Vanadium redox battery

| Specific energy | 10–20 Wh/kg (36–72 J/g) |

|---|---|

| Energy density | 15–25 Wh/L (54–65 kJ/L) |

| Charge/discharge efficiency | 75-80%<.[1] |

| Time durability | 10–20 years |

| Cycle durability | >10,000 cycles |

| Nominal cell voltage | 1.15–1.55 V |

The vanadium redox (and redox flow) battery is a type of rechargeable flow battery that employs vanadium ions in different oxidation states to store chemical potential energy. The present form (with sulfuric acid electrolytes) was patented by the University of New South Wales in Australia in 1986. [2] An earlier German Patent on a titanium chloride flow battery was registered and granted in July 1954 to Dr. Walter Kangro, but most of the development of flow batteries was carried out by NASA researchers in the 1970s. Although the use of vanadium in batteries had been suggested earlier by Pissoort,[3] by NASA researchers and by Pellegri and Spaziante in 1978,[4] the first known successful demonstration and commercial development of the all-vanadium redox flow battery employing vanadium in a solution of sulfuric acid in each half was by Maria Skyllas-Kazacos and co-workers at the University of New South Wales in the 1980s.[5]

There are currently a number of suppliers and developers of these battery systems including Ashlawn Energy in the United States, Renewable Energy Dynamics (RED-T) in Ireland, Cellstrom GmbH in Austria, Cellennium in Thailand, and Prudent Energy in China.[6][7][8] The vanadium redox battery (VRB) is the product of over 25 years of research, development, testing and evaluation in Australia, Europe, North America and elsewhere.

The vanadium redox battery exploits the ability of vanadium to exist in solution in four different oxidation states, and uses this property to make a battery that has just one electroactive element instead of two.

The main advantages of the vanadium redox battery are that it can offer almost unlimited capacity simply by using larger and larger storage tanks, it can be left completely discharged for long periods with no ill effects, it can be recharged simply by replacing the electrolyte if no power source is available to charge it, and if the electrolytes are accidentally mixed the battery suffers no permanent damage.

The main disadvantages with vanadium redox technology are a relatively poor energy-to-volume ratio, and the system complexity in comparison with standard storage batteries.

Operation

A vanadium redox battery consists of an assembly of power cells in which the two electrolytes are separated by a proton exchange membrane. Both electrolytes are vanadium based, the electrolyte in the positive half-cells contains VO2+ and VO2+ ions, the electrolyte in the negative half-cells, V3+ and V2+ ions. The electrolytes may be prepared by any of several processes, including electrolytically dissolving vanadium pentoxide (V2O5) in sulfuric acid (H2SO4). The solution remains strongly acidic in use.

In vanadium flow batteries, both half-cells are additionally connected to storage tanks and pumps so that very large volumes of the electrolytes can be circulated through the cell. This circulation of liquid electrolytes is somewhat cumbersome and does restrict the use of vanadium flow batteries in mobile applications, effectively confining them to large fixed installations, although one company has focused on electric vehicle applications, using rapid replacement of electrolyte to refuel the battery.

When the vanadium battery is charged, the VO2+ ions in the positive half-cell are converted to VO2+ ions when electrons are removed from the positive terminal of the battery. Similarly in the negative half-cell, electrons are introduced converting the V3+ ions into V2+. During discharge this process is reversed and results in a typical open-circuit voltage of 1.41 V at 25 °C.

Other useful properties of vanadium flow batteries are their very fast response to changing loads and their extremely large overload capacities. Studies by the University of New South Wales have shown that they can achieve a response time of under half a millisecond for a 100% load change, and allowed overloads of as much as 400% for 10 seconds. The response time is mostly limited by the electrical equipment. Round trip efficiency in practical applications is around 65-75%.[9]

Sulfuric acid-based vanadium batteries only work between about 10 to 40 °C. Below that temperature range, the ion-infused sulfuric acid crystallizes.Cite error: The <ref> tag has too many names (see the help page).

- Two 5-kW units installed in St. Petersburg, Florida, under the auspices of USF's Power Center for Utility Explorations.

- A 100 kWh unit supplied with 18 kW stacks manufactured by Cellstrom (Austria) has been installed in Vierakker (Gelderland, The Netherlands) as part of an integrated energy concept called 'FotonenBoer'/'PhotonFarmer' (InnovationNetwork/Foundation Courage)

- A 400 kW, 500 kWh output balancer in use on a solar power project in the Bilacenge Village in Sumba Island, Indonesia.

See also

- Polysulfide bromide battery

- Battery (electricity)

- Flow battery

- Lead–acid battery

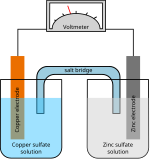

- Electrochemical cell

- Fuel cell

- Energy storage

References

- ^ Vanadium Battery Group University of New South Wales

- ^ M. Skyllas-Kazacos, M. Rychcik and R. Robins, in AU Patent 575247 (1986), to Unisearch Ltd.

- ^ P. A. Pissoort, in FR Patent 754065 (1933)

- ^ A. Pelligri and P. M. Spaziante, in GB Patent 2030349 (1978), to Oronzio de Nori Impianti Elettrochimici S.p.A.

- ^ M. Rychcik and M. Skyllas-Kazacos, J. Power Sources, 22 (1988) 59-67

- ^ http://gigaom.com/cleantech/made-in-china-prudent-energy-lands-22m-for-flow-batteries/

- ^ http://www.techfinance.ca/modules/mergers/merg.php?mergid=1009&dnd=20090129

- ^ http://www.pdenergy.com/contact_info.html

- ^ VRB Power Systems FAQ Archived 2010-02-13 at the Wayback Machine

Additional references

- Comprehensive Vanadium report on uses and applications.

- Presentation paper from the IEEE summer 2001 conference

- UNSW Site on Vanadium batteries

- Report by World Energy

- World Map Of Global Vanadium Deposits Vanadium geology is fairly unique compared to a base metals oar body.

External links

- VRB at UNSW

- VRB at everything2

- History of the VRB

- Current demand

- The Need for Vanadium Redox Energy Storage in Wind Turbine Generators Net electricity generation from all forms of renewable energies in America increased by over 15% between 2005 and 2009.