Gas metal arc welding

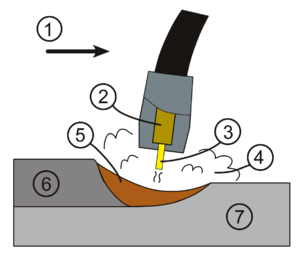

Gas metal arc welding (GMAW), sometimes referred to by its subtypes metal inert gas (MIG) welding or metal active gas (MAG) welding, is a semi-automatic or automatic arc welding process in which a continuous and consumable wire electrode and a shielding gas are fed through a welding gun. A constant voltage, direct current power source is most commonly used with GMAW, but constant current systems, as well as alternating current, can be used. There are four primary methods of metal transfer in GMAW, called globular, short-circuiting, spray, and pulsed-spray, each of which has distinct properties and corresponding advantages and limitations.

Originally developed for welding aluminum and other non-ferrous materials in the 1940s, GMAW was soon applied to steels because it allowed for lower welding time compared to other welding processes. The cost of inert gas limited its use in steels until several years later, when the use of semi-inert gases such as carbon dioxide became common. Further developments during the 1950s and 1960s gave the process more versatility and as a result, it became a highly used industrial process. Today, GMAW is the most common industrial welding process, preferred for its versatility, speed and the relative ease of adapting the process to robotic automation. The automobile industry in particular uses GMAW welding almost exclusively. Unlike welding processes that do not employ a shielding gas, such as shielded metal arc welding, it is rarely used outdoors or in other areas of air volatility. A related process, flux cored arc welding, often does not utilize a shielding gas, instead employing a hollow electrode wire that is filled with flux on the inside.

Development

The principles of gas metal arc welding began to be understood in the early 1800s, after Humphry Davy discovered the short pulsed electric arcs in 1800[1] and then Vasily Petrov independently produced the continuous electric arc in 1802[2] (soon followed by Davy). In his work published in 1803 Petrov proposed the usage of electric arc in welding, having managed to perform a simple experimental welding.[2] But it was not until the 1880s that the technology became developed with the aim of industrial usage. At first, the practical method of carbon arc welding invented by Nikolay Benardos was used,[3] utilising carbon electrodes known from the time of Davy and Petrov. By the late 1880s, metal electrodes had been invented by Nikolay Slavyanov (1888)[4] and C. L. Coffin (1890). In 1920, an early predecessor of GMAW was invented by P. O. Nobel of General Electric. It used a bare electrode wire and direct current, and used arc voltage to regulate the feed rate. It did not use a shielding gas to protect the weld, as developments in welding atmospheres did not take place until later that decade. In 1926 another forerunner of GMAW was released, but it was not suitable for practical use.[5]

It was not until 1948 that GMAW was finally developed by the Battelle Memorial Institute. It used a smaller diameter electrode and a constant voltage power source, which had been developed by H. E. Kennedy. It offered a high deposition rate, but the high cost of inert gases limited its use to non-ferrous materials and cost savings were not obtained. In 1953, the use of carbon dioxide as a welding atmosphere was developed, and it quickly gained popularity in GMAW, since it made welding steel more economical. In 1958 and 1959, the short-arc variation of GMAW was released, which increased welding versatility and made the welding of thin materials possible while relying on smaller electrode wires and more advanced power supplies. It quickly became the most popular GMAW variation. The spray-arc transfer variation was developed in the early 1960s, when experimenters added small amounts of oxygen to inert gases. More recently, pulsed current has been applied, giving rise to a new method called the pulsed spray-arc variation.[6]

As noted, GMAW is currently one of the most popular welding methods, especially in industrial environments. It is used extensively by the sheet metal industry and, by extension, the automobile industry. There, the method is often used for arc spot welding, thereby replacing riveting or resistance spot welding. It is also popular for automated welding, in which robots handle the workpieces and the welding gun to quicken the manufacturing process.[7] Generally, it is unsuitable for welding outdoors, because the movement of the surrounding air can dissipate the shielding gas and thus make welding more difficult, while also decreasing the quality of the weld. The problem can be alleviated to some extent by increasing the shielding gas output, but this can be expensive and may also affect the quality of the weld. In general, processes such as shielded metal arc welding and flux cored arc welding are preferred for welding outdoors, making the use of GMAW in the construction industry rather limited. Furthermore, the use of a shielding gas makes GMAW an unpopular underwater welding process, but can be used in space since there is no oxygen to oxidize the weld.[citation needed]

Equipment

To perform gas metal arc welding, the basic necessary equipment is a welding gun, a wire feed unit, a welding power supply, an electrode wire, and a shielding gas supply.

