam is directly steered along an arbitrary path, while its intensity is kept constant. In time-domain mode, the usual mode, the horizontal deflection is proportional to time (measured out by a "sweep oscillator" in the oscilloscope, visually progressing across the screen at a constant rate), and the vertical deflection is proportional to the measured signal(s). In the less-common X-Y mode, both the horizontal and vertical deflections are proportional to measured signals. The electron gun is always centered in the tube neck; the problem of ion production is either ignored or mitigated by using an aluminized screen.

Tubes designed for oscilloscope use are longer and narrower than tubes designed for raster scan use, greatly reducing the maximum deflection angle required. This allows for the use of electrostatic deflection instead of magnetic deflection. In this case, deflection is caused by applying an electrical field via deflection plates built into the tube's neck. This method allows the electron beam to be steered much more rapidly than with a magnetic field, where the inductance of the electromagnets imposes relatively severe limits on the maximum frequency in the signal that can be accurately represented. The reduced deflection angle also removes any need for dynamic focusing of the electron beam (which would be difficult to accomplish at the required high deflection speeds). Finally, the limited angle makes it much easier to ensure that the beam deflection produced is a linear function of the signal being traced.

There are problems with electrostatic deflection, however. One is that the deflection plates appear as a fairly large capacitive load to the deflection amplifiers, requiring large current flows to charge and discharge this capacitance rapidly. Another, more subtle, problem is that when the electrostatic charge switches, electrons which are already part of the way through the deflection plate region will only be partially deflected. This results in the electron beam 'slewing' along the screen behind the change in charge.

Extremely high performance oscilloscopes avoid these problem by subdividing the vertical (and sometimes horizontal) deflection plates into a series of plates along the length of the "deflection" region of the CRT, and electrically joined by a delay line terminated in its characteristic impedance; the timing of the delay line is set to match the velocity of the electrons through the deflection region. In this way, a change of charge "flows along" the deflection plate along with the electrons that it should affect, almost negating its effect on those electrons which are already partially through the region. Resultantly, the beam (as seen on the screen) slews almost instantly from the old point to the new point. In addition, because the entire deflection system operates as a matched-impedance load, the problem of driving a large capacitive load is mitigated.

A few tubes designed for use in so-called dual beam oscilloscopes contain an electron gun that produces two electron beams. The horizontal deflection of these beams is usually (though not always) shared, while the vertical deflection plates are independent (allowing a time-domain display to show two signals simultaneously).

Many modern oscilloscope tubes pass the electron beam through an expansion mesh. This mesh acts like a lens for electrons and has the effect of roughly doubling the deflection of the electron beam, allowing the use of a larger faceplate for the same length of tube envelope. The expansion mesh also tends to increase the "spot size" on the screen, but this tradeoff is usually acceptable.

If the electron beam is made to change position too quickly, an insufficient amount of excitation of phosphor may occur, rendering the image difficult or impossible to observe. Oscilloscope CRTs designed for the fastest use pass the electron beam through a micro-channel plate just before the electrons reach the screen. Through the phenomenon of secondary emission, this plate greatly multiplies the number of electrons reaching the phosphor screen, amplifying the light produced by the electron beam.

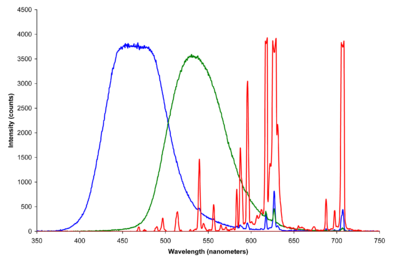

The phosphors used in the screens of oscilloscope tubes are also different from those used in the screens of display tubes. Because the display may be a single-shot event, these phosphor are usually have much longer persistence than those chosen for a CRT displaying a moving picture. Also, its color is usually chosen for maximum efficiency. For oscilloscope displays viewed by the human eye, this usually leads to the iconic P31 green trace. This phosphor yields the best trade-off between visibility, photographability, and resistance to burning by the electron beam. For displays meant to be photographed, the deep blue trace of P11 phosphor is sometimes chosen, while for extremely slow displays, very-long persistence phosphors such as P7, which produce an amber or yellow afterimage, may be used.

The phosphor screen of most oscilloscope tubes contains a permanently-marked internal graticule, dividing the screen using Cartesian coordinates. This internal graticule allows for the easy measurement of signals with no worries about parallax error. Less expensive oscilloscope tubes may instead have an external graticule of glass or acrylic plastic. In either case, the graticule can often be illuminated for use in a darkened room.