Welding gun and wire feed unit

The typical GMAW welding gun has a number of key parts—a control switch, a contact tip, a power cable, a gas nozzle, an electrode conduit and liner, and a gas hose. The control switch, or trigger, when pressed by the operator, initiates the wire feed, electric power, and the shielding gas flow, causing an electric arc to be struck. The contact tip, normally made of copper and sometimes chemically treated to reduce spatter, is connected to the welding power source through the power cable and transmits the electrical energy to the electrode while directing it to the weld area. It must be firmly secured and properly sized, since it must allow the passage of the electrode while maintaining an electrical contact. Before arriving at the contact tip, the wire is protected and guided by the electrode conduit and liner, which help prevent buckling and maintain an uninterrupted wire feed. The gas nozzle is used to evenly direct the shielding gas into the welding zone—if the flow is inconsistent, it may not provide adequate protection of the weld area. Larger nozzles provide greater shielding gas flow, which is useful for high current welding operations, in which the size of the molten weld pool is increased. The gas is supplied to the nozzle through a gas hose, which is connected to the tanks of shielding gas. Sometimes, a water hose is also built into the welding gun, cooling the gun in high heat operations.[8]

The wire feed unit supplies the electrode to the work, driving it through the conduit and on to the contact tip. Most models provide the wire at a constant feed rate, but more advanced machines can vary the feed rate in response to the arc length and voltage. Some wire feeders can reach feed rates as high as 30.5 m/min (1200 in/min),[9] but feed rates for semiautomatic GMAW typically range from 2 to 10 m/min (75–400 in/min).[10]

Tool Style

The top electrode holder is a semiautomatic air-cooled holder; compressed air is circulated through it to maintain moderate temperatures. It is used with lower current levels for welding lap- or butt joints. The second most common type of electrode holder is a semiautomatic water-cooled; the only difference being that water takes the place of air. It uses higher current levels for welding T- or corner joints. The third typical holder type is an automatic electrode holder that is water cooled; this holder is used typically with automated equipment.[11]

Power supply

Most applications of gas metal arc welding use a constant voltage power supply. As a result, any change in arc length (which is directly related to voltage) results in a large change in heat input and current. A shorter arc length will cause a much greater heat input, which will make the wire electrode melt more quickly and thereby restore the original arc length. This helps operators keep the arc length consistent even when manually welding with hand-held welding guns. To achieve a similar effect, sometimes a constant current power source is used in combination with an arc voltage-controlled wire feed unit. In this case, a change in arc length makes the wire feed rate adjust in order to maintain a relatively constant arc length. In rare circumstances, a constant current power source and a constant wire feed rate unit might be coupled, especially for the welding of metals with high thermal conductivities, such as aluminum. This grants the operator additional control over the heat input into the weld, but requires significant skill to perform successfully.[12]

Alternating current is rarely used with GMAW; instead, direct current is employed and the electrode is generally positively charged. Since the anode tends to have a greater heat concentration, this results in faster melting of the feed wire, which increases weld penetration and welding speed. The polarity can be reversed only when special emissive-coated electrode wires are used, but since these are not popular, a negatively charged electrode is rarely employed.[13]

Electrode

Electrode selection is based primarily on the composition of the metal being welded, the process variation being used, joint design and the material surface conditions. Electrode selection greatly influences the mechanical properties of the weld and is a key factor of weld quality. In general the finished weld metal should have mechanical properties similar to those of the base material with no defects such as discontinuities, entrained contaminants or porosity within the weld. To achieve these goals a wide variety of electrodes exist. All commercially available electrodes contain deoxidizing metals such as silicon, manganese, titanium and aluminum in small percentages to help prevent oxygen porosity. Some contain denitriding metals such as titanium and zirconium to avoid nitrogen porosity.[14] Depending on the process variation and base material being welded the diameters of the electrodes used in GMAW typically range from 0.7 to 2.4 mm (0.028–0.095 in) but can be as large as 4 mm (0.16 in). The smallest electrodes, generally up to 1.14 mm (0.045 in)[15] are associated with the short-circuiting metal transfer process, while the most common spray-transfer process mode electrodes are usually at least 0.9 mm (0.035 in).[16][17]

Shielding gas

Shielding gases are necessary for gas metal arc welding to protect the welding area from atmospheric gases such as nitrogen and oxygen, which can cause fusion defects, porosity, and weld metal embrittlement if they come in contact with the electrode, the arc, or the welding metal. This problem is common to all arc welding processes; for example, in the older Shielded-Metal Arc Welding process (SMAW), the electrode is coated with a solid flux which evolves a protective cloud of carbon dioxide when melted by the arc. In GMAW, however, the electrode wire does not have a flux coating, and a separate shielding gas is employed to protect the weld. This eliminates slag, the hard residue from the flux that builds up after welding and must be chipped off to reveal the completed weld.

The choice of a shielding gas depends on several factors, most importantly the type of material being welded and the process variation being used. Pure inert gases such as argon and helium are only used for nonferrous welding; with steel they do not provide adequate weld penetration (argon) or cause an erratic arc and encourage spatter (with helium). Pure carbon dioxide, on the other hand, allows for deep penetration welds but encourages oxide formation, which adversely affect the mechanical properties of the weld. Its low cost makes it an attractive choice, but because of the reactivity of the arc plasma, spatter is unavoidable and welding thin materials is difficult. As a result, argon and carbon dioxide are frequently mixed in a 75%/25% to 90%/10% mixture. Generally, in short circuit GMAW, higher carbon dioxide content increases the weld heat and energy when all other weld parameters (volts, current, electrode type and diameter) are held the same. As the carbon dioxide content increases over 20%, spray transfer GMAW becomes increasingly problematic, especially with smaller electrode diameters.[18]

Argon is also commonly mixed with other gases, oxygen, helium, hydrogen, and nitrogen. The addition of up to 5% oxygen (like the higher concentrations of carbon dioxide mentioned above) can be helpful in welding stainless steel, however, in most applications carbon dioxide is preferred.[19] Increased oxygen makes the shielding gas oxidize the electrode, which can lead to porosity in the deposit if the electrode does not contain sufficient deoxidizers. Excessive oxygen, especially when used in application for which it is not prescribed, can lead to brittleness in the heat affected zone. Argon-helium mixtures are extremely inert, and can be used on nonferrous materials. A helium concentration of 50%–75% raises the required voltage and increases the heat in the arc, due to helium's higher ionization temperature. Hydrogen is sometimes added to argon in small concentrations (up to about 5%) for welding nickel and thick stainless steel workpieces. In higher concentrations (up to 25% hydrogen), it may be used for welding conductive materials such as copper. However, it should not be used on steel, aluminum or magnesium because it can cause porosity and hydrogen embrittlement. Additionally, nitrogen is sometimes added to argon to a concentration of 25%–50% for welding copper, but the use of nitrogen, especially in North America, is limited.[citation needed]

Shielding gas mixtures of three or more gases are also available. Mixtures of argon, carbon dioxide and oxygen are marketed for welding steels. Other mixtures add a small amount of helium to argon-oxygen combinations, these mixtures are claimed to allow higher arc voltages and welding speed. Helium is also sometimes used as the base gas, with small amounts of argon and carbon dioxide added. However, because it is less dense than air, helium is less effective in shielding the weld than argon– which is denser than air. It also can lead to arc stability and penetration issues, and increased spatter. due to its much more energetic arc plasma. Helium is also more expensive than other shielding gases. Other specialized and often proprietary gas mixtures claim even greater benefits for specific applications.[20]