Oscilloscope tubes almost never contain integrated implosion protection (see below). External implosion protection must always be provided, either in the form of an external graticule or, for tubes with an internal graticule, a plain sheet of glass or plastic. The implosion protection shield is often colored to match the light emitted by the phosphor screen; this improves the contrast as seen by the user.

Computer displays

Graphical displays for early computers used vector monitors, a type of CRT similar to the oscilloscope but typically using magnetic, rather than electrostatic, deflection. Here, the beam traces straight lines between arbitrary points, repeatedly refreshing the display as quickly as possible. Vector monitors were also used by some late-1970s to mid-1980s arcade games such as Asteroids. Vector displays for computers did not noticeably suffer from the display artifacts of Aliasing and pixelization, but were limited in that they could display only a shape's outline (advanced vector systems could provide a limited amount of shading), and only a limited amount of crudely-drawn text (the number of shapes and/or textual characters drawn was severely limited, because the speed of refresh was roughly inversely proportional to how many vectors needed to be drawn). Some vector monitors are capable of displaying multiple colors, using either a typical tri-color CRT, or two phosphor layers (so-called "penetration color"). In these dual-layer tubes, by controlling the strength of the electron beam, electrons could be made to reach (and illuminate) either or both phosphor layers, typically producing a choice of green, orange, or red.

Other graphical displays used 'storage tubes', including Direct View Bistable Storage Tubes (DVBSTs). These CRTs inherently stored the image, and did not require periodic refreshing.

Some displays for early computers (those that needed to display more text than was practical using vectors, or that required high speed for photographic output) used Charactron CRTs. These incorporate a perforated metal character mask (stencil), which shapes a wide electron beam to form a character on the screen. The system selects a character on the mask using one set of deflection circuits, and selects the position to draw the character at using a second set. The beam is activated briefly to draw the character at that position. Graphics could be drawn by selecting the position on the mask corresponding to the code for a space (in practise, they were simply not drawn), which had a small round hole in the center; this effectively disabled the character mask, and the system reverted to regular vector behaviour.

Many of the early computer displays used "slow", or long-persistence, phosphors to reduce flicker for the operator. While it reduces eyestrain for relatively static displays, the drawback of long-persistence phosphor is that when the display is changed, it produces a visible afterimage that can take up to several seconds to fade. This makes it inappropriate for animation, or for real-time dynamic information displays.

Color tubes use three different phosphors which emit red, green, and blue light respectively. They are packed together in strips (as in aperture grille designs) or clusters (as in shadow mask CRTs). Color CRTs have three electron guns, one for each primary color, arranged either in a straight line or in a triangular configuration (the guns are usually constructed as a single unit). Each gun's beam reaches the dots of exactly one color; a grille or mask absorbs those electrons that would otherwise hit the wrong phosphor. Since each beam starts at a slightly different location within the tube, and all three beams are perturbed in essentially the same way, a particular deflection charge will cause the beams to hit a slightly different location on the screen (called a 'subpixel'). Color CRTs with the guns arranged in a triangular configuration are known as delta-gun CRTs, because the triangular formation resembles the shape of the Greek letter delta.

Dot pitch defines the "native resolution" of the display. On delta-gun CRTs, as the scanned resolution approaches the dot pitch resolution, moiré (a kind of soft-edged banding) appears, due to interference patterns between the mask structure and the grid-like pattern of pixels drawn. Aperture grille monitors do not suffer from vertical moiré, however, because the phosphor strips have no vertical detail.

The glass envelope

The outer glass allows the light generated by the phosphor out of the monitor, but (for color tubes) it must block dangerous X-rays generated by high energy electrons impacting the inside of the CRT face. For this reason, the glass is leaded (sometimes called "lead crystal"). Color tubes require significantly higher anode voltages than monochrome tubes (as high as 32,000 volts in large tubes), partly to compensate for the blockage of some electrons by the aperture mask or grille; the amount of X-rays produced increases with voltage. Because of leaded glass, other shielding, and protective circuits designed to prevent the anode voltage from rising too high in case of malfunction, the X-ray emission of modern CRTs is well within approved safety limits.

CRTs have a pronounced triode characteristic, which results in significant gamma (a nonlinear relationship between beam current and light intensity). In early televisions, screen gamma was an advantage because it acted to compress the screen contrast. However in systems where linear response is required (such as when desktop publishing), gamma correction is applied. The gamma characteristic exists today in all digital video systems.