The desirable rate of gas flow depends primarily on weld geometry, speed, current, the type of gas, and the metal transfer mode being utilized. Welding flat surfaces requires higher flow than welding grooved materials, since the gas is dispersed more quickly. Faster welding speeds, in general, mean that more gas needs to be supplied to provide adequate coverage. Additionally, higher current requires greater flow, and generally, more helium is required to provide adequate coverage than argon. Perhaps most importantly, the four primary variations of GMAW have differing shielding gas flow requirements—for the small weld pools of the short circuiting and pulsed spray modes, about 10 L/min (20 ft³/h) is generally suitable, while for globular transfer, around 15 L/min (30 ft³/h) is preferred. The spray transfer variation normally requires more because of its higher heat input and thus larger weld pool; along the lines of 20–25 L/min (40–50 ft³/h).[10]

Operation

For most of its applications gas metal arc welding is a fairly simple welding process to learn requiring no more than a week or two to master basic welding technique. Even when welding is performed by well-trained operators weld quality can fluctuate since it depends on a number of external factors. All GMAW is dangerous, though perhaps less so than some other welding methods, such as shielded metal arc welding.[21]

Technique

The basic technique for GMAW is quite simple, since the electrode is fed automatically through the torch. By contrast, in gas tungsten arc welding, the welder must handle a welding torch in one hand and a separate filler wire in the other, and in shielded metal arc welding, the operator must frequently chip off slag and change welding electrodes. GMAW requires only that the operator guide the welding gun with proper position and orientation along the area being welded. Keeping a consistent contact tip-to-work distance (the stick out distance) is important, because a long stickout distance can cause the electrode to overheat and will also waste shielding gas. Stickout distance varies for different GMAW weld processes and applications.[22][23][24][25] For short-circuit transfer, the stickout is generally 1/4 inch to 1/2 inch, for spray transfer the stickout is generally 1/2 inch. The position of the end of the contact tip to the gas nozzle are related to the stickout distance and also varies with transfer type and application. The orientation of the gun is also important—it should be held so as to bisect the angle between the workpieces; that is, at 45 degrees for a fillet weld and 90 degrees for welding a flat surface. The travel angle, or lead angle, is the angle of the torch with respect to the direction of travel, and it should generally remain approximately vertical. However, the desirable angle changes somewhat depending on the type of shielding gas used—with pure inert gases, the bottom of the torch is often slightly in front of the upper section, while the opposite is true when the welding atmosphere is carbon dioxide.[26]

Quality

Two of the most prevalent quality problems in GMAW are dross and porosity. If not controlled, they can lead to weaker, less ductile welds. Dross is an especially common problem in aluminum GMAW welds, normally coming from particles of aluminum oxide or aluminum nitride present in the electrode or base materials. Electrodes and workpieces must be brushed with a wire brush or chemically treated to remove oxides on the surface. Any oxygen in contact with the weld pool, whether from the atmosphere or the shielding gas, causes dross as well. As a result, sufficient flow of inert shielding gases is necessary, and welding in volatile air should be avoided.[27]

In GMAW the primary cause of porosity is gas entrapment in the weld pool, which occurs when the metal solidifies before the gas escapes. The gas can come from impurities in the shielding gas or on the workpiece, as well as from an excessively long or violent arc. Generally, the amount of gas entrapped is directly related to the cooling rate of the weld pool. Because of its higher thermal conductivity, aluminum welds are especially susceptible to greater cooling rates and thus additional porosity. To reduce it, the workpiece and electrode should be clean, the welding speed diminished and the current set high enough to provide sufficient heat input and stable metal transfer but low enough that the arc remains steady. Preheating can also help reduce the cooling rate in some cases by reducing the temperature gradient between the weld area and the base material.[28]

Safety

Gas metal arc welding can be dangerous if proper precautions are not taken. Since GMAW employs an electric arc, welders wear protective clothing, including heavy leather gloves and protective long sleeve jackets, to avoid exposure to extreme heat and flames. In addition, the brightness of the electric arc is a source of the condition known as arc eye, an inflammation of the cornea caused by ultraviolet light and, in prolonged exposure, possible burning of the retina in the eye. Conventional welding helmets contain dark face plates to prevent this exposure. Newer helmet designs feature a liquid crystal-type face plate that self-darken upon exposure to high amounts of UV light. Transparent welding curtains, made of a polyvinyl chloride plastic film, are often used to shield nearby workers and bystanders from exposure to the UV light from the electric arc.[29]

Welders are also often exposed to dangerous gases and particulate matter. GMAW produces smoke containing particles of various types of oxides, and the size of the particles in question tends to influence the toxicity of the fumes, with smaller particles presenting a greater danger. Additionally, carbon dioxide and ozone gases can prove dangerous if ventilation is inadequate. Furthermore, because the use of compressed gases in GMAW pose an explosion and fire risk, some common precautions include limiting the amount of oxygen in the air and keeping combustible materials away from the workplace.[30] While porosity usually results from atmospheric contamination, too much shielding gas has a similar effect; if the flow rate is too high it may create a vortex that draws in the surrounding air, thereby contaminating the weld pool as it cools. The gas output should be felt (as a cool breeze) on a dry hand but not enough to create any noticeable pressure, this equates to between 20–25 psi (mild and stainless steel). Above 26 volts the gas debit should be augmented slightly since the weld pool takes longer to cool. As a factor that is often ignored, many flow meters are never adjusted and typically run between 35–45 psi. A healthy reduction of gas will not affect the quality of the weld, will save money on shielding gas and reduce the rate at which the tank must be replaced.

Metal transfer modes

Globular

GMAW with globular metal transfer is often considered the most undesirable of the four major GMAW variations, because of its tendency to produce high heat, a poor weld surface, and spatter. The method was originally developed as a cost efficient way to weld steel using GMAW, because this variation uses carbon dioxide, a less expensive shielding gas than argon. Adding to its economic advantage was its high deposition rate, allowing welding speeds of up to 110 mm/s (250 in/min).[31] As the weld is made, a ball of molten metal from the electrode tends to build up on the end of the electrode, often in irregular shapes with a larger diameter than the electrode itself. When the droplet finally detaches either by gravity or short circuiting, it falls to the workpiece, leaving an uneven surface and often causing spatter.[32] As a result of the large molten droplet, the process is generally limited to flat and horizontal welding positions. The high amount of heat generated also is a downside, because it forces the welder to use a larger electrode wire, increases the size of the weld pool, and causes greater residual stresses and distortion in the weld area.

Short-circuiting

Further developments in welding steel with GMAW led to a variation known as short-circuiting or short-arc GMAW, in which the current is lower than for the globular method. As a result of the lower current, the heat input for the short-arc variation is considerably reduced, making it possible to weld thinner materials while decreasing the amount of distortion and residual stress in the weld area. As in globular welding, molten droplets form on the tip of the electrode, but instead of dropping to the weld pool, they bridge the gap between the electrode and the weld pool as a result of the lower wire feed rate. This causes a short circuit and extinguishes the arc, but it is quickly reignited after the surface tension of the weld pool pulls the molten metal bead off the electrode tip. This process is repeated about 100 times per second, making the arc appear constant to the human eye. This type of metal transfer provides better weld quality and less spatter than the globular variation, and allows for welding in all positions, albeit with slower deposition of weld material. Setting the weld process parameters (volts, amps and wire feed rate) within a relatively narrow band is critical to maintaining a stable arc: generally between 100 to 200 amps at 17 to 22 volts for most applications. Also, using short-arc transfer can result in lack of fusion and insufficient penetration when welding thicker materials, due to the lower arc energy and rapidly freezing weld pool.[33] Like the globular variation, it can only be used on ferrous metals.[17][34][35]

Modified short-circuiting

There are proprietary derivatives of the short-circuiting transfer mode which use a modified waveform to reduce some of the problems found with short-circuiting, mainly spatter and a turbulent weld pool. Typically these systems sense the progression of the short circuit as it happens and modulate the current to limit the amount of force behind spatter and turbulence-producing events. Several manufacturers now sell welding power supplies which employ technology to this end: Miller Electric has a process called Regulated Metal Deposition (RMD), while Lincoln Electric sells their process called Surface Tension Transfer (STT). Other companies take a different approach to making short circuit transfer usable: Fronius has a technique called Cold Metal Transfer (CMT) which physically withdraws the electrode from the welding puddle at a certain rate and pattern.