CRT displays accumulate a static electrical charge on the screen, unless preventive measures are taken. This charge does not pose a safety hazard, but can lead to significant degradation of image quality through attraction of dust particles to the surface of the screen. Unless the display is regularly cleaned with a dry cloth or special cleaning tissue (using ordinary household cleaners may damage anti-glare protective layer on the screen), after a few months the brightness and clarity of the image drops significantly.

The high voltage (EHT) used for accelerating the electrons is provided by a transformer. For CRTs used in televisions, this is usually a flyback transformer that steps up the line (horizontal) deflection supply to as much as 32,000 volts for a color tube (Monochrome tubes and specialty CRTs may operate at much lower voltages). The output of the transformer is rectified and the pulsating output voltage is smoothed by a capacitor formed by the tube itself (the accelerating anode being one plate, the glass being the dielectric, and the grounded (earthed) Aquadag coating on the outside of the tube being the other plate). Before all-glass tubes, the structure between the screen and the electron gun was made from a heavy metal cone which served as the accelerating anode. Smoothing of the EHT was then done with a high voltage capacitor, external to the tube itself. In the earliest televisions, before the invention of the flyback transformer design, a linear high-voltage supply was used; because these supplies were capable of delivering much more current at their high voltage than flyback high voltage systems, in the case of an accident they proved extremely deadly. The flyback circuit design addressed this; in the case of a fault, the flyback system delivers relatively little current, making a person's chance of surviving a direct shock from the high voltage anode lead more hopeful (though by no means guaranteed).

The future of CRT technology

In recent years technologies such as liquid crystal displays (LCDs), and other newer technologies have made CRT-based computer displays mostly obsolete for mainstream users.[citation needed] The new screens are less bulky, consume less power and have a larger display area; as of mid-2006, LCDs have become directly comparable in price to CRTs of the same display area.[citation needed] However, color CRTs still find adherents in computer gaming, due to their high refresh rates, and higher resolution per dollar, and in the printing and broadcasting industries as well as in the video and photoshopping community, for the CRT's greater color fidelity and contrast. Improvements in LCD technology increasingly alleviate these concerns and demand for CRT screens is falling rapidly.[1] Producers are responding to this trend. For instance, in 2005 Sony announced that they would stop the production of CRT computer displays. Similarly, German manufacturer Loewe ceased production of CRT TVs in December 2005. Considering the shelf life of a typical user's CRT-based unit is 5-6 years, and the lowering of LCD-based unit's prices, the CRT will soon be seen as an obsolete display for most computers.

This trend is less progressed in television CRT displays. Due to the high cost of large LCD panels and plasma displays, a market niche for CRTs still exists as a cheaper alternative to these technologies. However, this situation is rapidly changing - in the United Kingdom the largest retailer of domestic electronic equipment, DSG (Dixons) reported that CRT models made up 80-90% of the volume of televisions sold at Christmas 2004, 15-20% a year later, and were expected to be less than 5% at the end of 2006. Dixons have announced that they will cease selling CRT televisions in 2007.[2]

Magnets

Magnets should never be put next to a color CRT, as they may cause magnetisation of the shadow mask, which will cause incorrect colors to appear in the magnetised area. This is called a "purity" problem, because it affects the purity of one of the primary colors, with the residual magnetism causing the undesired deflection of electrons from one gun to the wrong color's phosphor patch. This can be expensive to have corrected, although it may correct itself over a few days or weeks. Most modern television sets and nearly all newer computer monitors have a built-in degaussing coil, which upon power-up creates a brief, alternating magnetic field which decays in strength over the course of a few seconds (typically, the decay is implemented with a specialized resistor in the circuit which increases resistance with its increasing temperature as a result of the current passing through it). The coil's interaction with the shadow mask, screen band and chassis components is the reason for the characteristic 'hum' associated with turning on many CRT-equipped displays. This degaussing field is strong enough to remove most cases of shadow mask magnetisation.

It is possible to purchase or build an external degaussing coil, which can aid in demagnetising older sets, or in cases where the built-in coil is ineffective. A transformer, which produces a large alternating magnetic field (one can typically be found in soldering guns, though not soldering irons), may also be used to degauss a monitor, by holding it up to the center of the monitor, activating it, and slowly moving the gun in ever wider concentric circles past the edge of the monitor until the shimmering colors can no longer be seen (if a soldering gun is being used, ensure that the hot tip is facing AWAY from the glass (and the user)). To see the shimmering colors clearly, you may need to display a white or light-colored screen. This process may need to be repeated several times to fully remove severe magnetisation.