RMD and STT achieve the modified short circuiting via software that controls the current. The RMD process breaks the process into seven steps:

- Wet: Let the ball on the end of the wire wet-out to the puddle.

- Pinch: Increase the current to a level high enough to initiate a pinch effect.

- Clear: Maintain and slightly increase the pinch current to clear the short circuit while simultaneously watching for pinch detection.

- Blink: Upon pinch detection, rapidly decrease the current. Pinch detection occurs before the short clears. The inverter “shuts off” and current decays to a low level before the short circuit breaks.

- Ball: Increase current to form a ball for the next short circuit.

- Background: Drop the current to a low enough level to allow a short circuit to occur.

- Pre-short: If the background current exists for a relatively long time, the pre-short period drops current to an even lower level to make sure arc force does not produce excessive puddle agitation.

Spray

Spray transfer GMAW was the first metal transfer method used in GMAW, and well-suited to welding aluminum and stainless steel while employing an inert shielding gas. In this GMAW process, the weld electrode metal is rapidly passed along the stable electric arc from the electrode to the workpiece, essentially eliminating spatter and resulting in a high-quality weld finish. As the current and voltage increases beyond the range of short circuit transfer the weld electrode metal transfer transitions from larger globules through small droplets to a vaporized stream at the highest energies.[36] Since this vaporized spray transfer variation of the GMAW weld process requires higher voltage and current than short circuit transfer, and as a result of the higher heat input and larger weld pool area (for a given weld electrode diameter), it is generally used only on workpieces of thicknesses above about 6.4 mm (0.25 in).[37] Also, because of the large weld pool, it is often limited to flat and horizontal welding positions and sometimes also used for vertical-down welds. It is generally not practical for root pass welds.[38] When a smaller electrode is used in conjunction with lower heat input, its versatility increases. The maximum deposition rate for spray arc GMAW is relatively high; about 60 mm/s (150 in/min).[17][31][39]

Pulsed-spray

A more recently developed method, the pulse-spray metal transfer mode is based on the principles of spray transfer but uses a pulsing current to melt the filler wire and allow one small molten droplet to fall with each pulse. The pulses allow the average current to be lower, decreasing the overall heat input and thereby decreasing the size of the weld pool and heat-affected zone while making it possible to weld thin workpieces. The pulse provides a stable arc and no spatter, since no short-circuiting takes place. This also makes the process suitable for nearly all metals, and thicker electrode wire can be used as well. The smaller weld pool gives the variation greater versatility, making it possible to weld in all positions. In comparison with short arc GMAW, this method has a somewhat slower maximum speed (85 mm/s or 200 in/min) and the process also requires that the shielding gas be primarily argon with a low carbon dioxide concentration. Additionally, it requires a special power source capable of providing current pulses with a frequency between 30 and 400 pulses per second. However, the method has gained popularity, since it requires lower heat input and can be used to weld thin workpieces, as well as nonferrous materials.[17][40][41]

Bibliography

- Minnick, William H. (2007). Gas Metal Arc Welding Handbook Textbook. Tinley Park: Goodheart-Willcox. ISBN 978-1-59070-866-8.

{{cite book}}: Invalid|ref=harv(help) - Cary, Howard B.; Helzer, Scott C. (2005). Modern Welding Technology. Upper Saddle River, New Jersey: Pearson Education. ISBN 0-13-113029-3.

{{cite book}}: Invalid|ref=harv(help) - Kalpakjian, Serope; Schmid, Steven R. (2001). Manufacturing Engineering and Technology. Prentice Hall. ISBN 0-201-36131-0.

{{cite book}}: Invalid|ref=harv(help) - Lincoln Electric (1994). The Procedure Handbook of Arc Welding. Cleveland: Lincoln Electric. ISBN 978-99949-25-82-7.

{{cite book}}: Invalid|ref=harv(help) - Nadzam, Jeff, ed. (1997). Gas Metal Arc Welding Guidelines (PDF). Lincoln Electric.