In extreme cases, very strong magnets such as the now popular neodymium iron boron, or NIB magnets, can actually deform (and likely, permanently bend) the shadow mask. This will create an area of impure color rendition on the screen and if the shadow mask has been bent, such damage usually can't be repaired. Subjecting an old black and white television or monochrome (green or amber screen) computer monitor to magnets is generally harmless; this can be used as an effective demonstration tool for seeing the immediate and dramatic effect of a magnetic field on moving charged particles.

Health danger

Electromagnetics: Some believe the electromagnetic fields emitted by CRT monitors constitute a health hazard to the functioning of living cells. Exposure to these fields diminishes according to the inverse square law, which describes the propagation of all electromagnetic radiation: double the distance, quarter the power; monitor and television manuals typically recommend a minimum viewing distance of 85cm (34in). The EM energy is also less intense for the display's user than for a person located behind it, because the deflection yoke is closer to the rear.

It is well-known that electromagnetic waves of sufficient energy can harm human cells (see ionizing radiation), but it is not currently well-established that the weaker radiation commonly emitted by electronic devices (including CRTs) has long-term health effects (see Electromagnetic radiation hazard and Bioelectromagnetics).

Ionizing radiation: CRTs emit a small amount of X-ray band radiation as a result of the electron beam's bombardment of the shadow mask/aperture grille and phosphors. Almost all of this radiation is blocked by the thick leaded glass in the screen, so the amount of radiation escaping the front of the monitor is widely considered harmless. The Food and Drug Administration regulations in 21 CFR 1020 are used to strictly limit, for instance, television receivers to 0.5 milliroentgens per hour (mR/h) (0.13 µC/(kg·h) or 36 pA/kg) at a distance of 5 cm from any external surface; most CRT emissions fall well below this limit [1].

Early color television receivers (many of which are now highly collectible, see CT-100) were especially vulnerable due to primitive high voltage regulation systems. X-ray production is generally negligible in black-and-white sets (due to low acceleration voltage and beam current), and in virtually every color display since the late 1960s, when systems were added to shut down the horizontal deflection system (and therefore high voltage supply) should regulation of the acceleration voltage fail.

All television receivers and CRT displays equipped with a vacuum tube based high voltage rectifier or high voltage regulator tube also generate X-rays in these stages. These stages are universally housed in a metal enclosure called the "high voltage cage" to substantially reduce (and effectively eliminate) exposure. As examples, a 1B3 and a 6KB6 vacuum tube would be installed inside this metal enclosure. For both X-ray and electrical safety reasons, the set should never be operated with the cover of the high voltage cage opened.

Toxins: CRTs may contain toxic phosphors, although this is very uncommon in modern CRTs; breaking the glass envelope could release these toxins. Also, because of the X-ray hazard, the glass envelopes of most modern CRTs are made from heavily leaded glass, which may represent an environmental hazard, especially in the presence of acid rain leaking through landfills. Indirectly heated vacuum tubes (including CRTs) use barium compounds and other reactive materials in the construction of the cathode and getter assemblies; normally this material will be converted into oxides upon exposure to the air, but care should be taken to avoid contact with the inside of all broken tubes. In some juristictions, discarded CRTs are regarded as toxic waste.

Flicker: The constant refreshing of a CRT can cause headaches in migraine sufferers and seizures in epileptics, if they are photosensitive. Screen filters are available to reduce these effects. A high refresh rate (above 75 Hz) also helps to negate these effects.

High voltage: CRTs operate at very high voltages, which can persist long after the device containing the CRT has been switched off and/or unplugged, sometimes for up to several days. Residual charges of hundreds of volts can also remain in large capacitors in the power supply circuits of the device containing the CRT; these charges may persist for weeks. Modern circuits contain bleeder resistors, to ensure that the high-voltage supply is discharged to safe levels within a couple of minutes at most.

Those working inside CRT-containing equipment should know how and be able to safely discharge these hazards . In particular, the large rubber connector which looks like a suction cup is responsible for supplying accelerating voltage to the bell of the CRT. Under the suction cup is the ultor, which couples the accelerating voltage to the inside of the tube. Inside the glass bell is a coating of metallic paint, while the outside of the bell is coated with a conductive graphite coating called Aquadag; between the ultor's connection to the flyback transformer and the Aquadag, there is therefore a capacitance capable of maintaining the full accelerating voltage for weeks. While this accelerating voltage is high (typically from 7 kV to 50 kV depending on screen size, monochrome or color, direct view or projection), both the capacitance and flyback current are small (on the order of picofarads and nanoamperes respectively), so shocks from the accelerating voltage are typically embarrassing and painful but usually harmless. On the other hand, the voltages and available currents used in the deflection and power supply circuits can result in instantaneous death.

Implosion: All CRTs and other vacuum tubes operate under high vacuum so that air and gas molecules will not interfere with electron streams. CRTs have large viewing areas and proportionally larger bells required to accommodate the deflection of the electron beams to the rear of the screen. As a result, these highly evacuated glass bulbs have a large surface area, with each and every square inch exposed to atmospheric pressure.

As an example, consider a 17-inch (16-inch viewable) CRT at a mean sea-level atmospheric pressure of 14.7 pounds per square inch. Measuring the visible portion of the CRT and rounding up to the nearest inch (accounting for invisible portions of the face), a Viewsonic model E771 monitor has a screen of 13x10 inches, or 130 square inches. At 14.7 psi exterior pressure and a near-perfect internal vacuum, the face of this monitor is supporting over 1,900 pounds of air mass on its face alone. The entire CRT is conservatively supporting three times that—or nearly 6,000 pounds, the weight of three typical automobiles—across its entire surface. The larger the CRT, the more surface area, the more total exterior air pressure load.

Therefore, CRTs present an implosion hazard when mishandled. While a great deal of research has gone into implosion protective designs for CRTs, all CRTs present this risk to some degree. Early television receivers even included a "safety glass" to protect viewers from flying glass due to spontaneous structural failures of the CRT; with modern (early 1960s onward) banded and bonded-face CRTs, the safety glass has become redundant. Safety goggles, leather gloves, and heavy sweaters are considered indispensable safety equipment amongst experienced technicians and preservationists of early television equipment.

High vacuum safety

This article contains instructions, advice, or how-to content. |

Because of the strong vacuum within a CRT, they store a large amount of mechanical energy; they can implode very forcefully if the outer glass envelope is damaged. Most modern CRTs used in televisions and computer displays include a bonded, multi-layer faceplate that prevents implosion if the faceplate is damaged, but the bell of the CRT (back portions of the glass envelope) offers no such protection. Certain specialized CRTs (such as those used in oscilloscopes) do not even offer a bonded faceplate; these CRTs require an external plastic faceplate or other cover to render them implosion safe while in use. Before the use of bonded faceplates, one of the hazards was that a broken neck or envelope could cause the electron gun to be propelled at such a velocity that it would erupt through the face of the tube.

Unmounted CRTs should always be carried 'face' down. Use both hands, and grasp the tube under the face, wrapping your hands around the sides where the metal mounting frame is attached. Never carry a CRT by the neck! For added safety, carrying the tube in a closed, thick box or with a thick cloth wrapped around it (but not in such a way as to impair your grip on the tube) is a good idea; this will reduce the amount of flying debris should the tube break. Large tubes (over 19 inches) should be carried by two people.

When handling or disposing of a CRT, you must take steps to avoid creating an implosion hazard for yourself or your trash removal service. The most simple and safe method to make the tube safe is to identify the small sealed glass nib at the far back of the tube (this may be obscured by the electrical connector) and then (while wearing safety glasses and gloves) filing a small nick across this and then to break it off using a pair of pliers. A loud sucking sound will be heard as the air enters the tube, filling the vacuum. Once the vacuum is filled, the tube is destroyed, but it cannot implode.

Disposal of CRT

In October of 2001, the Environmental Protection Agency created rules for disposing of CRTs in the United States, stating that CRTs must be brought to special recycling places. In November of 2002, the EPA began fining companies that disposed of CRTs through landfills or incineration. Regulatory agencies, local and statewide, monitor the disposal of CRT's and other computer equipment.

See also

- Flat panel display

- Overscan in television

- Comparison of display technology

- Monoscope

- Image Dissector

- Charactron

- CRT projector

- Monitor Filter

- Williams tube

- Access Computer

References

- ^ Wong, May (October 22, 2006). "Flat Panels Drive Old TVs From Market". AP via Excite News. Retrieved 2006-10-22.

- ^ "The future is flat as Dixons withdraws sale of 'big box' televisions". London Evening Standard. November 26, 2006. Retrieved 2006-12-03.

Selected patents

- U.S. patent 1,691,324: Zworykin Television System

- U.S. patent 2,630,542: RCA Multicolor Television