{{cite book}}: Invalid|ref=harv(help) - Weman, Klas (2003). Welding processes handbook. New York: CRC Press LLC. ISBN 0-8493-1773-8.

{{cite book}}: Invalid|ref=harv(help) - Craig, Ed (1991). Gas Metal Arc & Flux Cored Welding Parameters. Chicago: Weldtrain. ISBN 978-0-9753621-0-5.

{{cite book}}: Invalid|ref=harv(help) - Anders, A. (2003). "Tracking down the origin of arc plasma science-II. early continuous discharges". IEEE Transactions on Plasma Science. 31: 1060–9. doi:10.1109/TPS.2003.815477.

{{cite journal}}: Invalid|ref=harv(help) - Todd, Robert H.; Allen, Dell K.; Alting, Leo (1994). Manufacturing processes reference guide. New York: Industrial Press. ISBN 978-0-8311-3049-7.

{{cite book}}: Invalid|ref=harv(help)

References

- ^ Anders 2003

- ^ a b Petrov Vasily Vladimirovich at weldworld.ru Template:Ru icon[self-published source?]

- ^ Benardos Nikolay Nikolayevich at weldworld.ru Template:Ru icon[self-published source?]

- ^ Slavyanov Nikolay Gavrilovich at weldworld.ru Template:Ru icon[self-published source?]

- ^ Cary & Helzer 2005, p. 7

- ^ Cary & Helzer 2005, pp. 8–9

- ^ Kalpakjian & Schmid 2001, p. 783

- ^ Nadzam 1997, pp. 5–6

- ^ Nadzam 1997, p. 6

- ^ a b Cary & Helzer 2005, pp. 123–5

- ^ Todd, Allen & Alting 1994[page needed]

- ^ Nadzam 1997, p. 1

- ^ Cary & Helzer 2005, pp. 118–9

- ^ Nadzam 1997, p. 15

- ^ Craig 1991, p. 22

- ^ Craig 1991, p. 105

- ^ a b c d Cary & Helzer 2005, p. 121

- ^ Craig 1991, p. 96

- ^ Craig 1991, pp. 40–1

- ^ Cary & Helzer 2005, pp. 357–9

- ^ Cary & Helzer 2005, p. 126

- ^ Craig 1991, p. 29

- ^ Craig 1991, p. 52

- ^ Craig 1991, p. 109

- ^ Craig 1991, p. 141

- ^ Cary & Helzer 2005, p. 125

- ^ Lincoln Electric 1994, 9.3-5 – 9.3-6

- ^ Lincoln Electric 1994, 9.3-1 – 9.3-2

- ^ Cary & Helzer 2005, p. 42

- ^ Cary & Helzer 2005, pp. 52–62

- ^ a b Cary & Helzer 2005, p. 117

- ^ Cary 2003, p. 50

- ^ Craig 1991, p. 11

- ^ Cary & Helzer 2005, p. 98

- ^ Cary 2003, pp. 49–50

- ^ Craig 1991, p. 82

- ^ Craig 1991, p. 90

- ^ Craig 1991, p. 98

- ^ Cary & Helzer 2005, p. 96

- ^ Cary & Helzer 2005, p. 99

- ^ Cary & Helzer 2005, p. 118

Further reading

- Trends in Welding Research. Materials Park, Ohio: ASM International. 2003. ISBN 0-87170-780-2.

{{cite book}}: Invalid|ref=harv(help) - Blunt, Jane; Balchin, Nigel C. (2002). Health and Safety in Welding and Allied Processes. Cambridge, UK: Woodhead. ISBN 1-85573-538-5.

{{cite book}}: Invalid|ref=harv(help) - Hicks, John (1999). Welded Joint Design. Industrial Press. ISBN 0-8311-3130-6.

{{cite book}}: Invalid|ref=harv(help)CS1 maint: location missing publisher (link)

External links

- ESAB Process Handbook

- OSHA Safety and Health Topics- Welding, Cutting, and Brazing

- Fume formation rates in gas metal arc welding - research article from the 1999 Welding Journal

- Edison Welding Institute

- GMAW from The Welding Institute